Patents

Literature

213results about How to "Maintenance operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

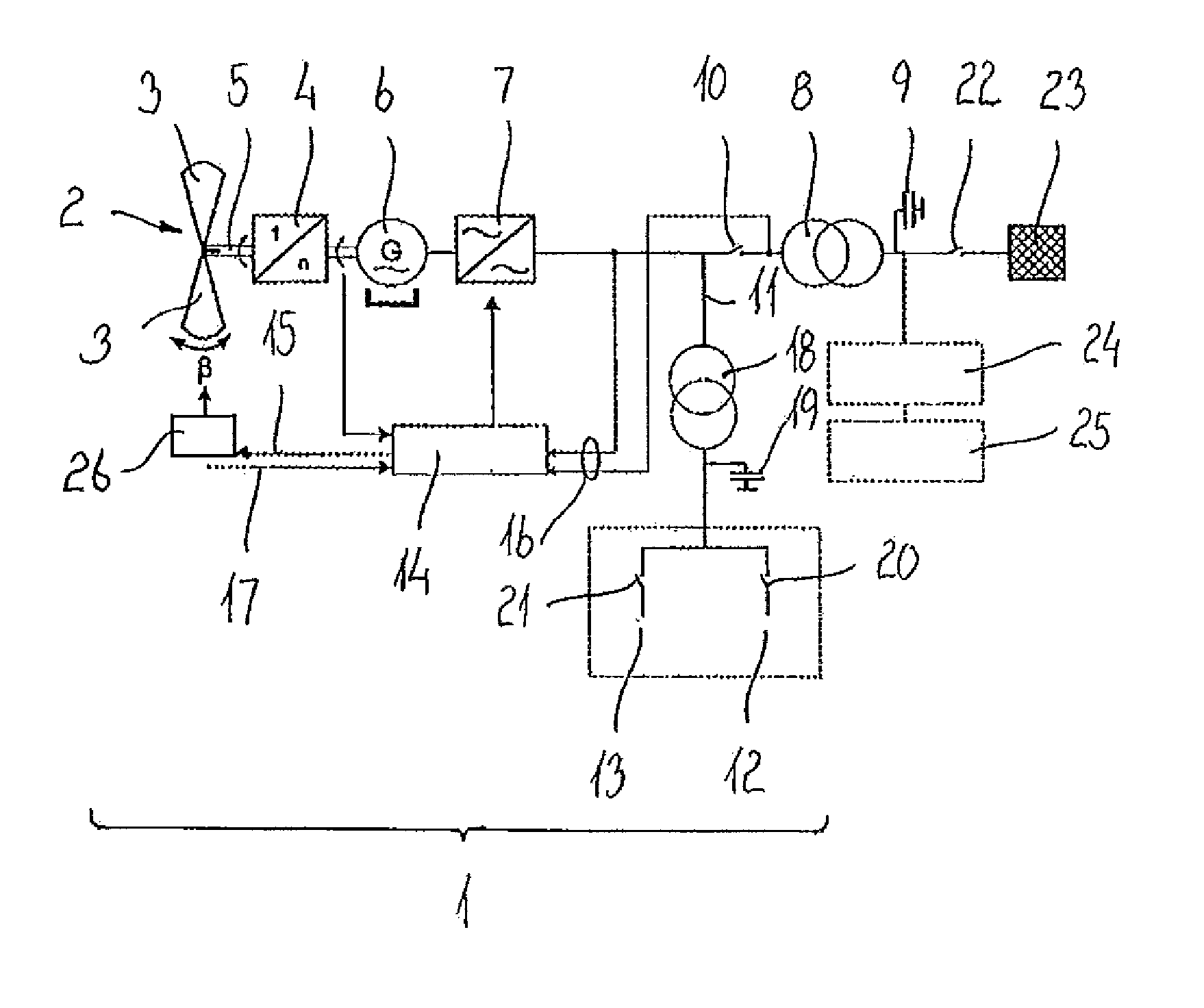

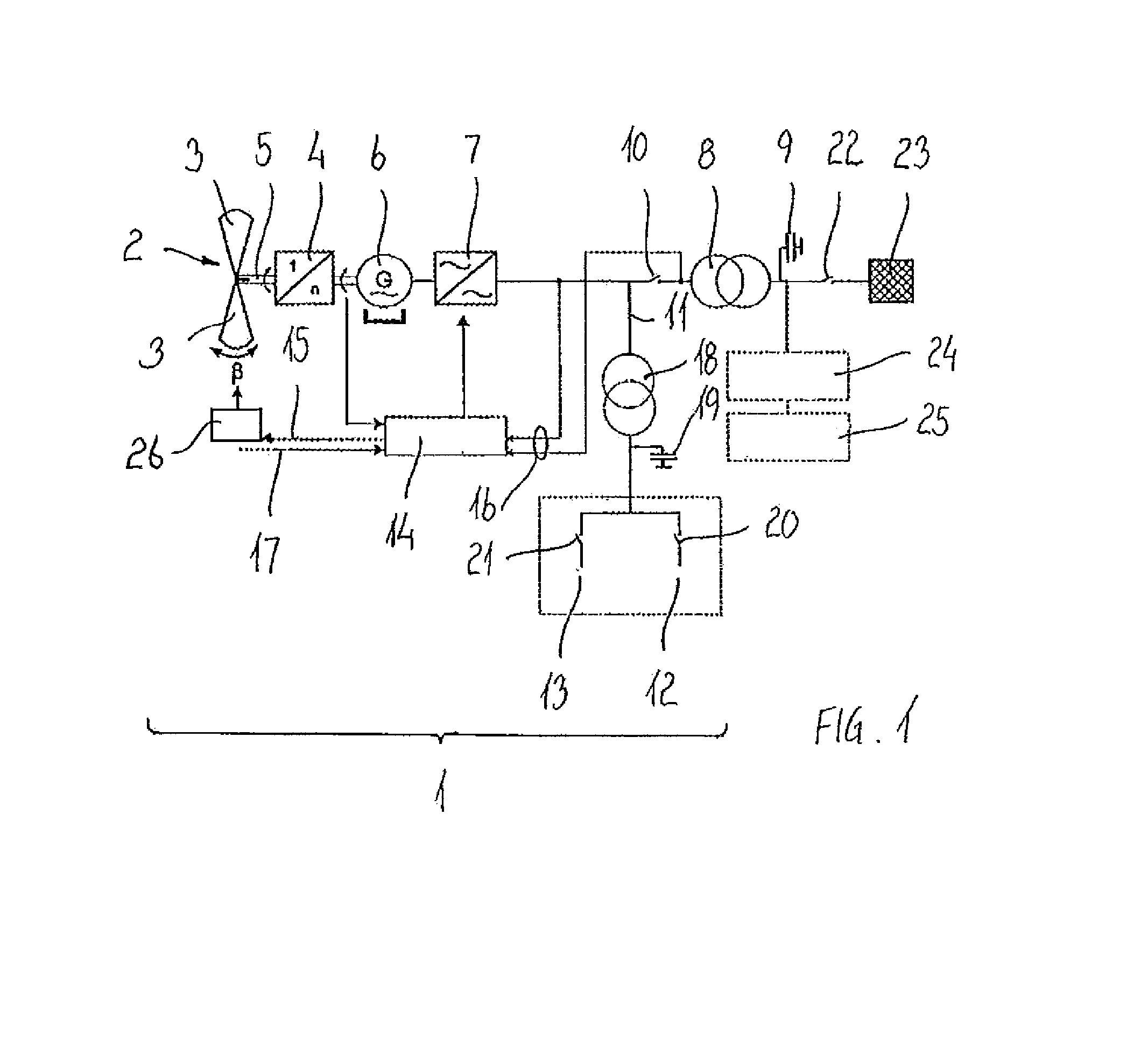

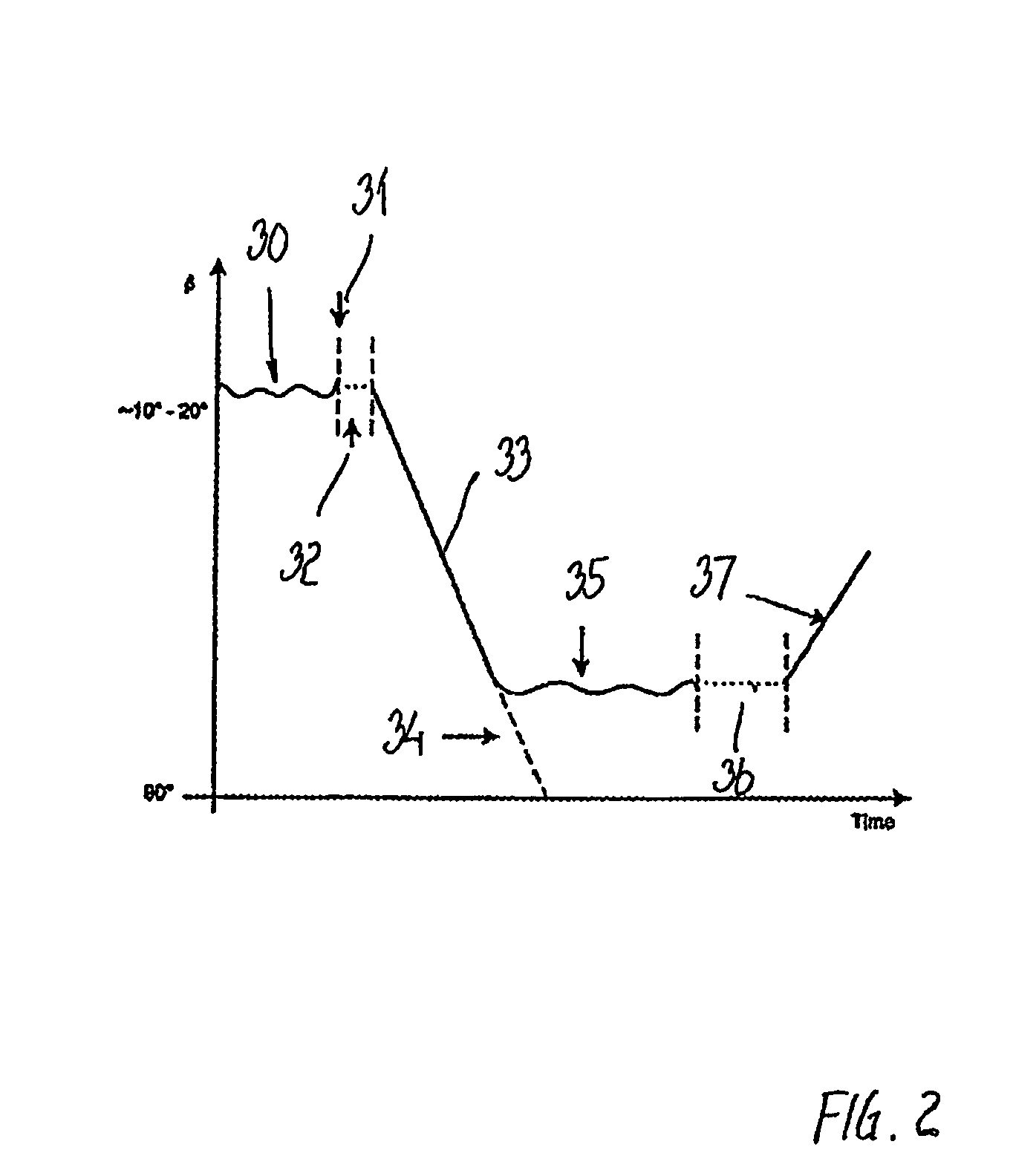

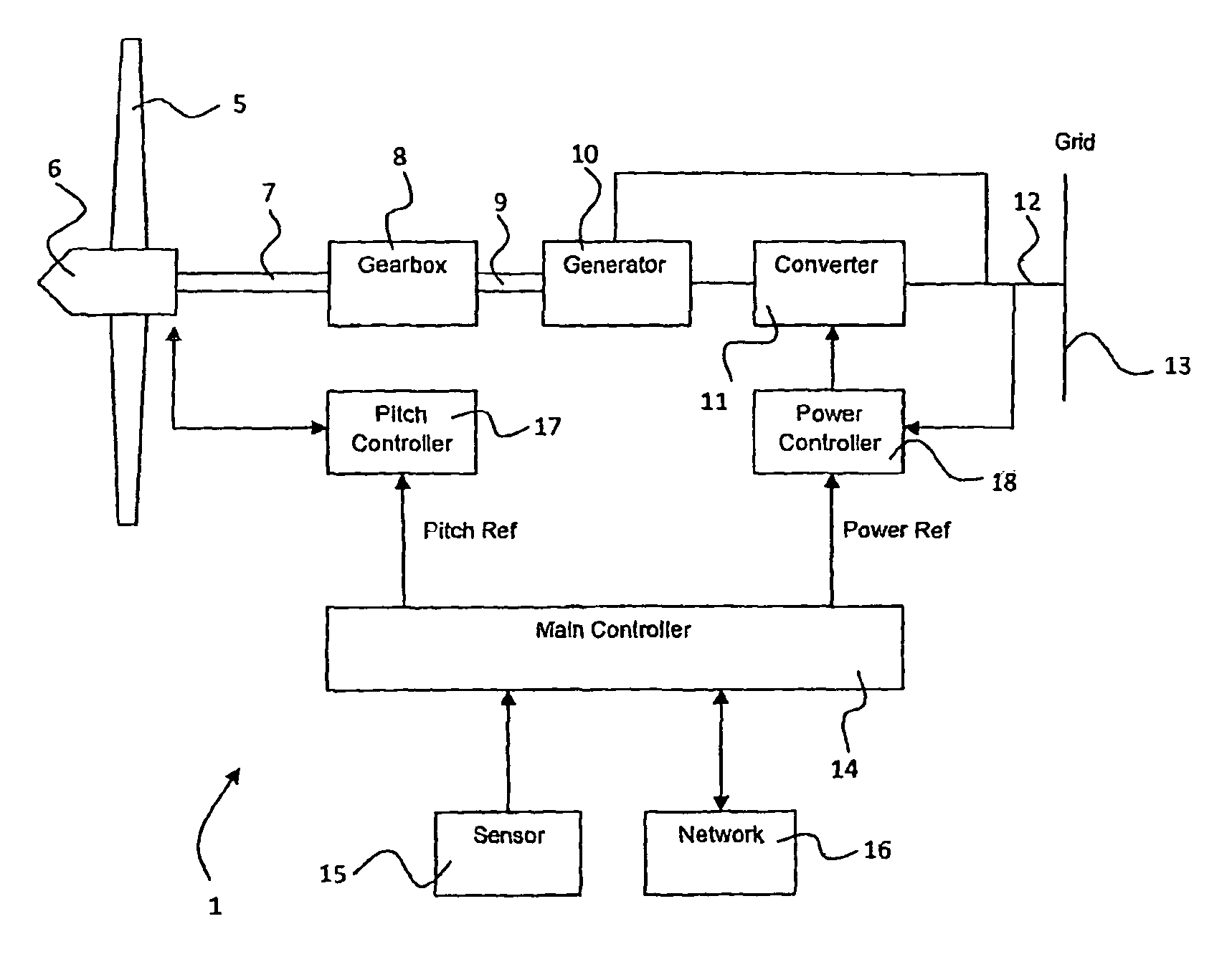

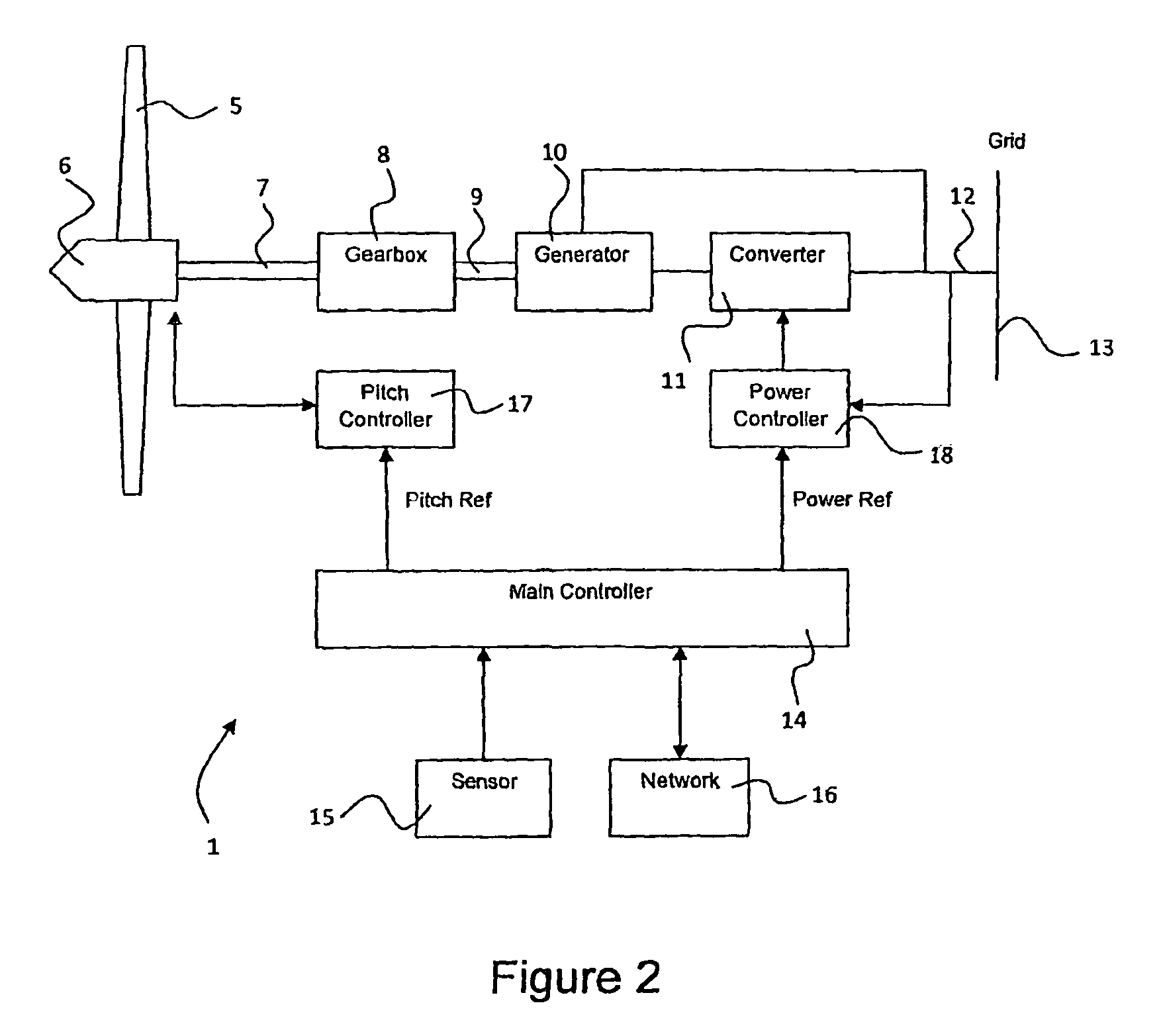

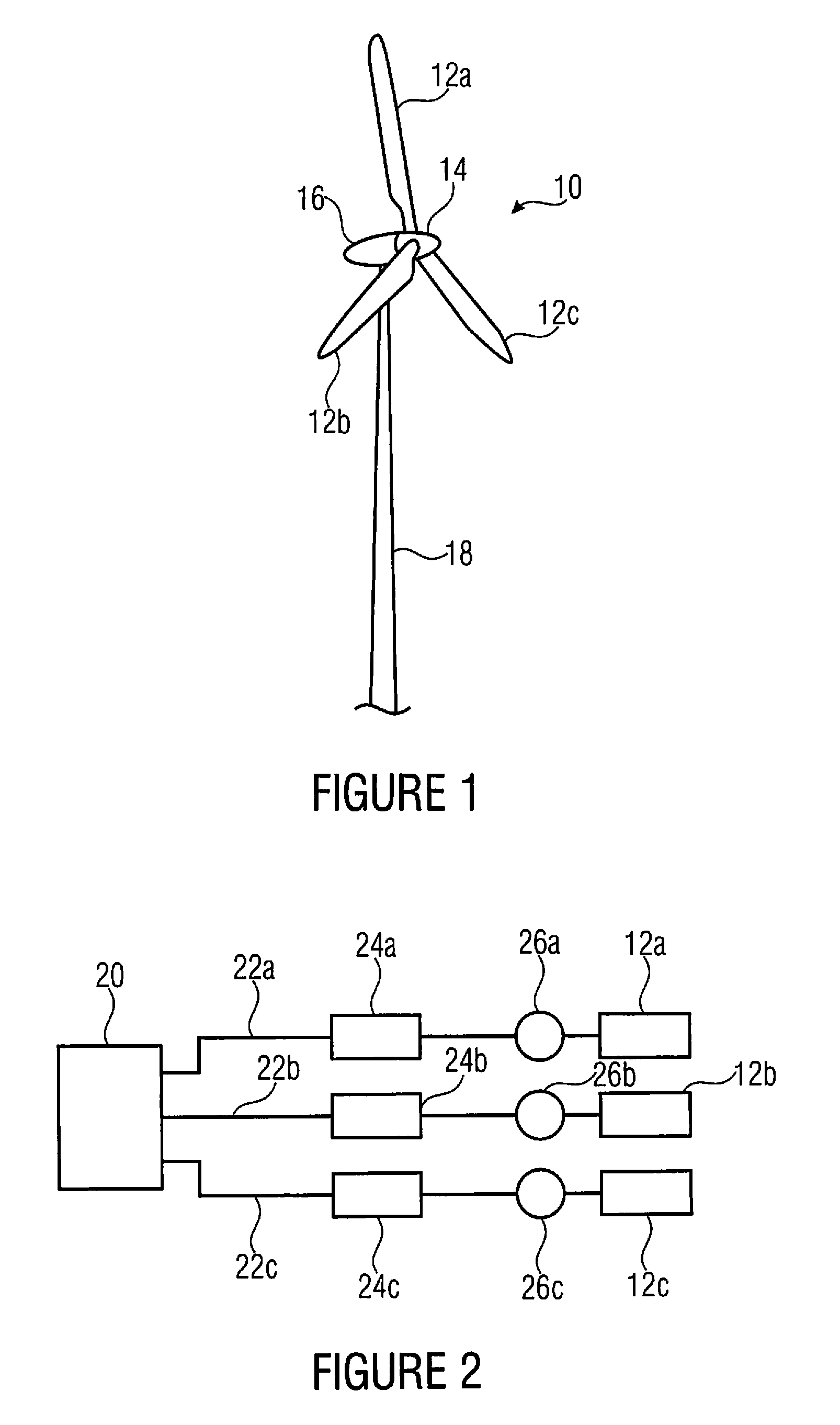

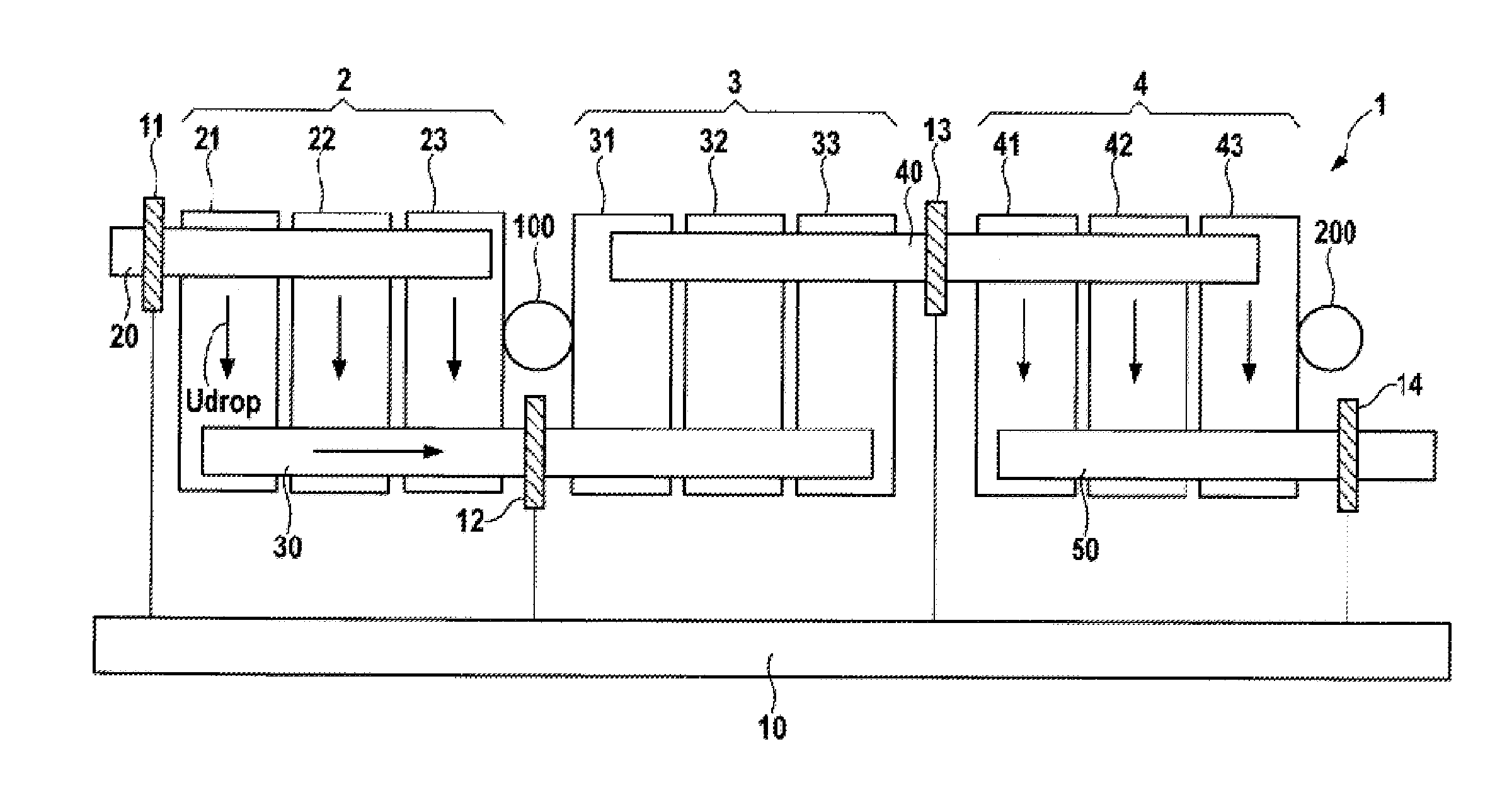

Wind turbine having a control method and controller for performing predictive control of a wind turbine generator

ActiveUS20130106107A1Reduced operating wearReduce tearingOptimise machine performanceWind motor controlWind forceElectric generator

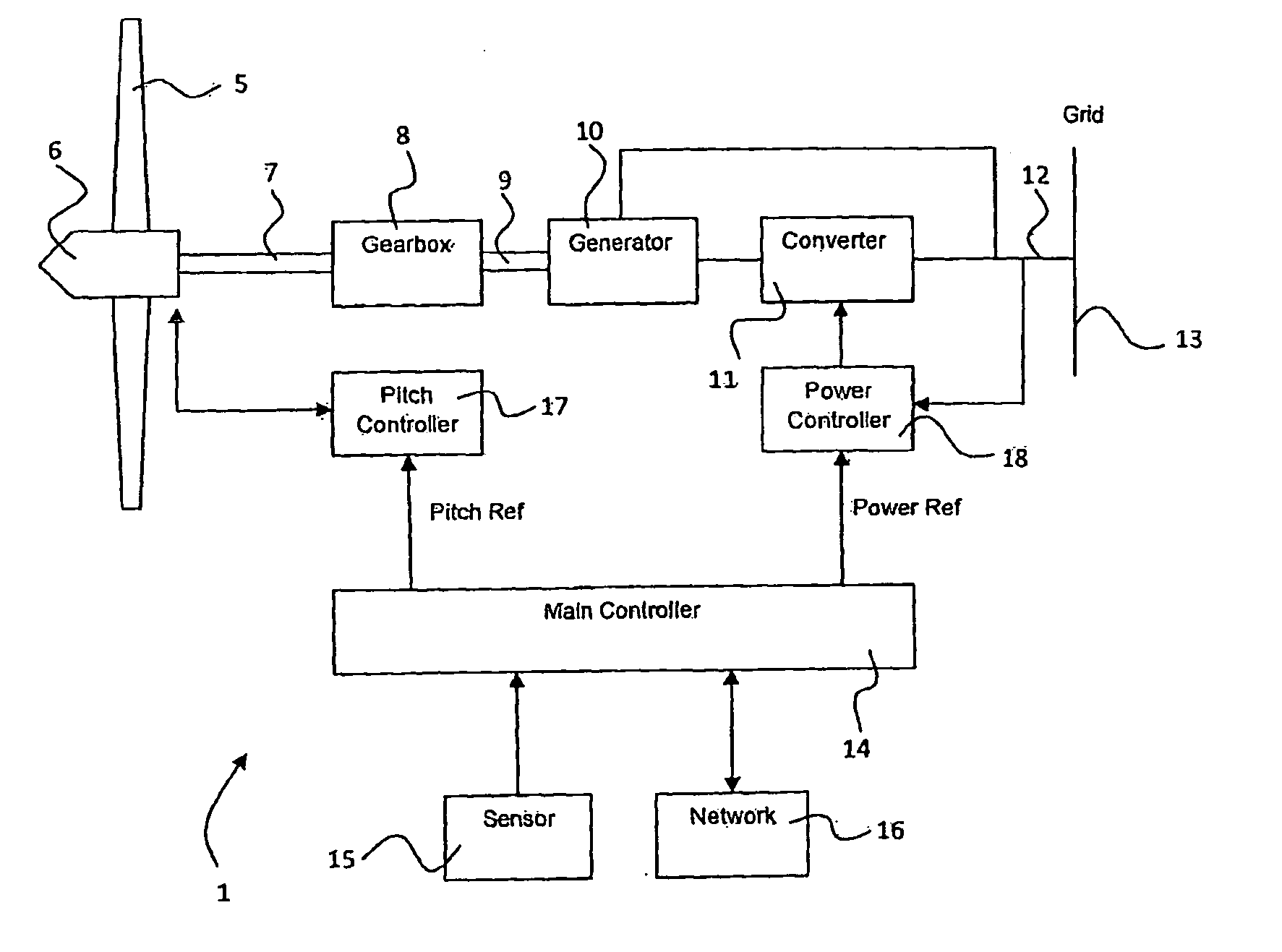

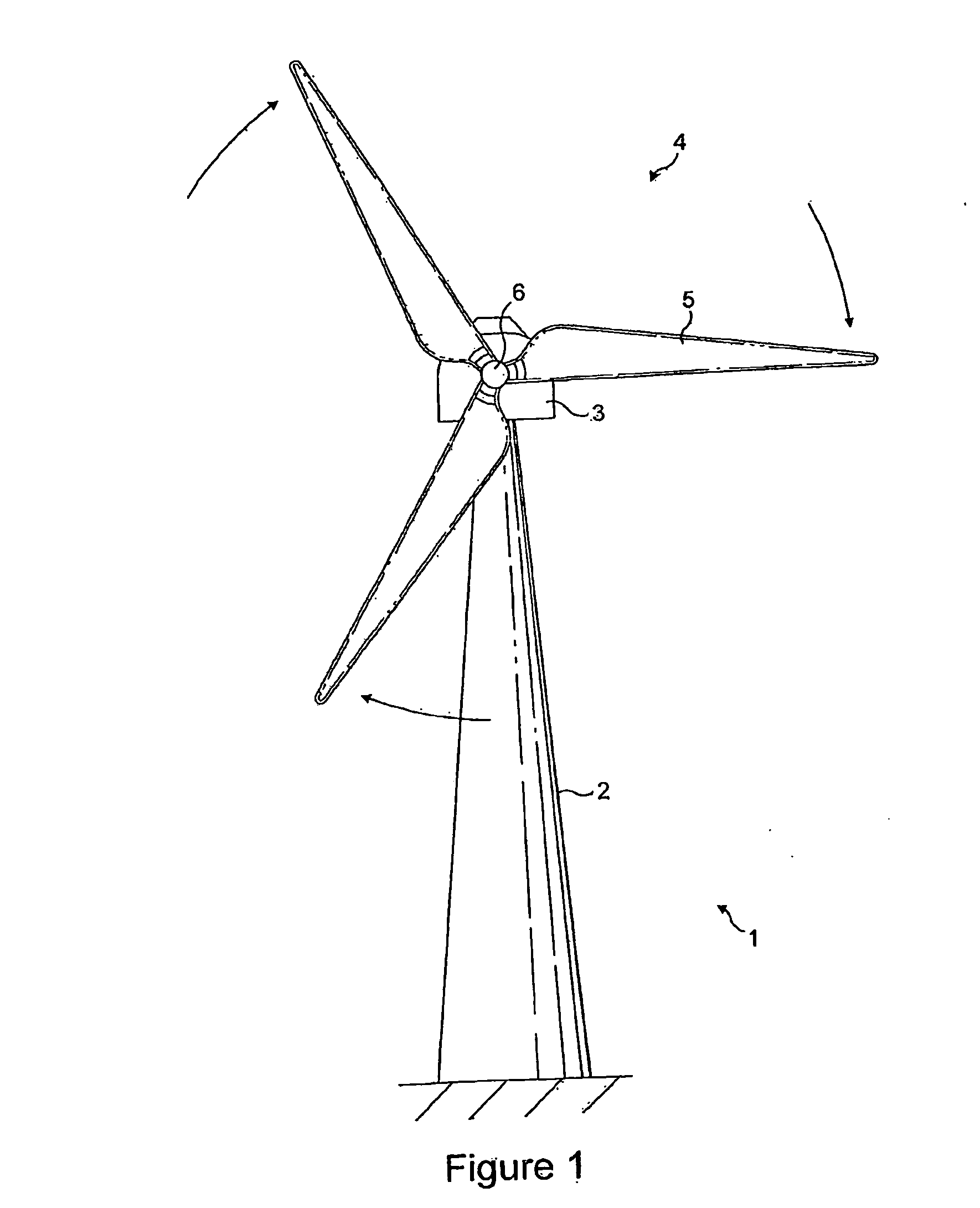

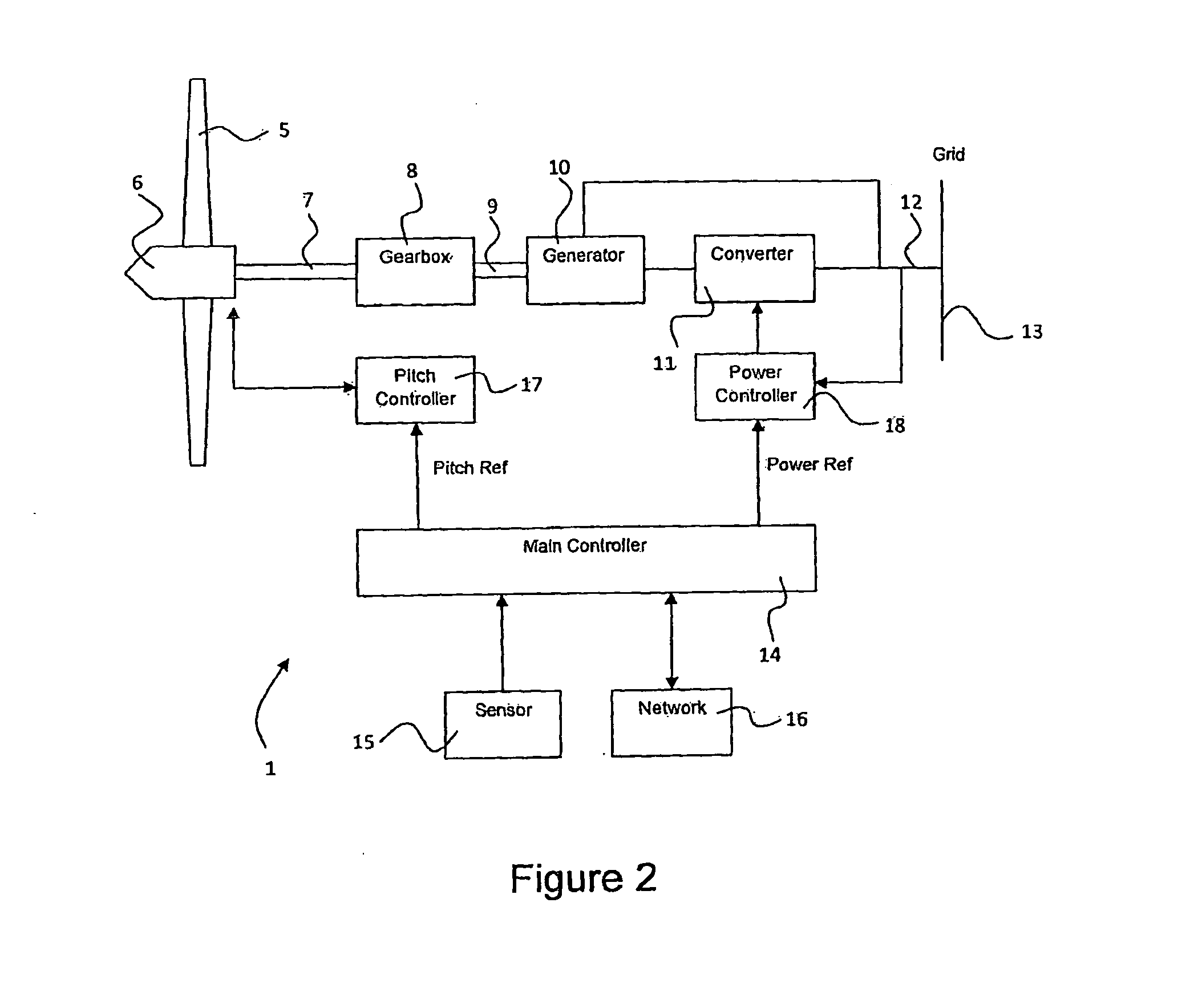

The application describes a wind turbine having a control method and controller for performing predictive control of a wind turbine generator. Based on the measured instantaneous wind speed, it is known to provide control signals to a wind turbine in order to control the pitch of the wind turbine rotor blades and the speed of the generator. However, it is difficult using instantaneous wind speed measurements to achieve smooth control, due to finite response speeds of the associated electro-mechanical systems, as well as the constantly changing control system inputs. The predictive control system described in the application assumes a model of generator speed based on the values of the incident wind speed v(t) and the values of a control signal u(t) output to the wind turbine in a feed forward loop. Here, the control signal can be for one or more of controlling either the power setting of the generator, or the pitch angle of the rotor blades. The predictive controller uses a rolling time series of values for v(t) and u(t) and based on a predicted response of the generator speed w(t) optimises the time series control signal u(t). The predicted response of the generator speed w(t) is based on model, that can be refined in real time as the wind turbine operates.

Owner:VESTAS WIND SYST AS

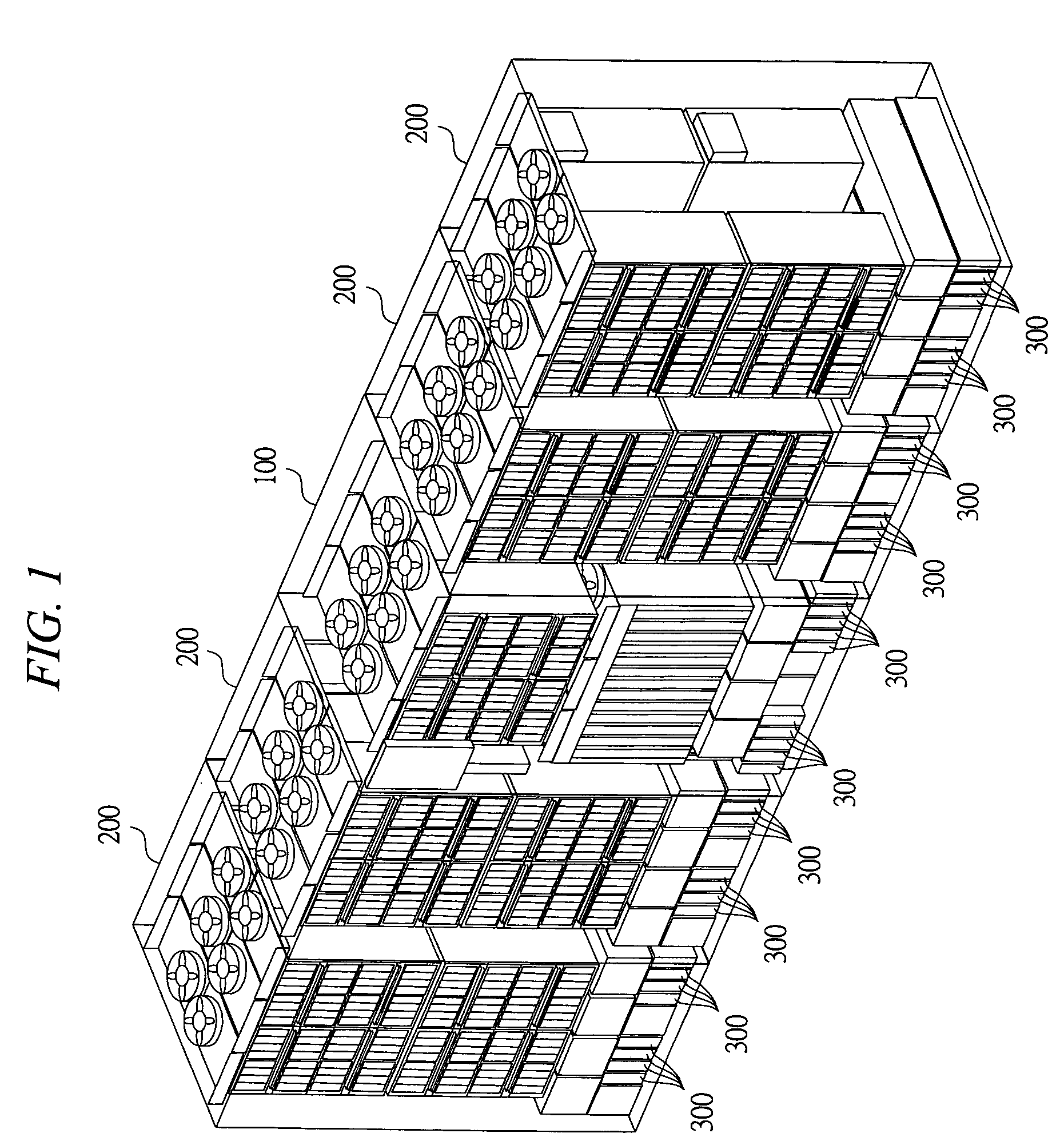

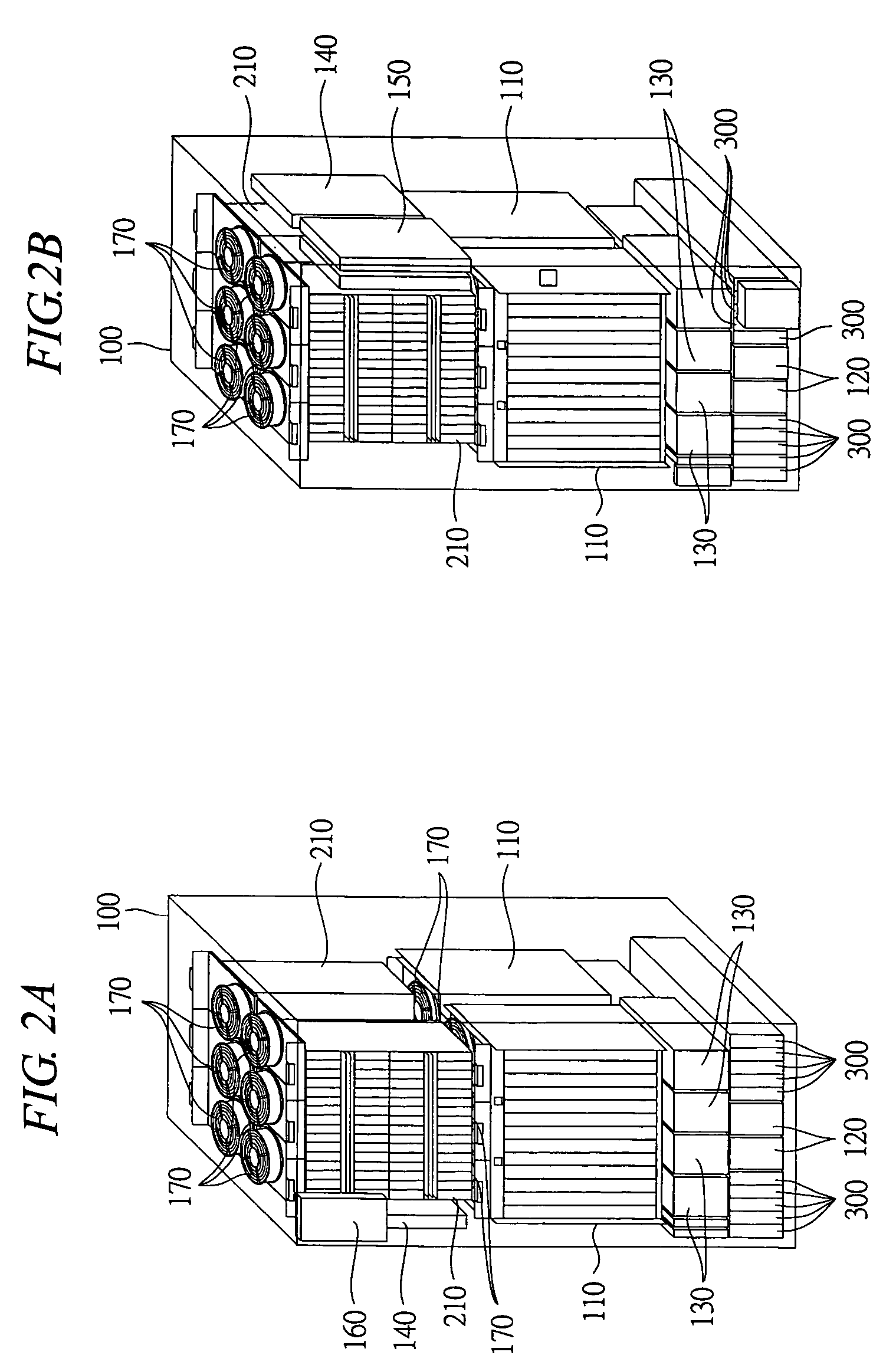

Disk array device

ActiveUS7133282B2Increased durabilityMaintenance operationReducing temperature influence on carrierBatteries circuit arrangementsElectrical batteryStandby power

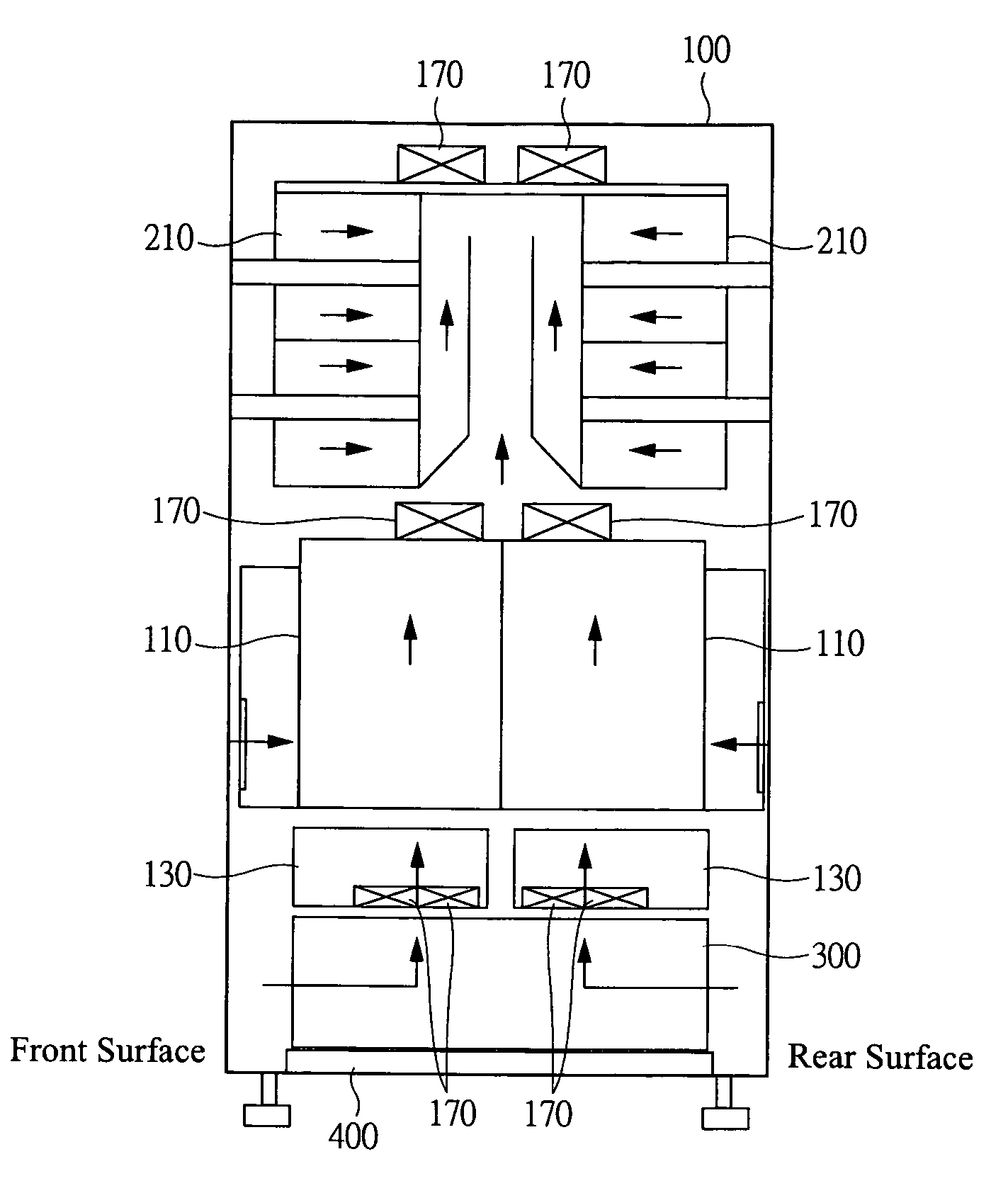

A disk array device can carry out battery backup including a destage process of data by a battery mounted in a case body of the disk array device and can enhance instantaneous power failure durability to an instantaneous power failure. A logic box mounts a channel controlling unit, a disk controlling unit, a cache memory and a switch; and a hard disk box mounts a plurality of memory devices. A battery box mounts a nickel hydrogen battery for supplying a backup power source at the time of a power failure and is disposed at a lower portion of each case body including the logic box and the hard disk box. The nickel hydrogen battery of the battery box is cooled through natural convection of air created inside the case body by a fan for cooling each of the logic box and the hard disk box.

