Movable heat pipe radiator used for heating coal stove

A heat pipe radiator, mobile technology, applied in the field of heat transfer, can solve the problems of low heat transfer coefficient of natural convection and radiation heat dissipation, heat diffusion resistance, poor heating effect, etc., to achieve excellent temperature uniformity, good heating effect, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and example.

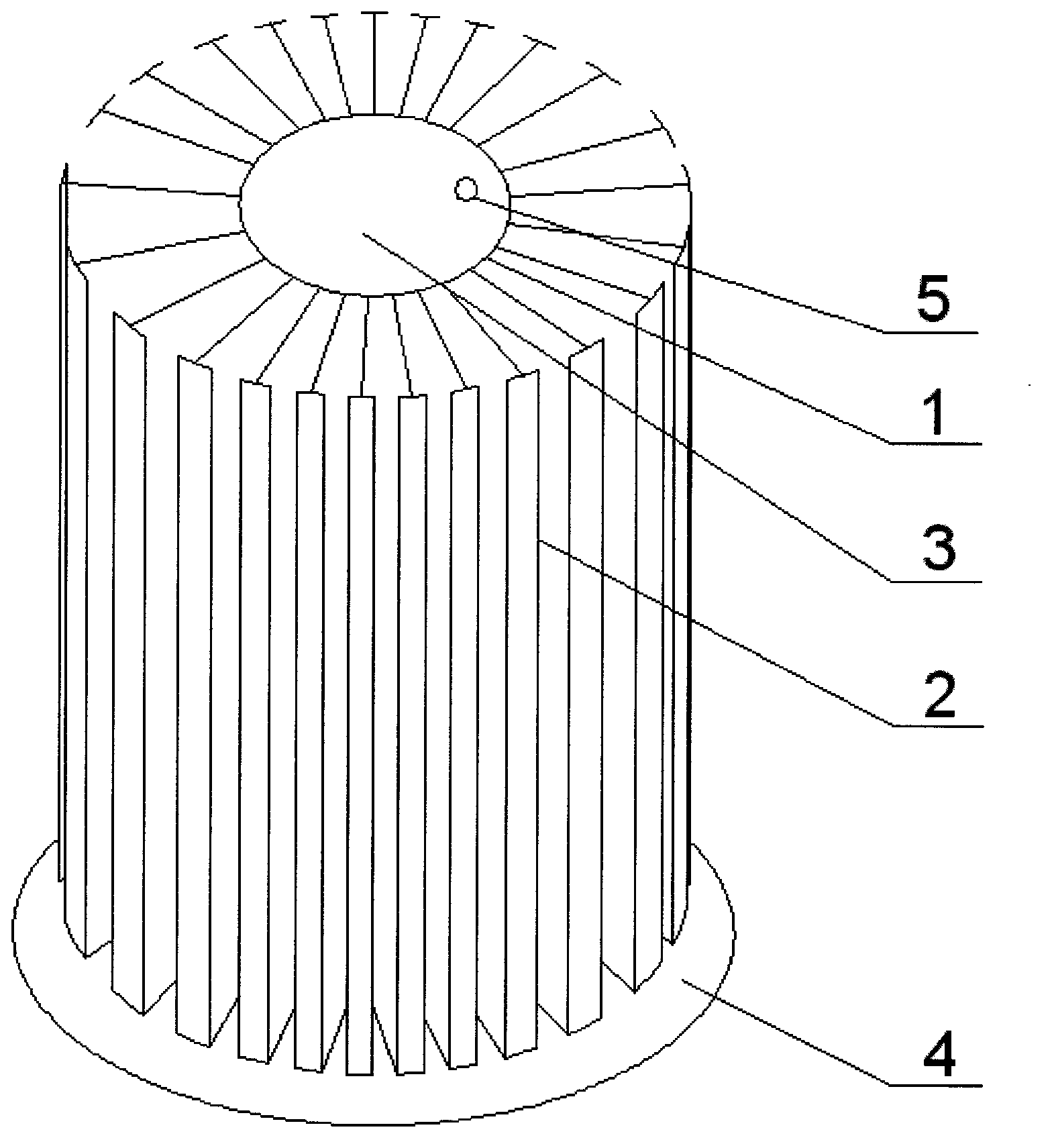

[0010] Such as figure 1 As shown, the outer wall of the heat pipe (1) is provided with heat dissipation fins (2), and the heat dissipation fins (2) are arranged and distributed around the circumference of the heat pipe (1) and vertically arranged along the length direction of the chimney base pipe (1).

[0011] The upper end nozzle of the heat conduction tube (1) is provided with a nozzle seal (3), the nozzle seal (3) is provided with a working fluid filling port (5), and the lower end of the heat conduction pipe (1) is provided with a seal end Plate (4), the diameter of the head end plate (4) is greater than the diameter of the heat pipe (1), consistent with the diameter of the upper opening of the combustion chamber of the stove, as the upper cover plate of the combustion chamber, it is convenient for heat and heat pipe ( 1) Heat exchange.

[0012] Working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com