Temperature-uniformizing non-stick cooker

A technology of pots and outer pots, which is applied to the structure of household utensils, kitchen utensils, cooking utensils, etc., can solve the problems of difficult cleaning, poor physical non-stick effect of the bottom of the pot, easy sticking of rice to the bottom of the pot, etc., and achieve good results , the effect of uniform temperature is good, and the effect of shortening the time to be consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

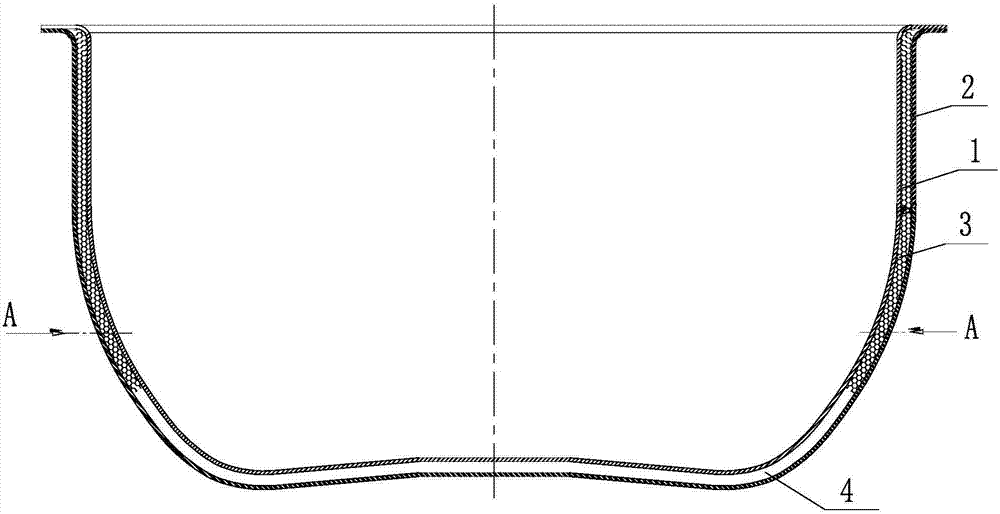

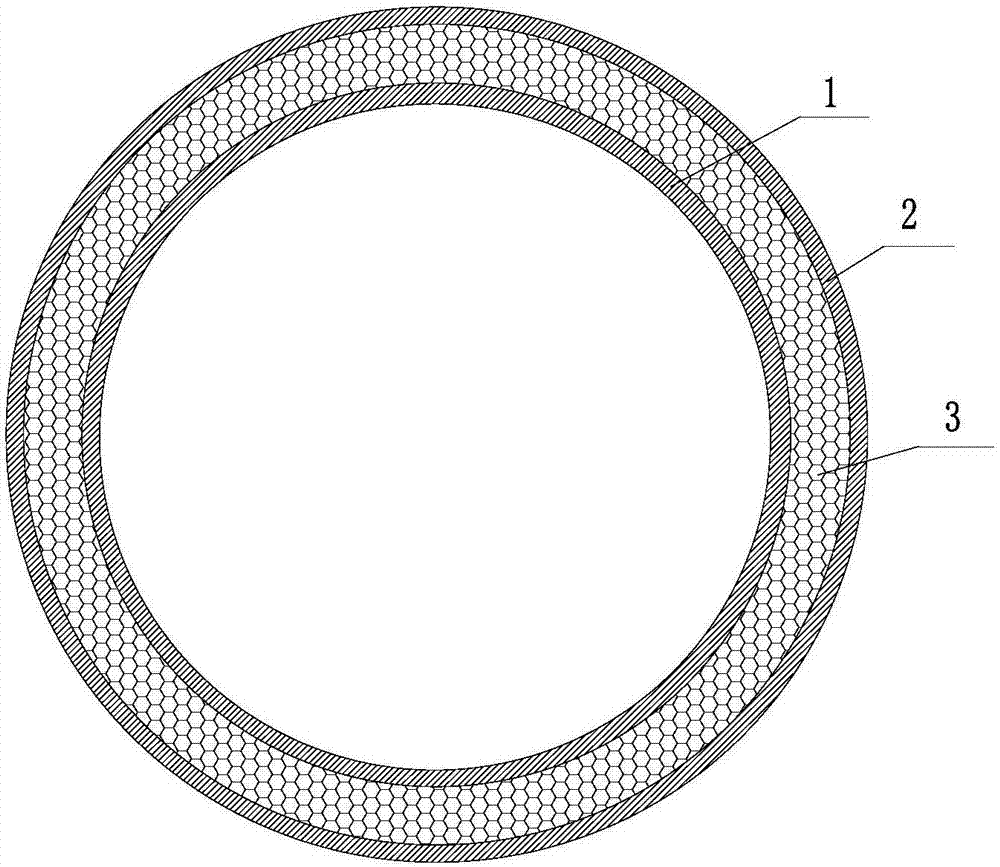

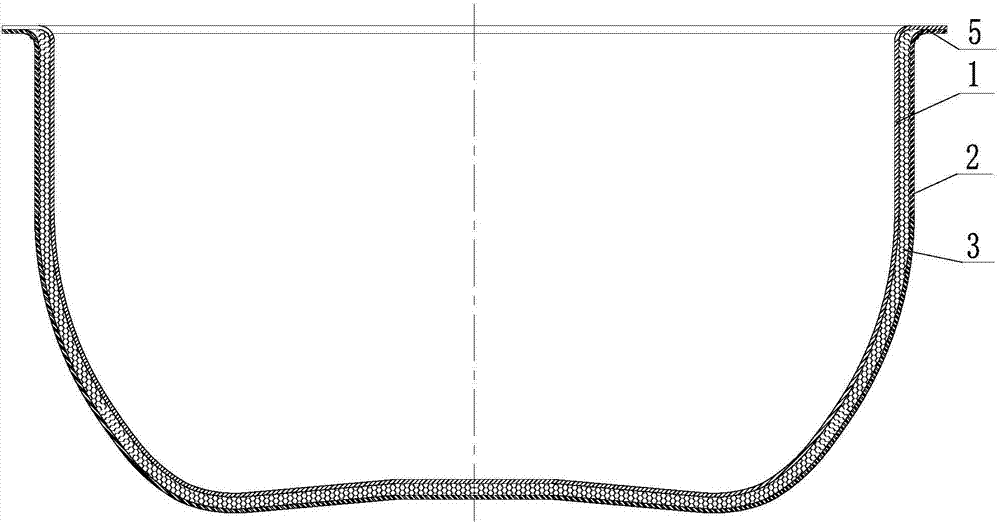

[0029] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0030] Such as Figure 1 ~ Figure 3 As shown, the non-stick cookware of this embodiment includes:

[0031] Inner pot 1;

[0032] Outer pot 2. The outer pot 2 is sleeved on the outside of the inner pot 1, and its upper end is sealed and connected with the upper end of the inner pot 1 to form a closed vacuum chamber 4;

[0033] The liquid wick 3 is sleeved outside the inner pot 1 in a ring structure and is located in the vacuum cavity 4, or the liquid wick 3 fills the vacuum cavity 4; The liquid wick 3 is fixed on the outer side wall of the inner pot 1 and / or the inner side wall of the outer pot 2; the liquid wick 3 is a porous foam metal piece;

[0034] The vacuum chamber 4 is provided with a liquid phase change working medium that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com