Owner:RAKUTEN GRP INC

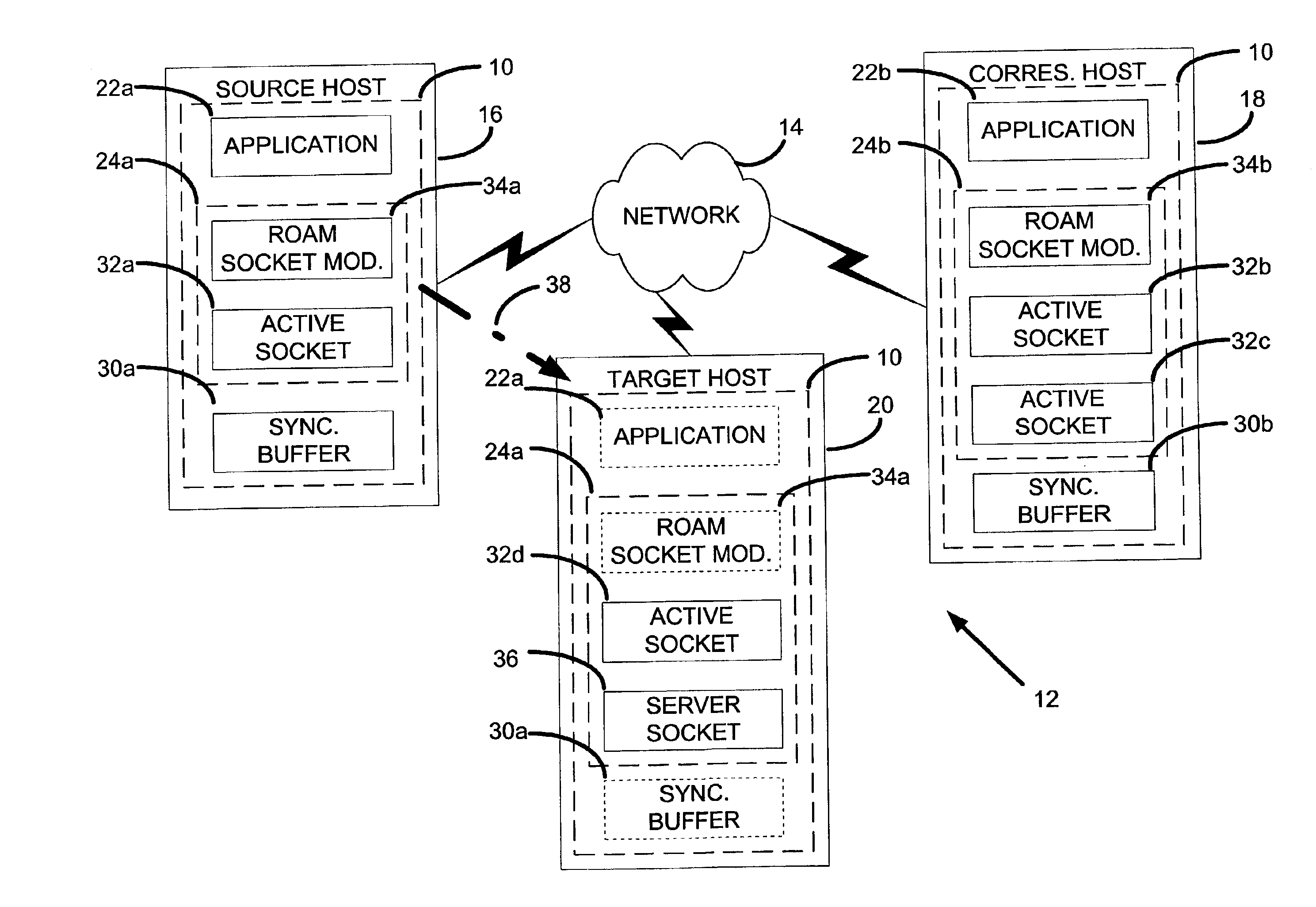

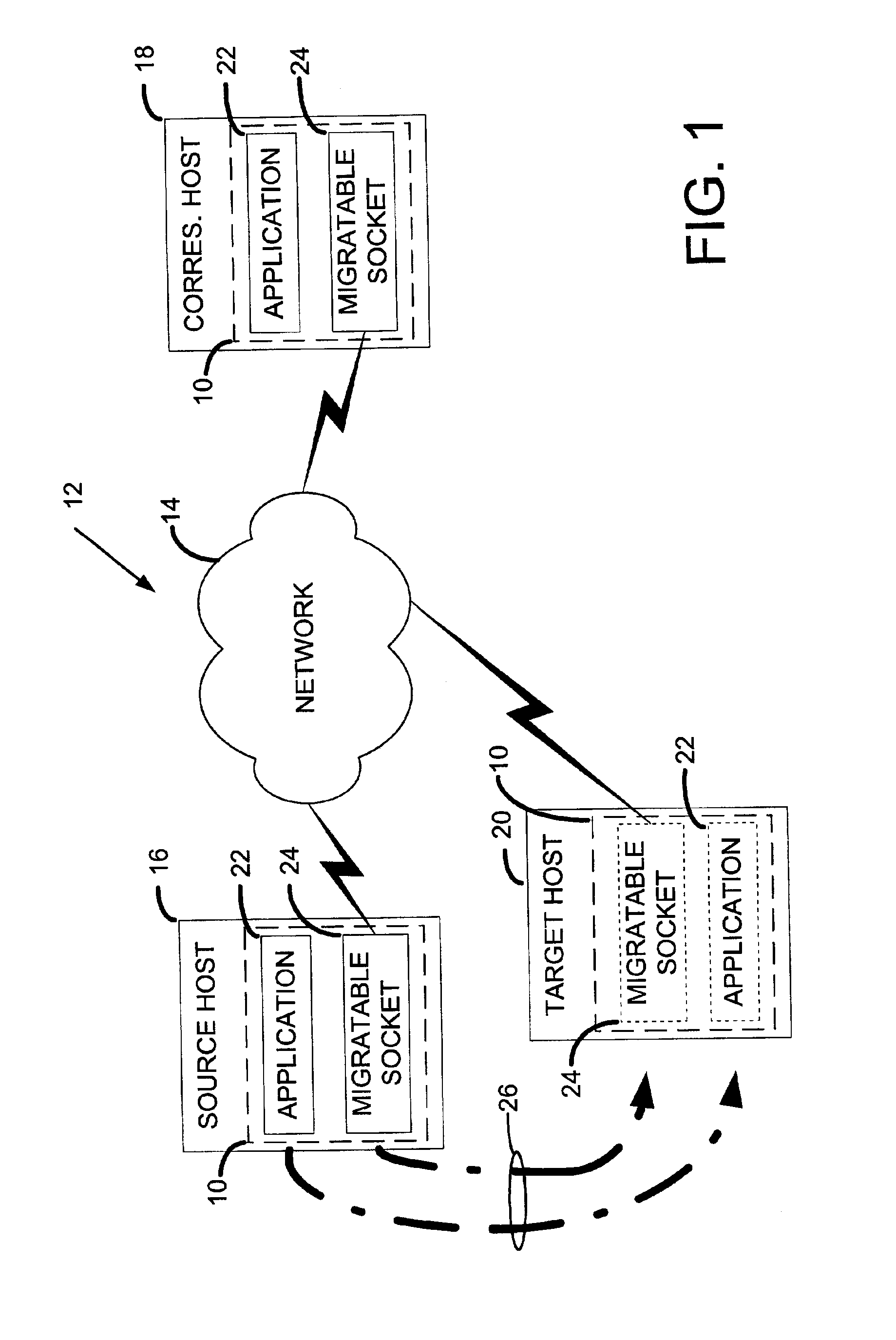

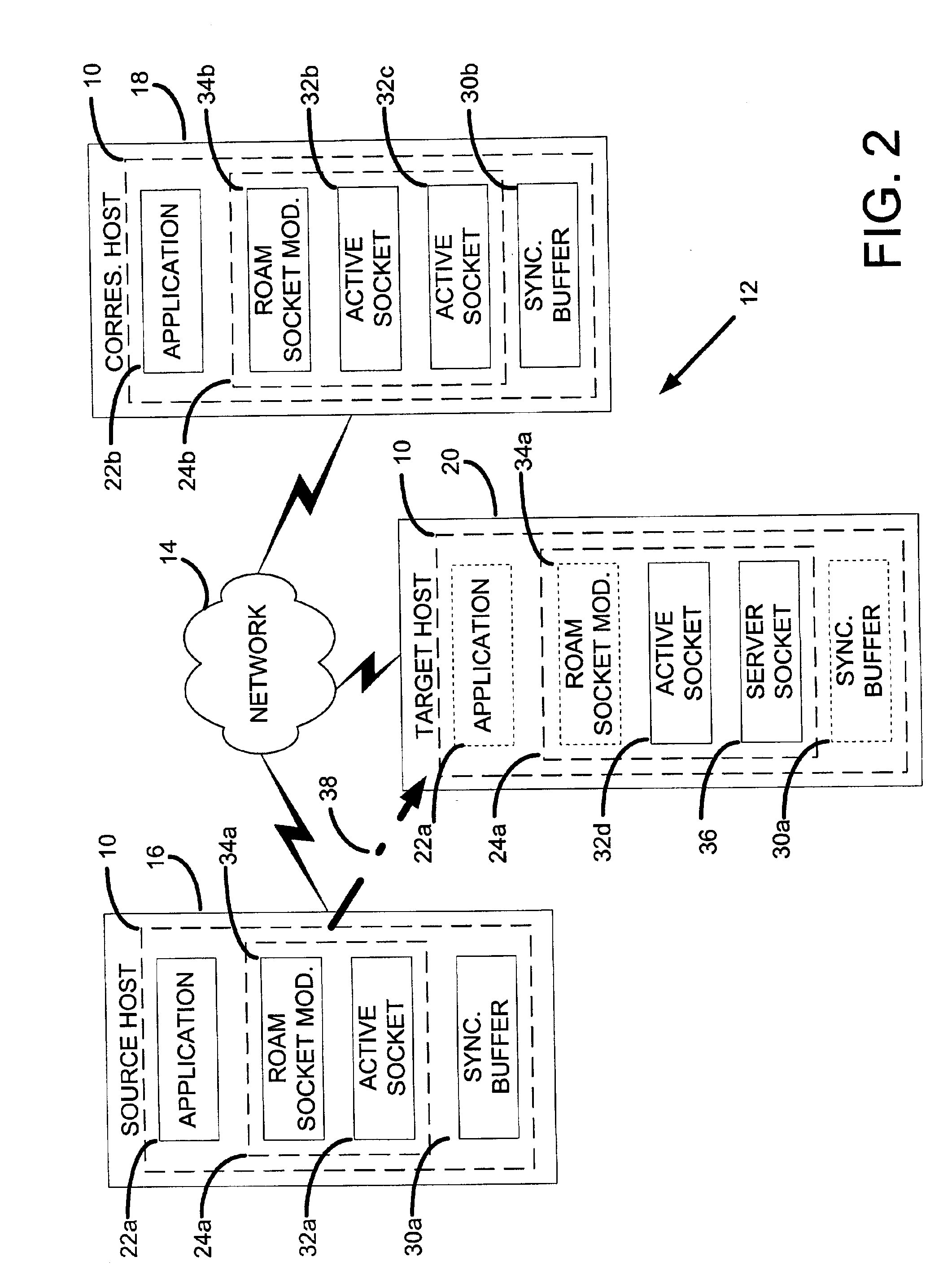

Communication socket migration among different devices

InactiveUS6920501B2Maintenance operationMultiple digital computer combinationsSecuring communicationMultiple applicationsPeer-to-peer

Owner:NTT DOCOMO INC

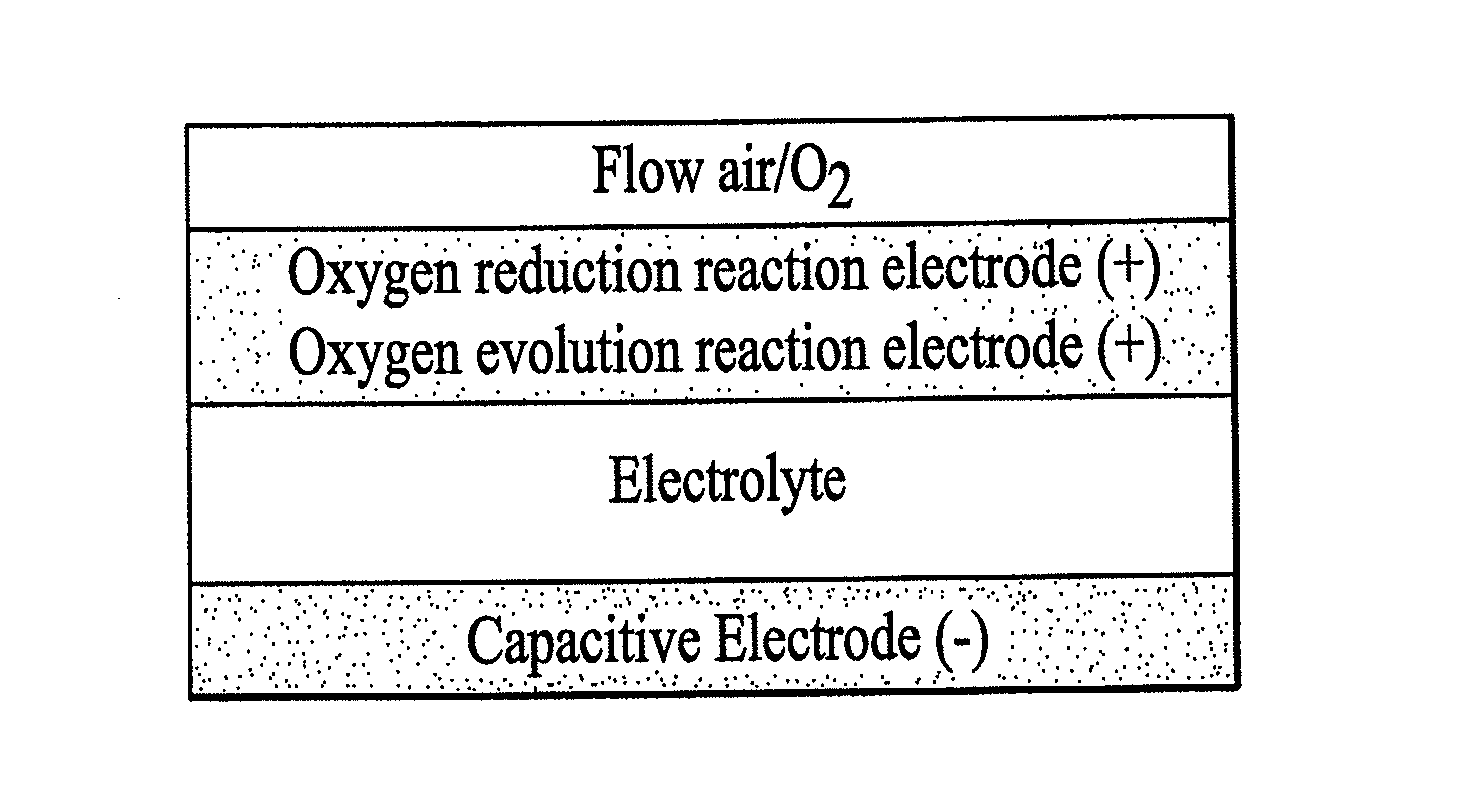

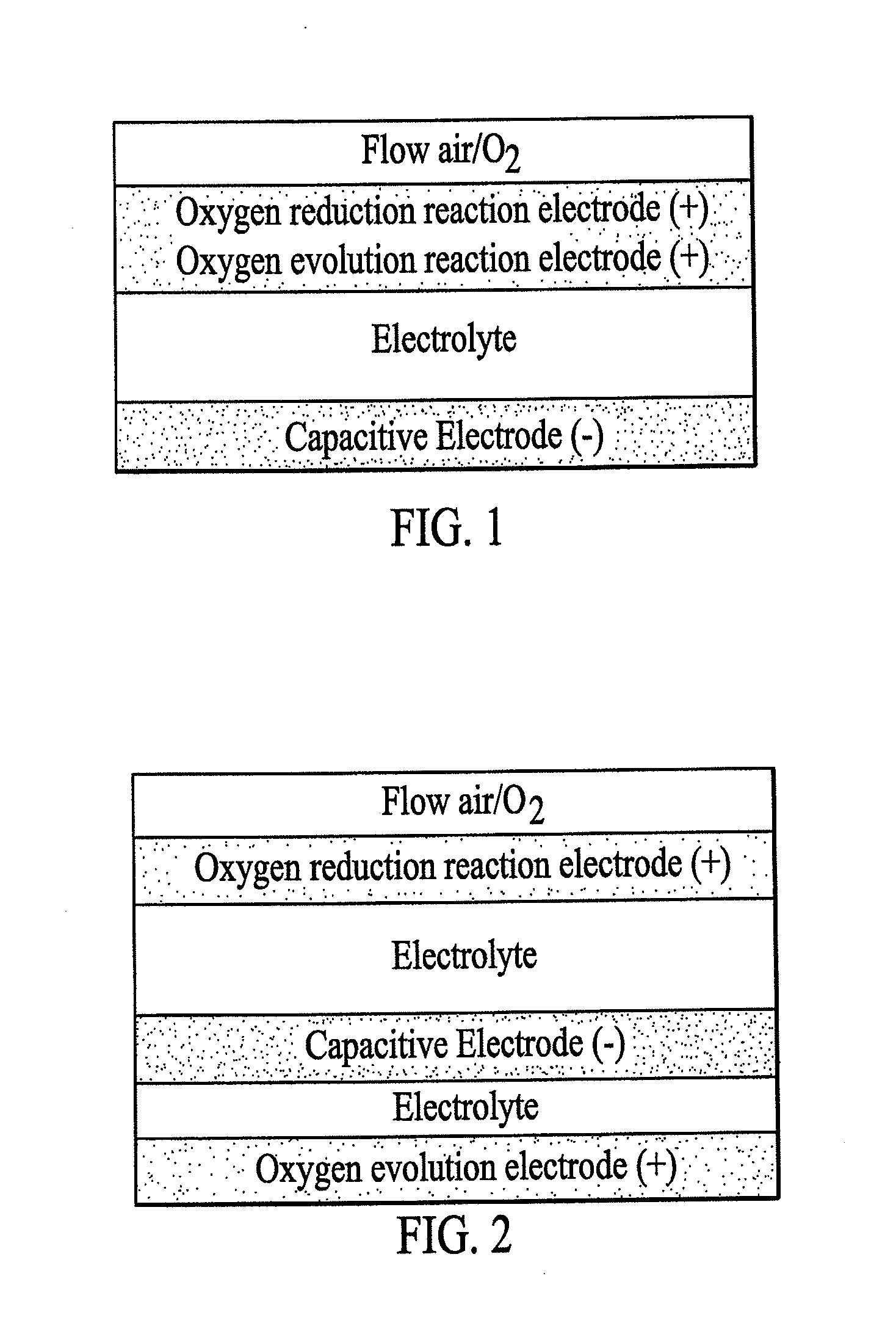

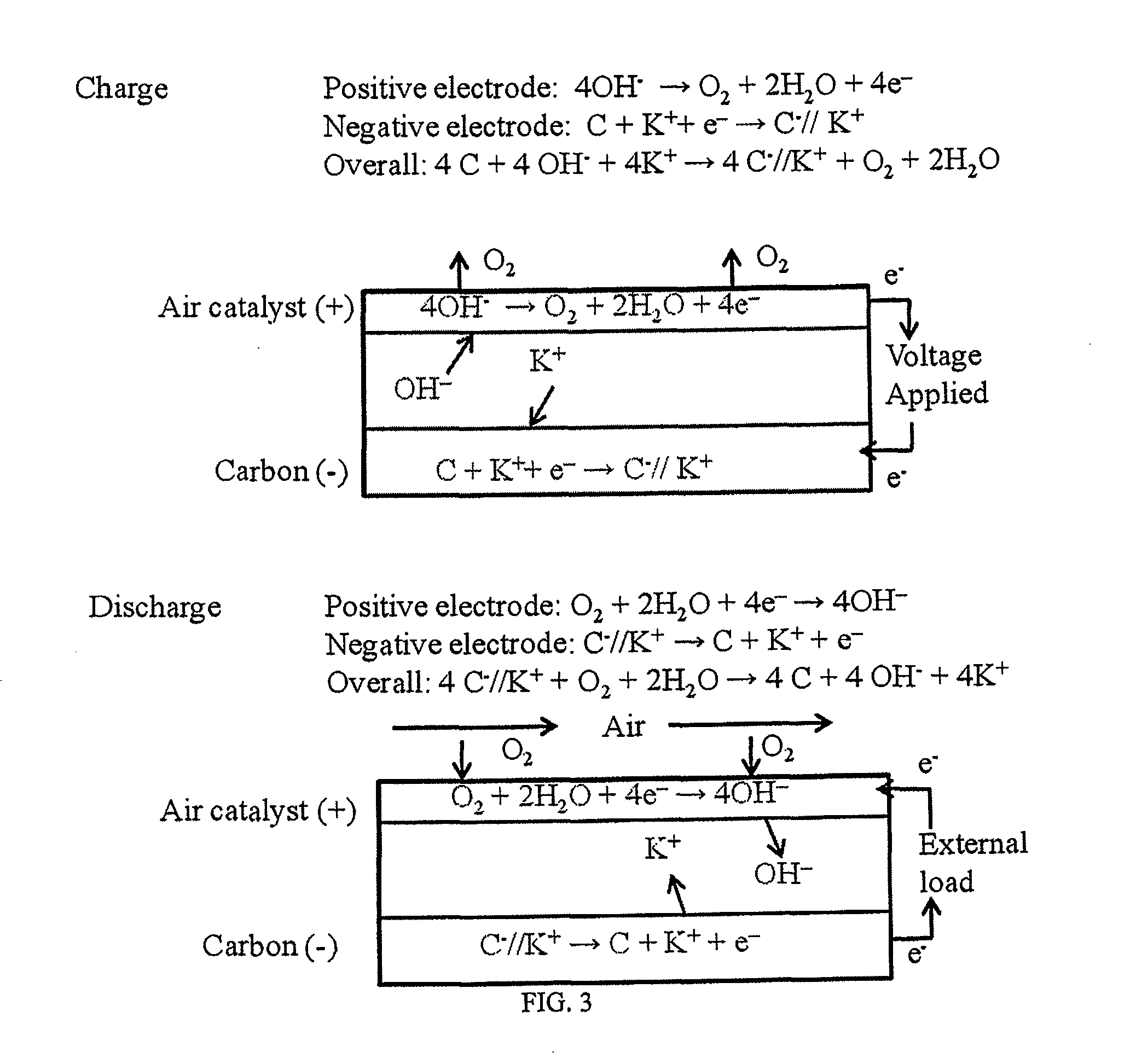

Rechargeable electrochemical energy storage device

InactiveUS20120140378A1Increase energy densityReduce weightFuel and primary cellsFuel and secondary cellsFuel cellsHybrid system

A rechargeable energy storage device is disclosed. In at least one embodiment the energy storage device includes an air electrode providing an electrochemical process comprising reduction and evolution of oxygen and a capacitive electrode enables an electrode process consisting of non-faradic reactions based on ion absorption / desorption and / or faradic reactions. This rechargeable energy storage device is a hybrid system of fuel cells and ultracapacitors, pseudocapacitors, and / or secondary batteries.

Owner:IMRA AMERICA

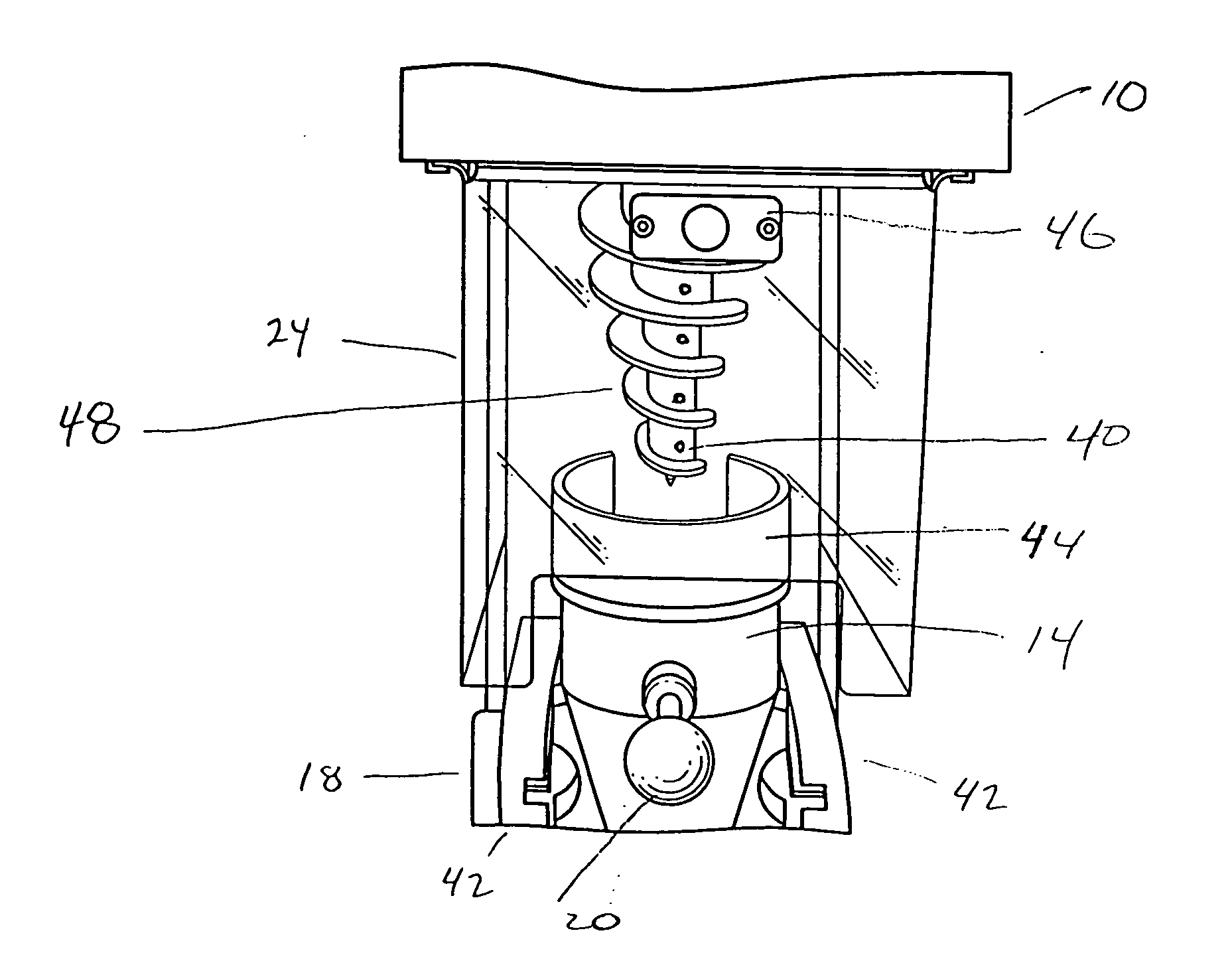

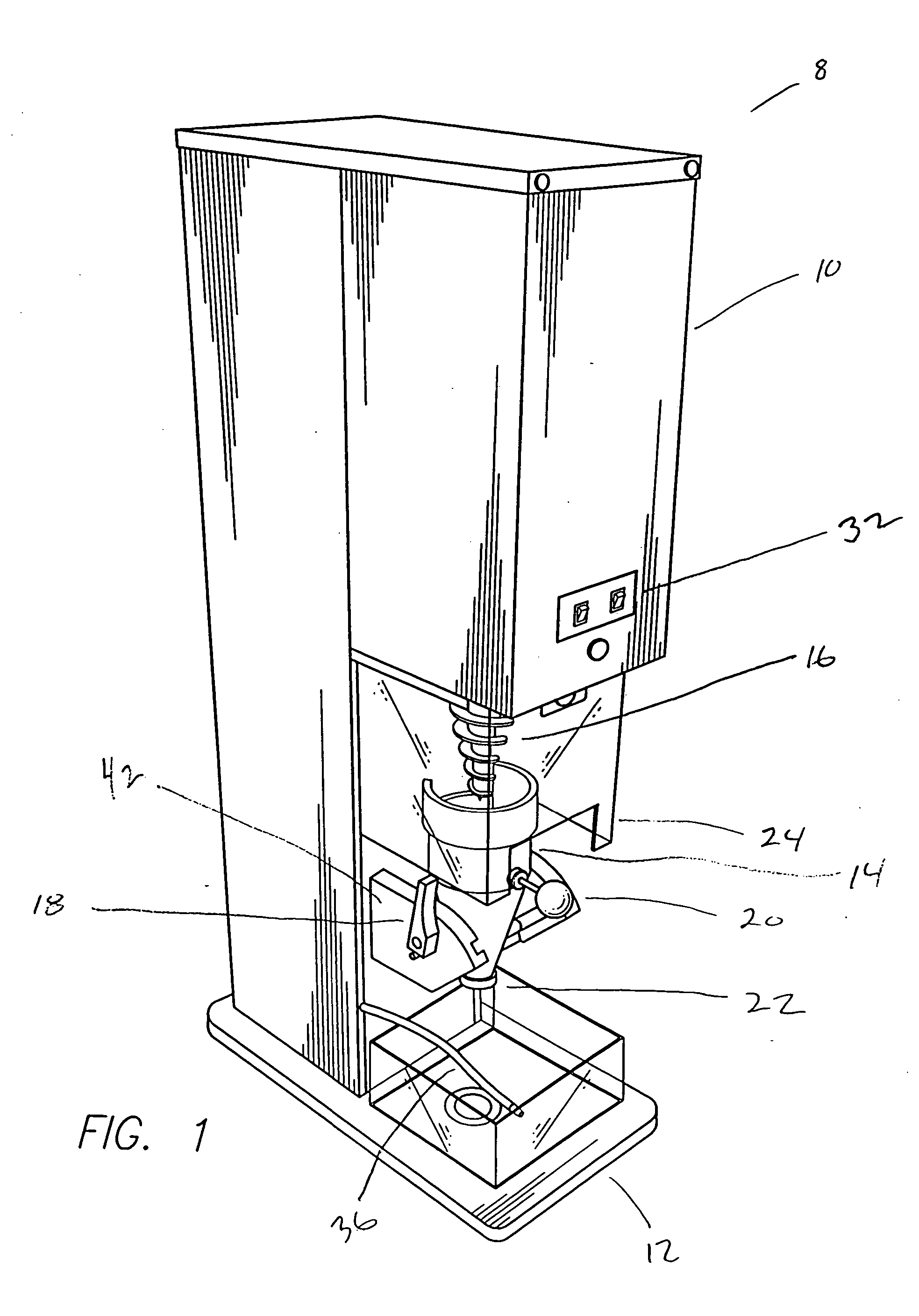

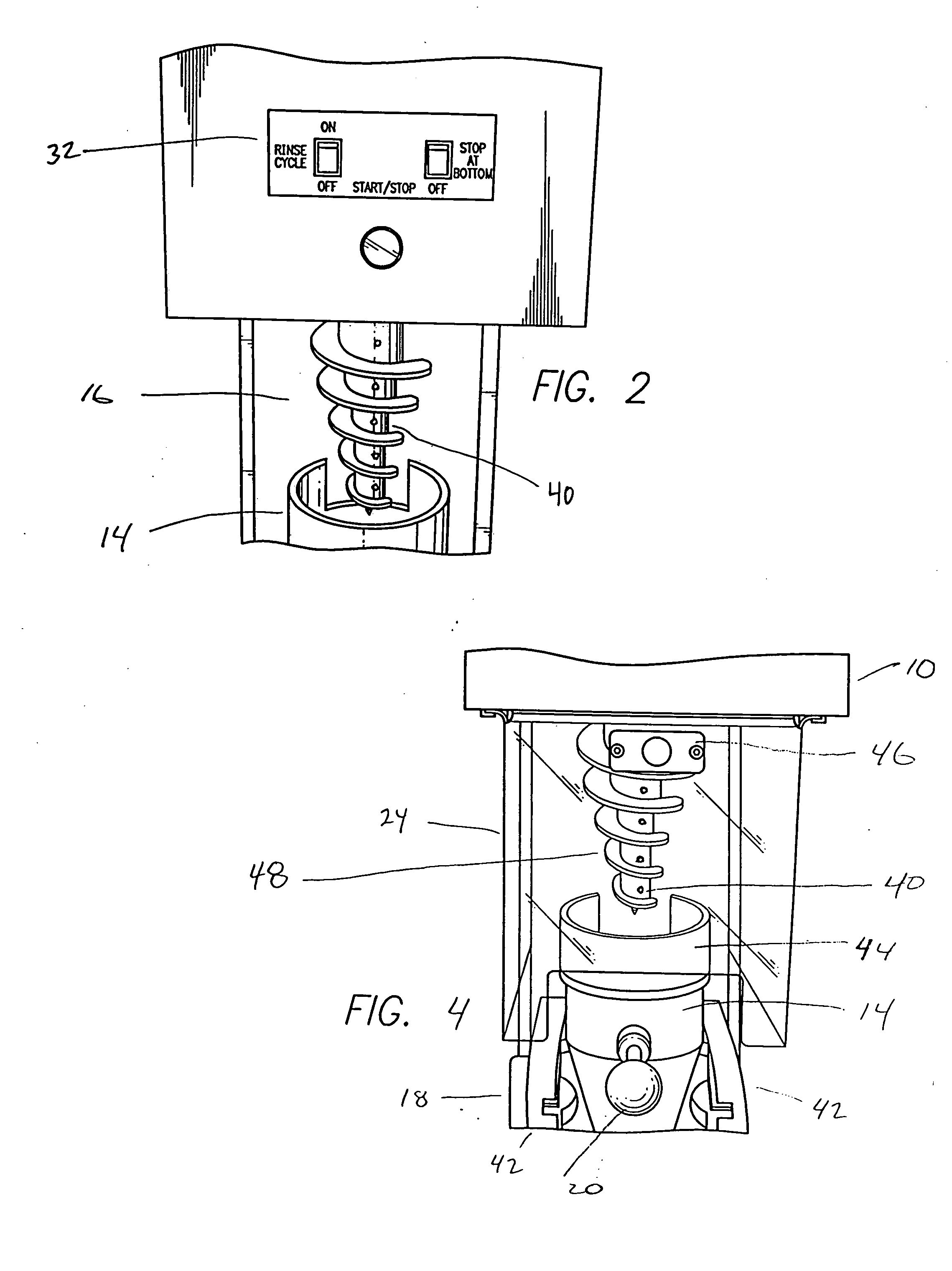

Frozen dessert dispensing machine

InactiveUS20050183426A1More consistencyHazardous operating conditionLighting and heating apparatusIce productionAdditive ingredientElectronic control system

A dessert machine is provided that produces a frozen dessert product. Frozen fruit and water are ground and spun with air introduced to create a frozen creamy smooth dessert. The frozen dessert machine has a distally tapered auger, having a spiral thread, that mixes the dessert ingredients into the desired consistency. The invention involves an electronic control system that ensures quality reproduction with every dessert produced. Additionally, the dessert machine provides safety interlocks for enhanced operator safety during production of the dessert product.

