Heat dissipating system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Before the present invention is described in greater detail, it should be noted that the same reference numerals have been used to denote like elements throughout the specification.

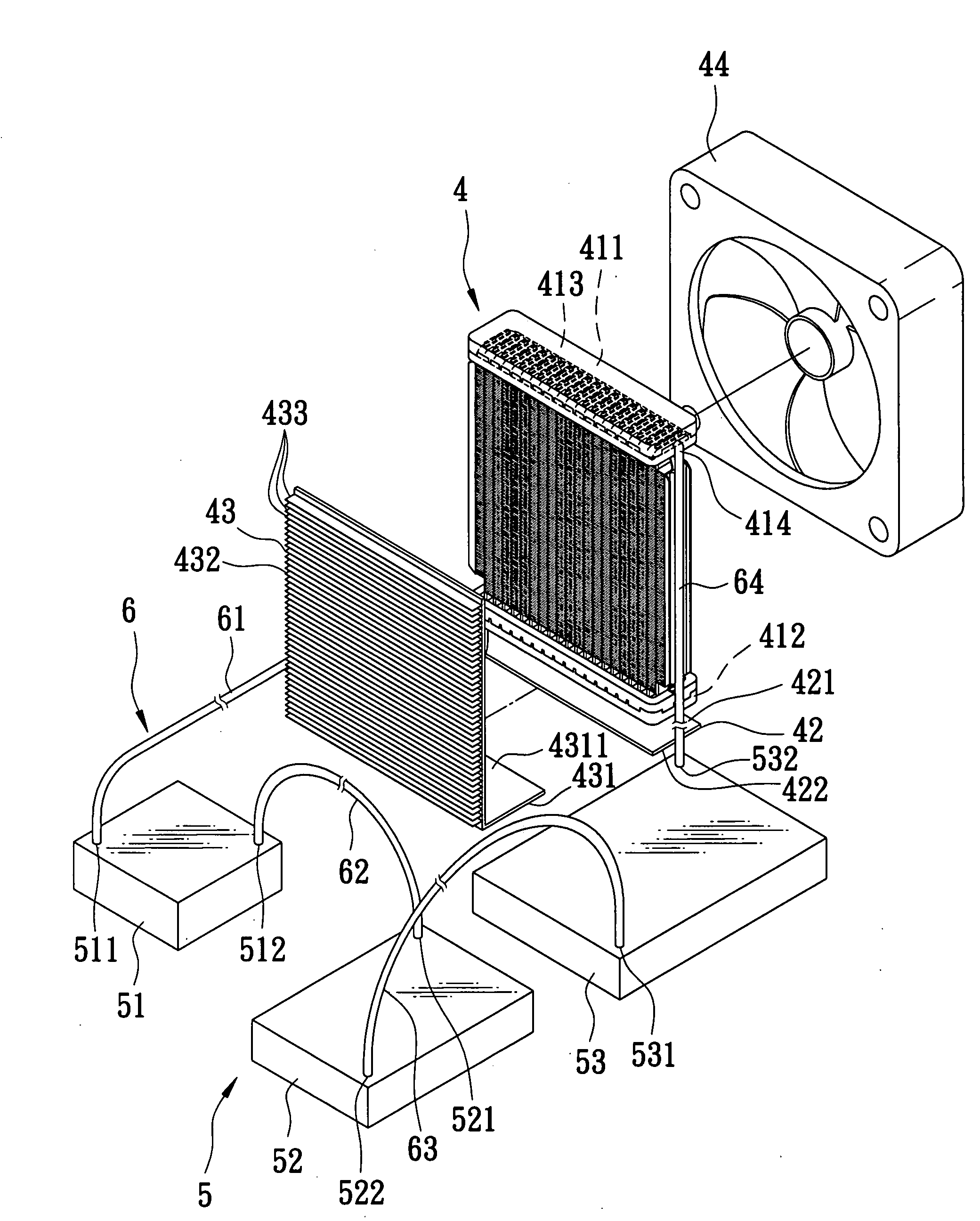

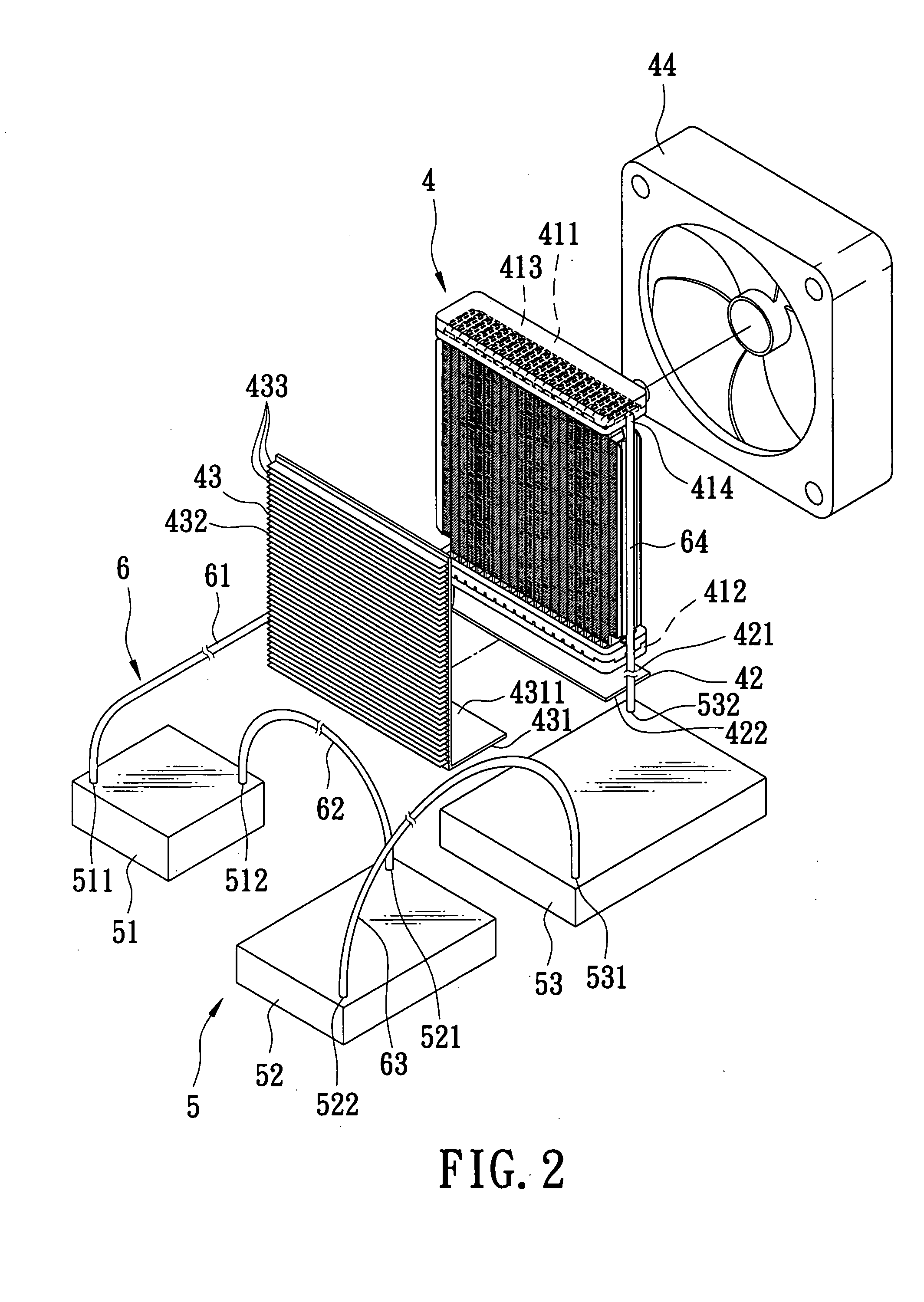

[0021]Referring to FIGS. 2 to 5, the first preferred embodiment of a heat dissipating system according to the present invention is installed in a computer module 3. The computer module 3 has a housing 33 defining upper and lower chambers 31, 32, a mounting board 34 fixed inside the lower chamber 32, and a plurality of module chips 35 mounted on the mounting board 34. The heat dissipating system of the present invention comprises a condenser 4, a heat-absorbing unit 5, and a tubing unit 6. The module chips 35 are heat sources to undergo heat dissipation by the system of the present invention. The condenser 4 is disposed in the upper chamber 31 of the computer module 3, and includes a vapor-receiving part 411 formed on a top end thereof, an inlet 414 connected fluidly to the vapor-receiving part 411, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com