Non-magnetic high-temperature test device

A test device and high-temperature technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of fixed structure size, high energy consumption, and inability to meet the work requirements of test components without interference, and achieve stepless temperature adjustment , good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

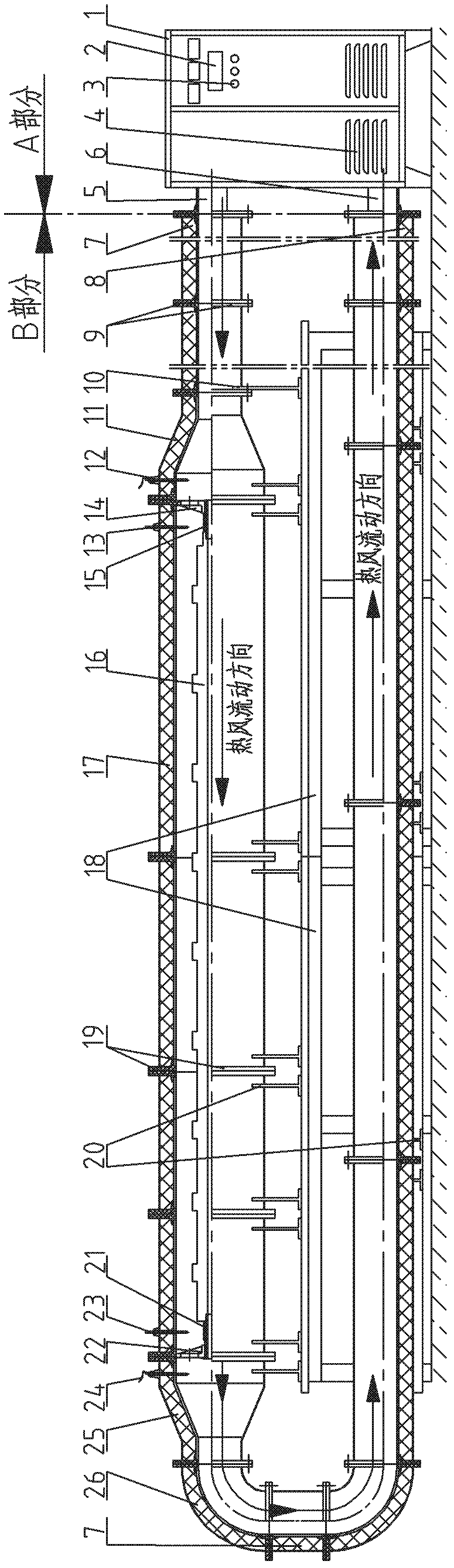

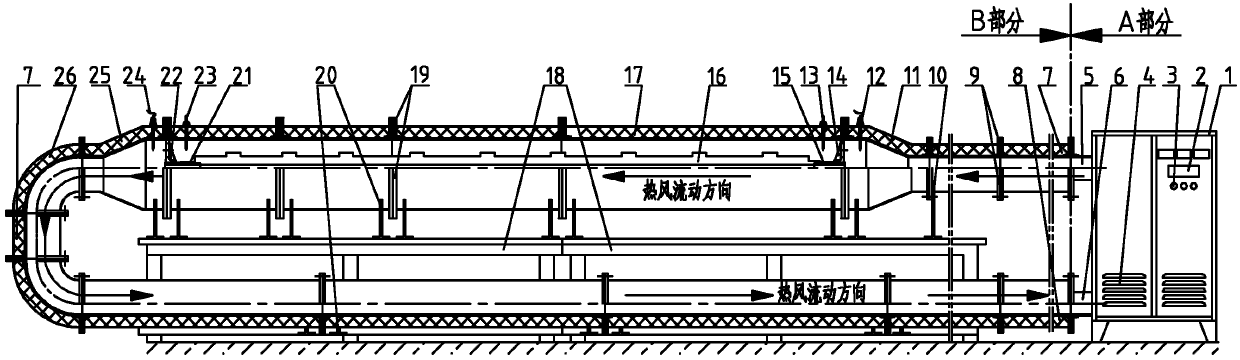

[0026] figure 1 The structure of an embodiment of the non-magnetic high-temperature testing device of the present invention is shown. The non-magnetic high-temperature testing device of this embodiment is a non-standard horizontal tube-type drying device, mainly composed of part A and part B.

[0027] Part A is a hot air generator, which is composed of a box body 1, a heating system and a temperature control system placed in the box body. A temperature control instrument 2, a start button 3 are arranged on the panel of the box body 1, and an air channel 4 is arranged at the lower part. The side of the box body 1 has an upper interface 5 and a lower interface 6, which respectively allow the heated hot air to flow out and the utilized hot air to flow in, and are connected to the hot air circulation channel. The function of the hot air generator is to g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com