Owner:DESERT FREEZE

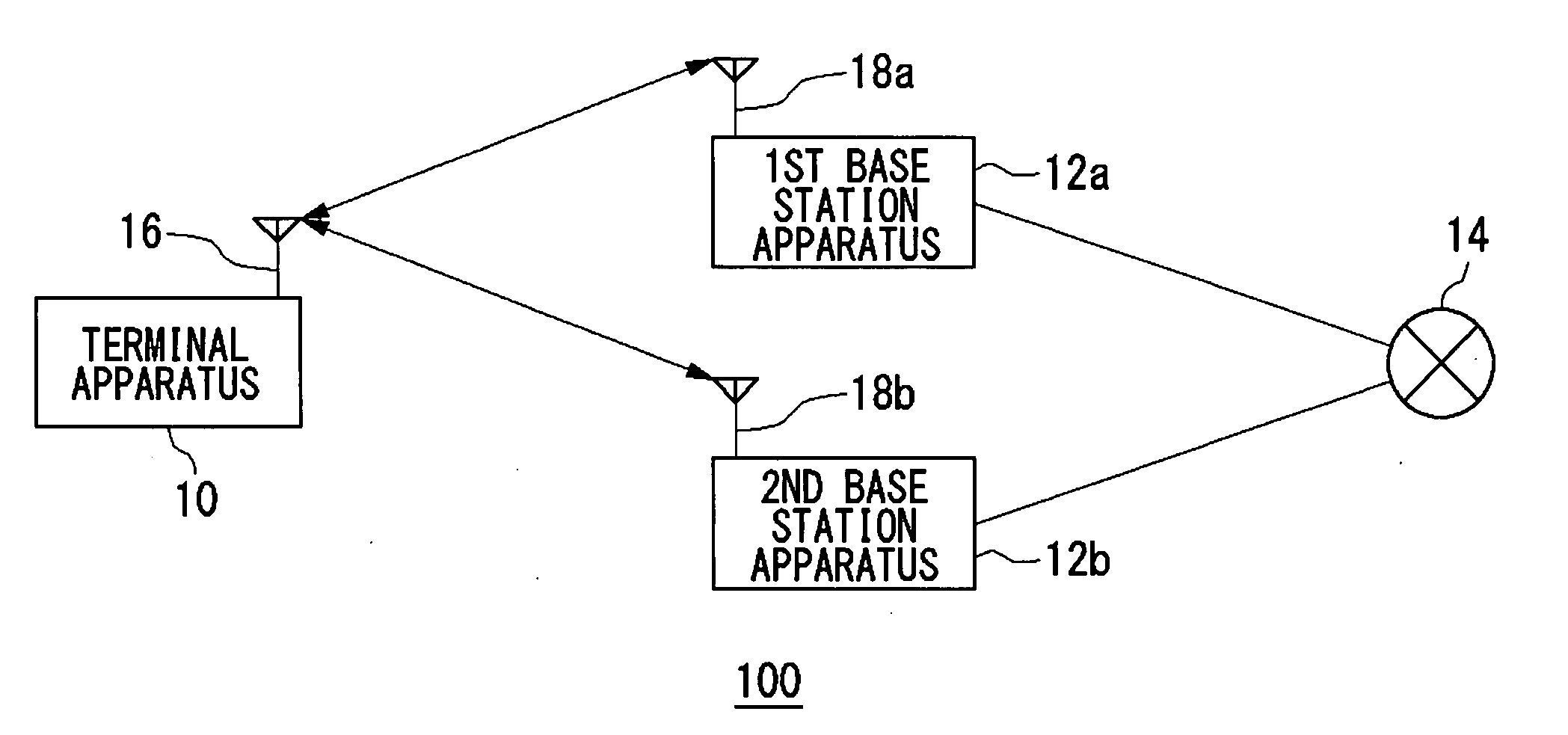

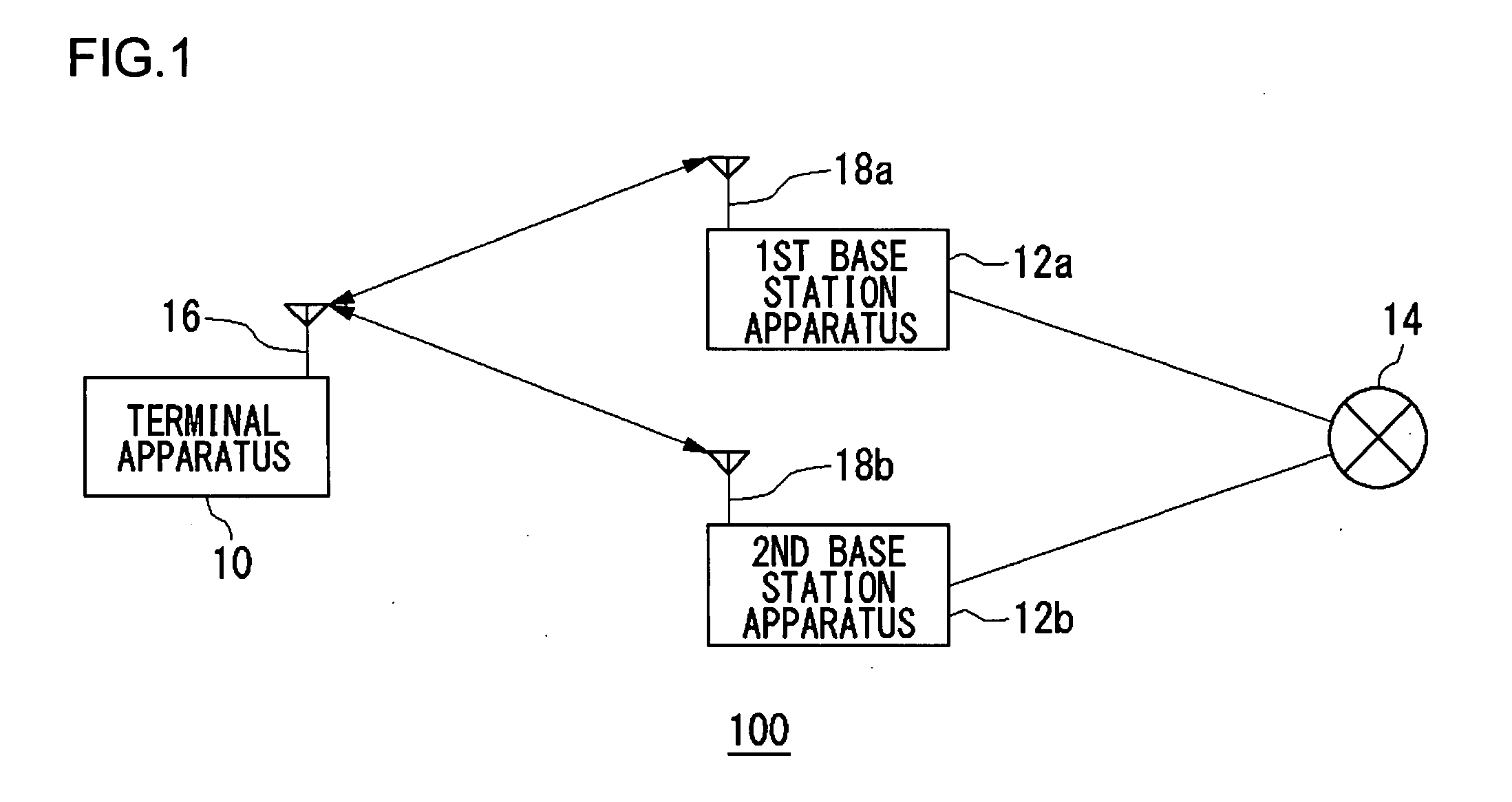

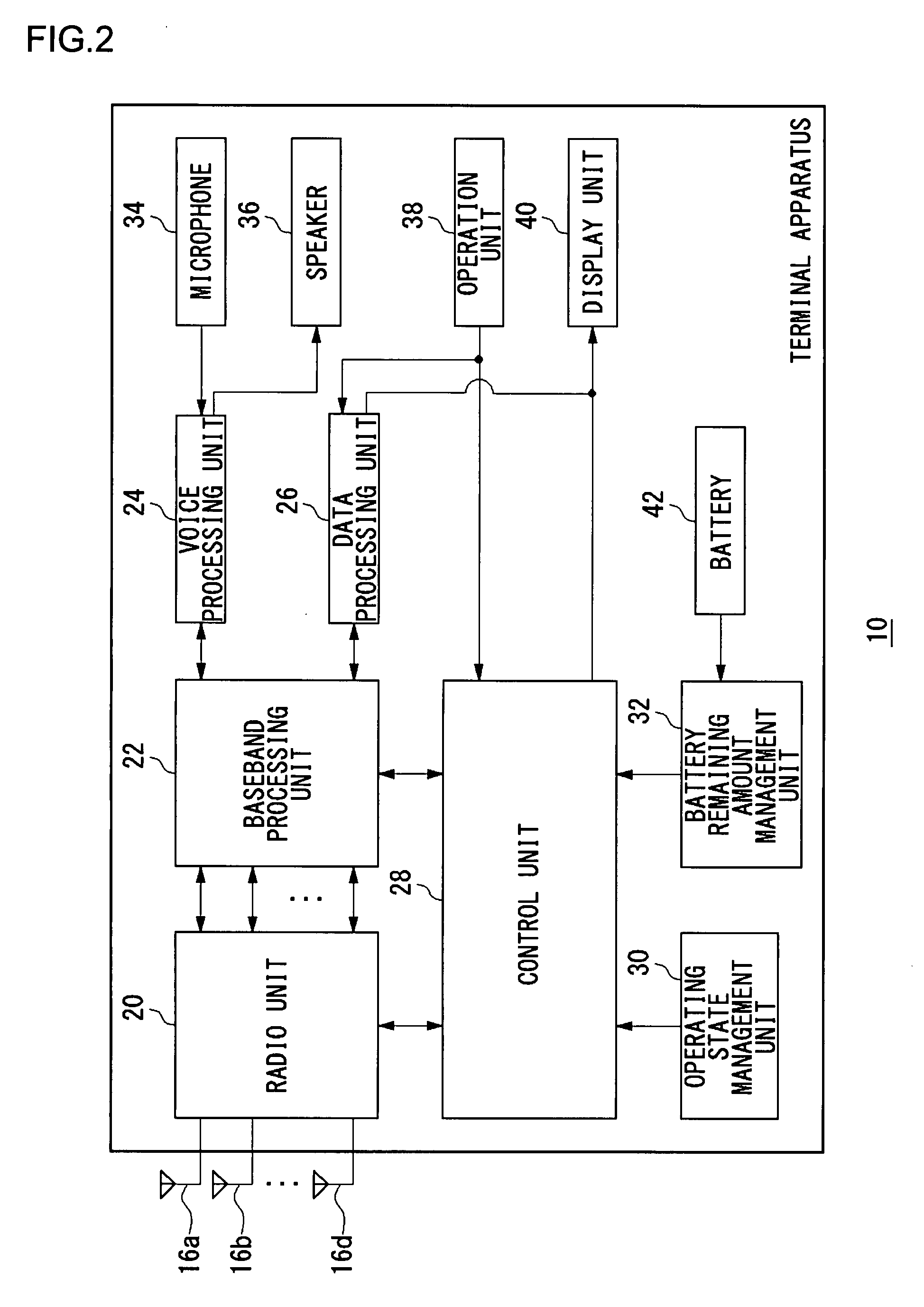

Method for controlling standby operations compatible with a plurality of wireless communication systems and method for performing operations compatible with a plurality of wireless communication systems

InactiveUS20080058000A1Reduce power consumptionQuality improvementPower managementTransmission systemsManagement unitCommunications system

A radio unit and a baseband processing unit perform wireless communications with a plurality of base station apparatuses compatible with a plurality of wireless communication schemes, respectively. A battery remaining amount management unit inspects a remaining amount of battery to be supplied to the radio unit and the like. A control unit controls standby operations that the radio unit and the baseband processing unit are to perform on the plurality of wireless communication schemes, based on the remaining amount of battery inspected by the battery remaining amount management unit. The control unit defines degrees of priority for the plurality of wireless communication schemes, respectively. As the remaining amount of battery becomes low, the control unit sets long a time interval of the standby operation for a base station compatible with a wireless communication scheme having a low degree of priority.

Owner:KYOCERA CORP

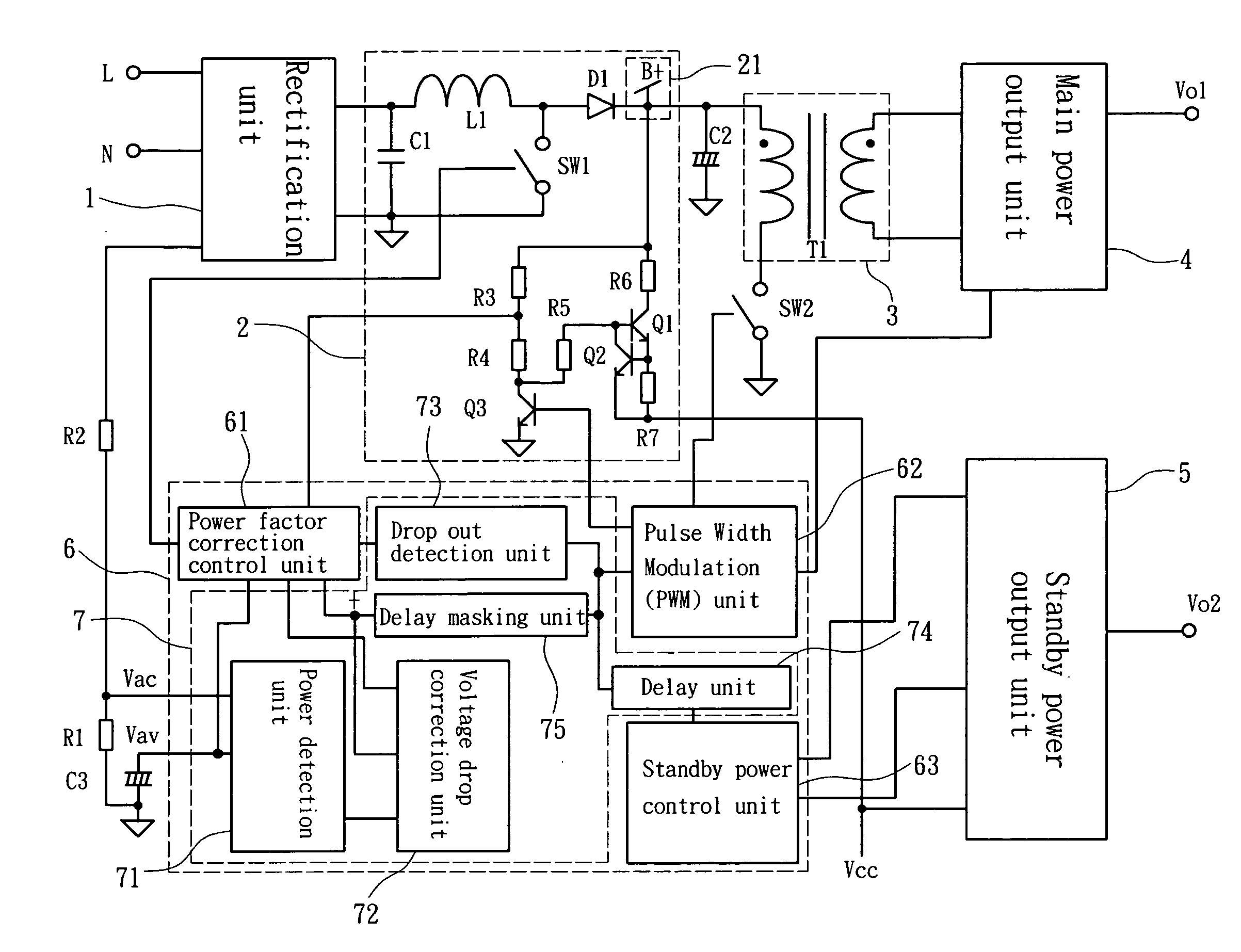

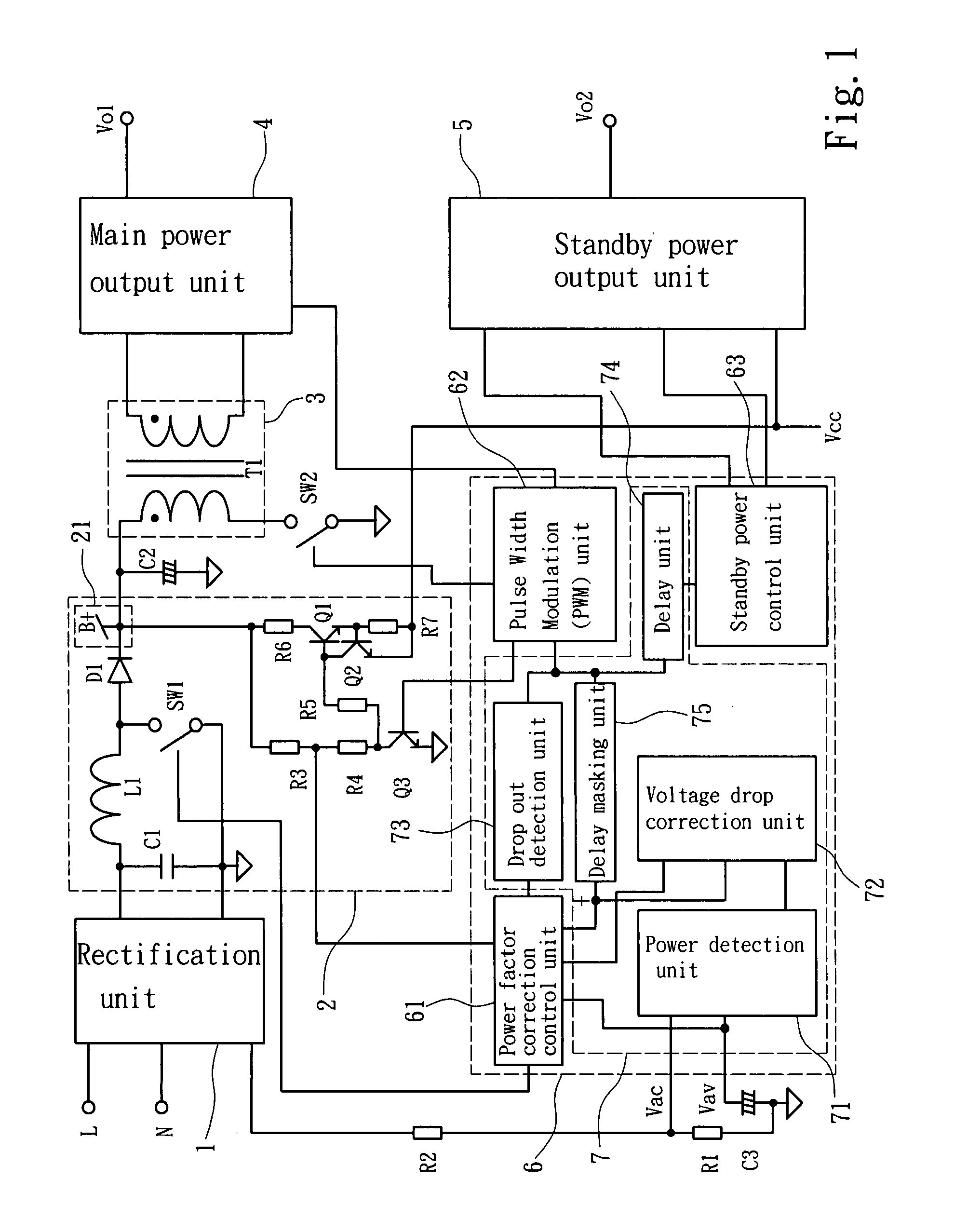

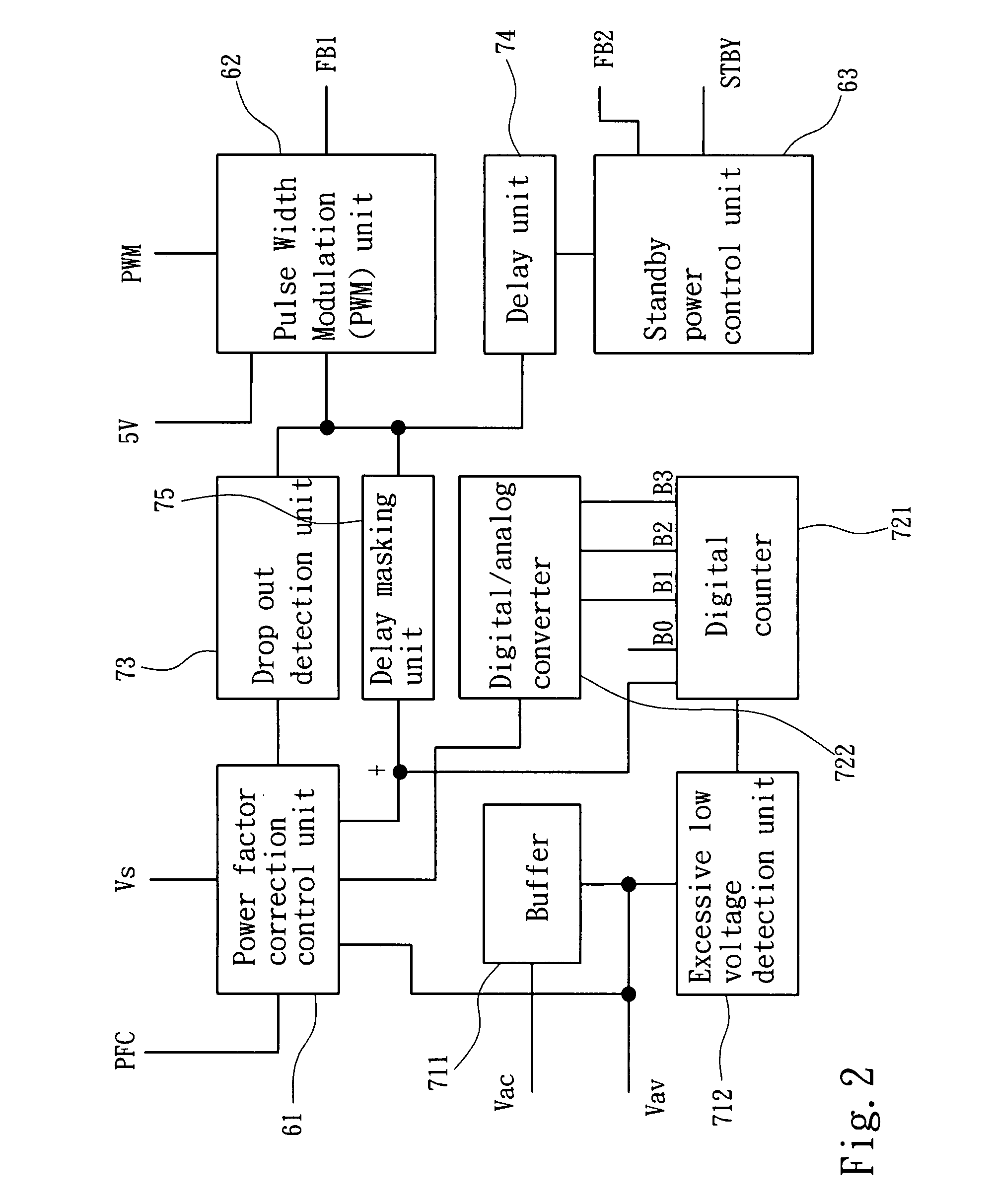

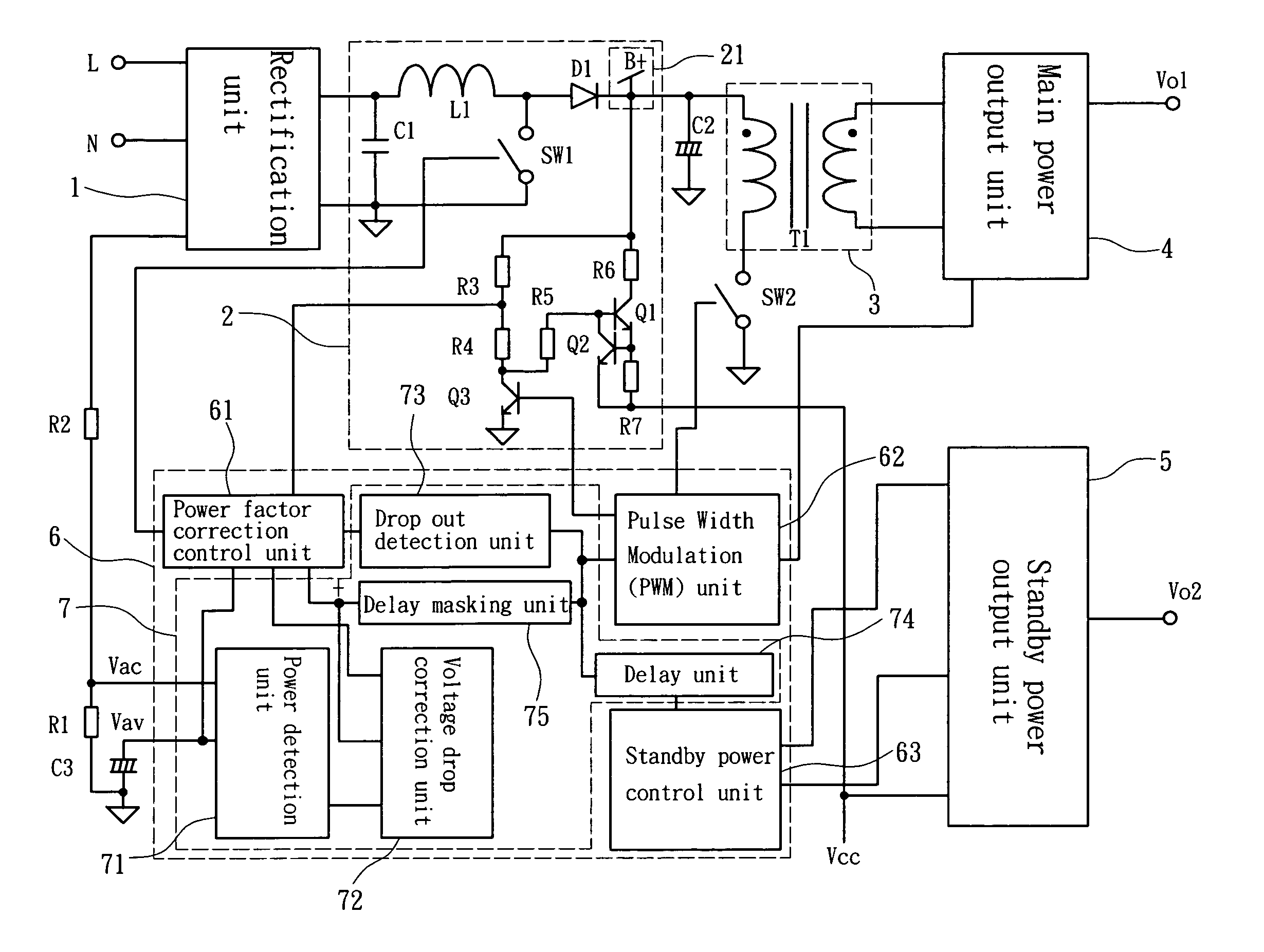

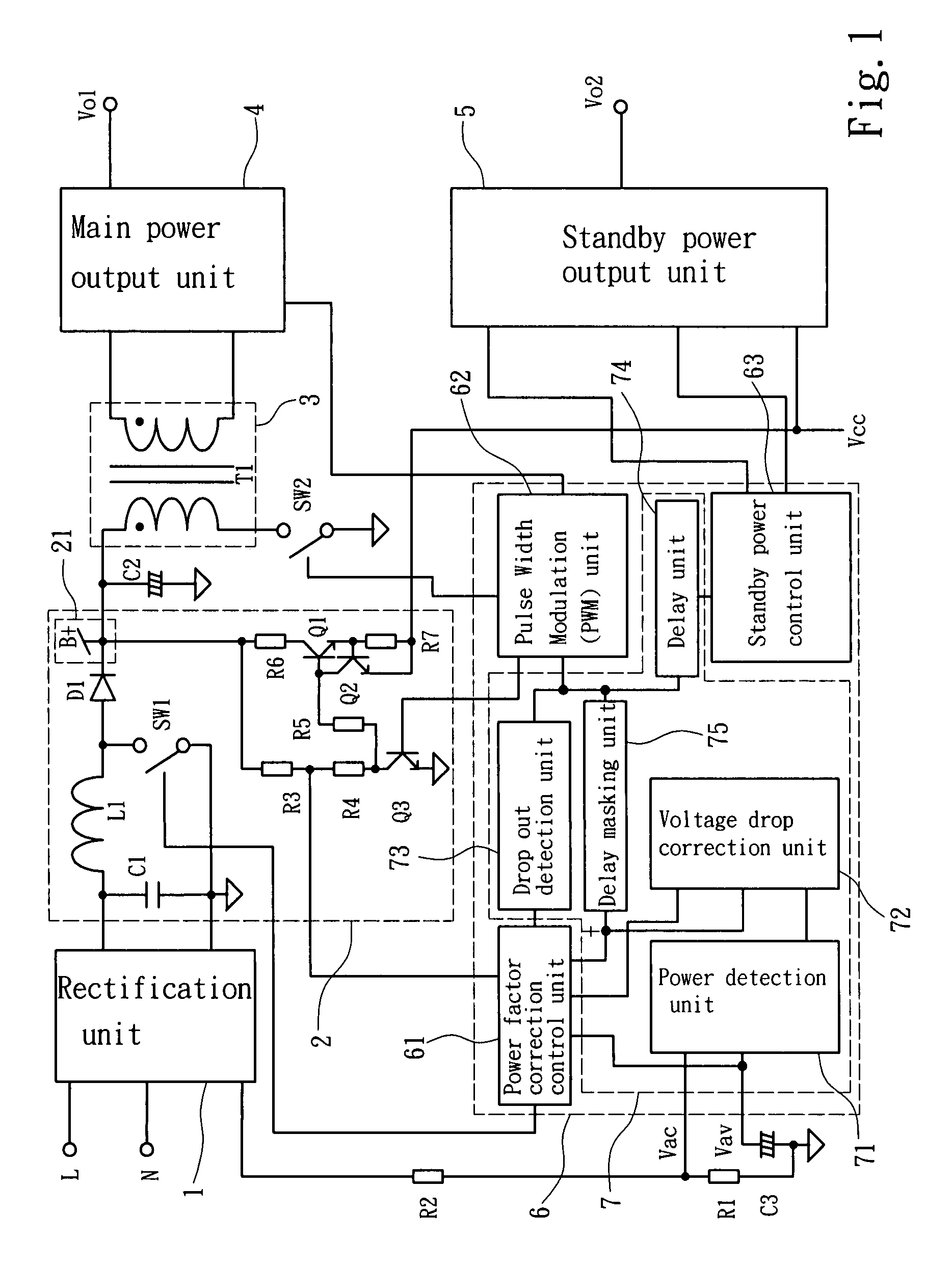

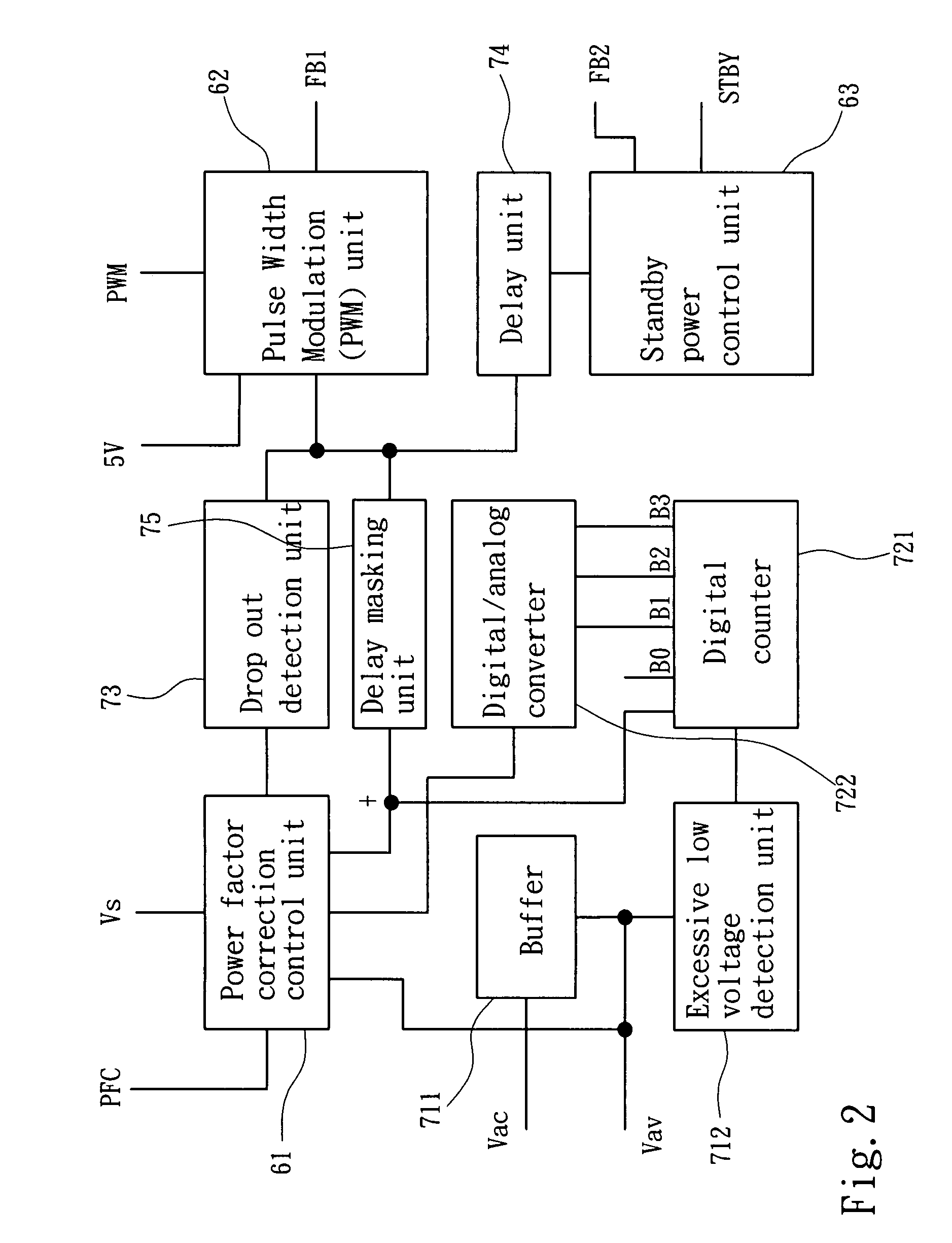

Power abnormal protection circuit

ActiveUS20080304195A1Avoid damageReduce switching lossesEfficient power electronics conversionEmergency protective arrangements for automatic disconnectionVoltage dropEngineering

A power abnormal protection circuit includes a power detection unit, a voltage drop correction unit, a drop out detection unit, a delay unit and a delay masking unit. By detecting an input power average value of a power supply occurring of a brown out condition can be determined. The power supply includes a power factor correction unit which has an output capacitor. By detecting the voltage of the output capacitor a drop out condition can be determined. When a power abnormal condition occurs all units of the power supply can be set off sequentially according to a delay time to protect circuit elements and a connecting computer.

Owner:SPI ELECTRONICS

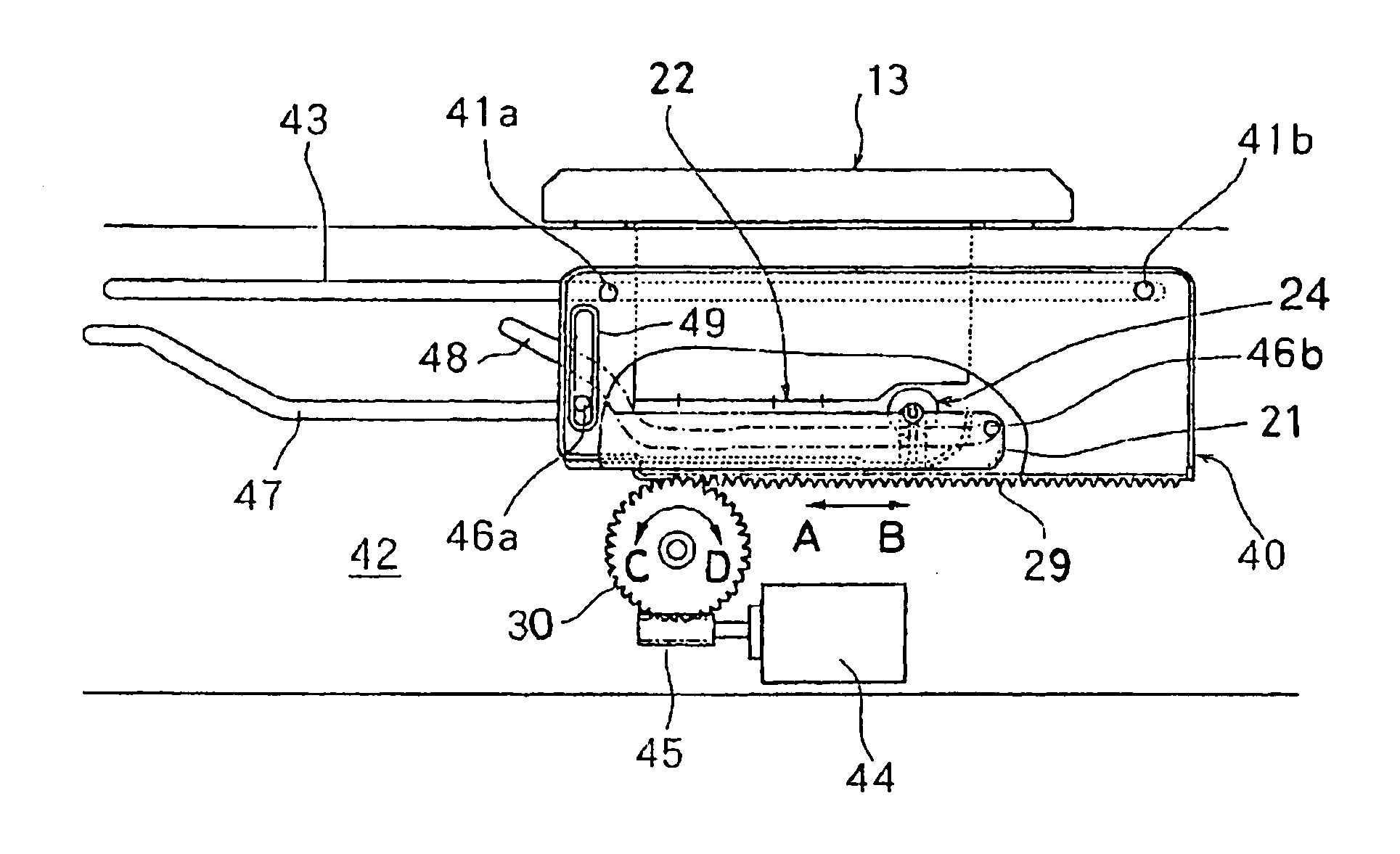

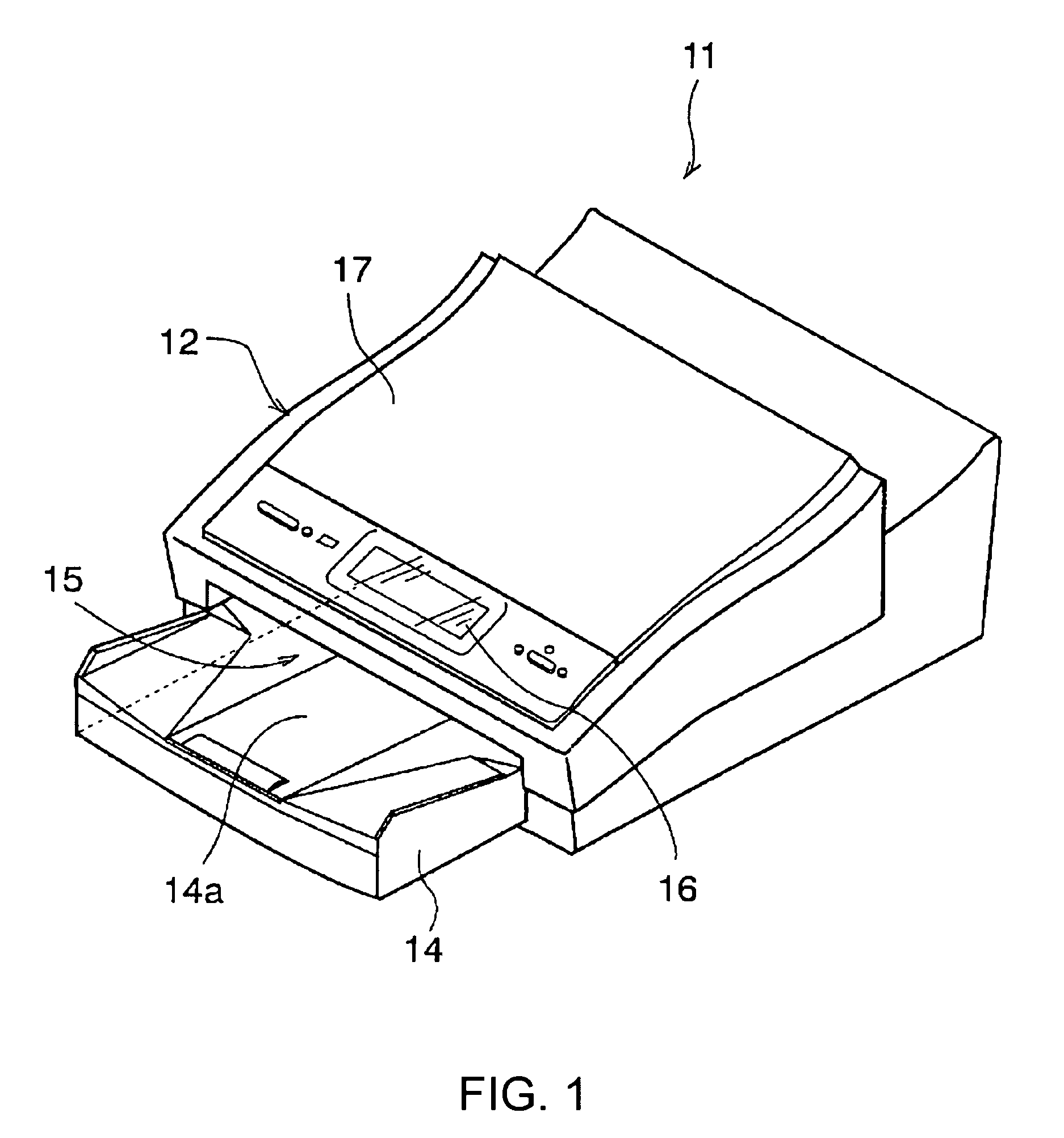

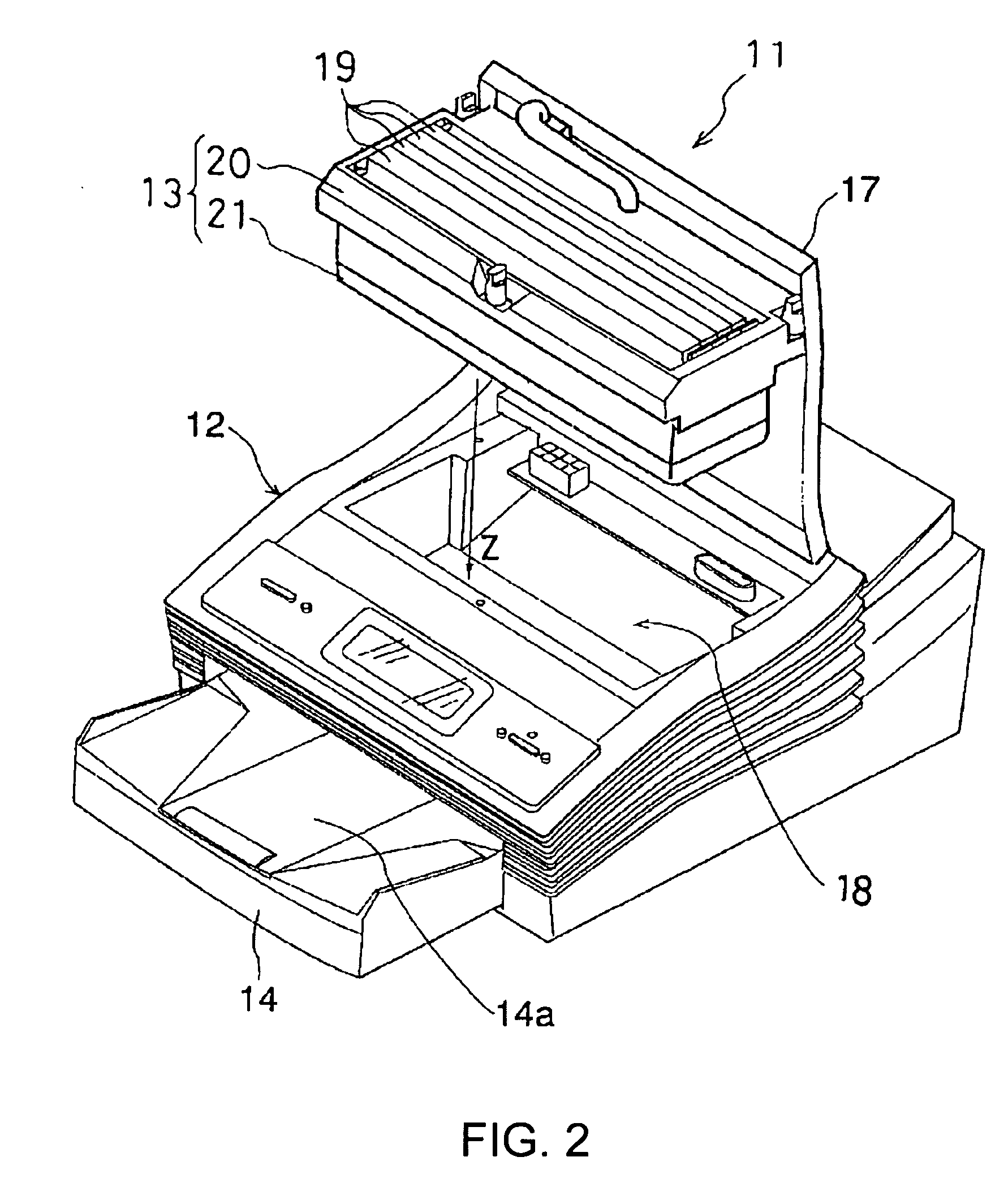

Liquid Discharging Apparatus and Control Method Therefor

InactiveUS20080049058A1Reduce printing timeTimely maintenanceOther printing apparatusLiquid dropWaste management

In a liquid discharging apparatus for discharging droplets from a liquid discharge nozzle to a discharge object to be discharged and in a method for controlling the liquid discharging apparatus, cleaning effects for the ink discharge nozzle and the adjacent areas can be enhanced, and the time required for a series of performance maintaining operations can be reduced. The apparatus includes a platen plate for supporting recording paper as the discharge object, defining a positional relationship between the discharge object and the liquid discharge head, and receiving the droplets discharged from the liquid discharge head. Ink droplets are preliminarily discharged from the ink discharge nozzle to the platen plate.

