Conduction cooling large-scale high-temperature superconducting magnet structure

A high-temperature superconducting and conduction cooling technology, which is applied to superconducting magnets/coils, magnetic objects, electrical components, etc., can solve problems such as the inability to guarantee the temperature uniformity of high-temperature superconducting magnets, and achieve improved cooling effects, simple structure, and refrigeration good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

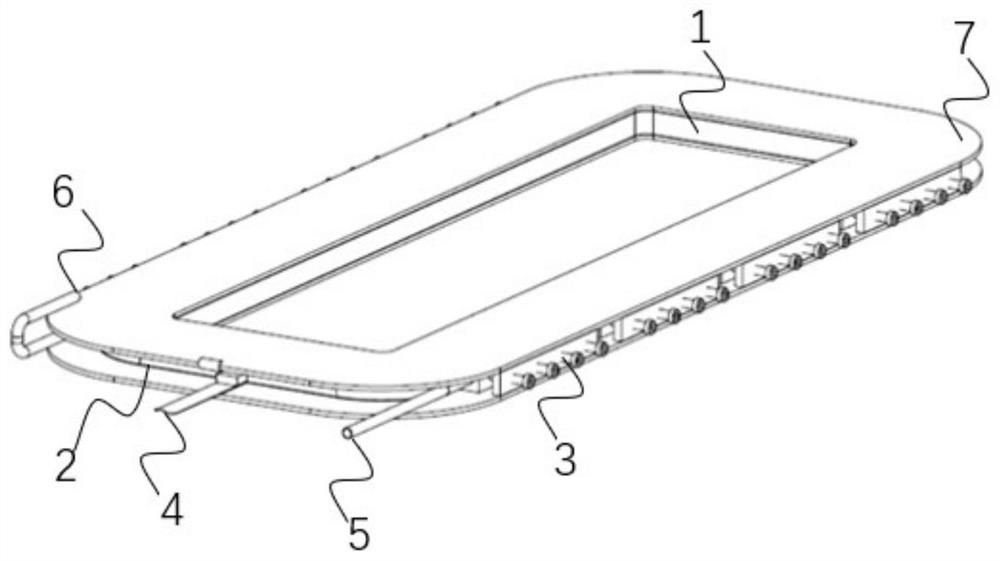

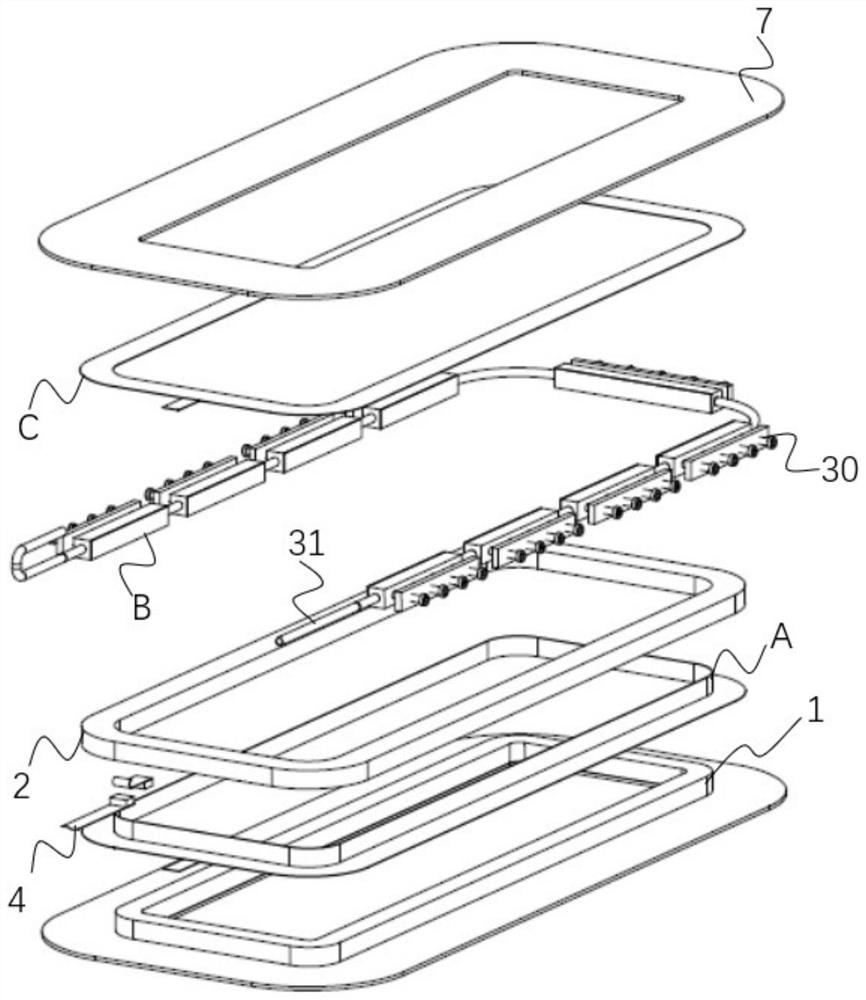

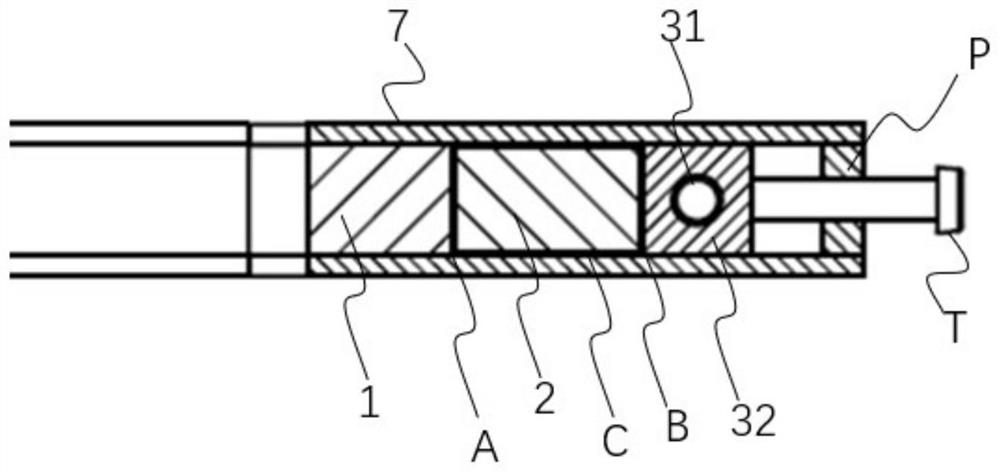

[0027] In Embodiment 1 of the present invention, in combination with figure 1 and figure 2 As shown, the conduction cooling large-scale high-temperature superconducting magnet structure includes a coil former 1, a single high-temperature superconducting coil group 2 wound on the coil former 1, and a cooling channel assembly 3; the coil former 1 and the high-temperature superconducting coil group 2 A first insulating layer A is arranged between them to prevent electrification of the coil skeleton; the high temperature superconducting coil group 2 is provided with an electrical connection component 4, and the electrical connection component 4 is used to excite the high temperature superconducting coil group 2; the cooling channel component 3 and the high temperature A second insulating layer B made of thermally conductive material is arranged between the superconducting coil groups 2 to prevent the cooling channel assembly 3 from being electrified as a whole; The outer surface...

Embodiment 2

[0032] Such as Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 mainly lies in that the conduction-cooled large-scale high-temperature superconducting magnet structure in this embodiment includes six high-temperature superconducting coil groups 2, and there is cooling between adjacent high-temperature superconducting coil groups 2. The plates 7 are electrically connected to the adjacent high-temperature superconducting coil groups 2 through the electrical connection assembly 4 . Including six stacked high-temperature superconducting coil groups 2 is a preferred illustration of this embodiment in conjunction with the accompanying drawings. In practical applications, the high-temperature superconducting coil group 2 is not limited to six, and there may be more or fewer , is not limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com