System and method for testing high-temperature mechanical property-temperature rise rate correlation parameters of composite material

A high-temperature mechanics, composite material technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of slow heating rate, non-constant heating rate, small test temperature range, etc., to achieve fast heating speed and heating rate. Adjustable, constant heating rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

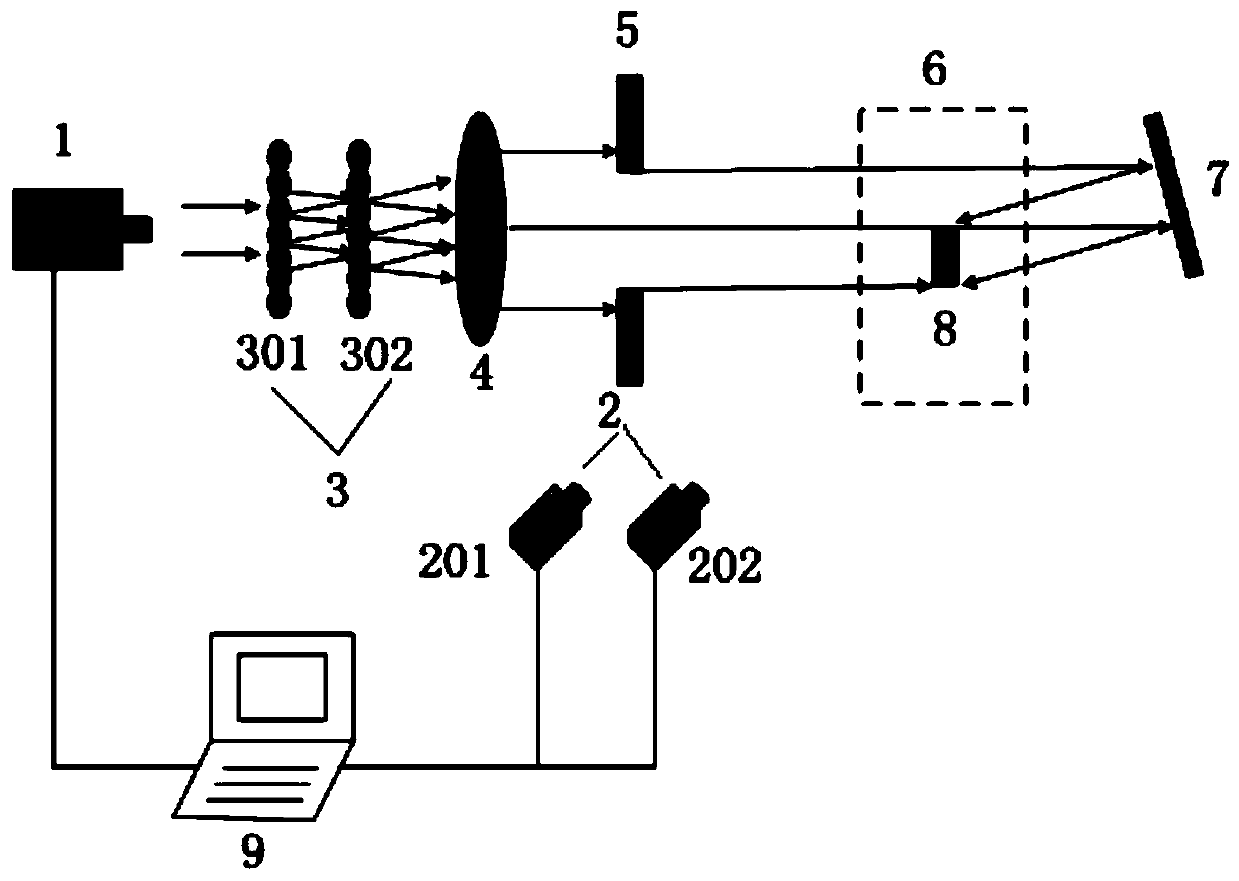

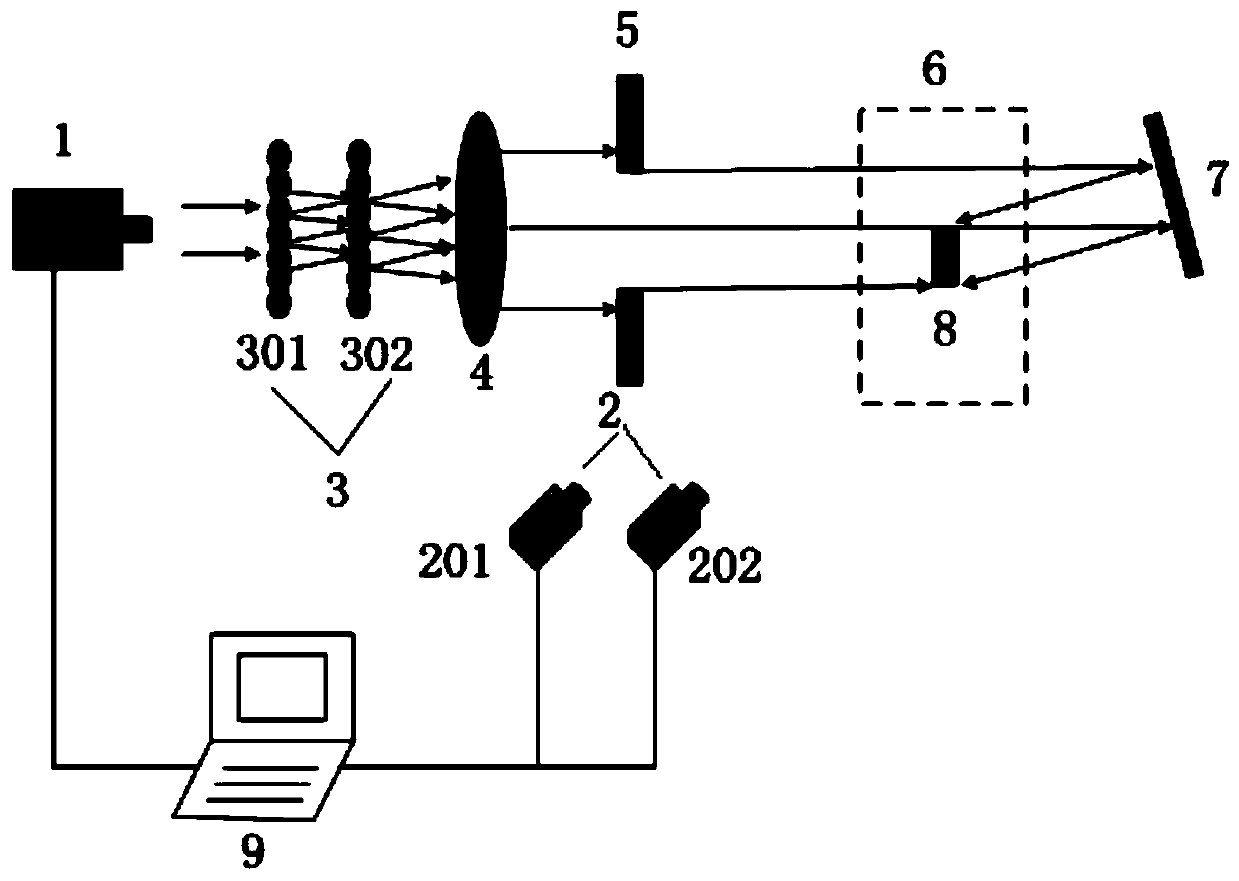

[0037] see figure 1 , the present invention provides a specific example of a composite material high temperature mechanical properties-heating rate correlation parameter testing system, the system includes a laser 1, a temperature measuring device 2, a microlens array 3, a collimating lens 4, an aperture 5, a universal test Machine 6, total reflection mirror 7 and temperature control servo system 9;

[0038] In this embodiment, preferably,

[0039] The laser 1 adopts a semiconductor laser, and its laser light output power is positively correlated with the current. The power range is 100W ~ 1000W and the power is continuously adjustable. The output power of the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com