Owner:SONY CORP

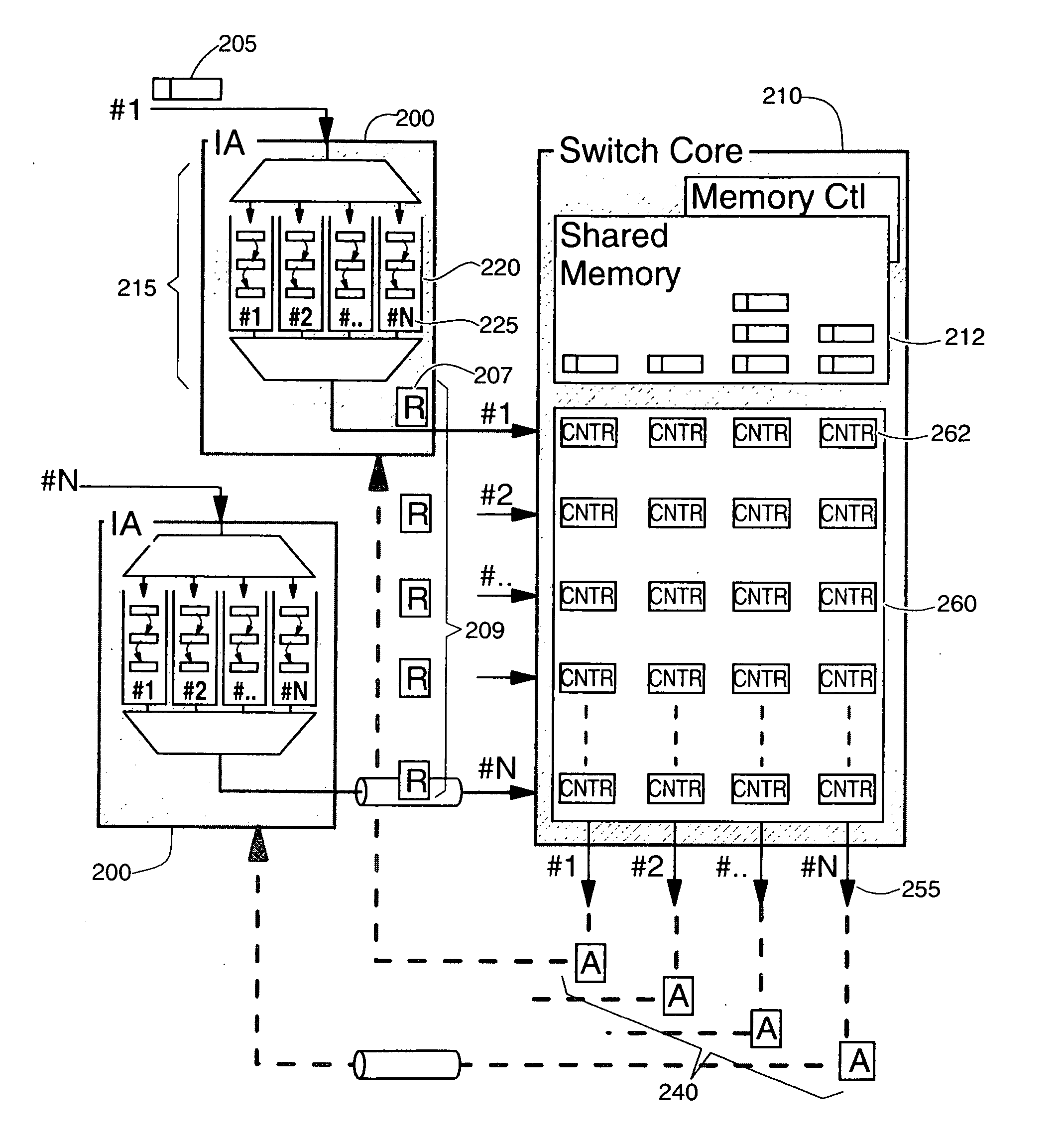

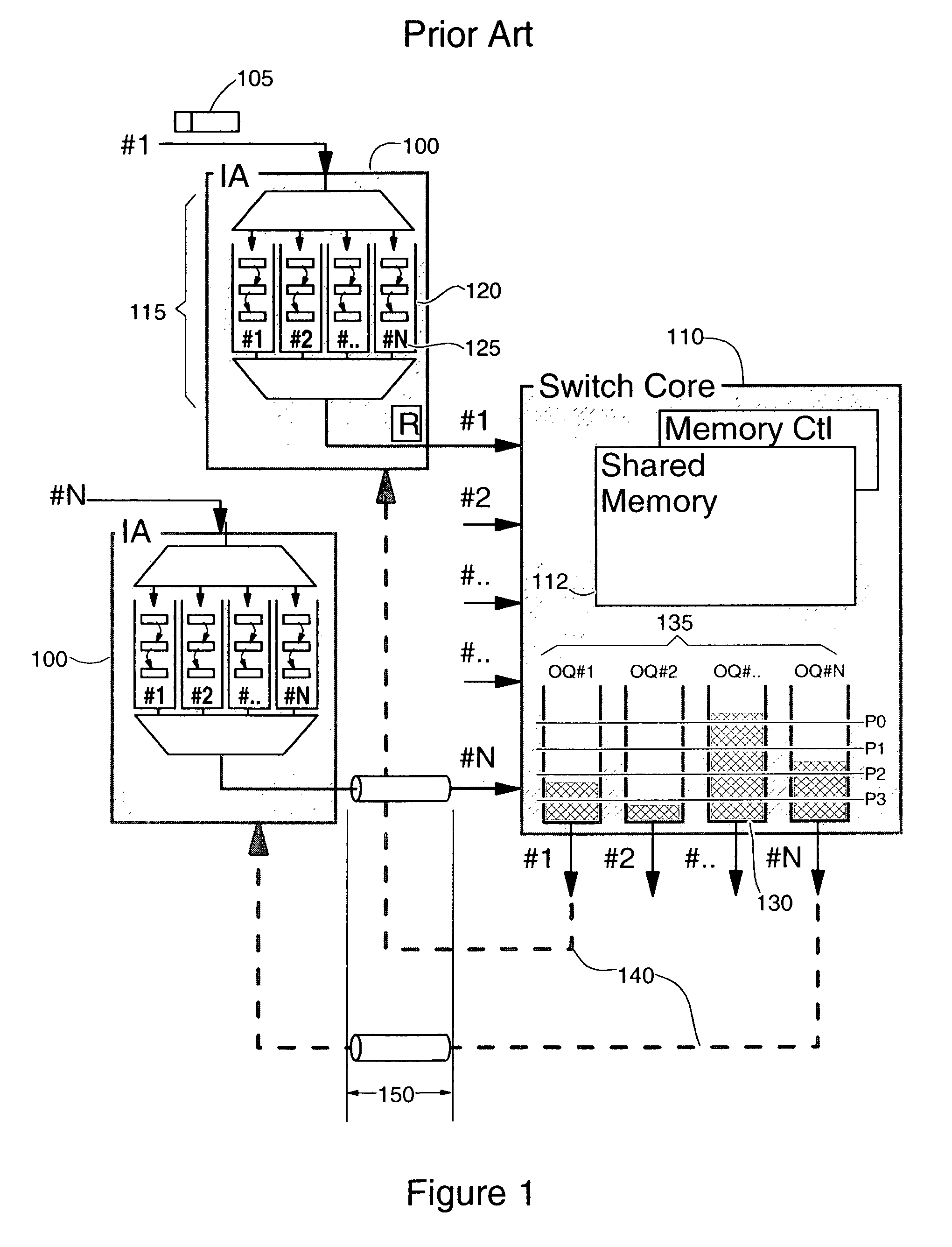

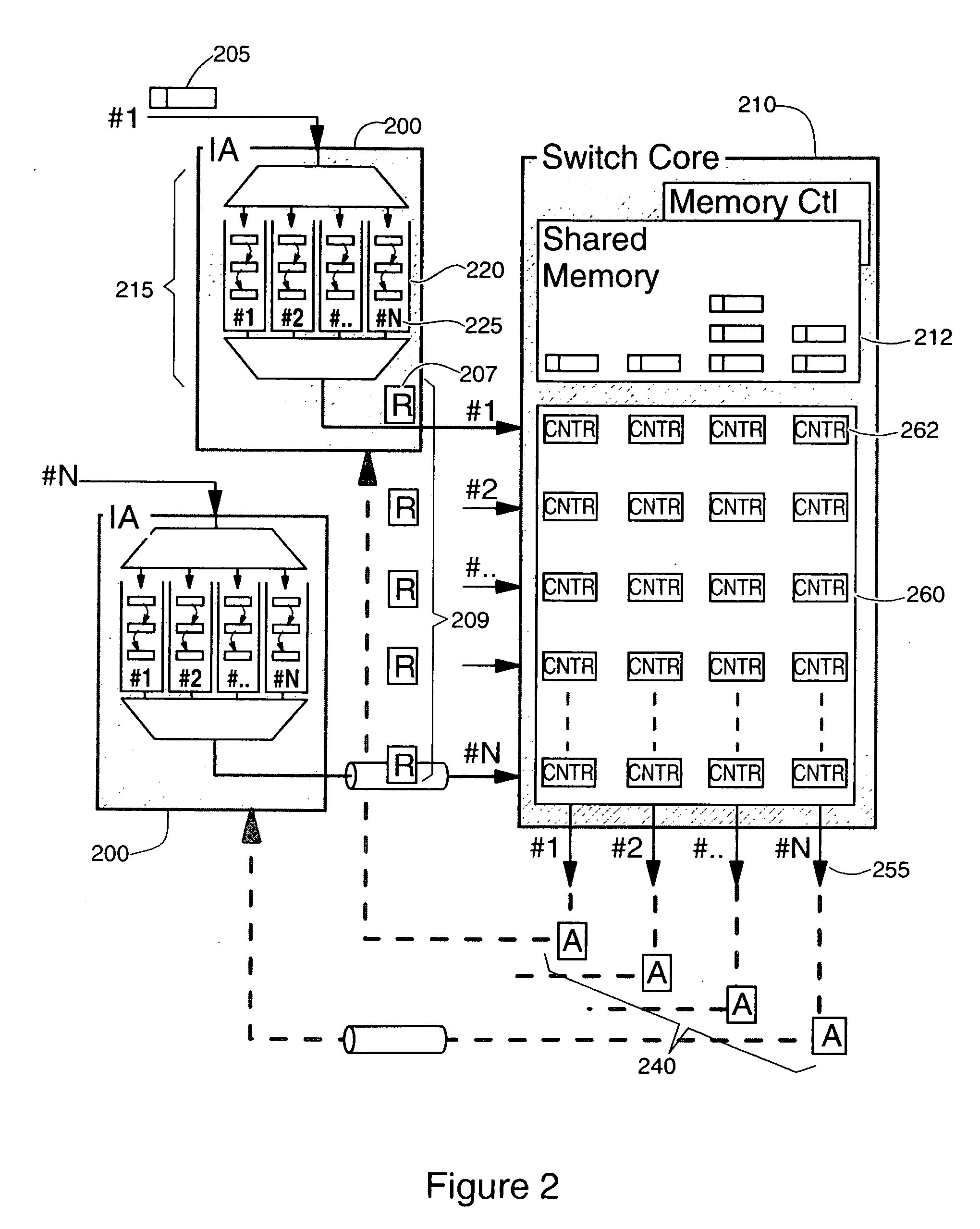

System and method for collapsing VOQ'S of a packet switch fabric

ActiveUS20050053077A1Maintenance operationWithout impact performanceData switching by path configurationTraffic congestionData buffer

A system and a method to avoid packet traffic congestion in a shared-memory switch core, while dramatically reducing the amount of shared memory in the switch core and the associated egress buffers, is disclosed. According to the invention, the virtual output queuing (VOQ) of all ingress adapters of a packet switch fabric are collapsed into its central switch core to allow an efficient flow control. The transmission of packets from an ingress buffer to the switch core is subject to a mechanism of request / acknowledgment. Therefore, a packet is transmitted from a virtual output queue to the shared-memory switch core only if the switch core can actually forward it to the corresponding egress buffer. A token based mechanism allows the switch core to determine the egress buffer's level of occupation. Therefore, since the switch core knows the states of the input and output adapters, it is able to optimize packet switching and to avoid packet congestion. Furthermore, since a packet is admitted in the switch core only if it can be transmitted to the corresponding egress buffer, the shared memory is reduced.

Owner:TWITTER INC

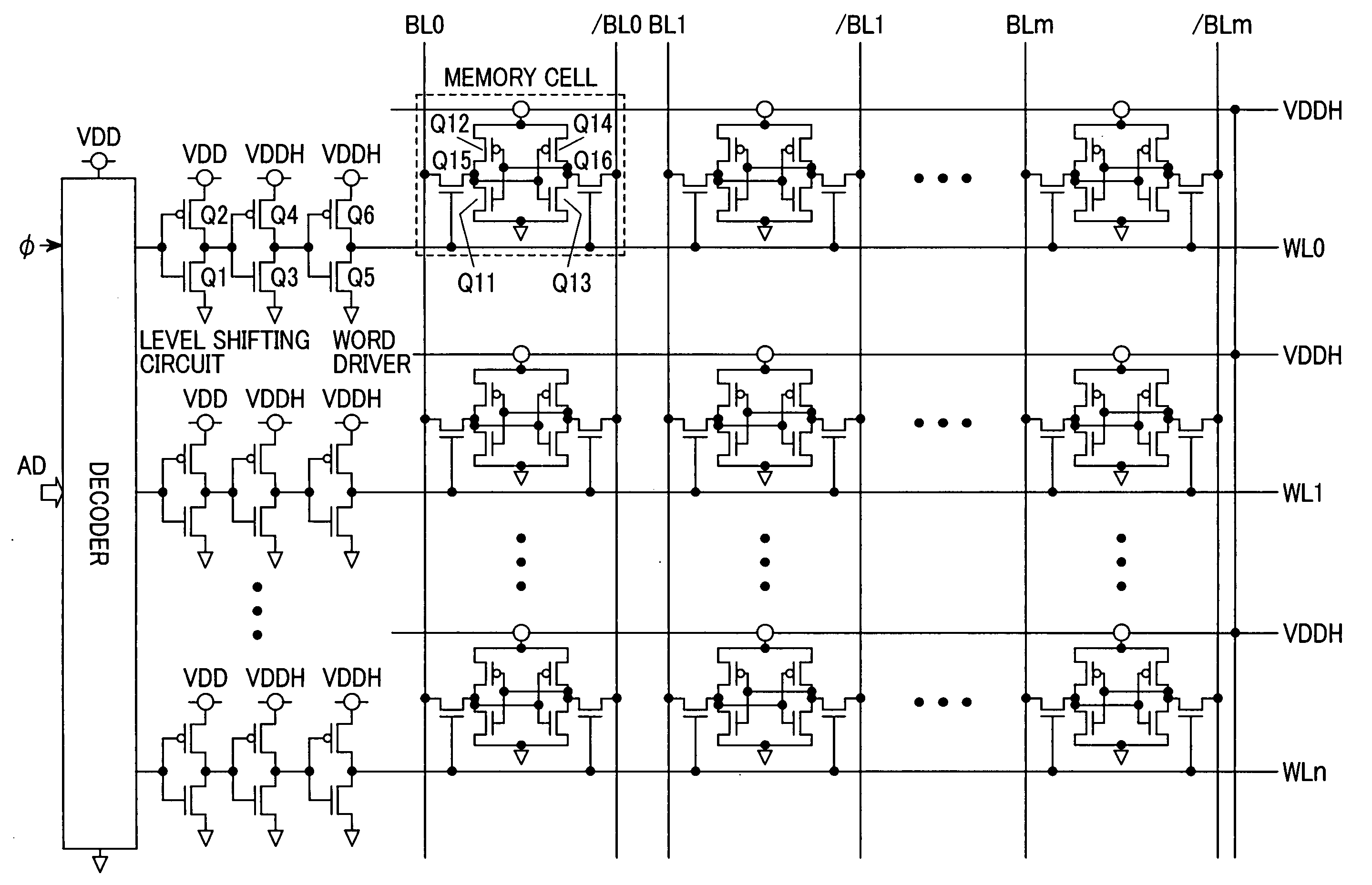

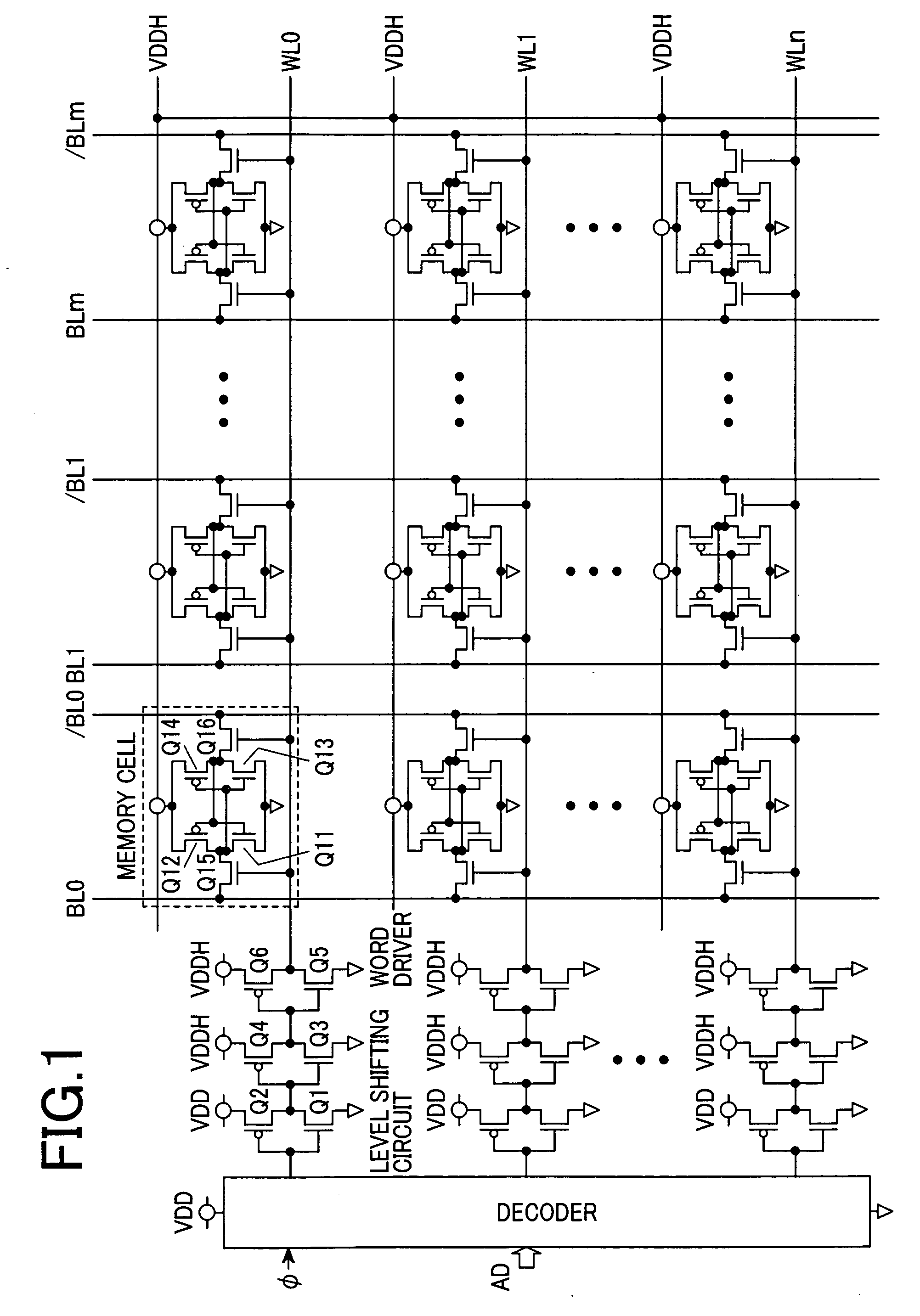

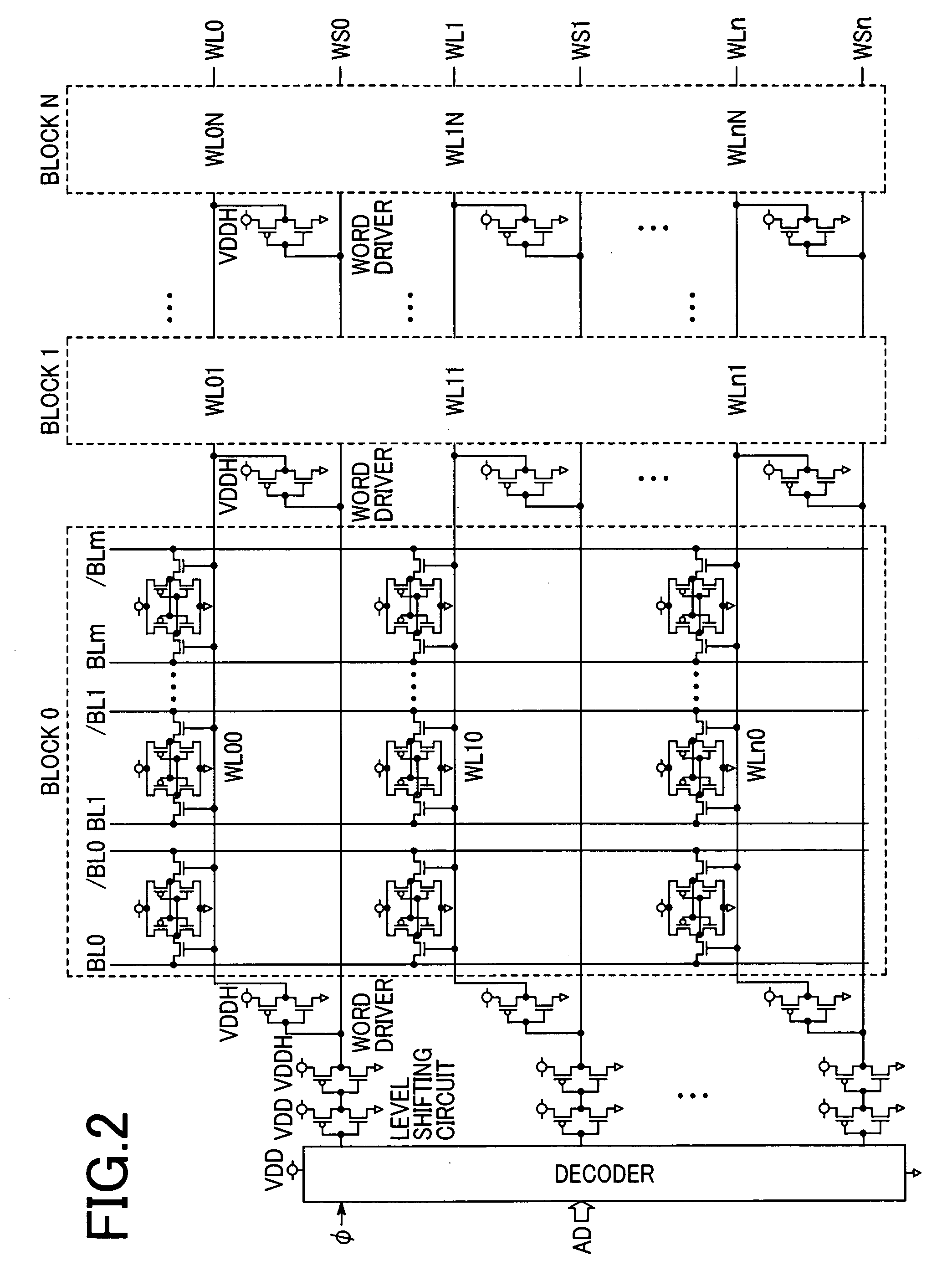

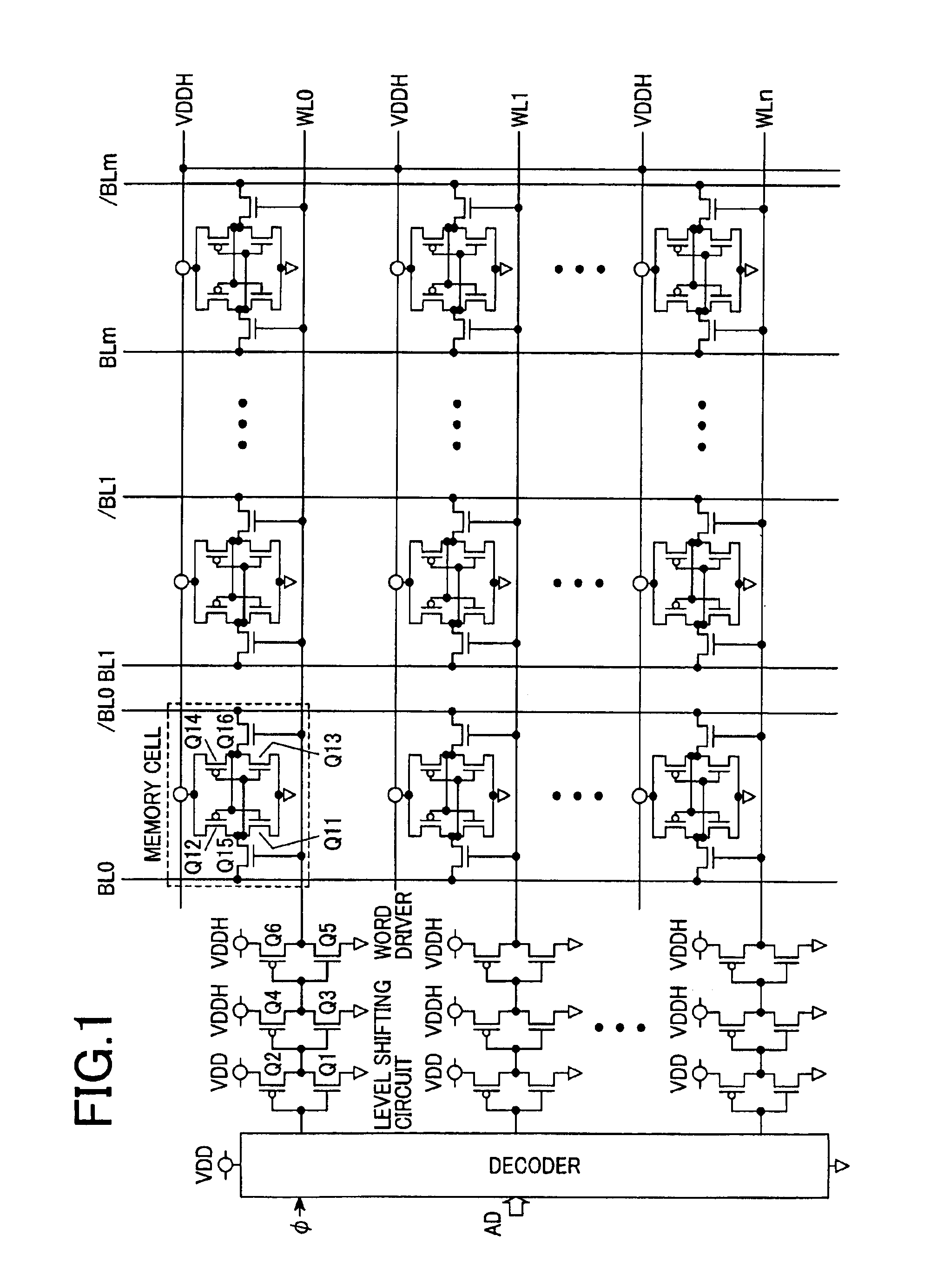

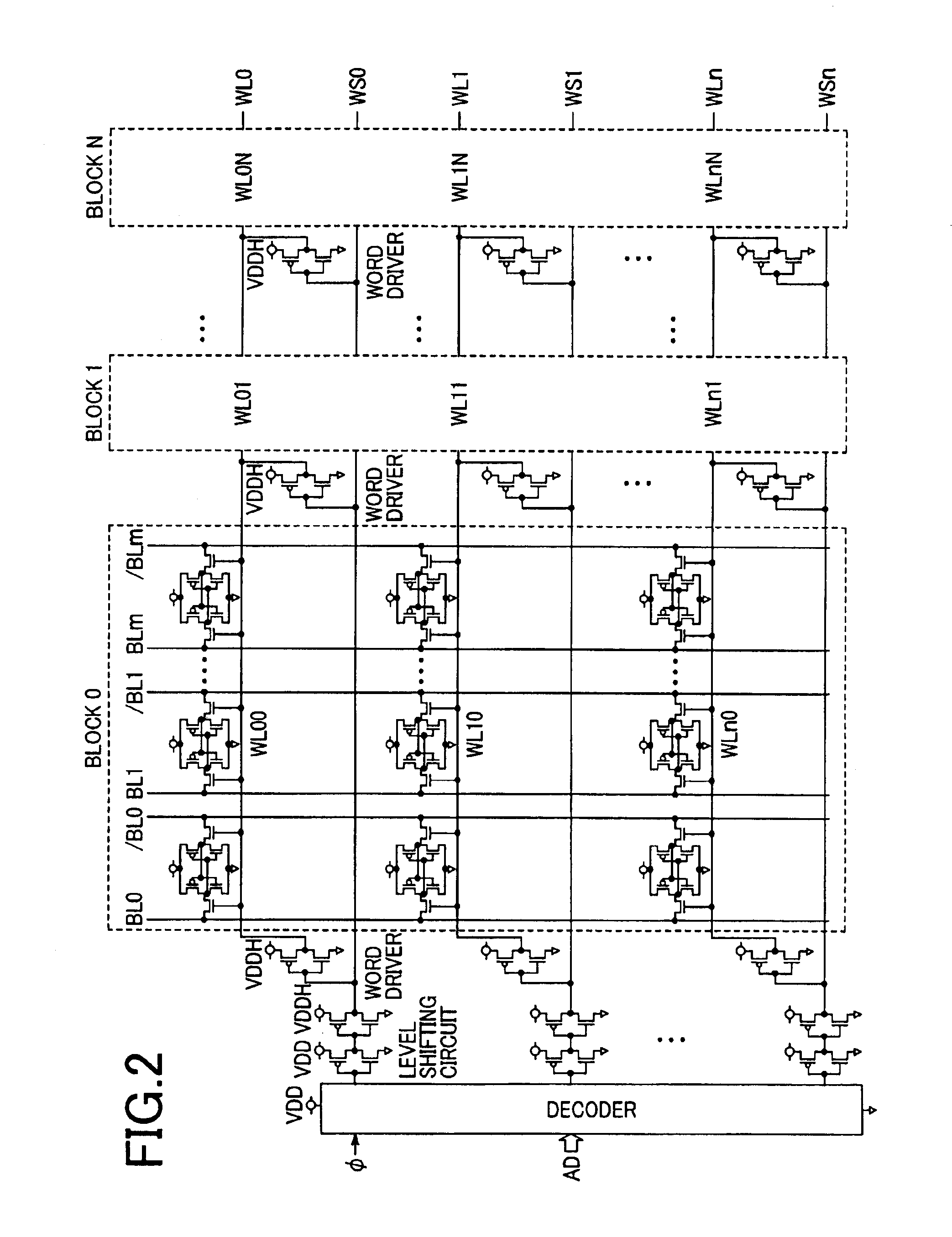

Semiconductor integrated circuit device

InactiveUS20050002224A1Maintaining operation marginLow power consumptionTransistorInstant pulse delivery arrangementsMOSFETIntegrated circuit

A semiconductor integrated circuit device endowed with memory circuits achieving high operation margin and low energy consumption with high speed and high integration. Composing a memory cell with a MOSFET having a first threshold voltage corresponding to a first voltage and supplying a selection signal corresponding to said first voltage to a word line by a word driver driven at said first voltage. Corresponding to a second voltage smaller than said first voltage, forming a selection signal sending to said word driver by a decoder comprising MOSFET with a second threshold voltage smaller than said first voltage, operating at said first voltage, and installing a first level shifting circuit including inverter circuits that form a selection signal corresponding to said first voltage by receiving a selection signal corresponding to said second voltage. Thereby, high operation margin and low energy consumption with high speed and high integration can be achieved.

Owner:HITACHI LTD

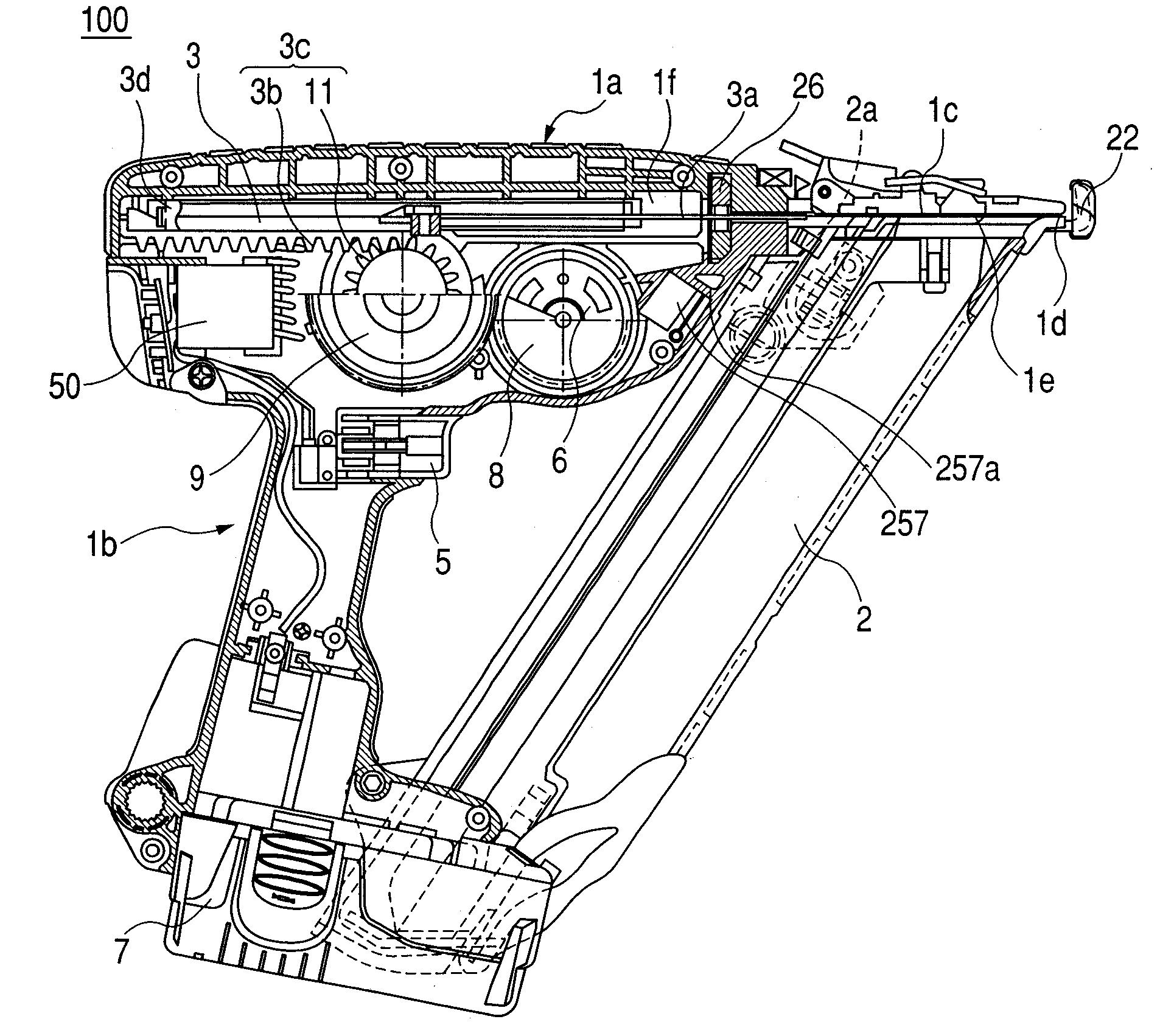

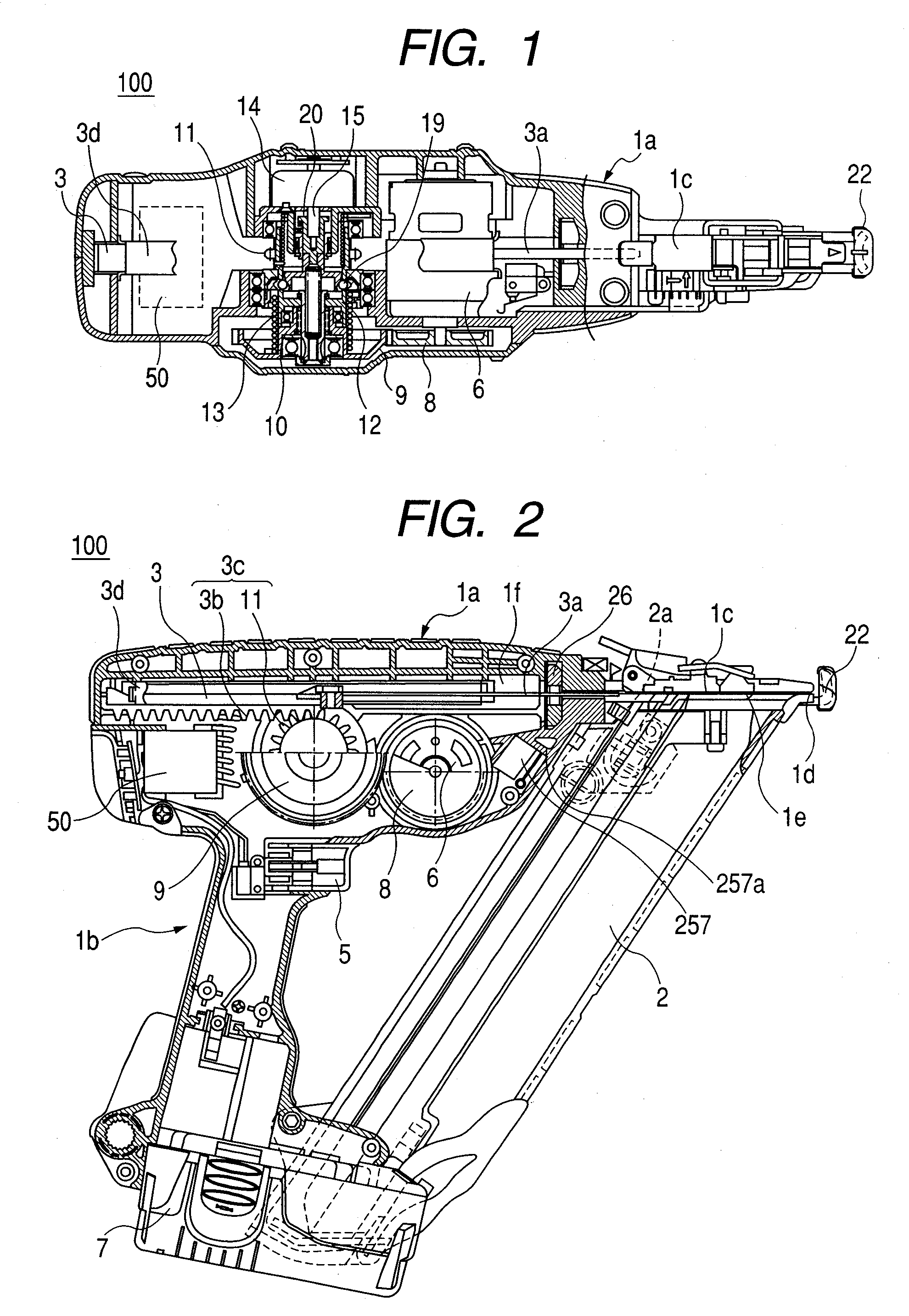

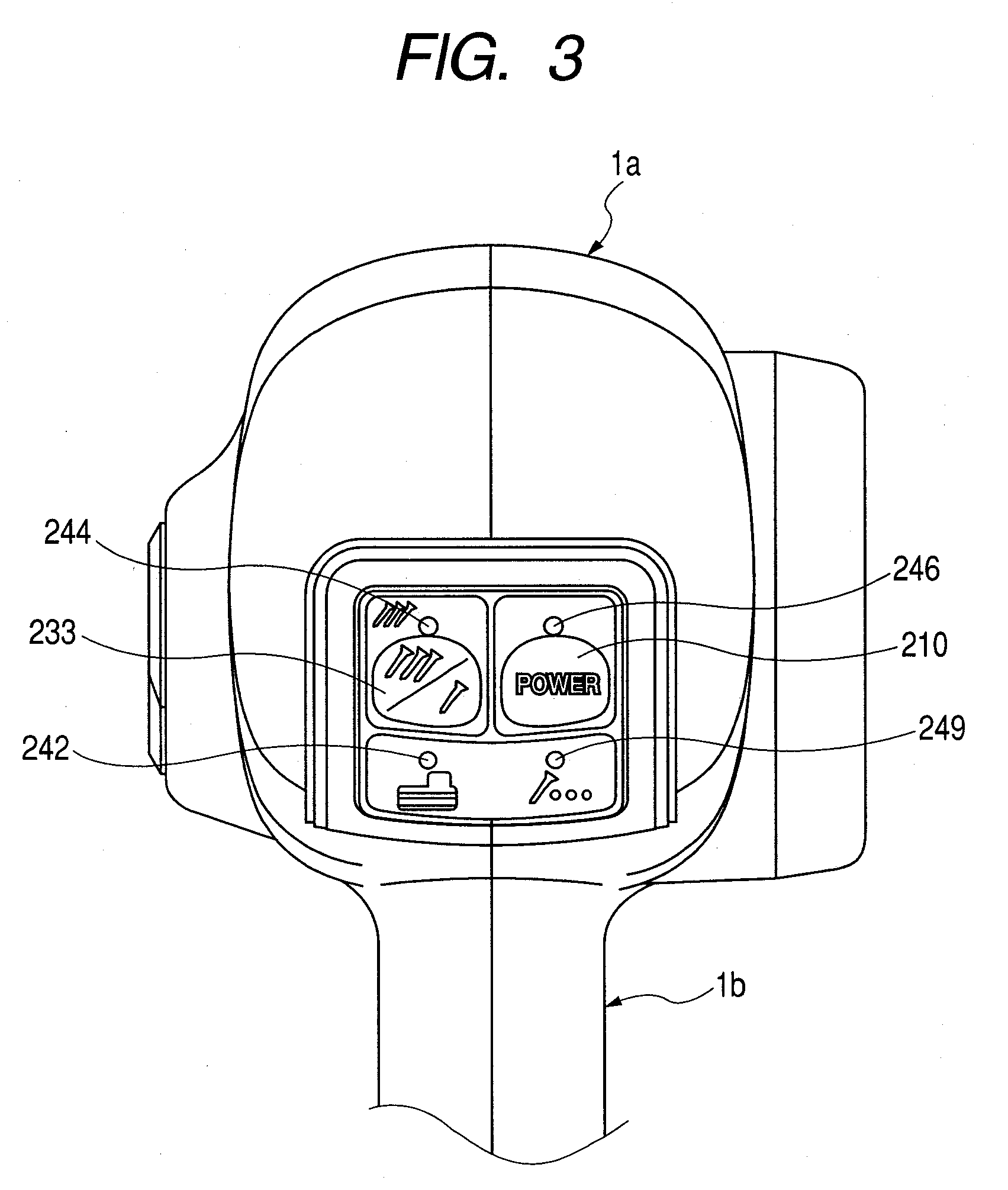

Electric driving machine

InactiveUS20080067213A1Maintenance operationEfficient use ofStapling toolsNailing toolsElectric driveElectric machinery

Even when a transient decrease has arisen in a battery voltage VBAT of a battery pack at startup of a motor that drives a flywheel, a power terminal Vcc and a reset terminal RES (or an input terminal IN of a reset IC) of a microcomputer are replenished with a normal voltage by the voltage accumulated by a capacitor of the backup power circuit, and hence a controller can maintain normal operation without involvement of faulty operation. As a result, even the battery pack whose battery has a smaller amount of remaining energy can be effectively utilized as the power source of an electric driving machine.

