Optical material high temperature transmittance testing device

A technology of optical materials and testing devices, which is applied in the direction of transmittance measurement, etc., can solve the problems of light transmittance decrease, transmittance characteristics deterioration, and inability to reflect material transmittance characteristics, etc., to improve measurement accuracy, good The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

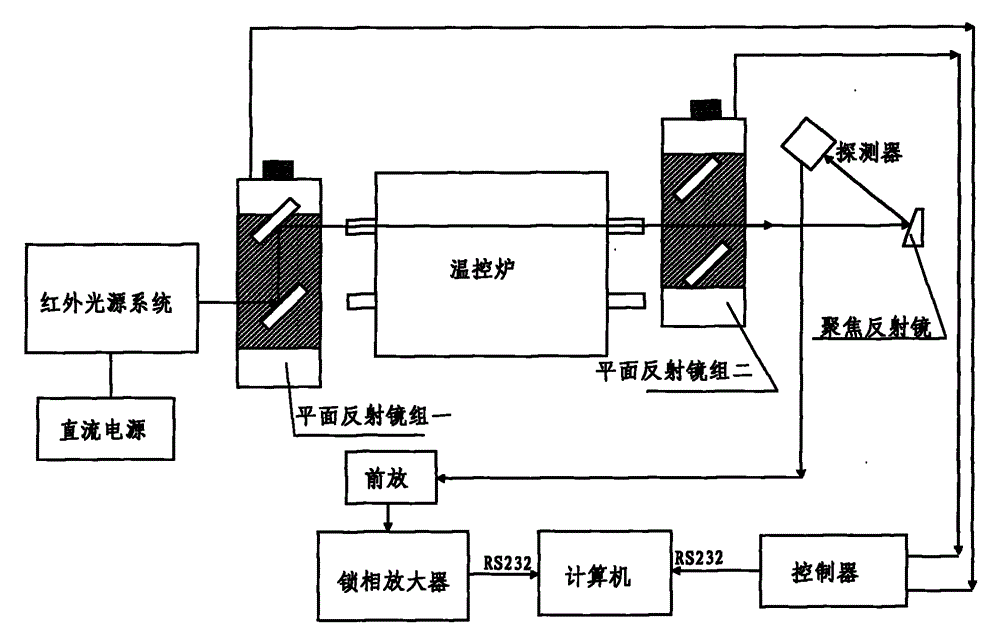

[0028] as figure 1 As shown, the high-temperature transmittance measuring instrument of the preferred embodiment of the present invention is composed of an infrared light source system, a plane mirror group 1, a precision temperature-controlled furnace, a plane mirror group 2, a focusing mirror, a photoelectric detection processing system, and a computer.

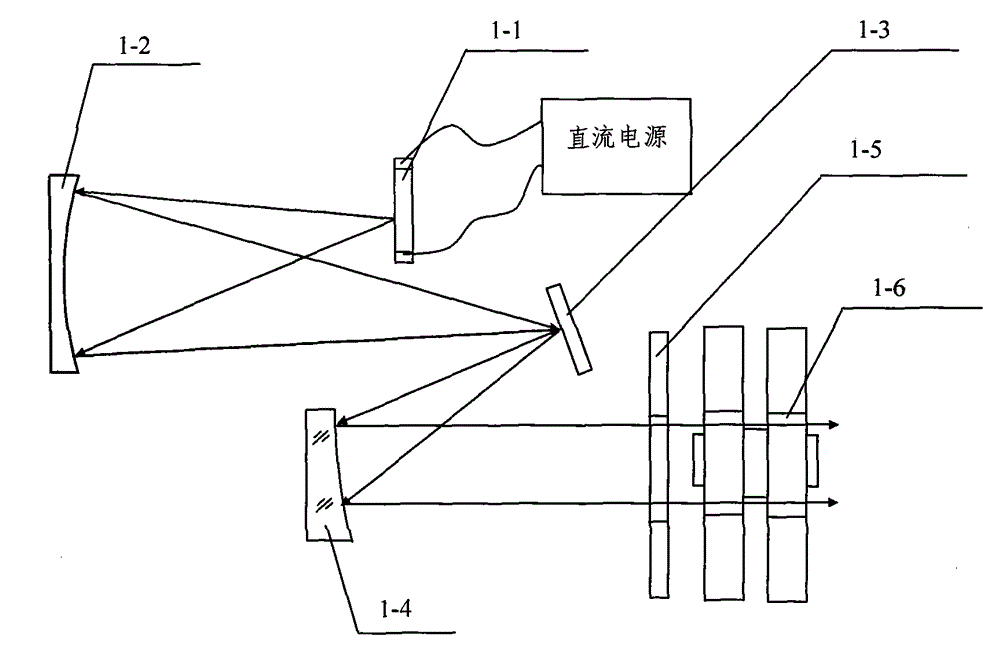

[0029] according to figure 2 As shown, the infrared light source system includes an infrared light source 1-1, a collimating mirror 1-4, an imaging lens 1-2, a plane mirror 1-3, a chopper 1-5, a filter group 1-6, and an infrared light source 1-1 is a silicon carbide rod lamp, and collimating mirror 1-4 is an off-axis parabolic reflector. The silicon carbon rod lamp is powered by a DC precision steady current source to provide continuous infrared light. The infrared light beam emitted by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com