Owner:HITACHI KOKI CO LTD

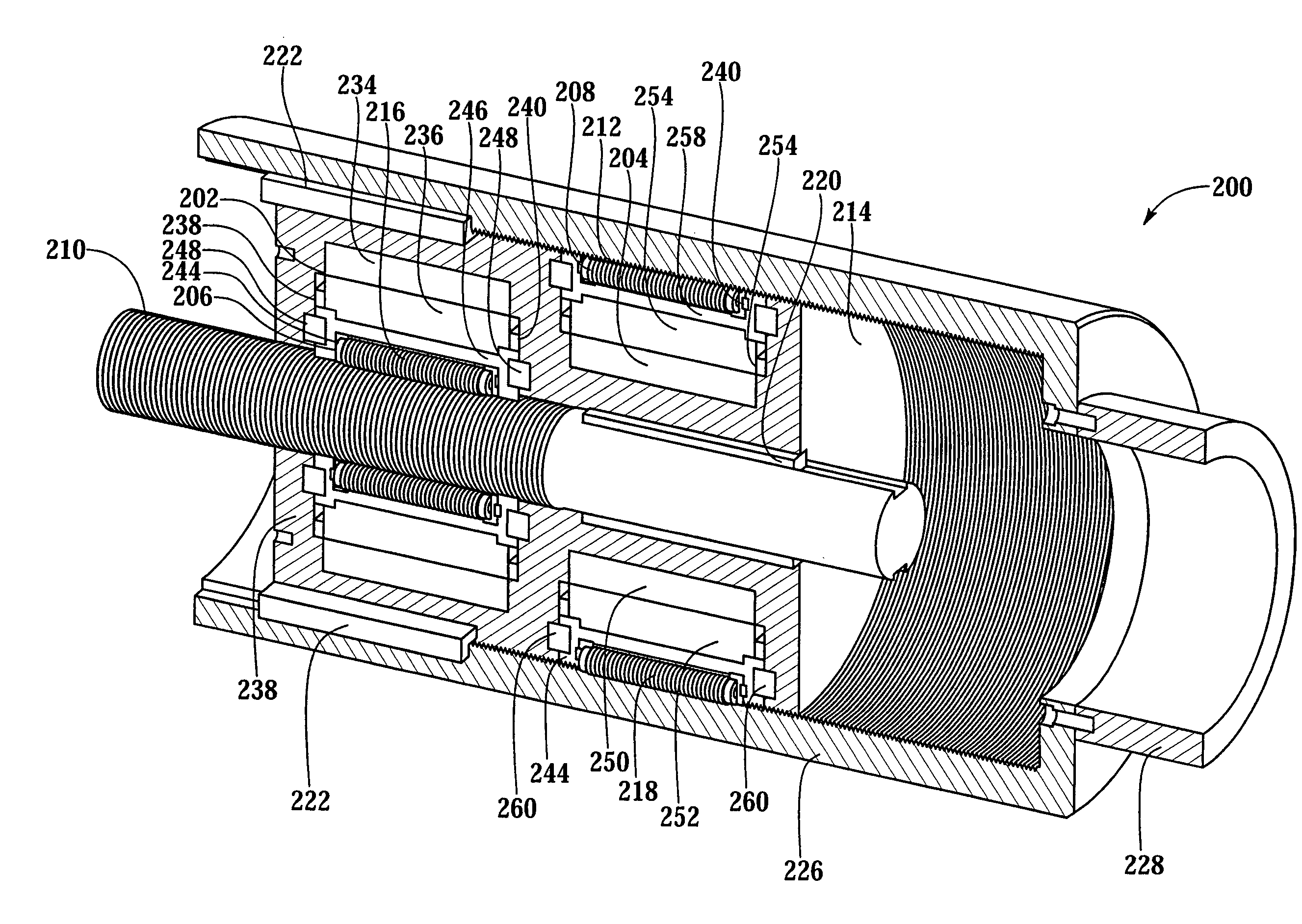

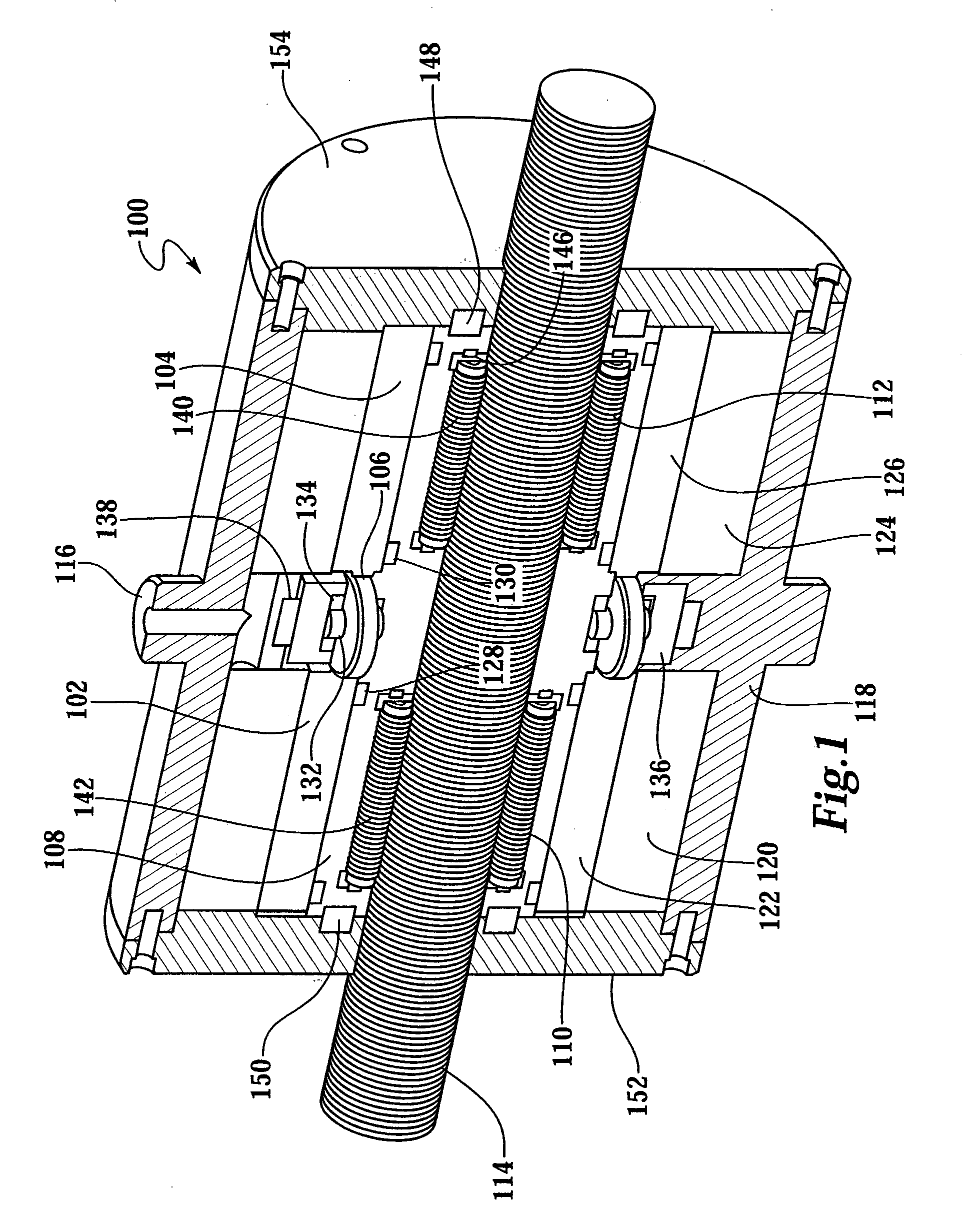

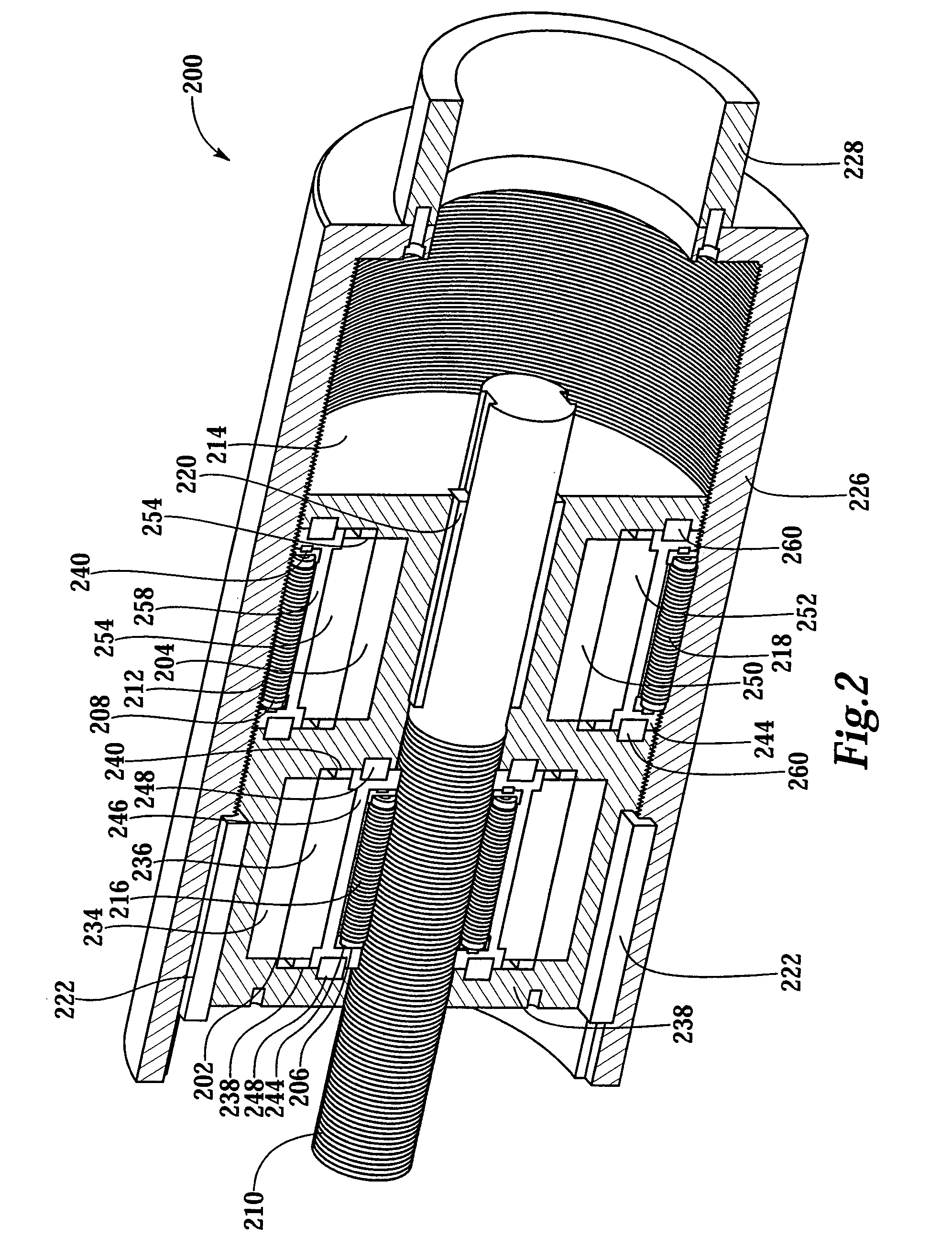

Fault tolerant linear actuator

InactiveUS20050168084A1RuggedImprove balanceGearingMechanical energy handlingPrime moverFault tolerance

In varying embodiments, the fault tolerant linear actuator of the present invention is a new and improved linear actuator with fault tolerance and positional control that may incorporate velocity summing, force summing, or a combination of the two. In one embodiment, the invention offers a velocity summing arrangement with a differential gear between two prime movers driving a cage, which then drives a linear spindle screw transmission. Other embodiments feature two prime movers driving separate linear spindle screw transmissions, one internal and one external, in a totally concentric and compact integrated module.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

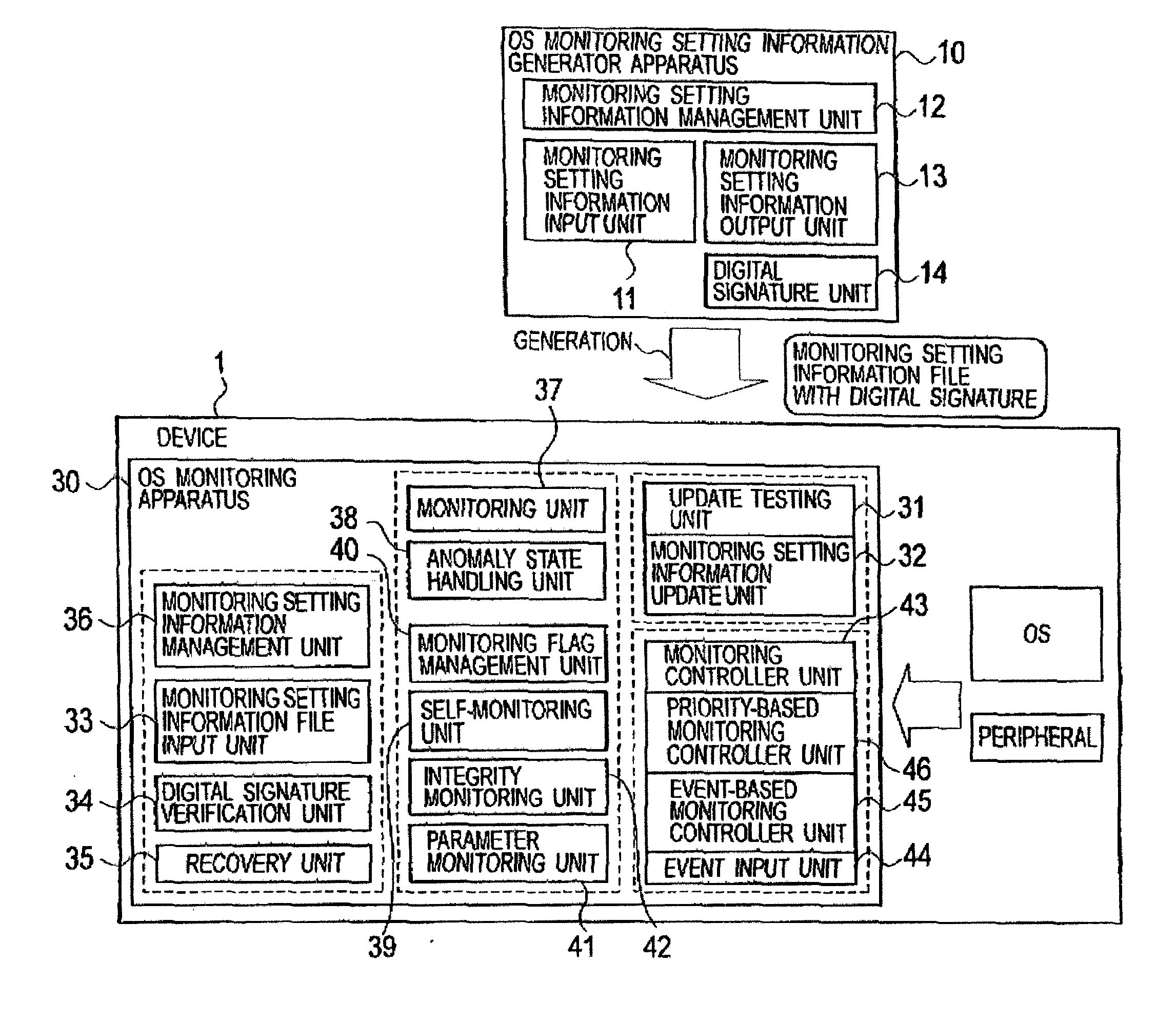

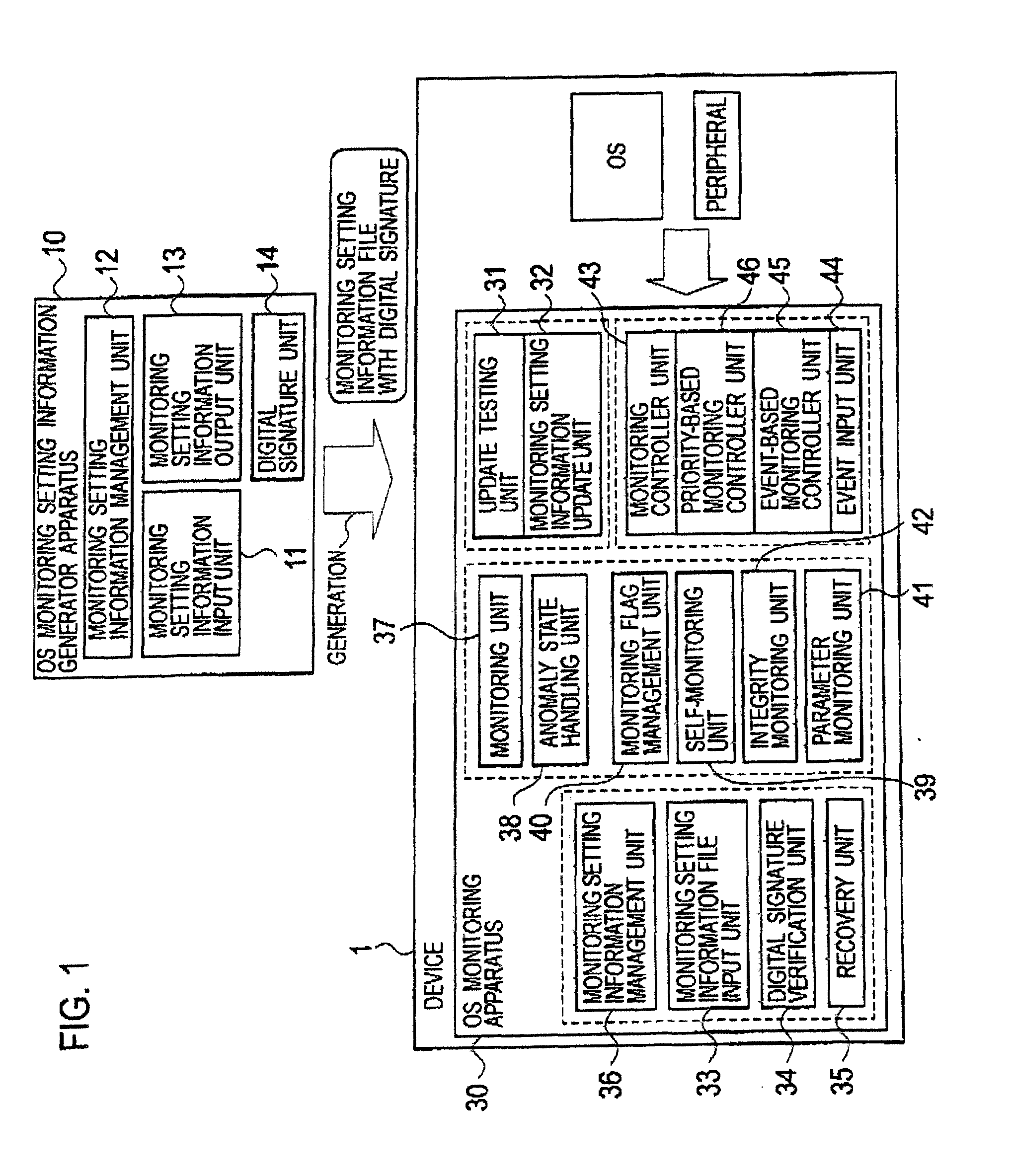

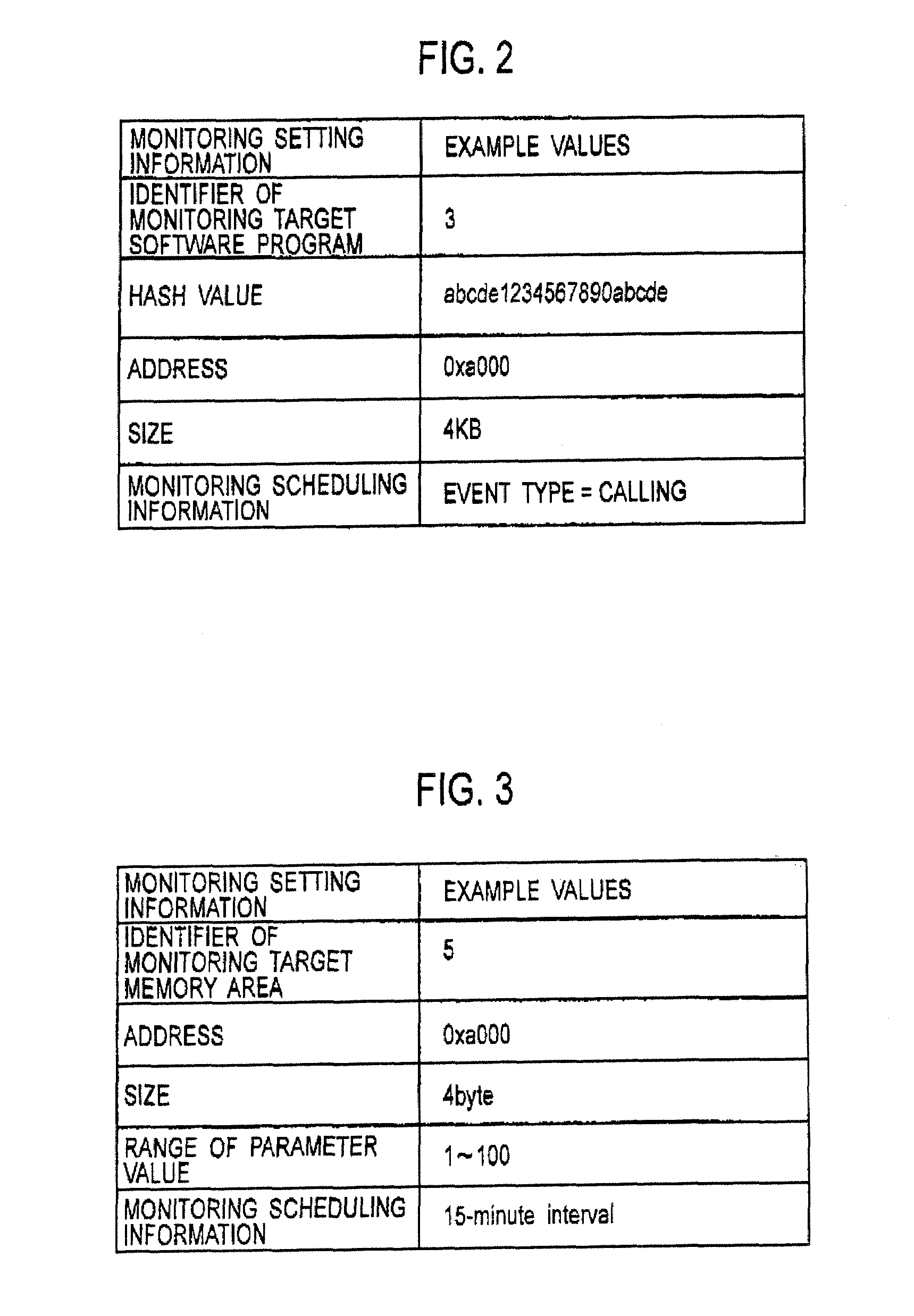

Operating system monitoring setting information generator apparatus and operating system monitoring apparatus

InactiveUS20080155509A1Maintenance operationEfficiently monitoring the integrity or soundness of an OS in a deviceDigital computer detailsComputer security arrangementsComputer securitySoftware

Disclosed is an operating system monitoring setting information generator apparatus including: a monitoring setting information management unit configured to store monitoring setting information used for monitoring of an operating system monitoring apparatus; a monitoring setting information output unit configured to generate a monitoring setting information file including the monitoring setting information stored by the monitoring setting information management unit, version information and binding information indicating a correspondence with a monitoring target software program, and to output the generated monitoring setting information file; and a digital signature unit configured to generate a digital signature of the monitoring setting information file, and to add the generated digital signature to the monitoring setting information file.

Owner:NTT DOCOMO INC

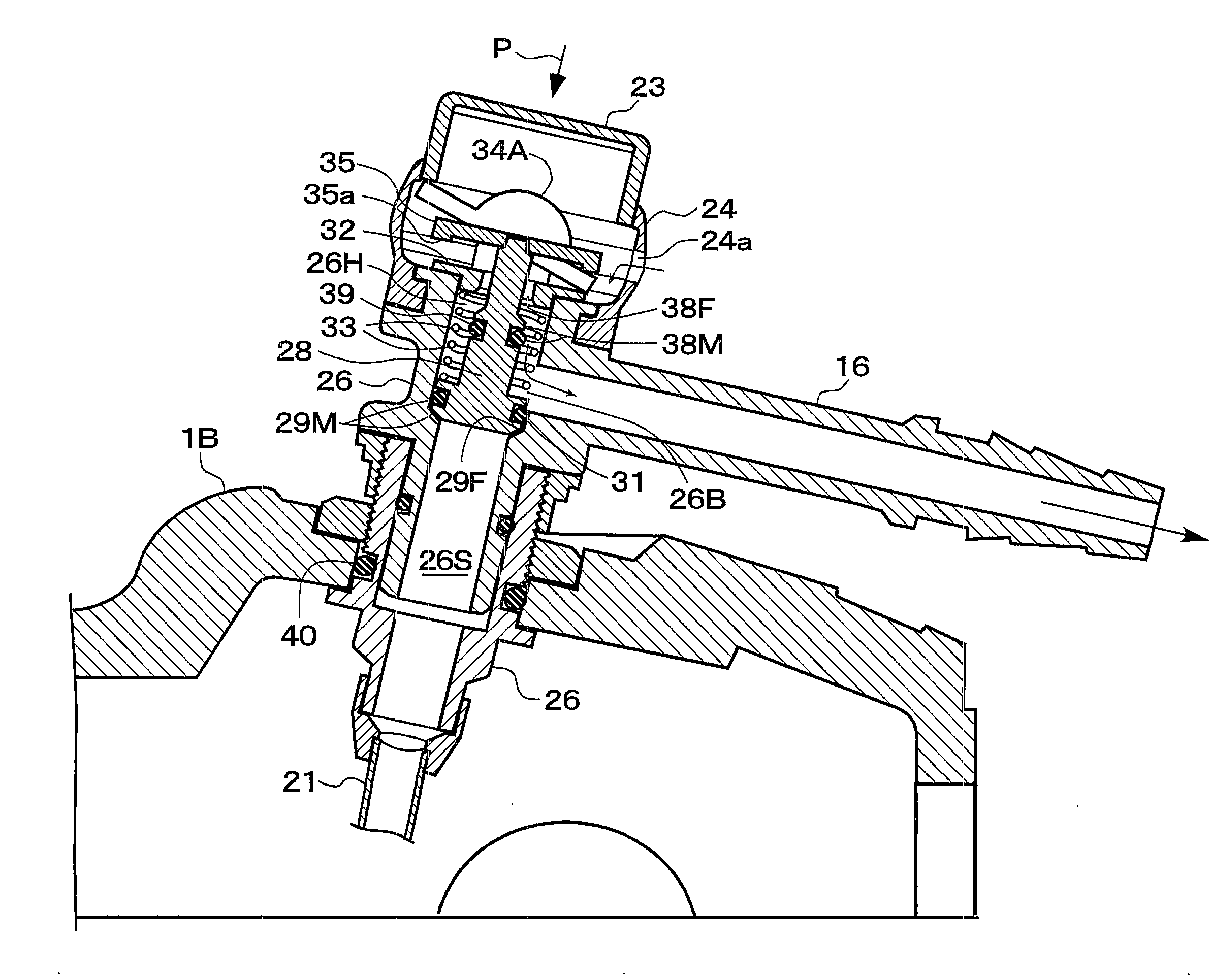

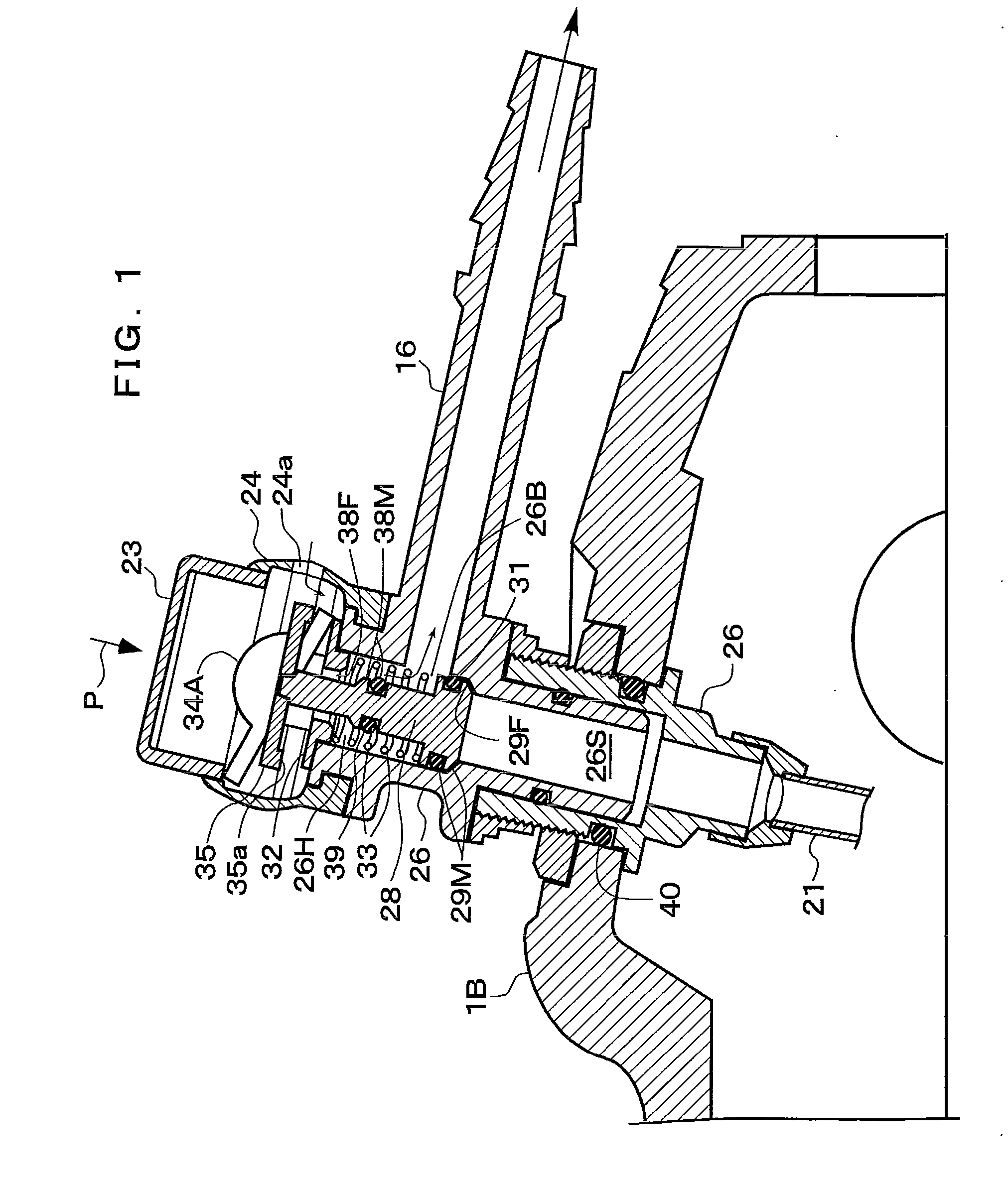

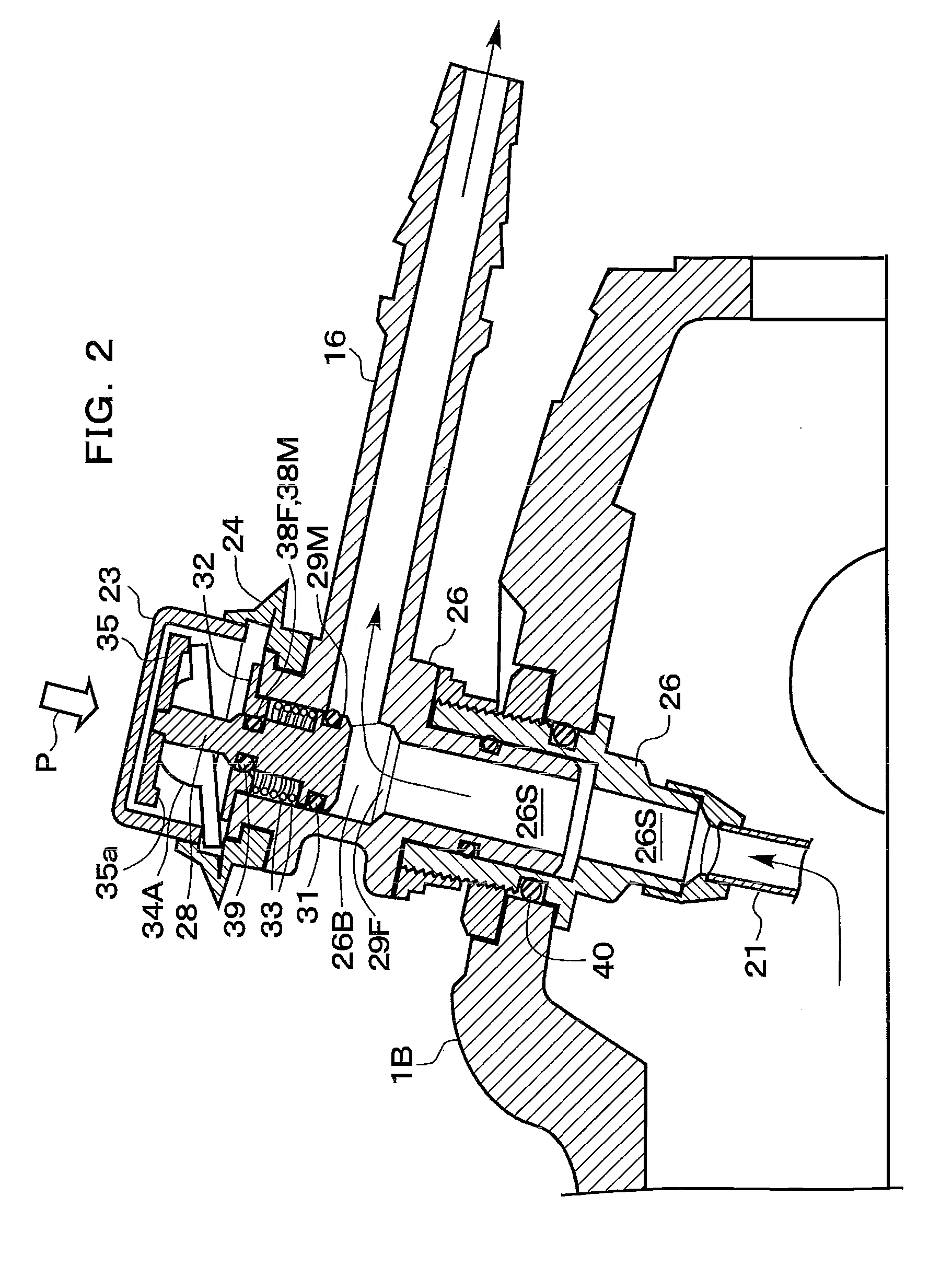

Endoscope sucking operation apparatus

When a suction button is pushed in a pushing operation direction, the suction button pushes down longer lever ends of inversion levers, shorter lever ends of the inversion levers are pushed up based on a seesaw operation and the principle of leverage, and a piston body coupled through a coupling body moves in a direction opposed to a pushing operation direction against an urging force of a spring in cooperation with this upward movement. As a result, a valve moving portion moves away from a valve receiving portion to open a suction duct valve portion and suction is carried out, but the piston body retires to an outer periphery side of a bent duct when the valve portion is opened, and hence a suction duct is widened, thereby facilitating suction of even, e.g., a fluid having high viscosity.

Owner:FUJIFILM CORP

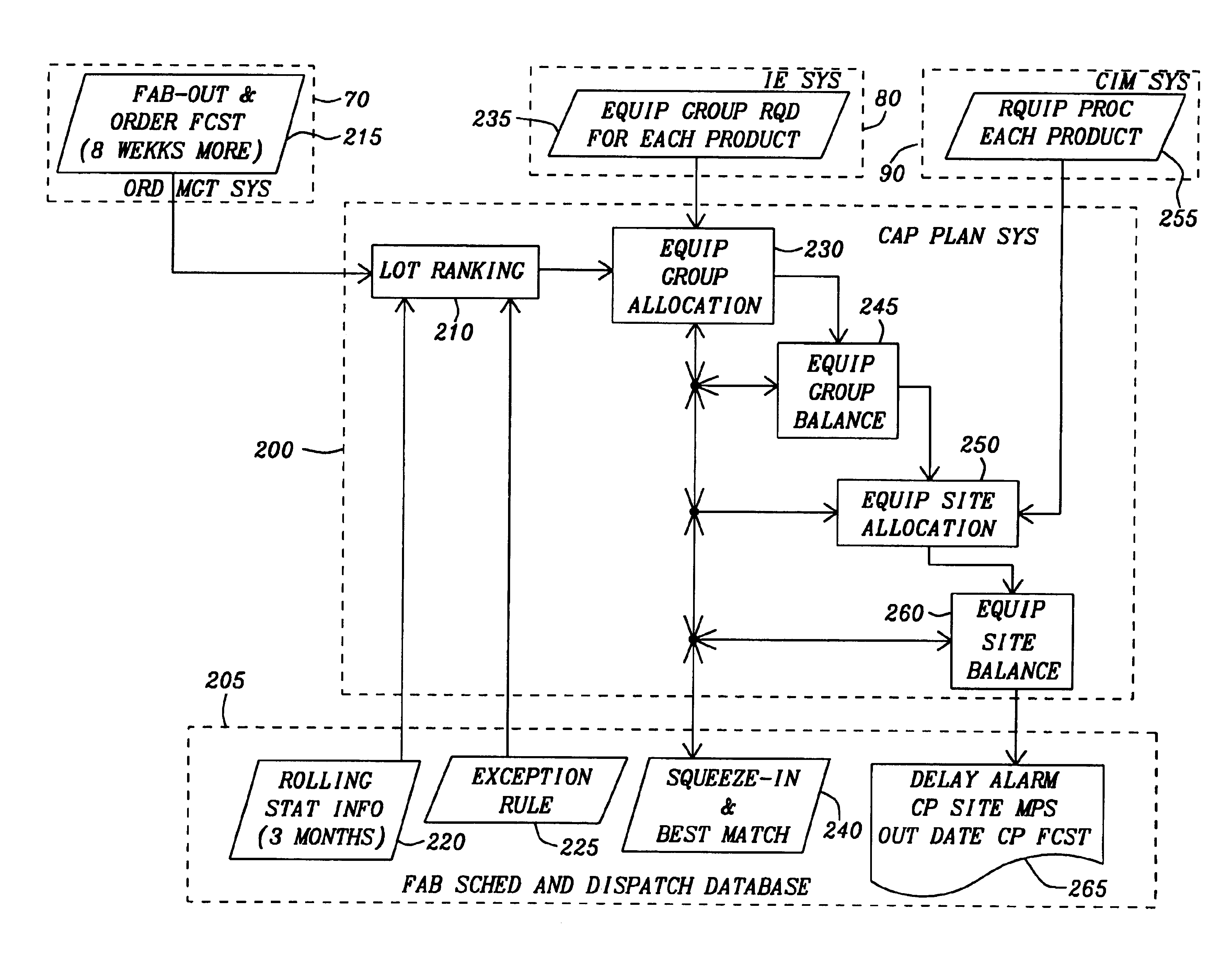

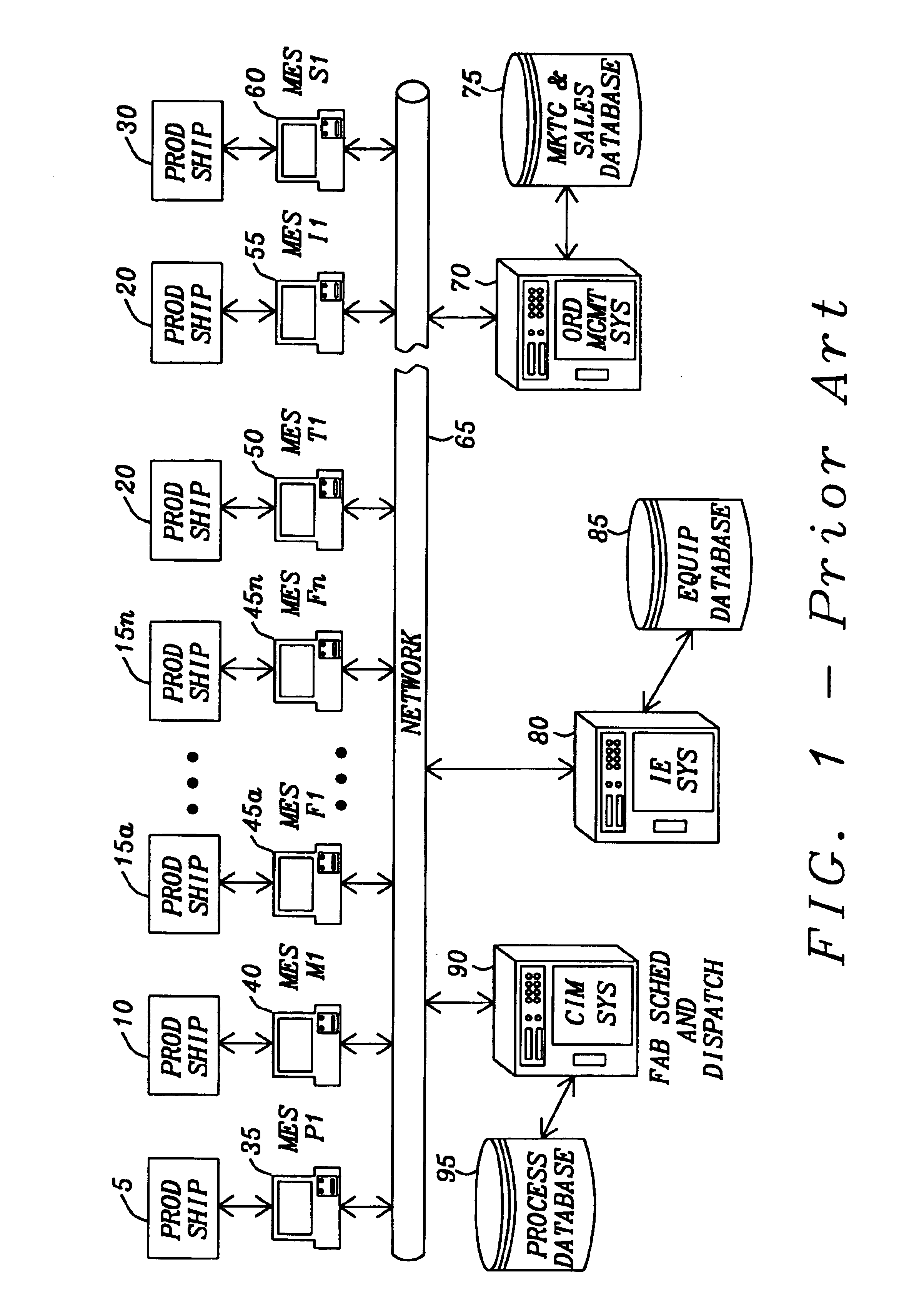

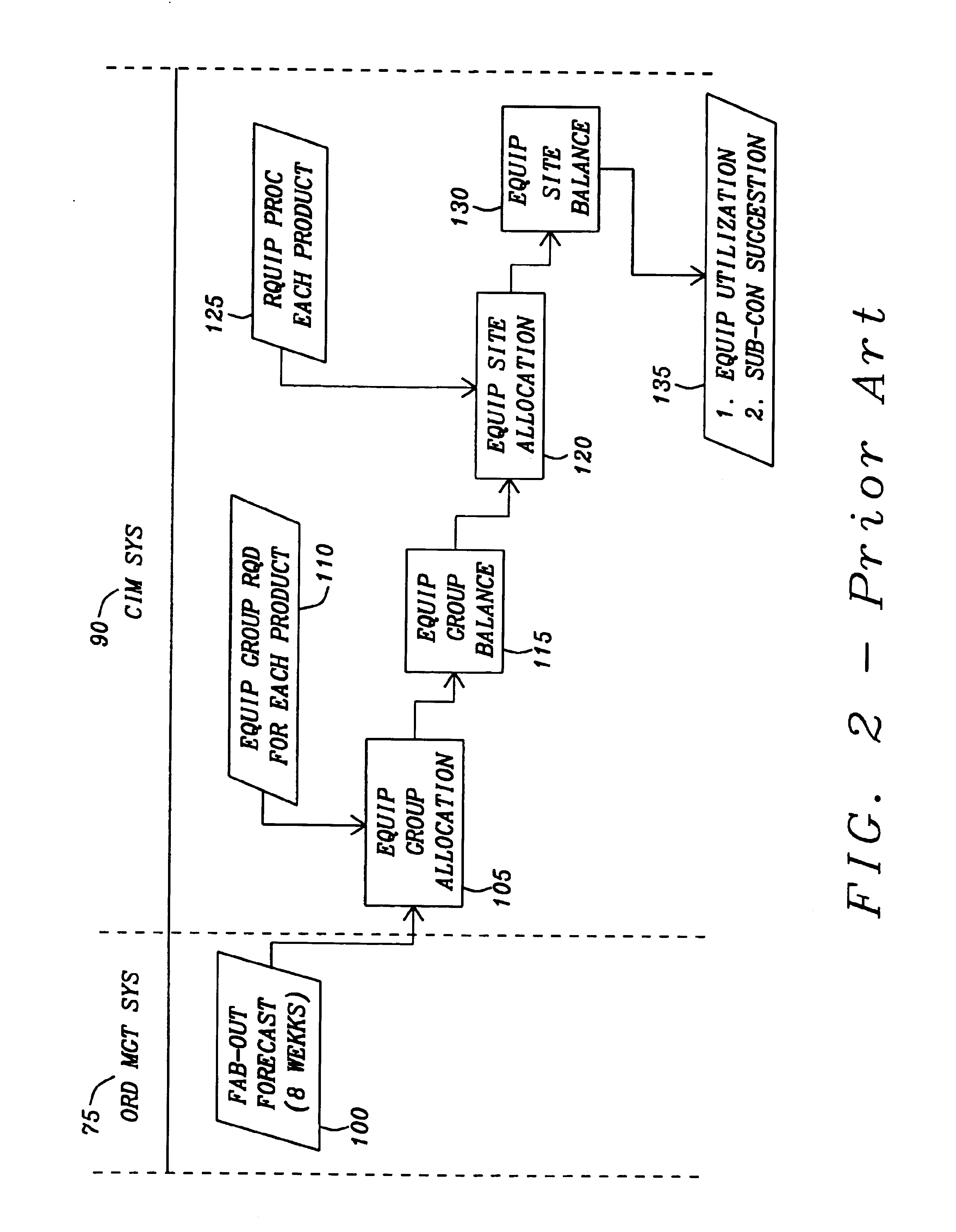

Heuristics for efficient supply chain planning in a heterogeneous production line

InactiveUS6920366B1Low utilizationMaintenance operationResourcesSpecial data processing applicationsOrder management systemComputer-integrated manufacturing

A computer integrated manufacturing system executes a program process that performs a capacity planning method that allocates usage of a plurality of manufacturing elements of a manufacturing enterprise by major and minor apparatus, squeezing for overhead cost consideration, and site balance for maintain basic operation. The program process begins by receiving at least one fabrication forecast describing scheduling and types of product lots that are predicted to be fabricated within a first period of time by the manufacturing enterprise from at least one order management system of the manufacturing enterprise. Rolling statistics of products lots fabricated during a second period of time are retrieved from a data retention device of the computer integrated manufacturing system. Capacity planning for the allocation of the product lot predicted to be fabricated by the manufacturing elements is performed.

Owner:TAIWAN SEMICON MFG CO LTD

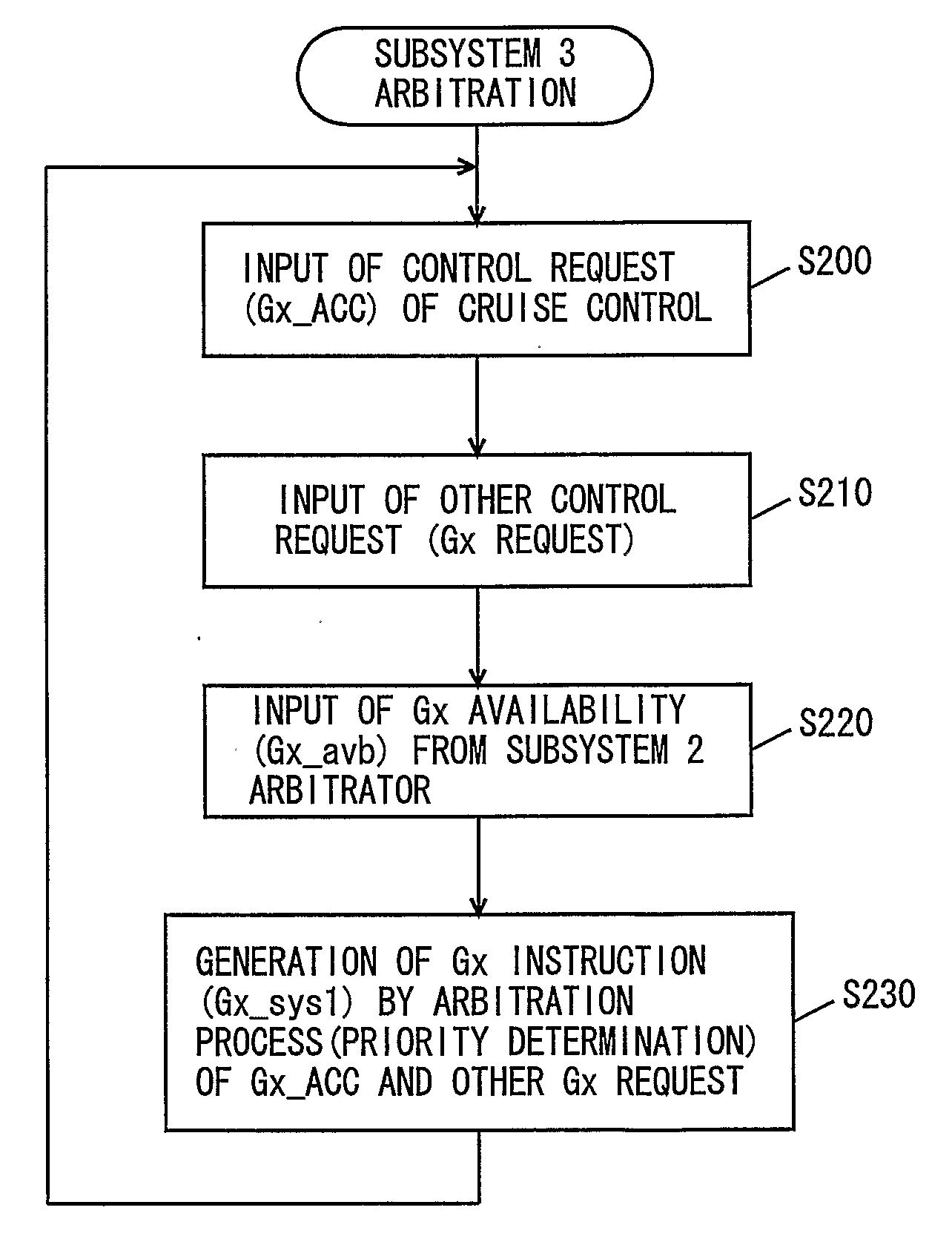

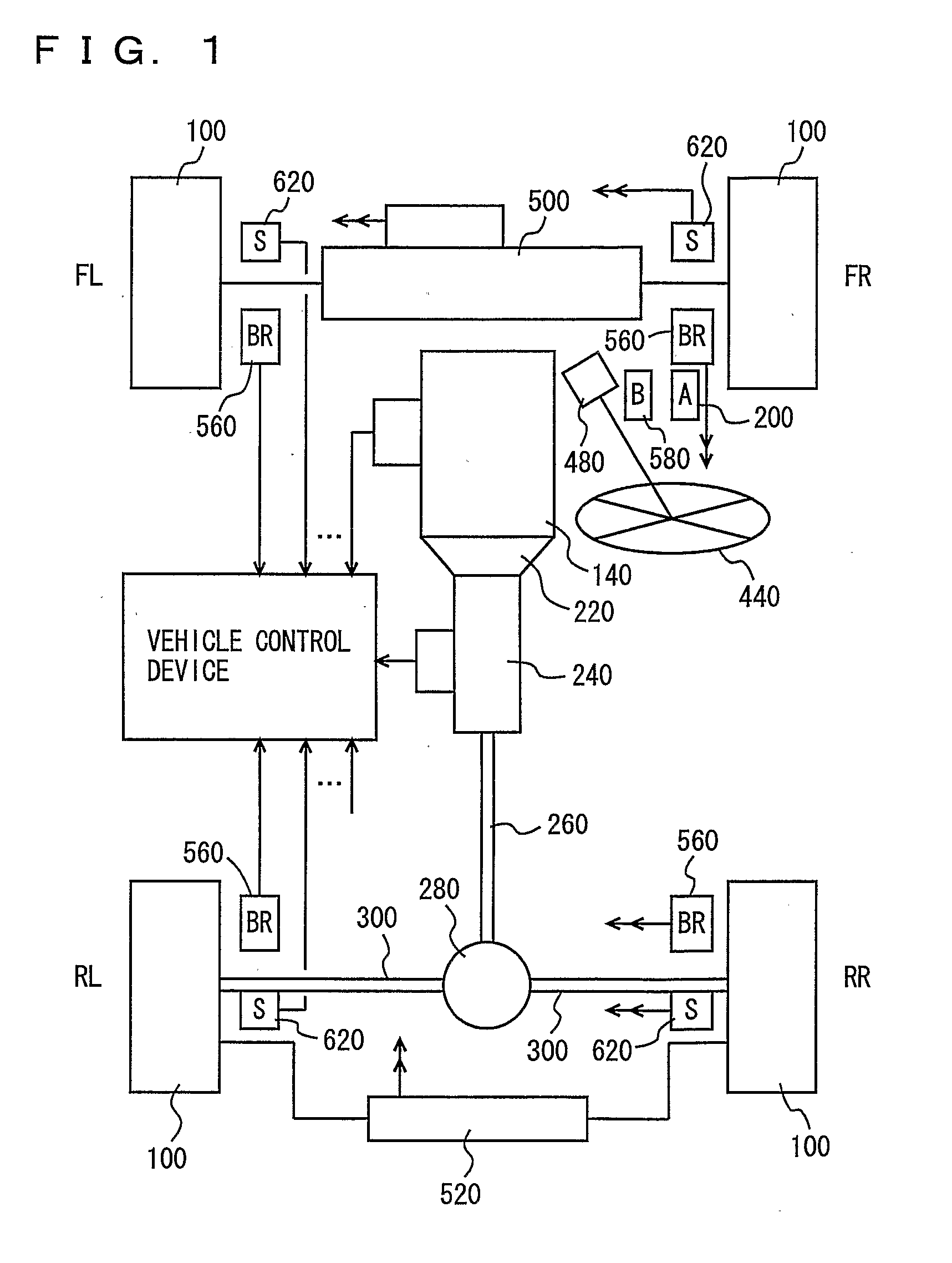

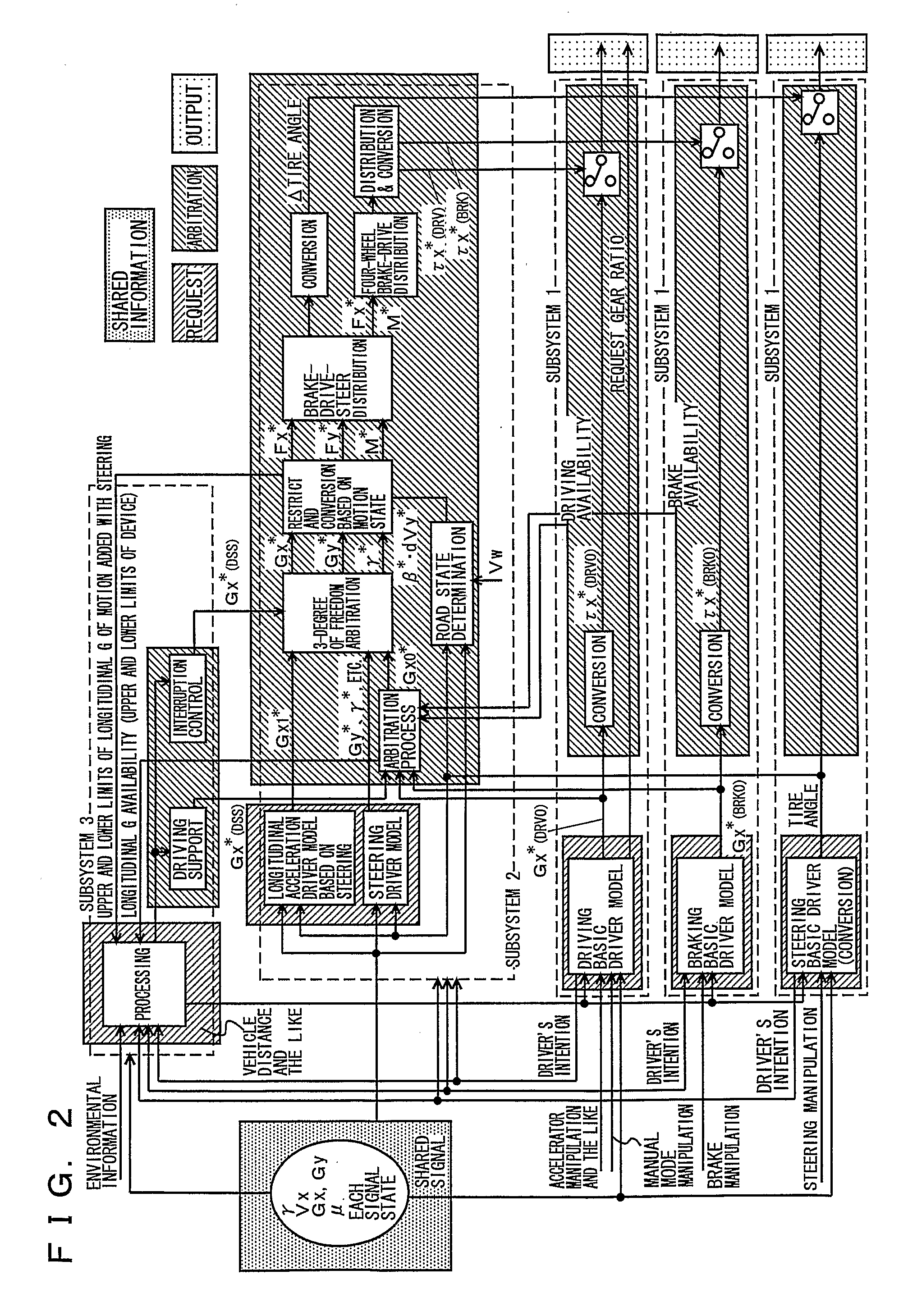

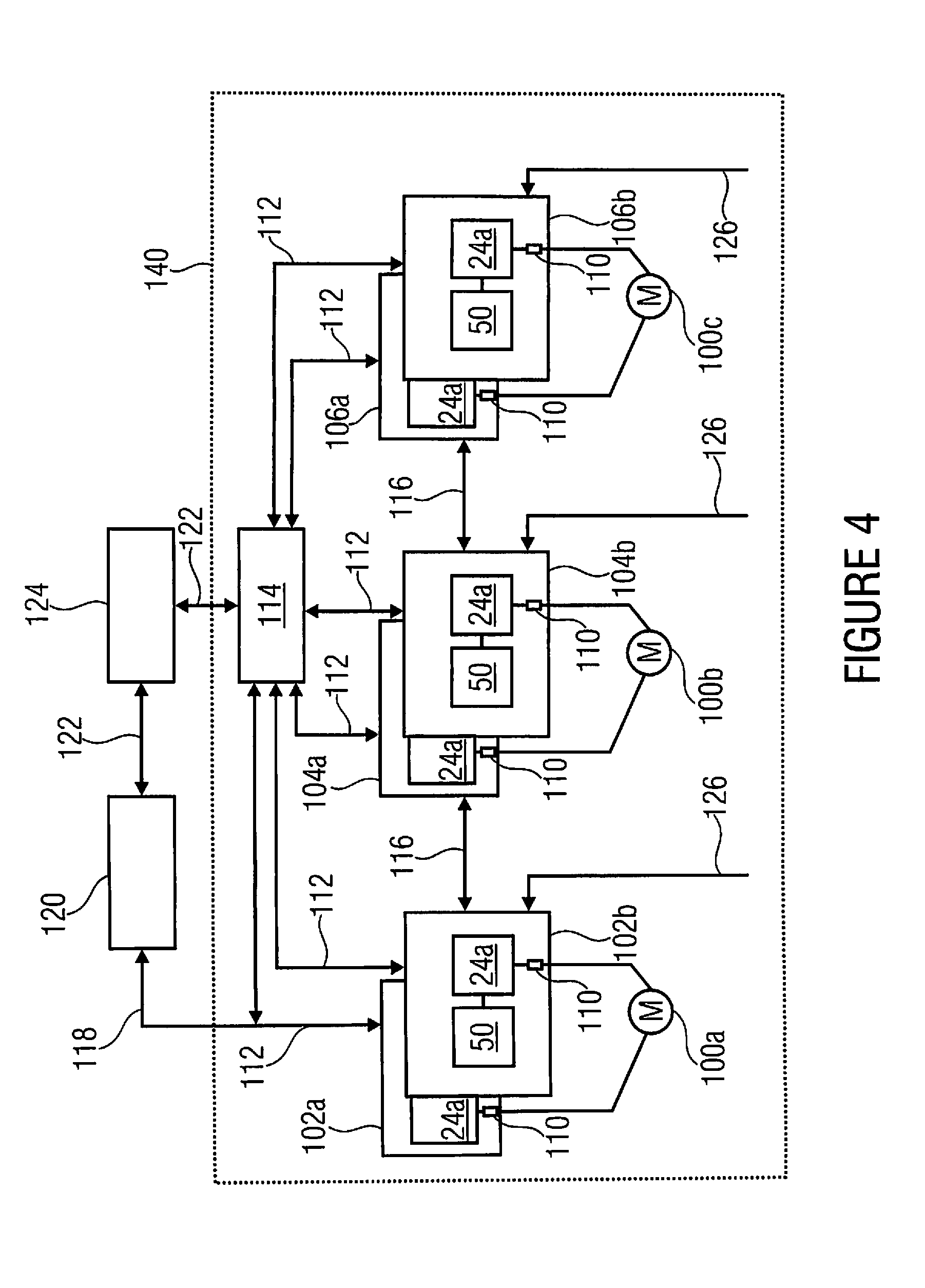

Vehicle integrated control system

InactiveUS20070169007A1Easy to addFail-safe faculty improvedVehicle testingRegistering/indicating working of vehiclesControl systemBraking system

An integrated control system includes subsystem with a driving system control subsystem controlling a driving system, a brake system control subsystem controlling a brake system, and a steering system control subsystem controlling a steering system, a subsystem stabilizing a current dynamic state of the vehicle, a subsystem realizing a driving support function such as automatic cruising, and a storage unit for storing shared signals. Each subsystem includes a request unit, an arbitration unit, and an output unit.

Owner:TOYOTA JIDOSHA KK

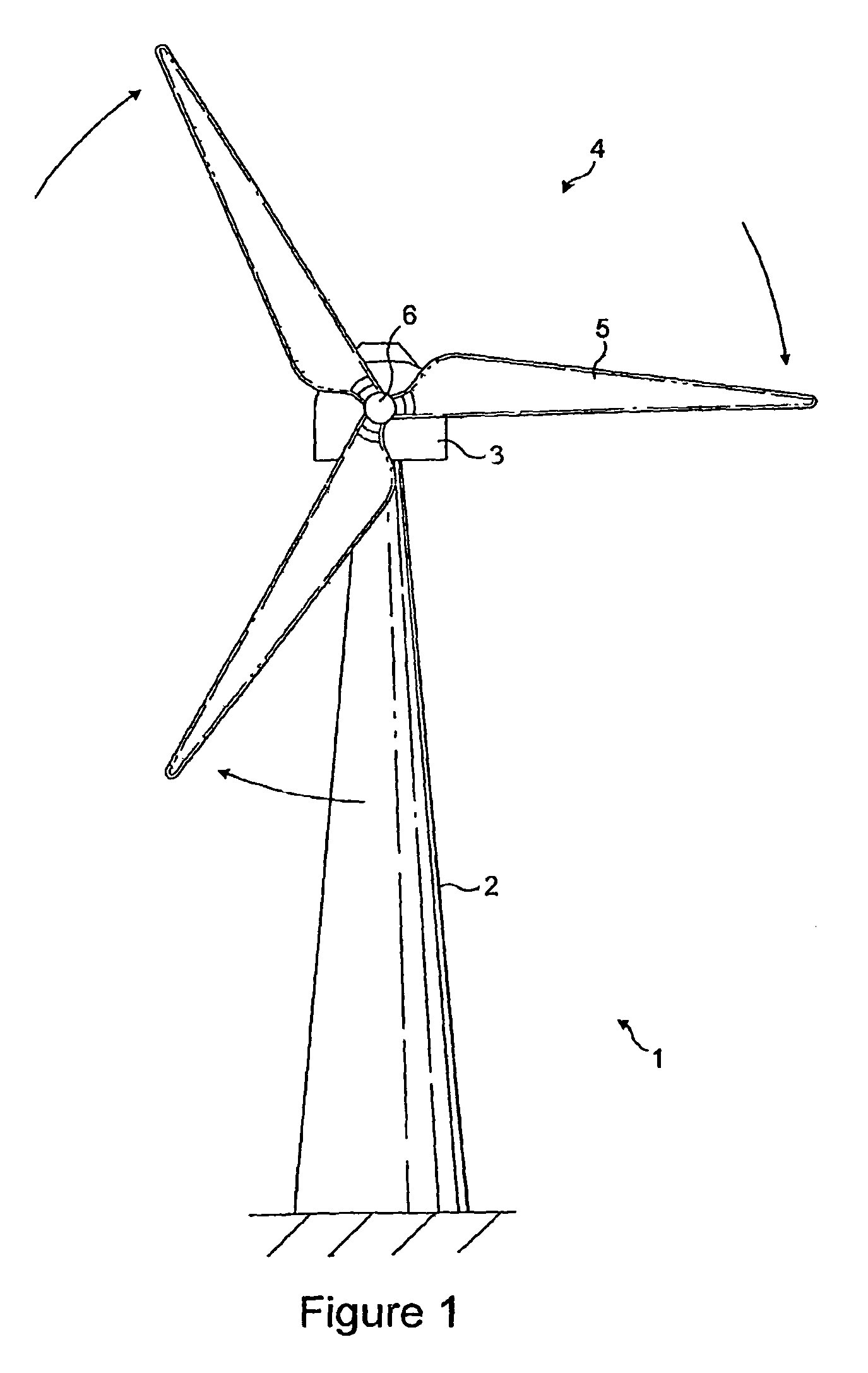

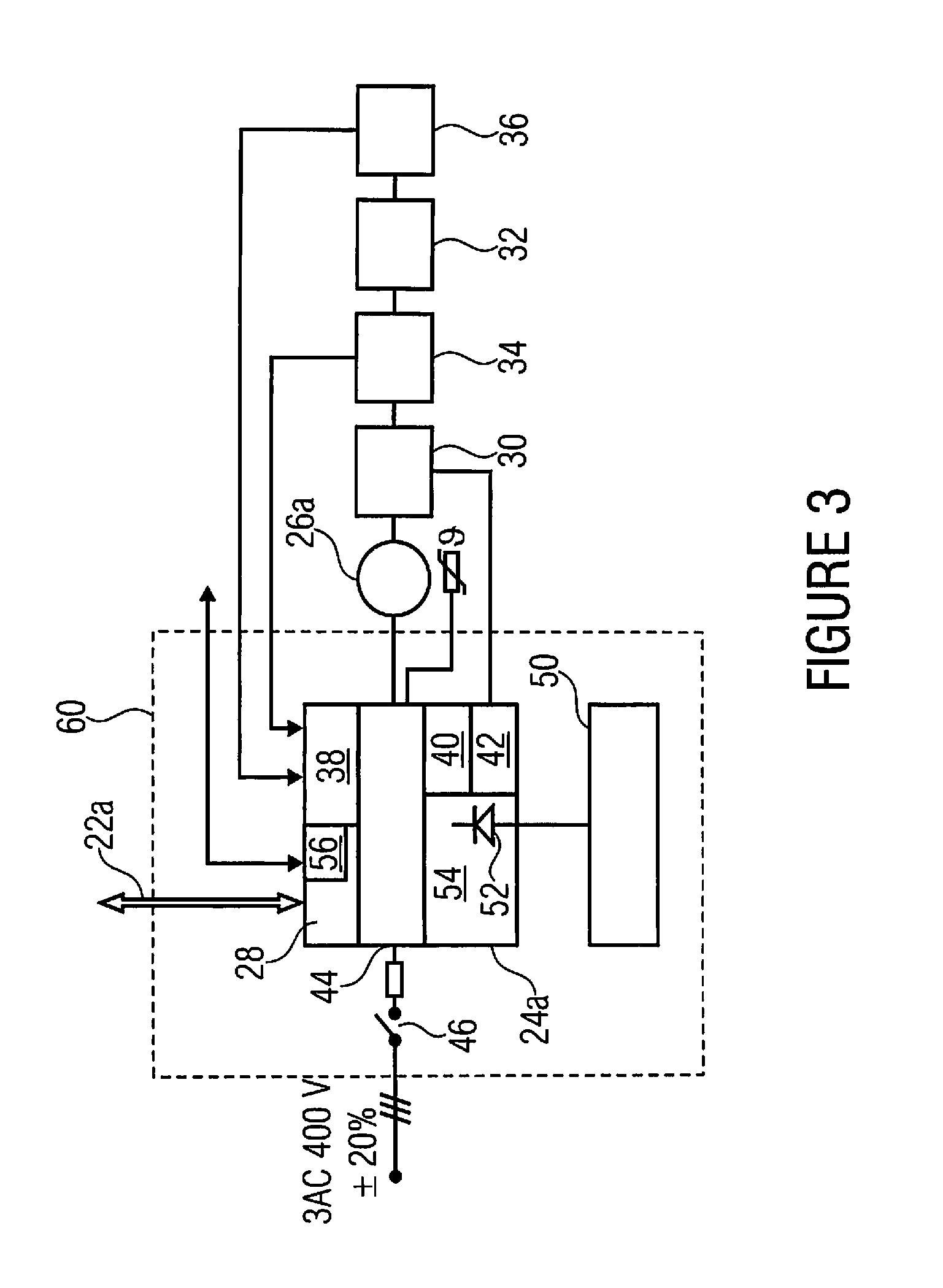

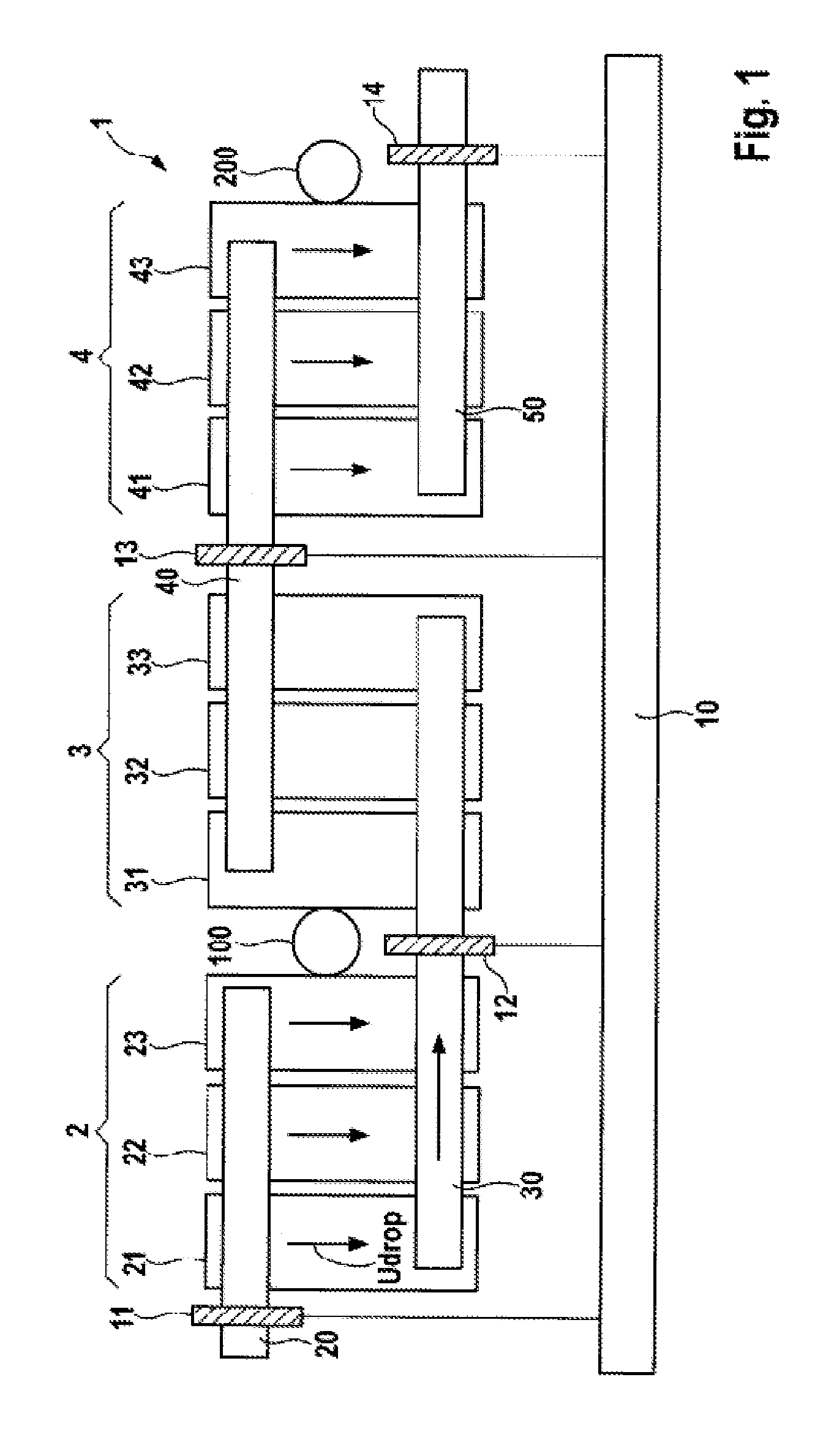

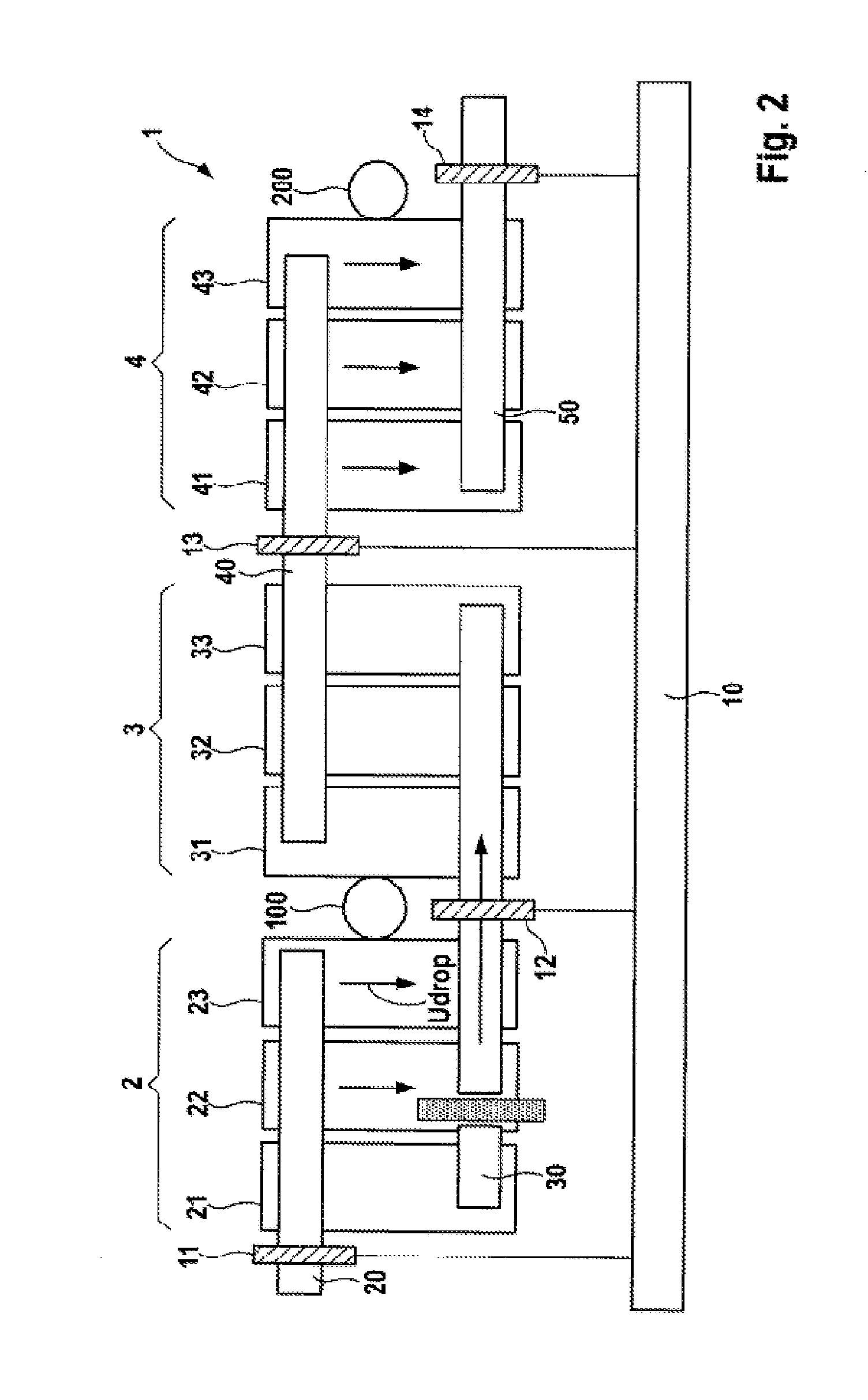

Method of maintaining wind turbine components operational and a turbine comprising components suitable for operational maintenace

ActiveUS8084874B2Maintenance operationReduced availabilityPropellersPump componentsPower gridTurbine

The invention relates to a wind turbine (1) which is connected to an electrical power grid (23) and which uses a magnet generator (6) as the only electrical power generator element both in the normal operation thereof and during periods in which the turbine is disconnected from the electrical power grid. The aforementioned wind turbine can perform operations in order to maintain the wind turbine systems operational, with the continued generation of electrical power, and to adjust the quantity of electrical power produced for power consumption during the periods in which the turbine is disconnected from the electrical power grid.

Owner:ADWEN OFFSHORE SL

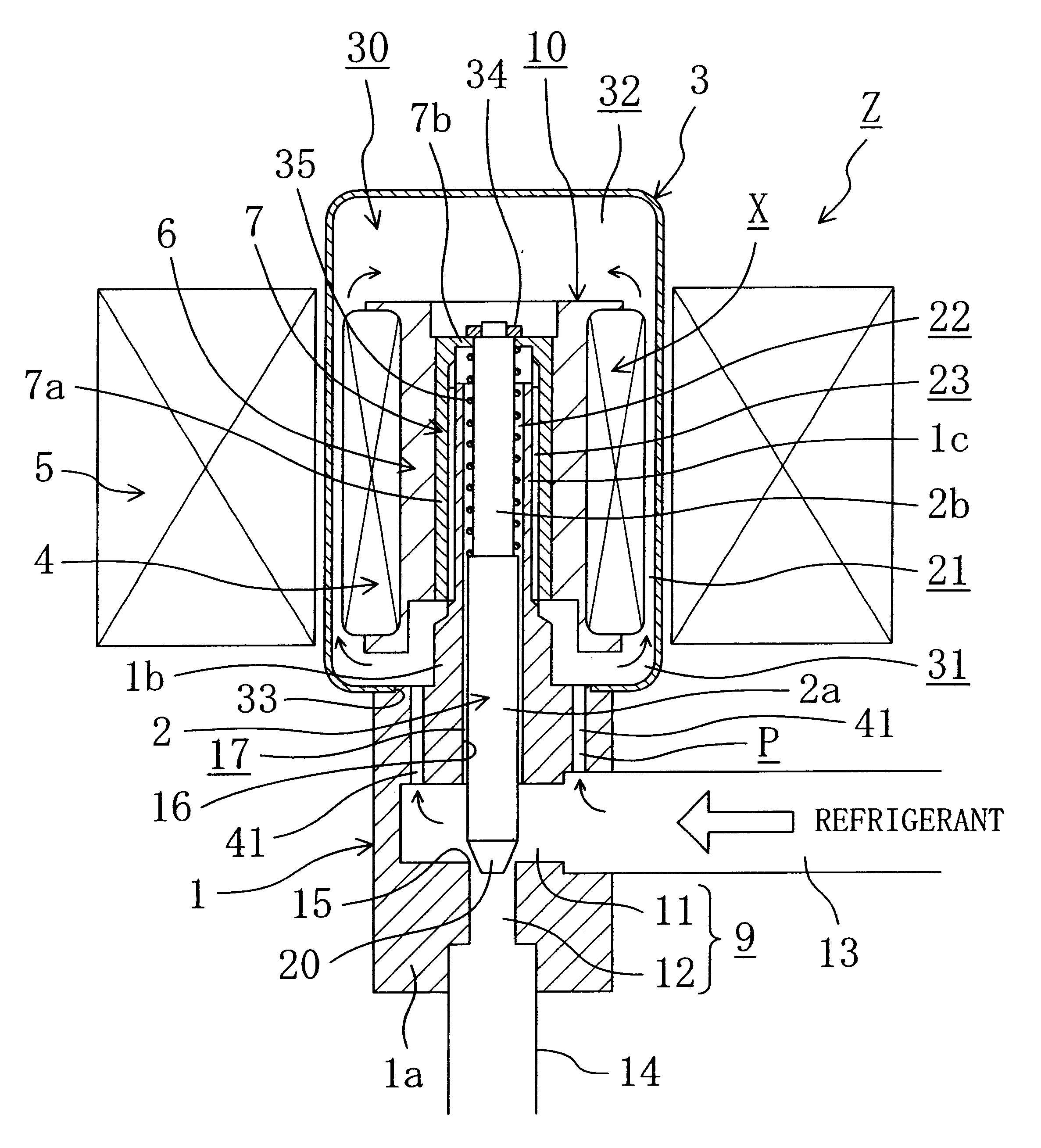

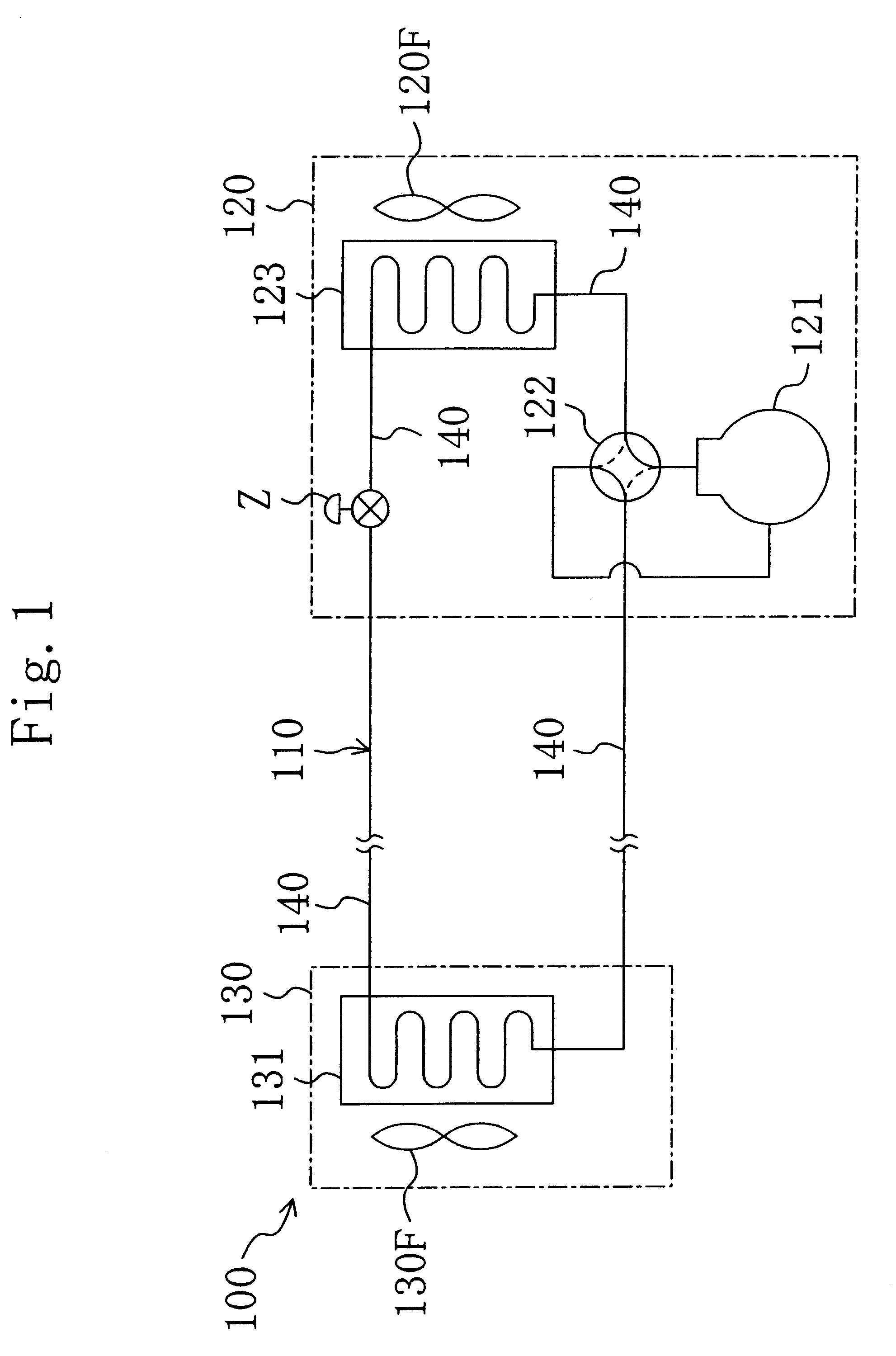

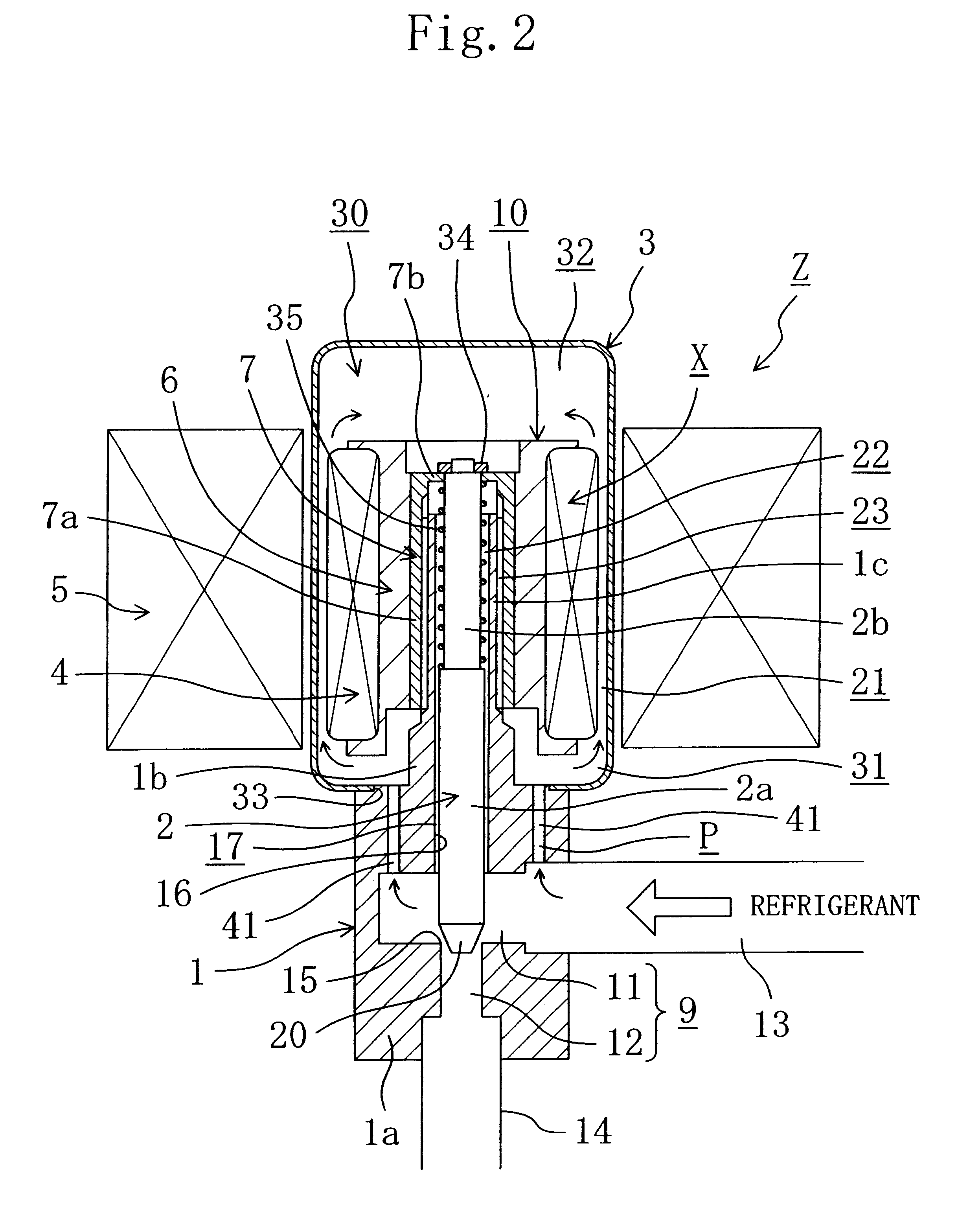

Refrigerating device

InactiveUS6481229B1Ensure reliabilityMaintenance operationTemperature control without auxillary powerOperating means/releasing devices for valvesNuclear engineeringHeat exchanger

The present invention provides means for selecting a direct drive type electrically driven expansion valve (Z). The present invention includes a compressor (121), an external heat exchanger (123), a direct drive type electrically driven expansion valve (Z), and an internal heat exchanger (131). The rating torque equivalent friction factor E of the direct drive type electrically driven expansion valve (Z) is set to 0.31 or more.

Owner:DAIKIN IND LTD

Wind turbine having a control method and controller for performing predictive control of a wind turbine generator

ActiveUS9217416B2Prolong lifeStable controlWind motor controlEngine fuctionsControl signalControl system

The application describes a wind turbine having a control method and controller for performing predictive control of a wind turbine generator. Based on the measured instantaneous wind speed, it is known to provide control signals to a wind turbine in order to control the pitch of the wind turbine rotor blades and the speed of the generator. However, it is difficult using instantaneous wind speed measurements to achieve smooth control, due to finite response speeds of the associated electro-mechanical systems, as well as the constantly changing control system inputs. The predictive control system described in the application assumes a model of generator speed based on the values of the incident wind speed v(t) and the values of a control signal u(t) output to the wind turbine in a feed forward loop. Here, the control signal can be for one or more of controlling either the power setting of the generator, or the pitch angle of the rotor blades. The predictive controller uses a rolling time series of values for v(t) and u(t) and based on a predicted response of the generator speed w(t) optimizes the time series control signal u(t). The predicted response of the generator speed w(t) is based on model, that can be refined in real time as the wind turbine operates.

Owner:VESTAS WIND SYST AS

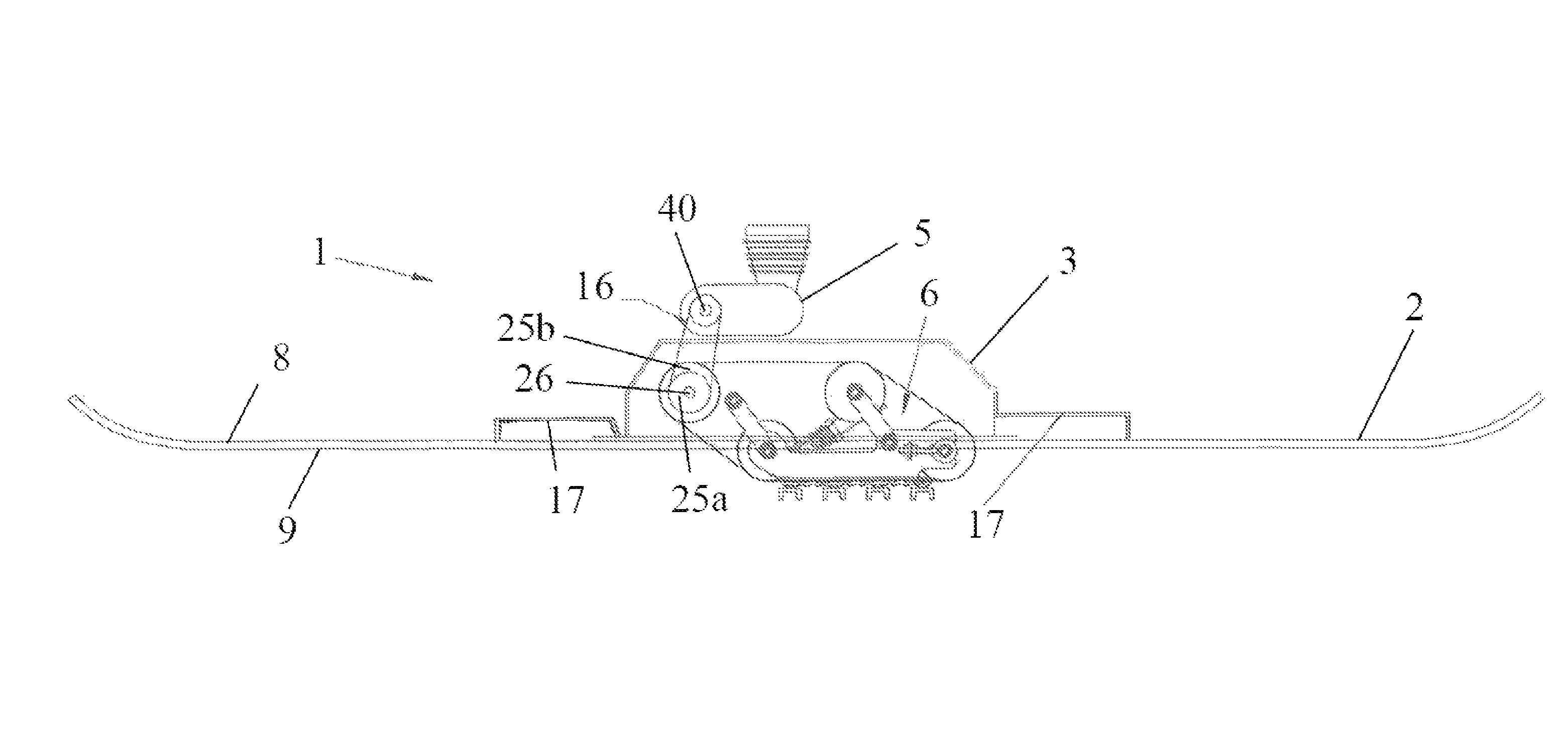

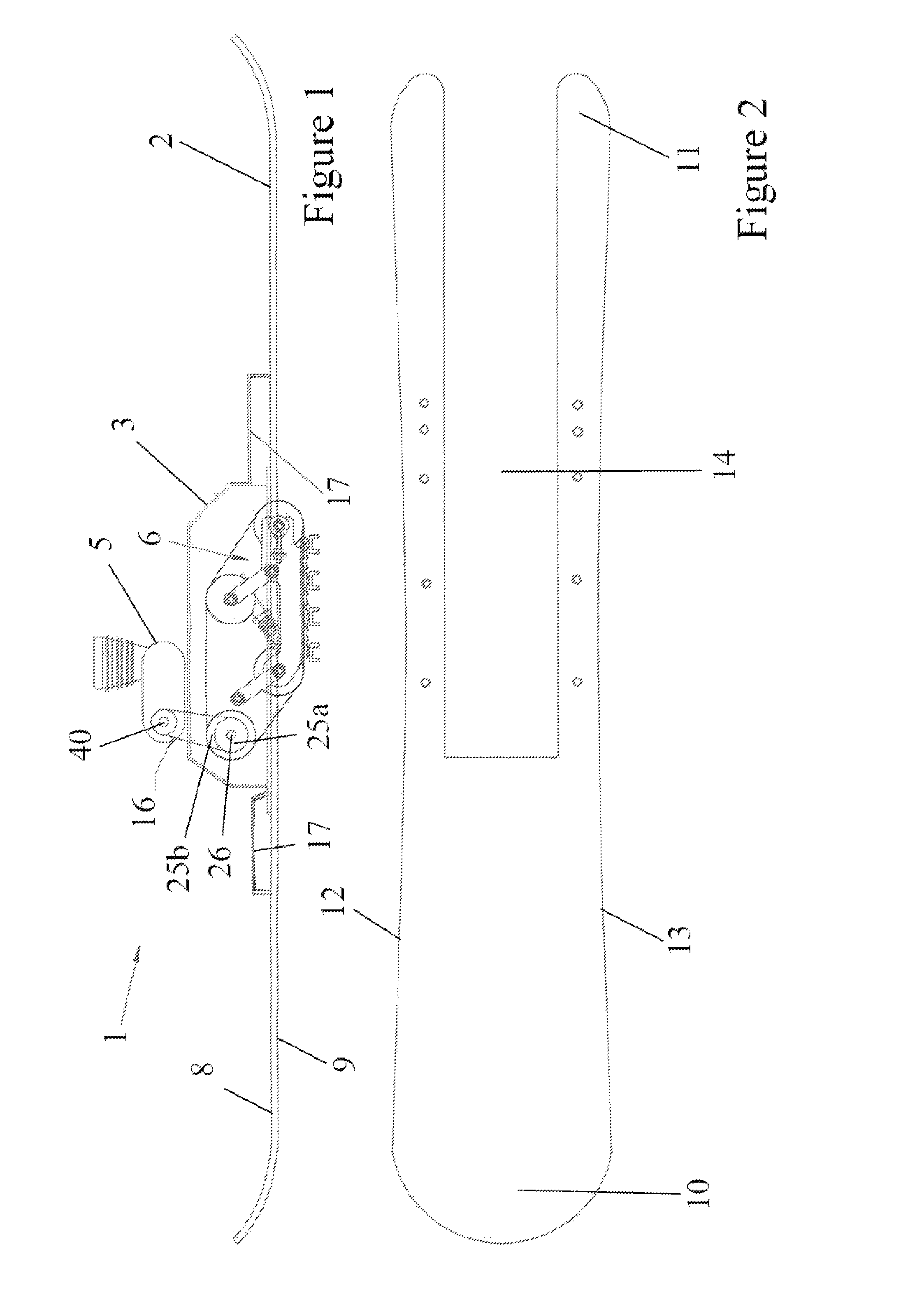

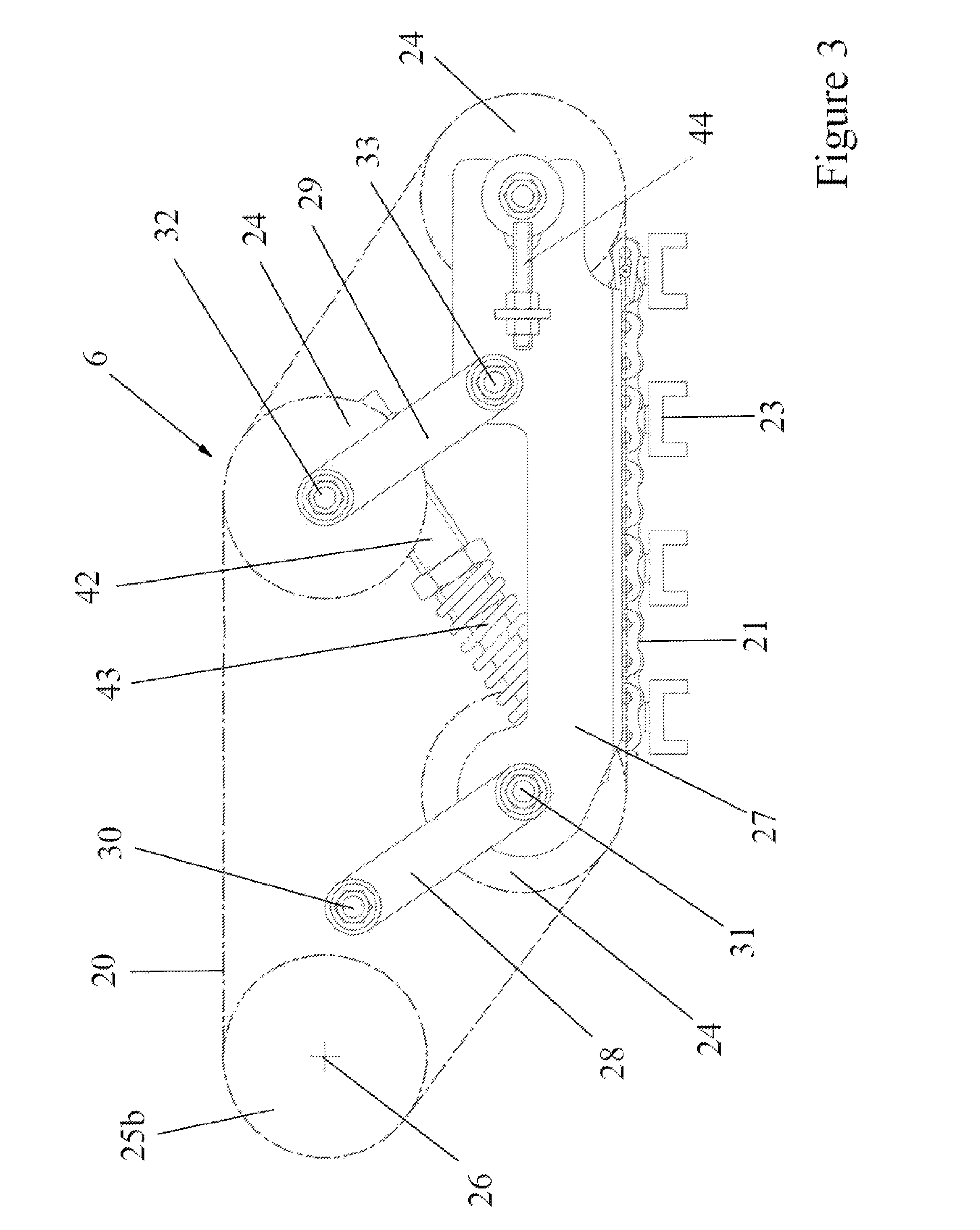

Motorized snowboard

ActiveUS8991541B1Prevent buildupMaintenance operationSnowboardsSkisEngineeringElectrical and Electronics engineering

Owner:MAIER JASON N

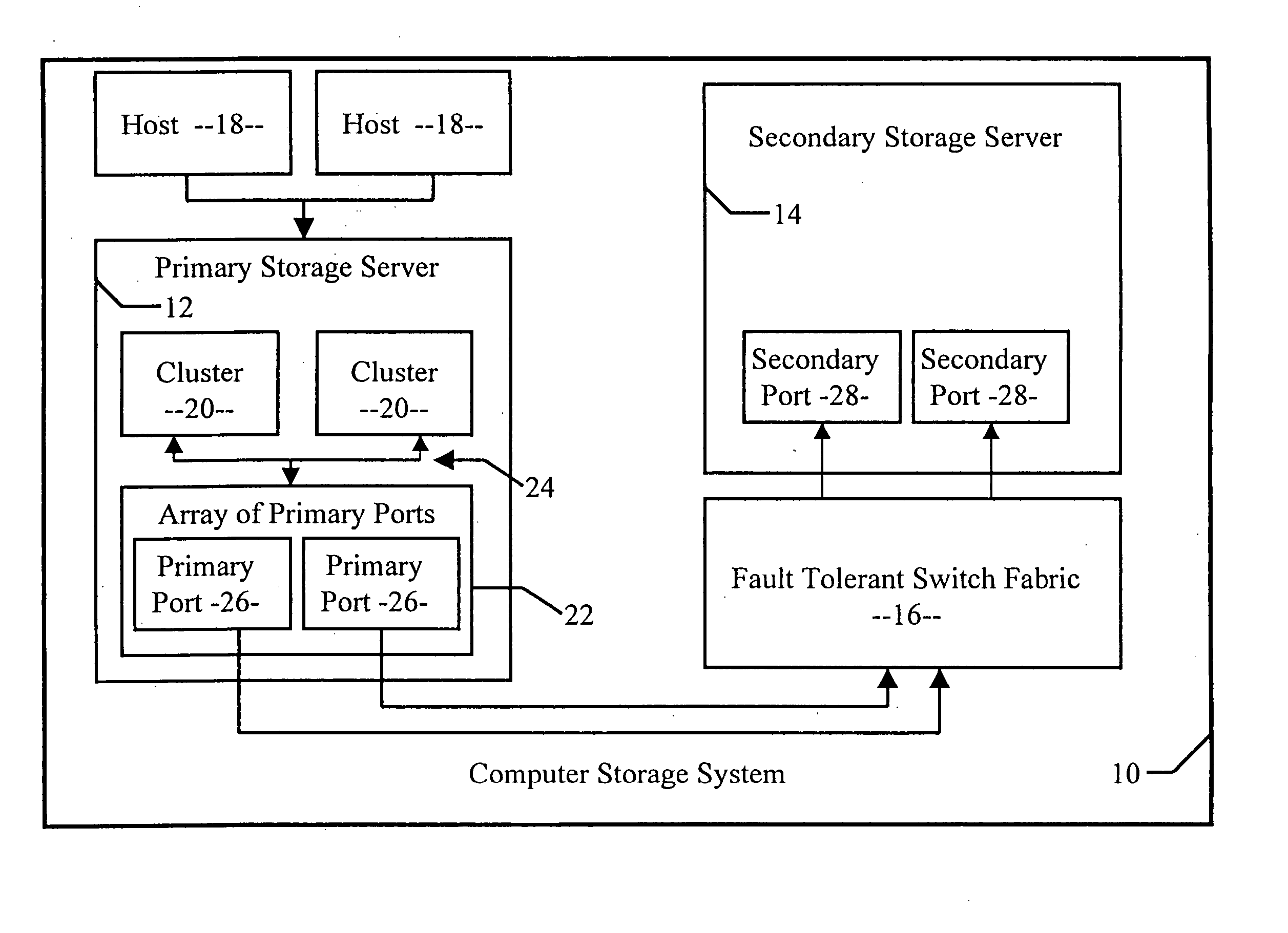

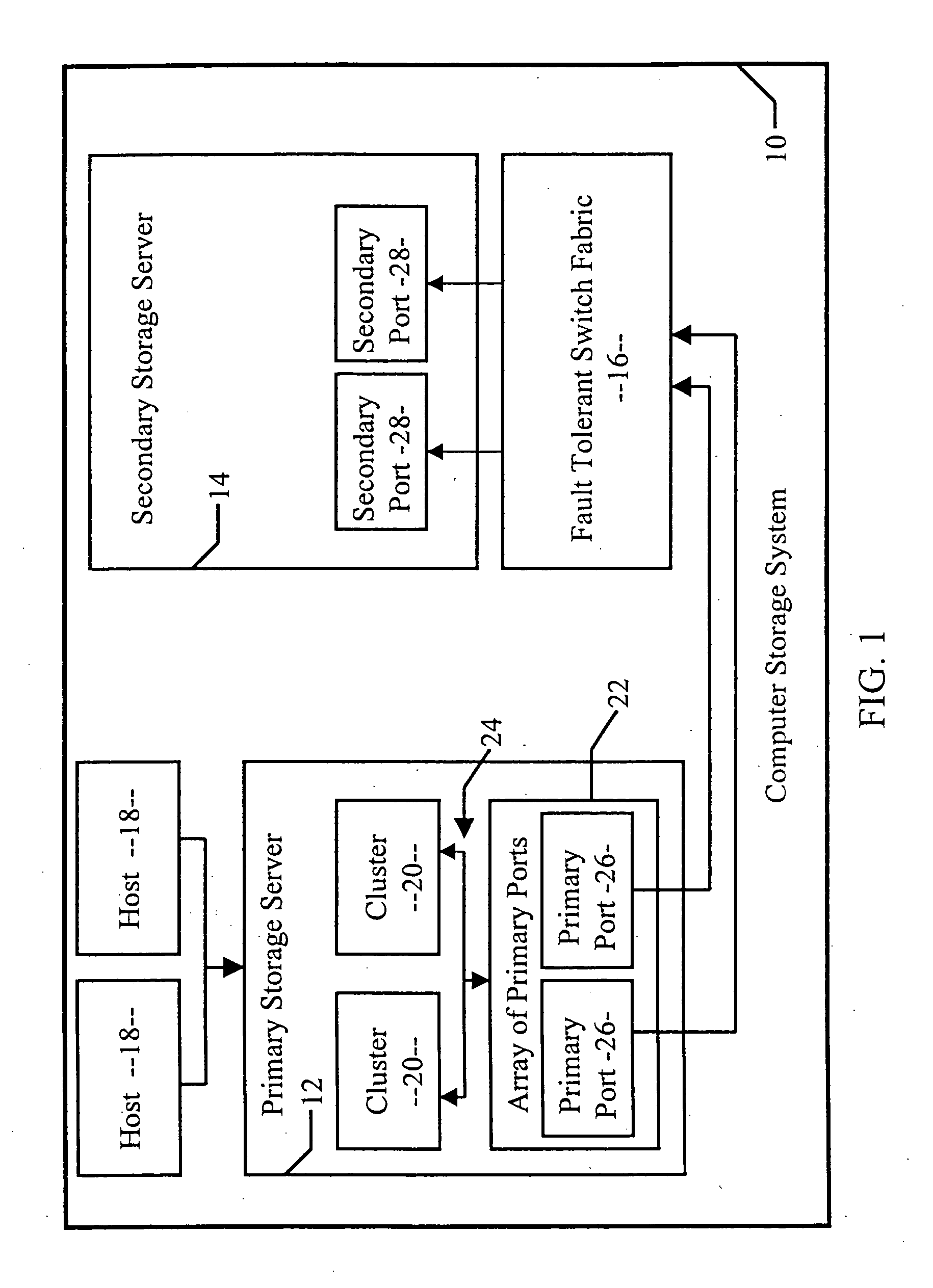

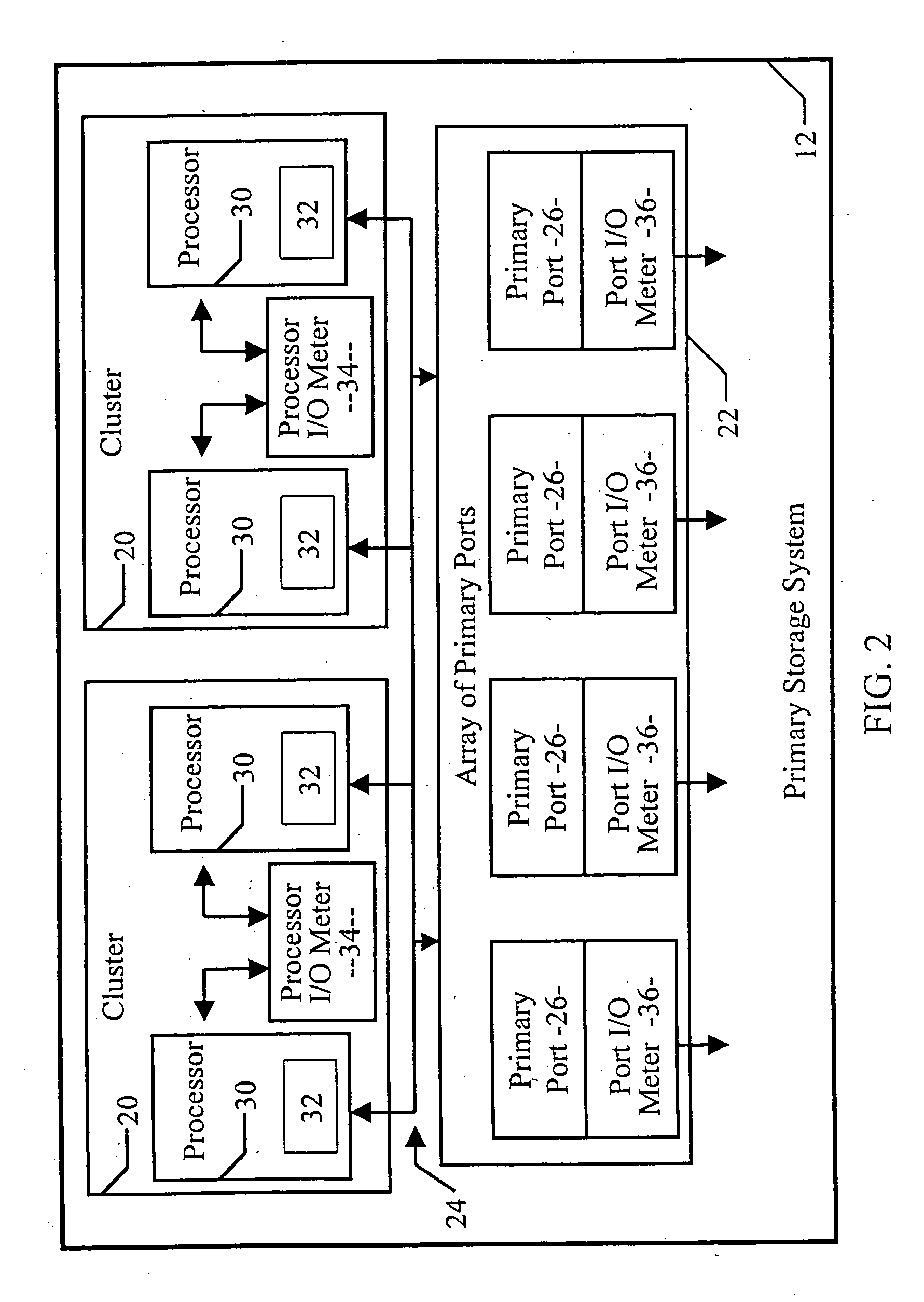

Method of balancing work load with prioritized tasks across a multitude of communication ports

ActiveUS20050210321A1Maximize high-priority task completionAvoid hungerError detection/correctionDigital computer detailsData transmissionComputer science

A processor is used to evaluate information regarding the number, size, and priority level of data transfer requests sent to a plurality of communication ports. Additional information regarding the number, size, and priority level of data requests received by the communication ports from this and other processors is evaluated as well. This information is applied to a control algorithm that, in turn, determines which of the communication ports will receive subsequent data transfer requests. The behavior of the control algorithm varies based on the current utilization rate of communication port bandwidths, the size of data transfer requests, and the priority level of the these transfer requests.

Owner:IBM CORP

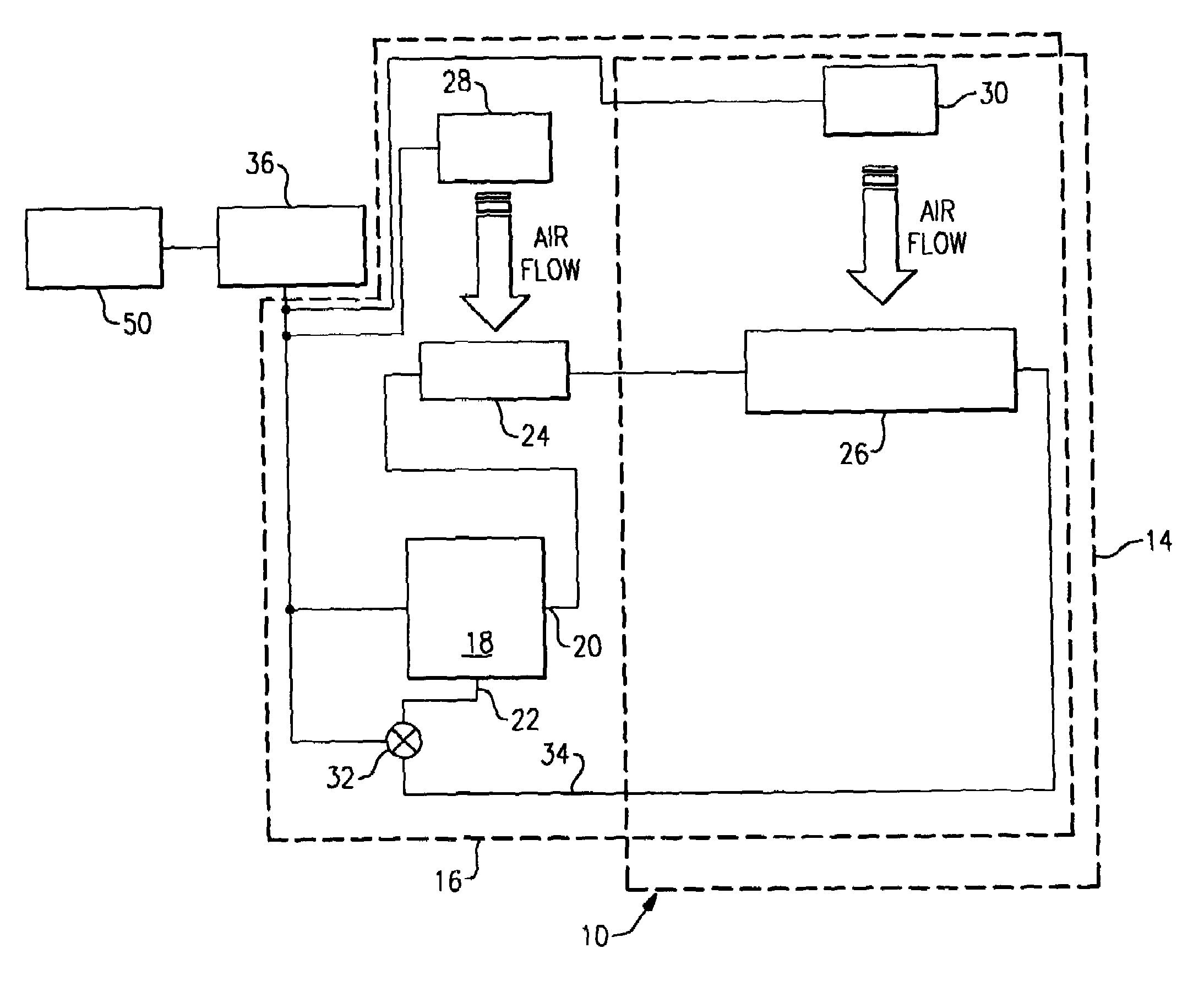

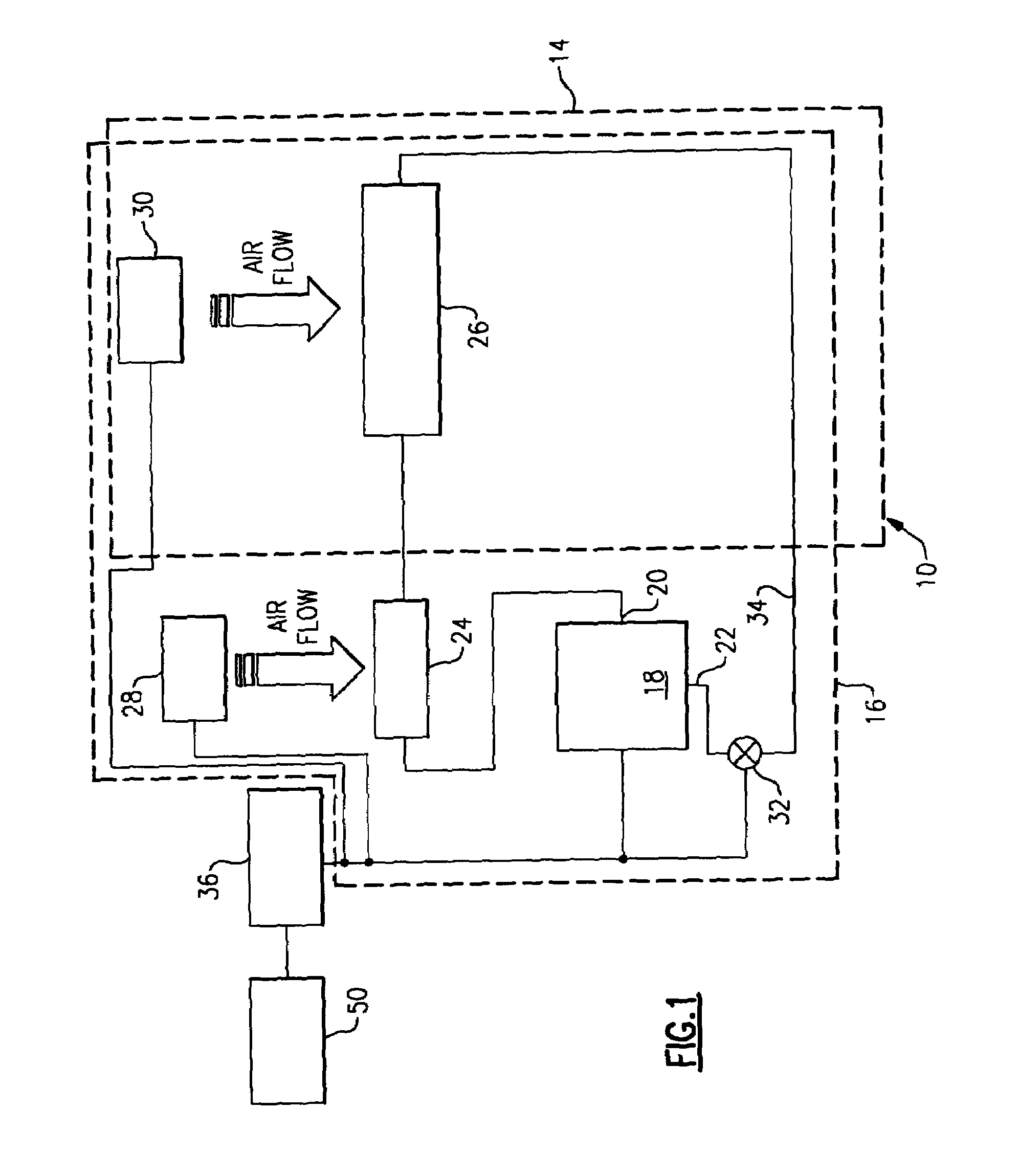

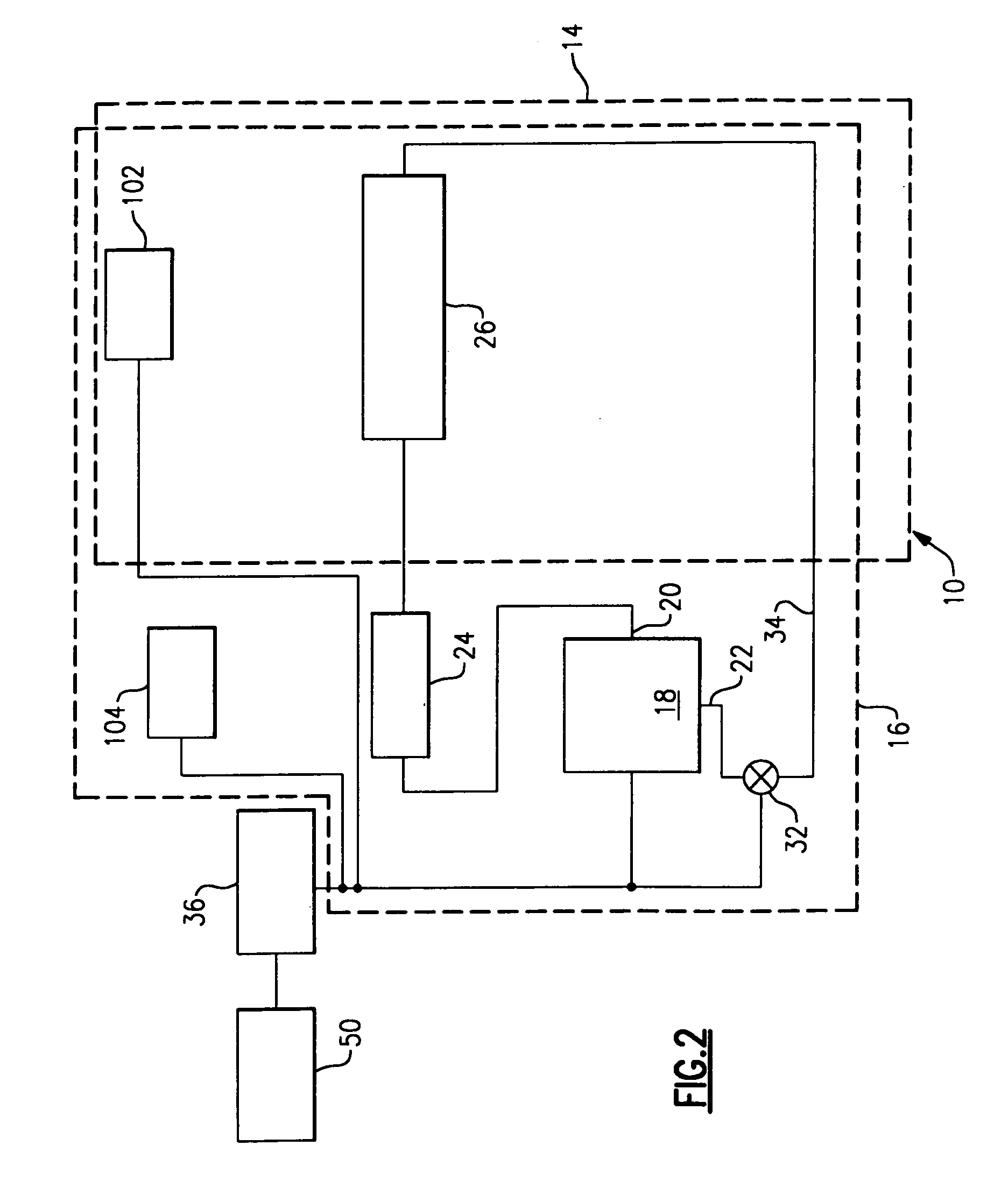

Transport Refrigeration system

InactiveUS7043927B2Maintenance operationCompression machines with non-reversible cycleFluid circulation arrangementElectronic controllerEngineering

A transport refrigeration system, the transport refrigeration system including a container defining an enclosed volume and a refrigeration module coupled to the container. The refrigeration module is disposed to regulate the temperature of the enclosed volume and includes a compressor having a discharge port and a suction port, a condenser heat exchanger unit operatively coupled to the discharge port, an evaporator heat exchanger unit operatively coupled to the suction port, a condenser fan disposed proximate to the condenser heat exchanger unit, an evaporator fan disposed proximate to the evaporator heat exchanger unit; and a suction modulation valve coupled to the suction port. The transport refrigeration system further includes a bypass module coupled to the refrigeration module. The bypass module includes: a bypass mode switch having a normal operation position and bypass operation position; and an operational mode switch having a full cool position and fan only position. The transport refrigeration system also includes an electronic controller coupled to the bypass module. When the bypass mode switch is in the normal operation position the electronic controller regulates the operation of the refrigeration module. When the bypass mode switch is in the bypass operation position, the compressor, the condenser fan, the evaporator fan and the suction modulation valve are selectively operated by the position of the operational mode switch.

Owner:CARRIER CORP

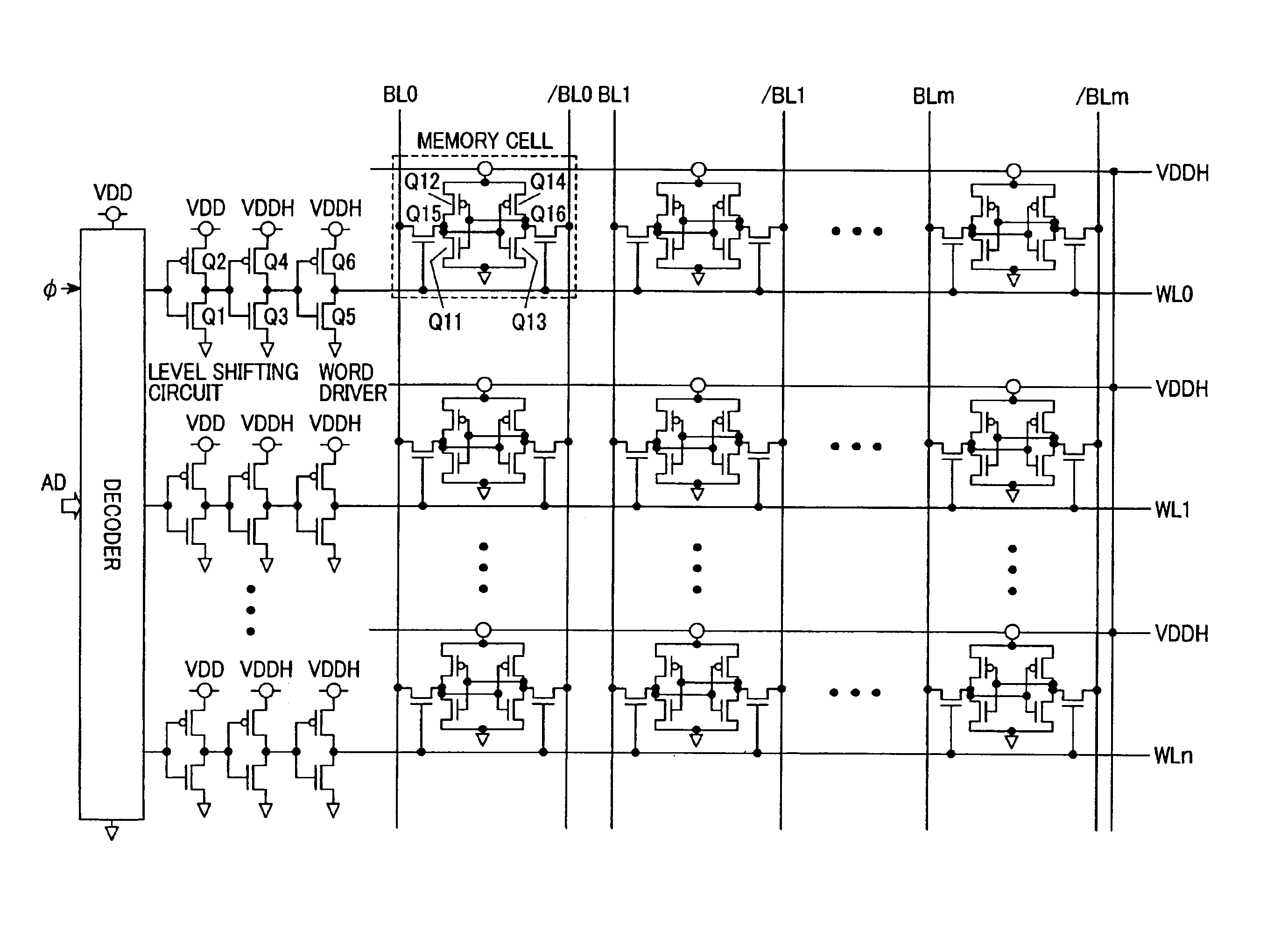

Semiconductor integrated circuit device

InactiveUS6920071B2Maintenance operationReduce power consumptionTransistorInstant pulse delivery arrangementsMOSFETLevel shifting

A semiconductor integrated circuit device endowed with memory circuits achieving high operation margin and low energy consumption with high speed and high integration. Composing a memory cell with a MOSFET having a first threshold voltage corresponding to a first voltage and supplying a selection signal corresponding to said first voltage to a word line by a word driver driven at said first voltage. Corresponding to a second voltage smaller than said first voltage, forming a selection signal sending to said word driver by a decoder comprising MOSFET with a second threshold voltage smaller than said first voltage, operating at said first voltage, and installing a first level shifting circuit including inverter circuits that form a selection signal corresponding to said first voltage by receiving a selection signal corresponding to said second voltage. Thereby, high operation margin and low energy consumption with high speed and high integration can be achieved.

Owner:HITACHI LTD

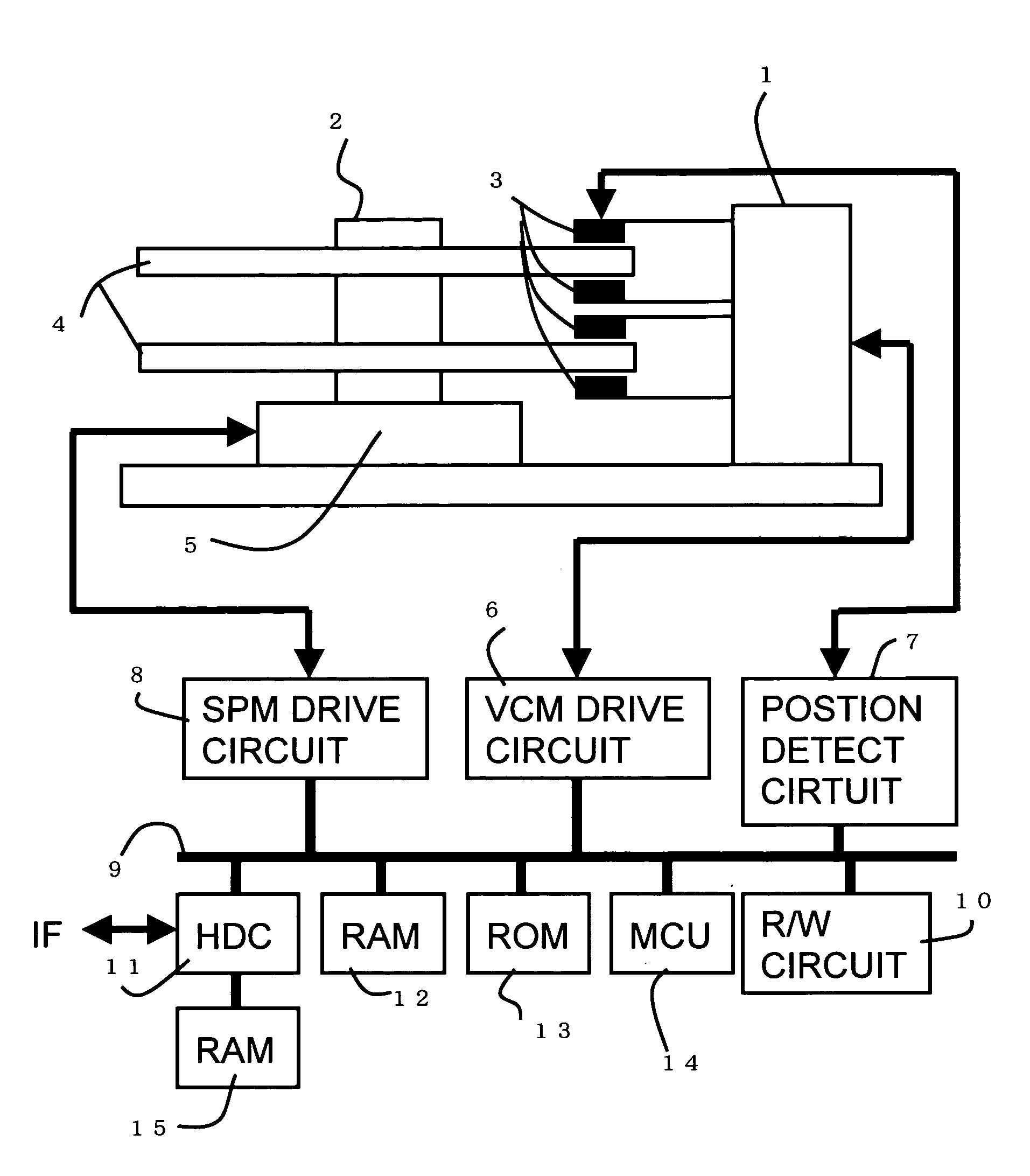

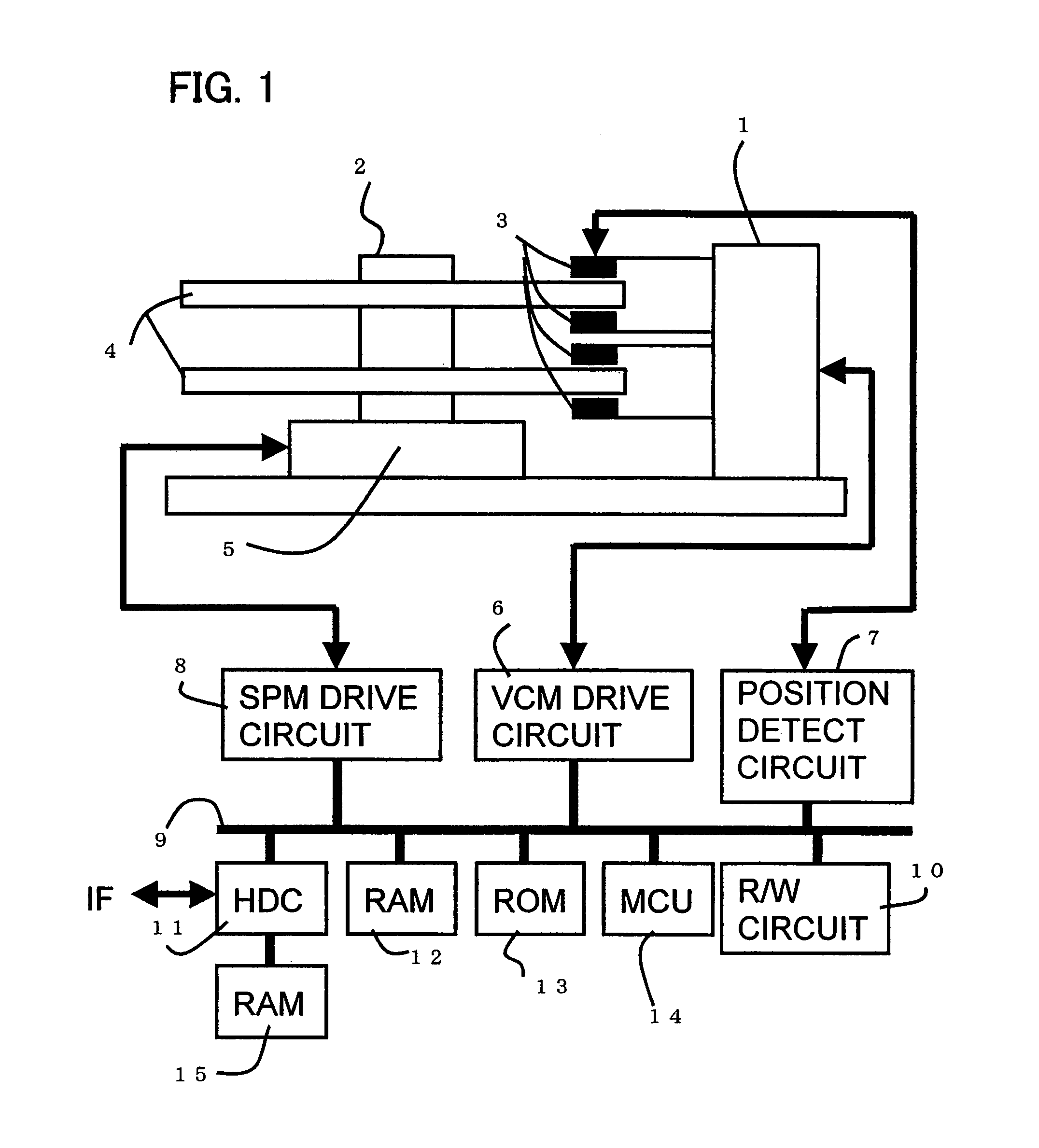

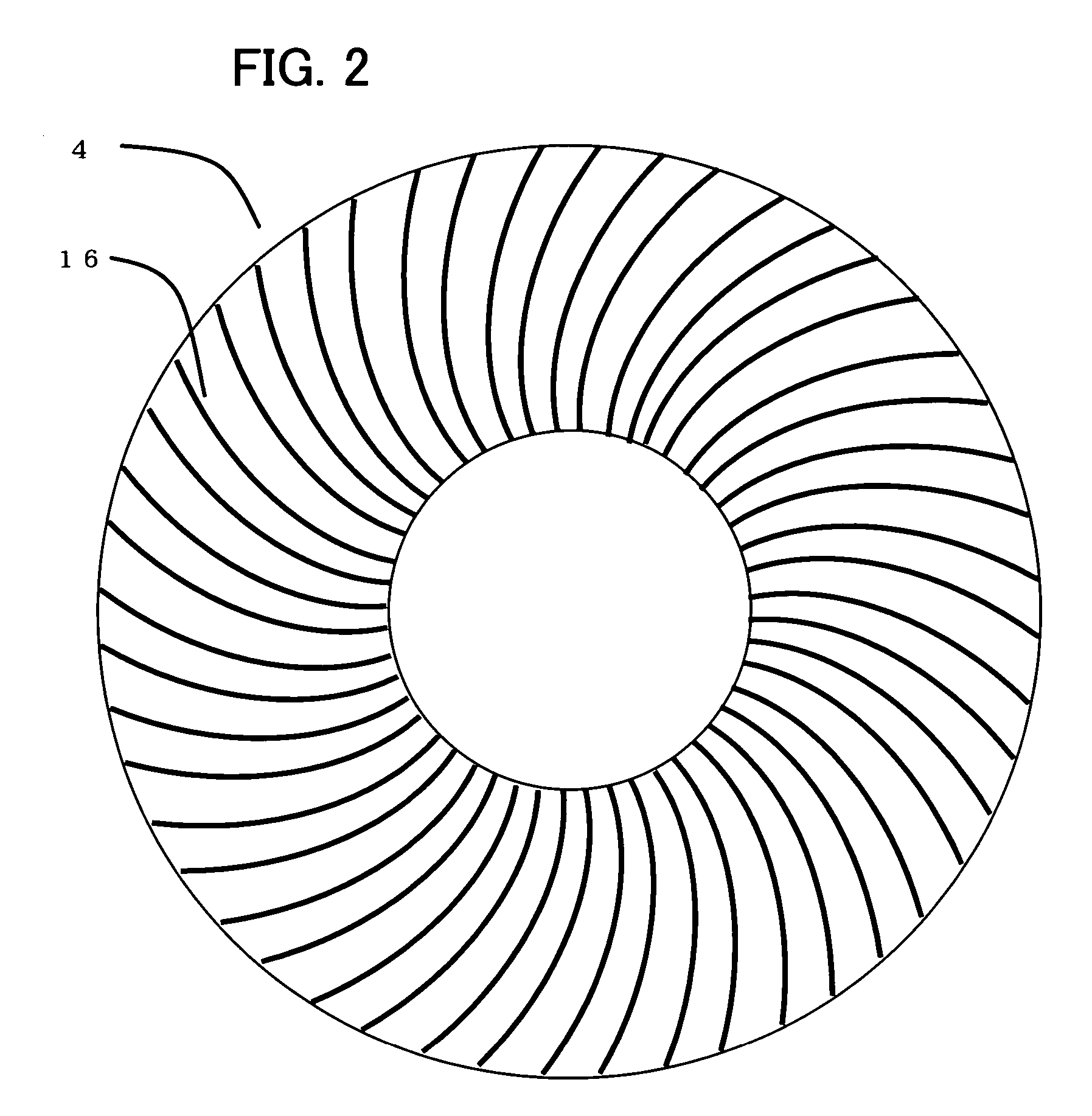

Head position control method, head position control device, and disk device

ActiveUS7265934B2Easy to controlMaintenance operationCombination recordingTrack finding/aligningControl systemPosition control

A position control device corrects the displacement of the head by disturbance applied to the disk device by the control system. An adaptive control to an unknown disturbance frequency is performed. The frequency estimation block for estimating the external vibration frequency from a signal that is based on the position error according to the adaptive rule, and a correction table for sequentially correcting the constants of the compensator using this external vibration frequency, are provided. Since the constants of the compensator are sequentially corrected according to the estimated angular frequency, highly accurate follow up control to an external vibration frequency in a wide range becomes possible.

Owner:KK TOSHIBA

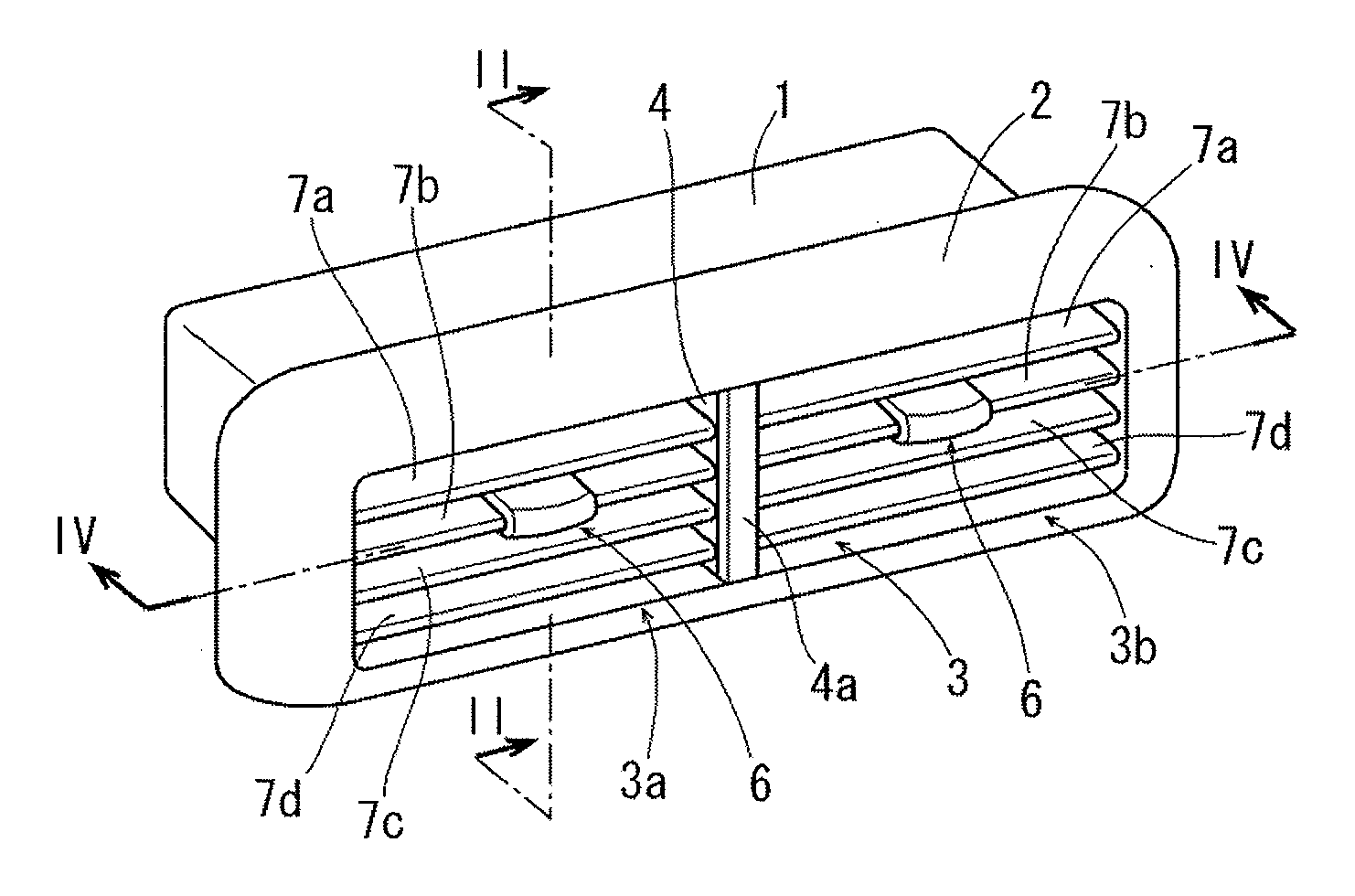

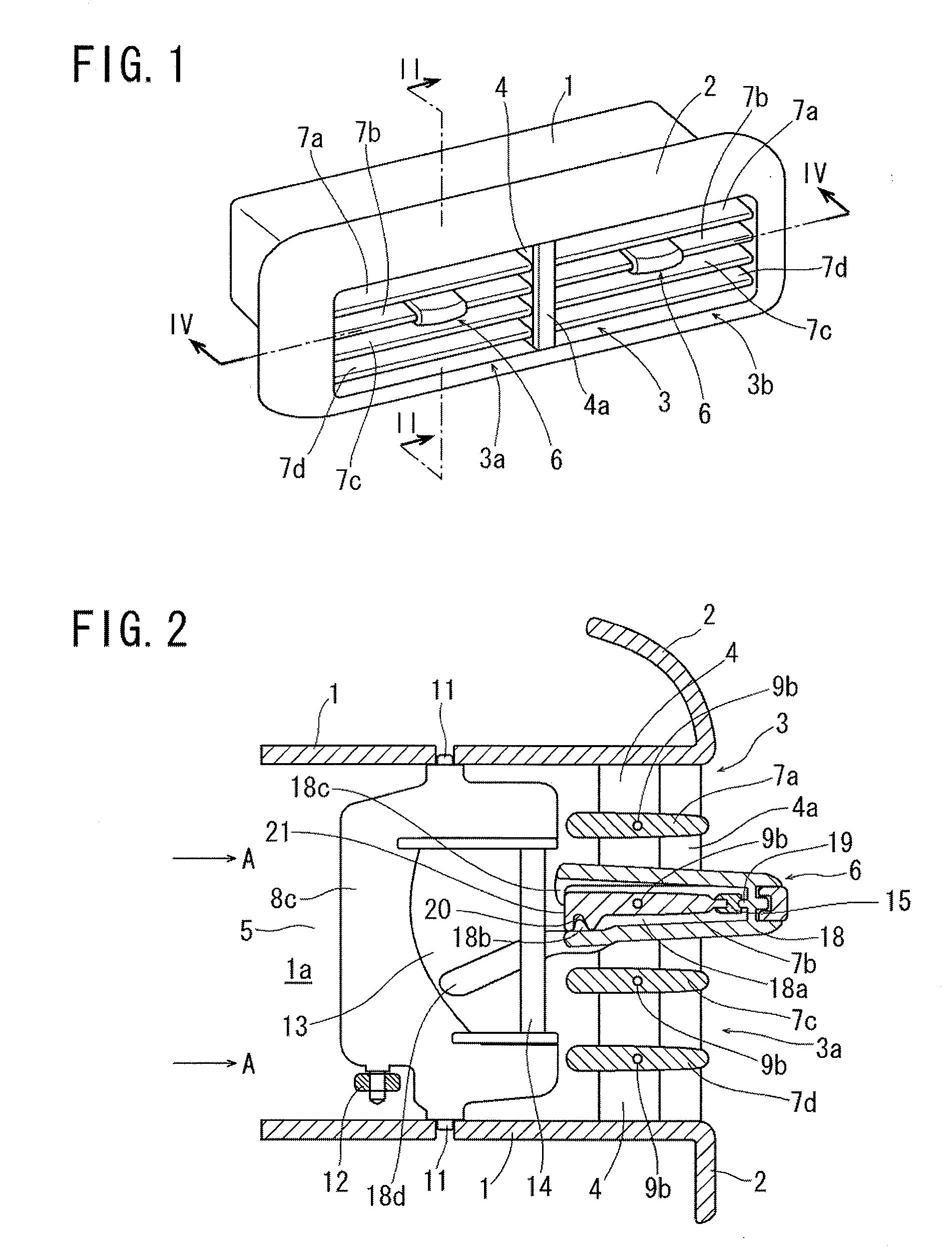

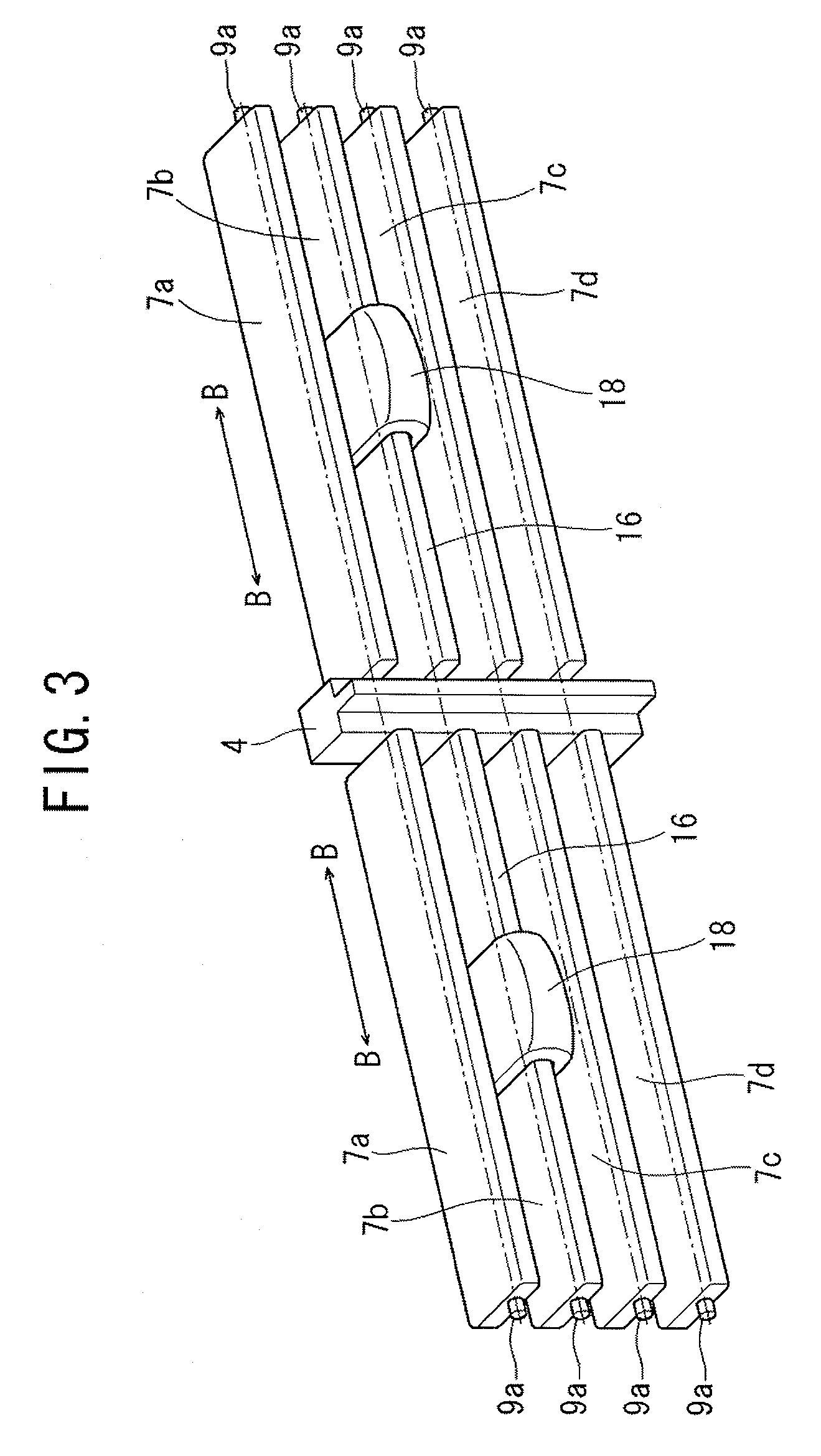

Supporting structure for adjustable air guide vanes

InactiveUS20090137200A1Stable load resistanceImprove the sense of operationLighting and heating apparatusVehicle heating/cooling devicesLoad resistanceThermoplastic elastomer

A structure for supporting an air guide vane in a supply opening for air conditioning prevents abrupt changes of load resistance to rotation of the air guide van and provides a good operational feel when rotating the air guide vane. A supporting member of the air guide vane is an olefin-based thermoplastic elastomer having a hardness of between Shore A80 and Shore D60. The degree of mold transferability of olefin-based thermoplastic elastomer is characteristically lower than that of other thermoplastic elastomers. By virtue of molding an olefin-based thermoplastic elastomer microscopic concavities and convexities are formed on the surface of the supporting member. The rotation shaft of the air guide vane is supported by multiple point contacts with the inner surface respective through-holes.

Owner:MORIROKU TECH

Control device for controlling the angular setting of a rotor blade of a wind power plant and wind power plant

InactiveUS20130028740A1Maintenance operationPropellersPump componentsFrequency changerPeaking power plant

A control device that is implemented to control an angular setting of a rotor blade of a wind power plant includes a drive motor including first and second windings that are galvanically isolated from one another, wherein the drive motor can be driven by both or only one of the first and second windings to change an angular setting of the rotor blade relative to the hub on which the rotor blade is mounted. Separate pitch controllers including separate frequency converters and separate emergency power supplies are implemented to provide the windings with drive signals. A wind power plant includes a respective controller for each of a plurality of rotor blades mounted on a hub. The pitch controllers provide a redundant system allowing control of the angular setting of a rotor blade of a wind power plant even when one of the pitch controllers for the drive motor has failed.

Owner:KARL E BRINKMANN GMBH

Power abnormal protection circuit

ActiveUS7495875B2Avoid damageReduce switching lossesEfficient power electronics conversionEmergency protective arrangements for automatic disconnectionVoltage dropDelayed time

A power abnormal protection circuit includes a power detection unit, a voltage drop correction unit, a drop out detection unit, a delay unit and a delay masking unit. By detecting an input power average value of a power supply occurring of a brown out condition can be determined. The power supply includes a power factor correction unit which has an output capacitor. By detecting the voltage of the output capacitor a drop out condition can be determined. When a power abnormal condition occurs all units of the power supply can be set off sequentially according to a delay time to protect circuit elements and a connecting computer.

Owner:SPI ELECTRONICS

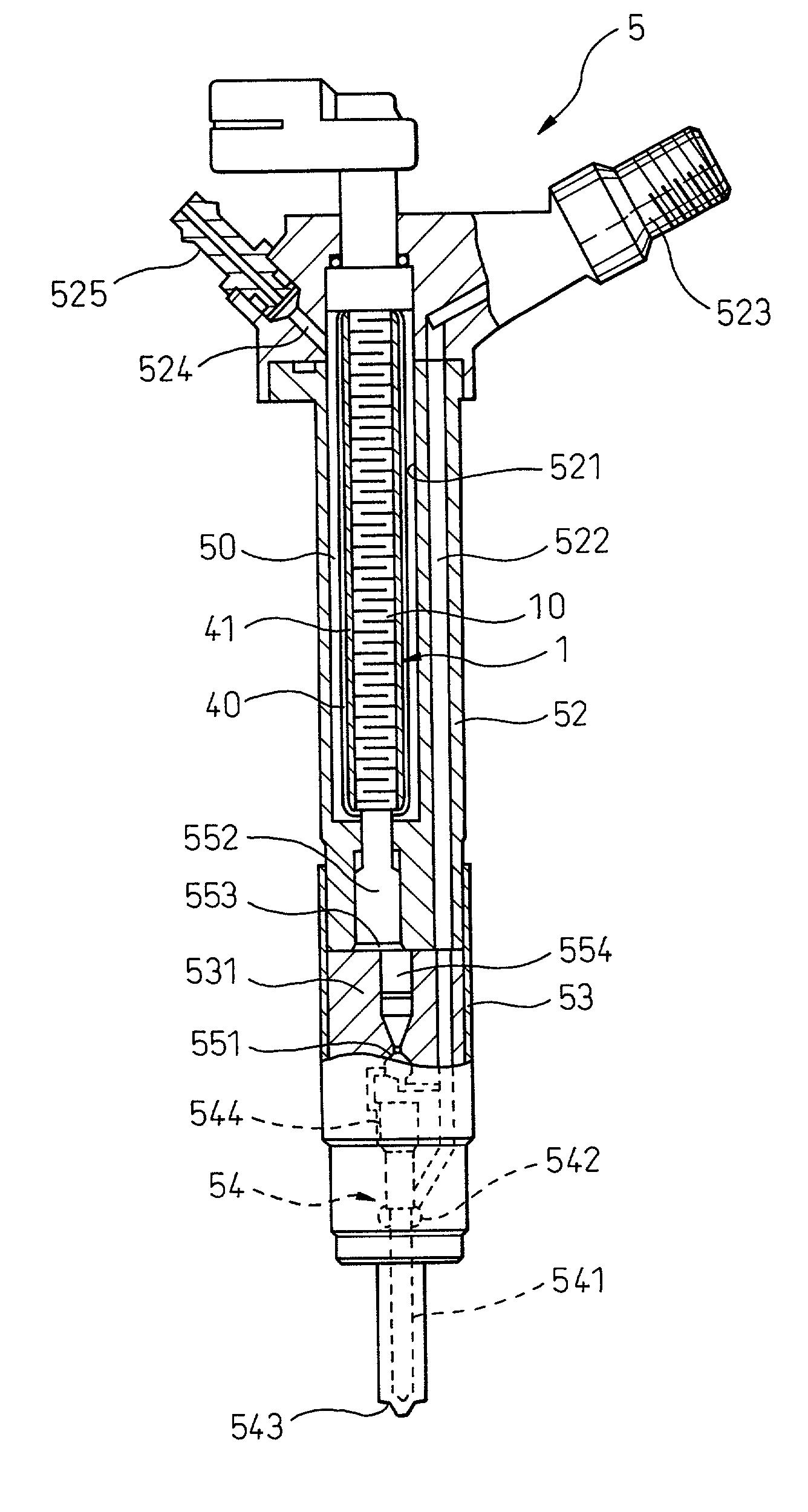

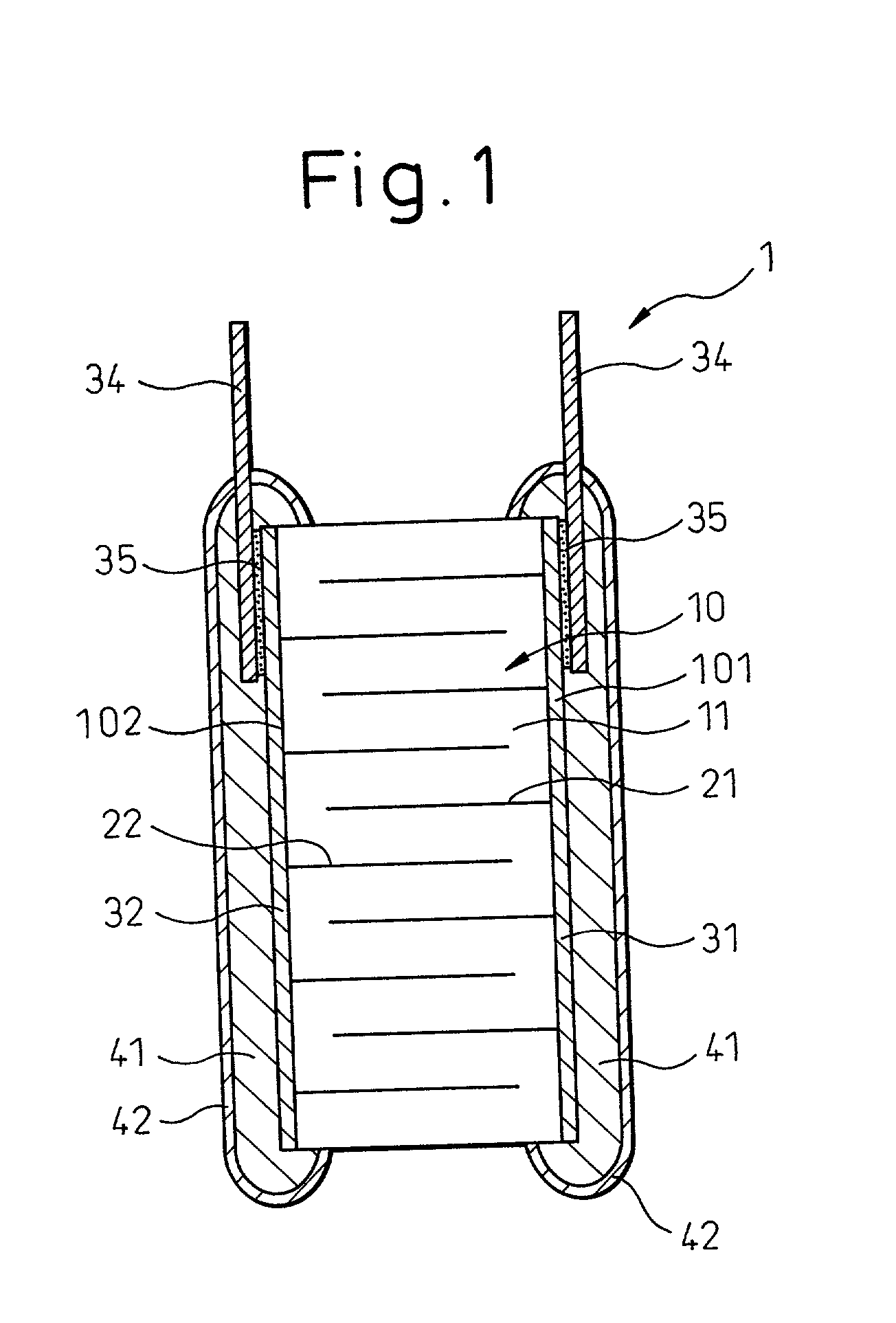

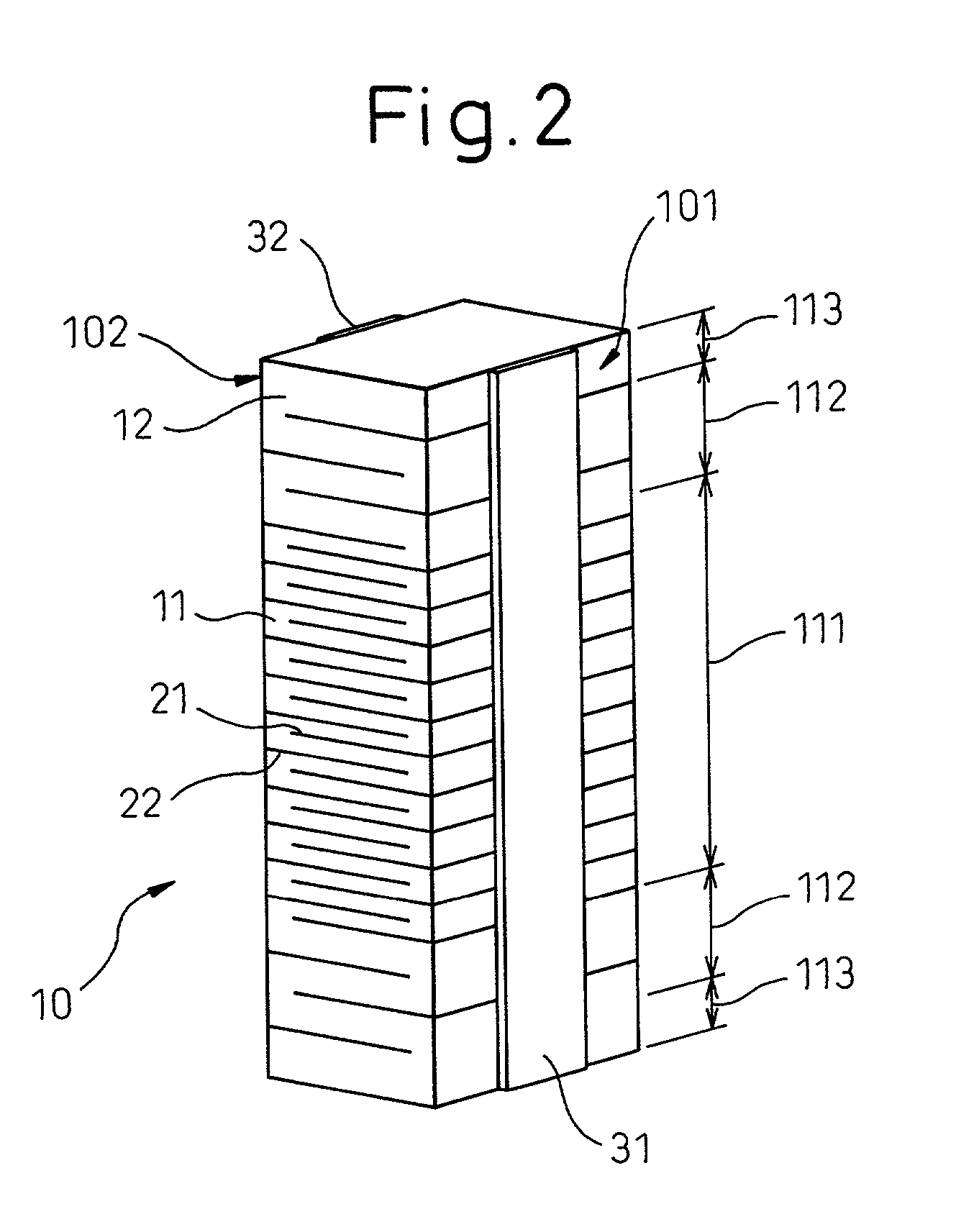

Piezoelectric element and injector using the same

InactiveUS20020153431A1Prevent moisture intrusionMaintenance operationPiezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusHigh humidityInorganic materials

A piezoelectric element and an injector using the same piezoelectric element are disclosed, which are so high in reliability as not to be shorted even in a high humidity environment, are small in size, are low in cost and are high in heat radiation capability. The piezoelectric element comprises a ceramic laminate (10) including a plurality of ceramic layers of a piezoelectric ceramic (11) and a plurality of internal electrode layers (21, 22), stacked alternately. At least an organic insulating layer (41) of an organic material is formed on at least a part of the surface of the ceramic laminate (10), and at least an inorganic insulating layer (42) of an inorganic material is formed on the organic insulating layer (41).

Owner:DENSO CORP

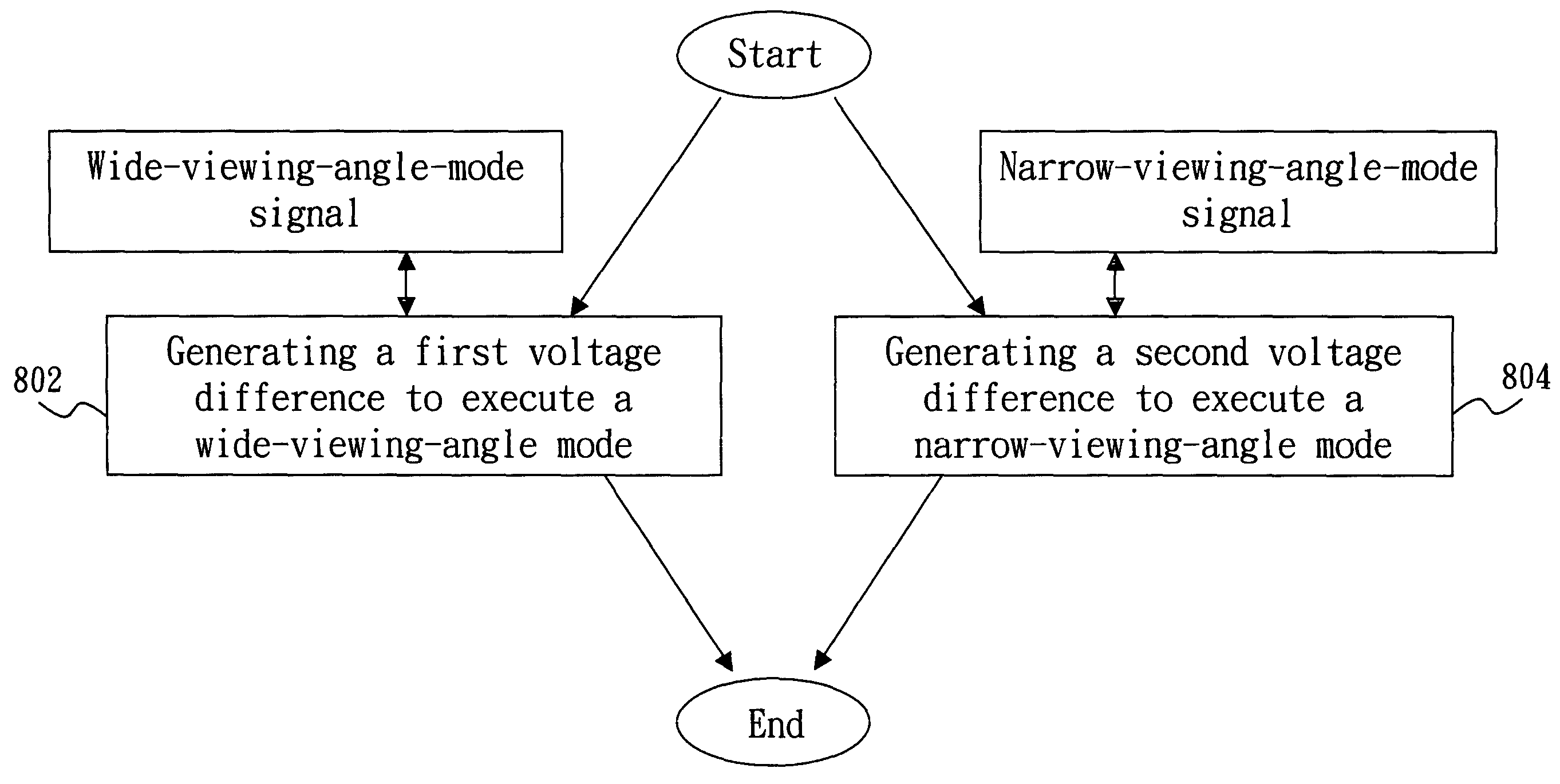

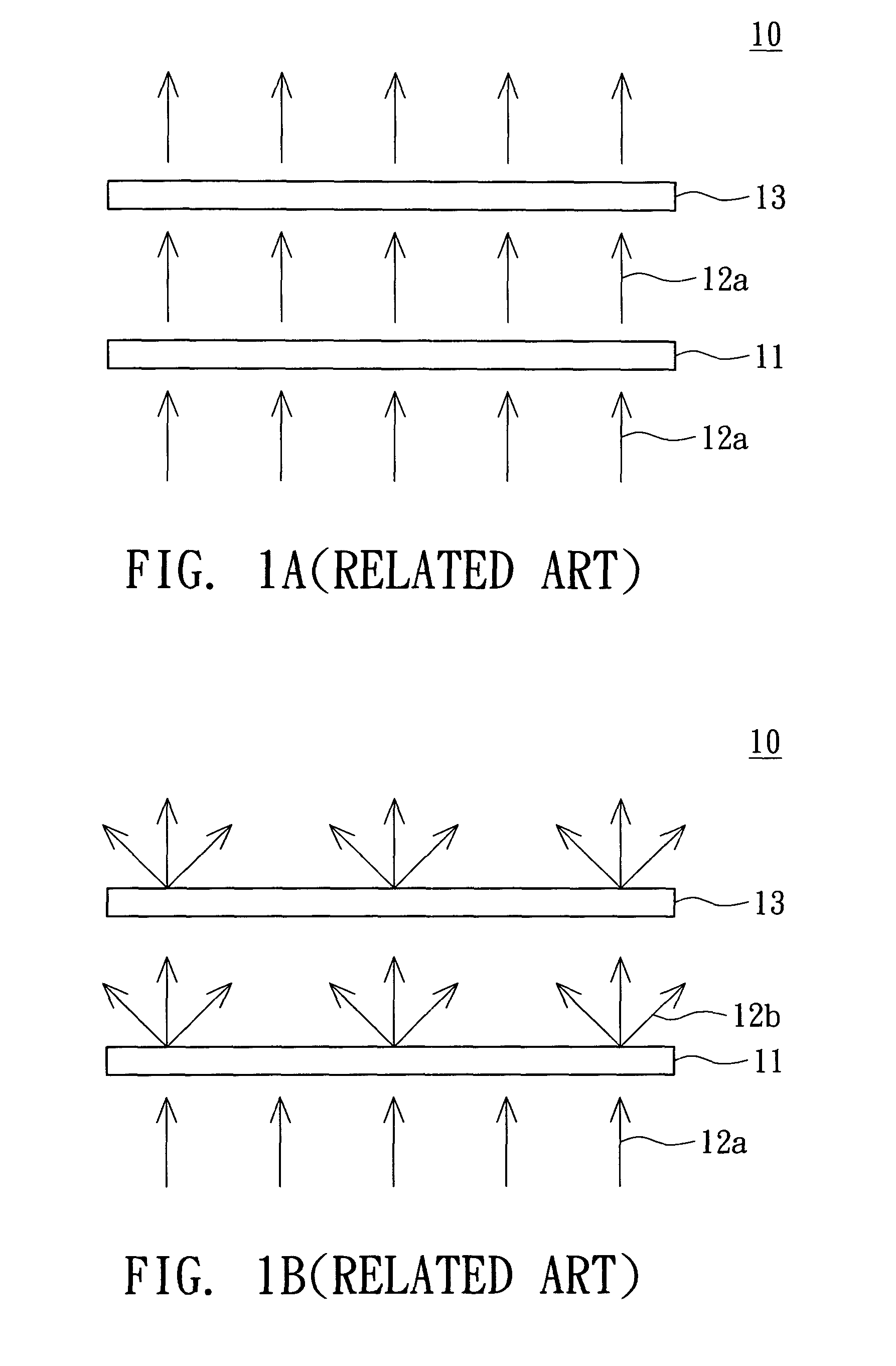

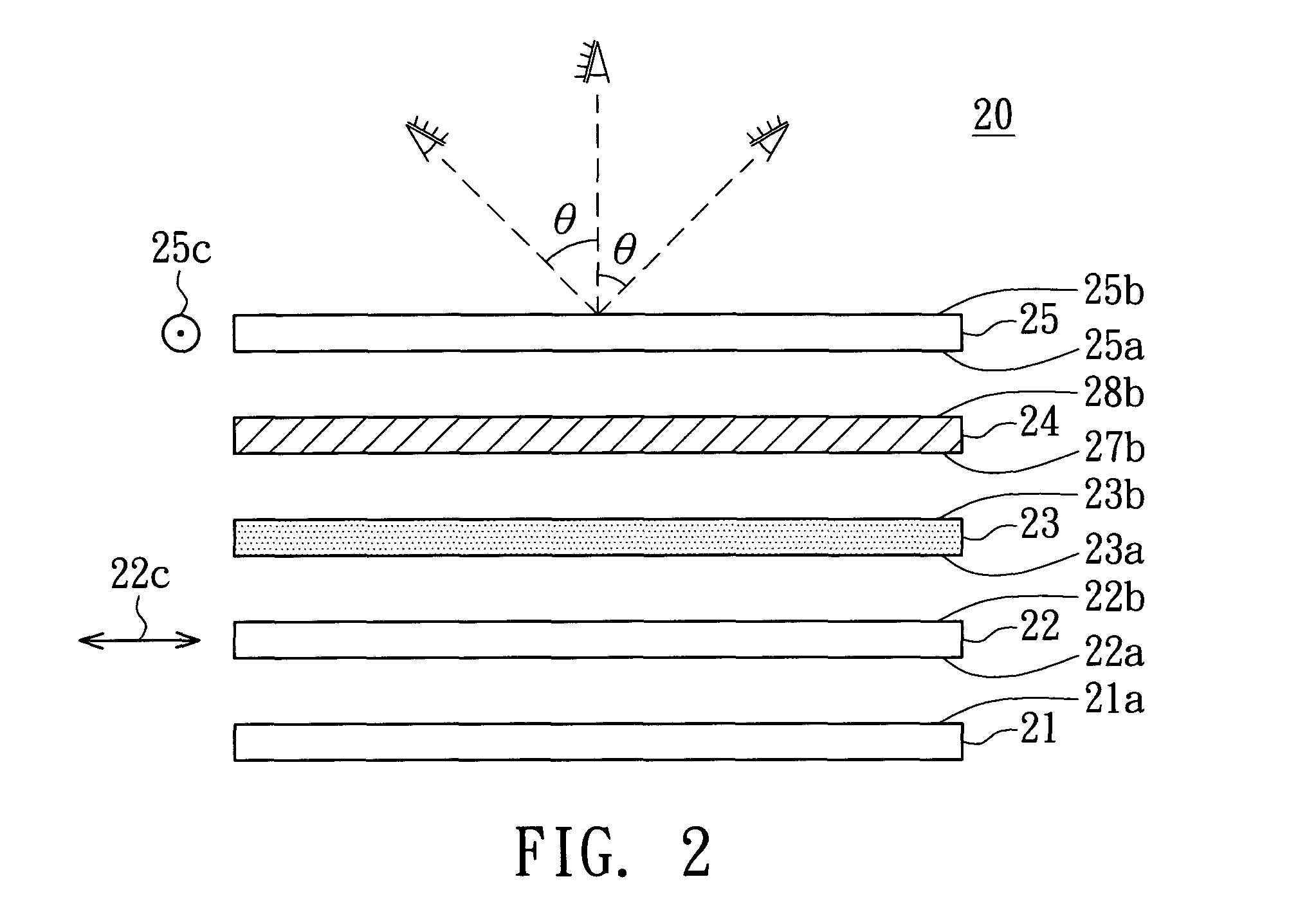

Adjustable-viewing-angle liquid crystal display

ActiveUS7728801B2Improve practicalityMaintenance operationTelevision system detailsAdvertisingLiquid-crystal displayComputer module

An LCD includes a backlight module, two polarizers, an LCD panel and a viewing-angle-adjustable device. The polarizers are disposed over the backlight module. The LCD panel and the first viewing-angle-adjusting device are disposed between the polarizers. The viewing-angle-adjusting device comprises a first substrate, a first electrode, a liquid crystal layer, a second electrode and a second substrate. The first electrode is disposed on the first substrate. The liquid crystal layer is disposed on the first electrode. The second electrode and the second substrate are disposed on the liquid crystal layer. The first liquid crystal layer is sealed between the first substrate and the second substrate. The second electrode is disposed on the bottom surface of the second substrate.

Owner:AU OPTRONICS CORP

Monitoring device for a battery, a lithium-ion battery, and method for the monitoring of a battery

ActiveUS20160111758A1Rapid and reliable disconnectionReliable and rapid detectionFinal product manufactureMaterial analysis by electric/magnetic meansElectrical batteryVoltage drop

A monitoring device for a battery, a lithium-ion battery with the monitoring device and a method for the monitoring of a battery, wherein the battery is provided with a plurality of cell composites comprising a number of mutually parallel-interconnected battery cells. The cell composites are also interconnected by means of electrical cell couplers, and one or more temperature sensors are arranged between the cell composites. Where a voltage drop across one or more of the battery cells on the electrical cell couplers exceeds a predetermined value and, simultaneously, a temperature occurs on at least one of the temperature sensors which exceeds a predetermined value, a fault signal is generated. The defective battery cell can then be isolated from the cell composite.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com