Supporting structure for adjustable air guide vanes

a technology of air guide vane and support structure, which is applied in the direction of ventilation system, heating type, lighting and heating apparatus, etc., can solve the problems of unstable rotational movement of the vane, poor operational feeling of the operation knob, and unstable operational feeling of the vane, so as to achieve stable load resistance to rotation and good operational feeling of the rotation of the air guide vane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

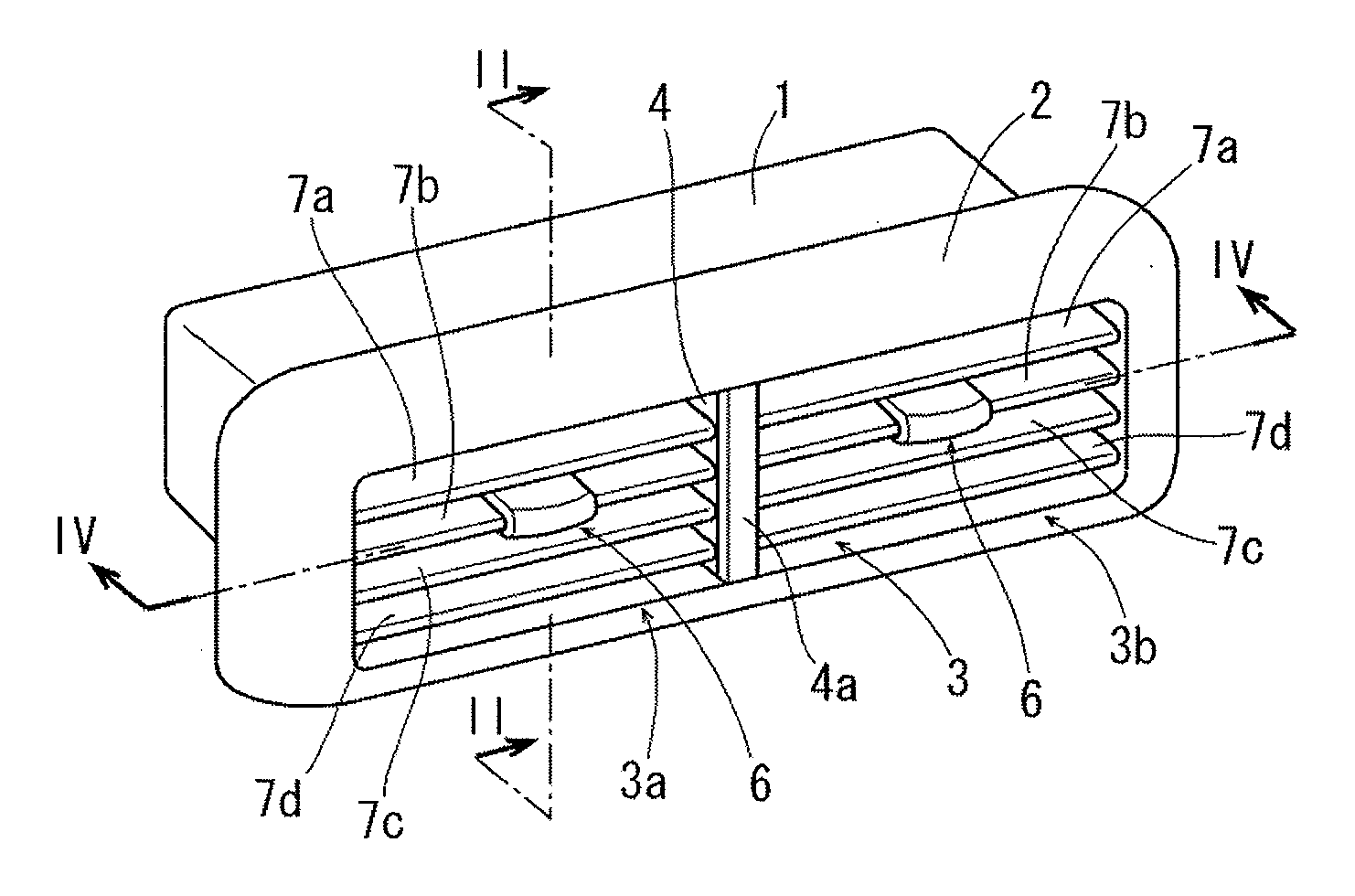

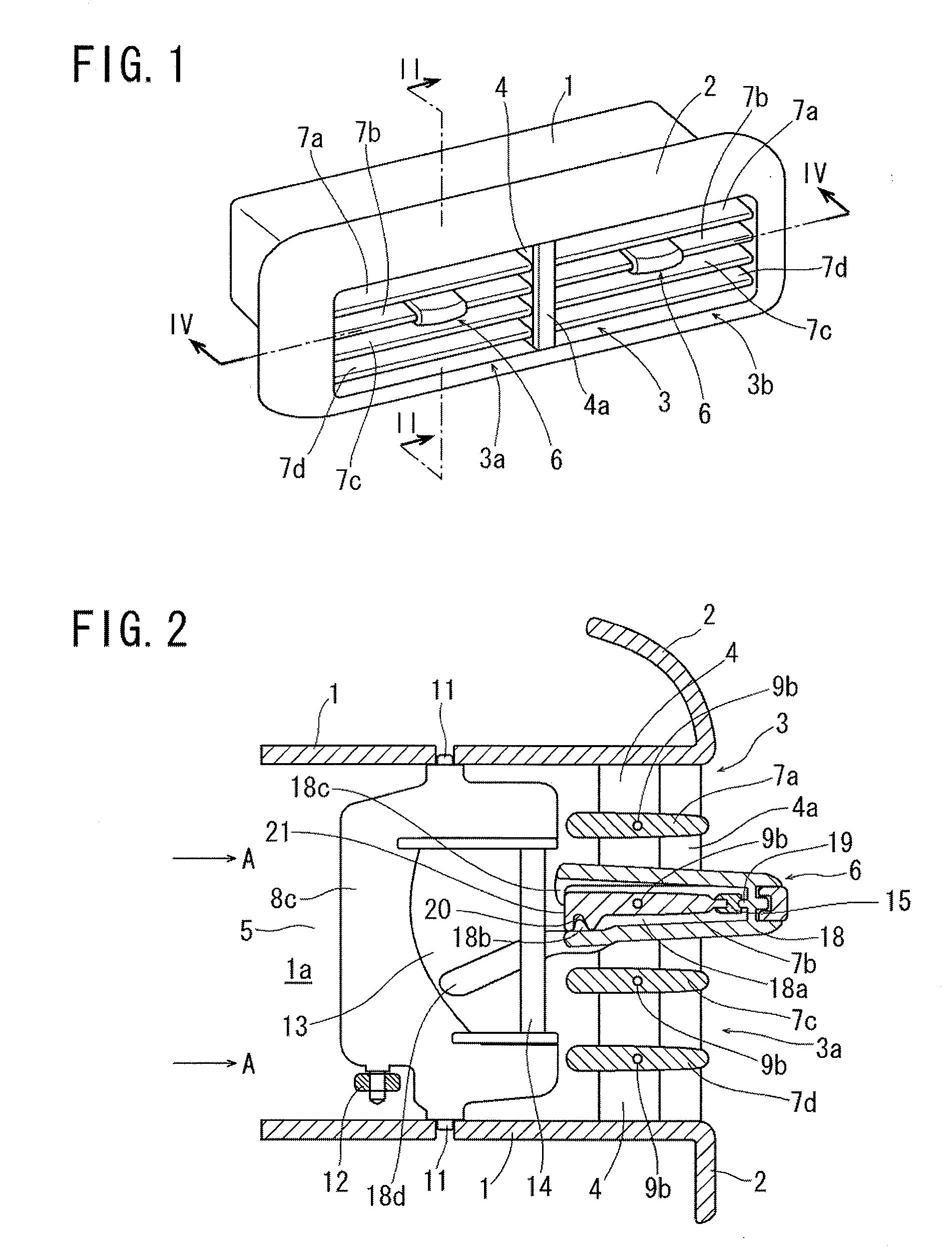

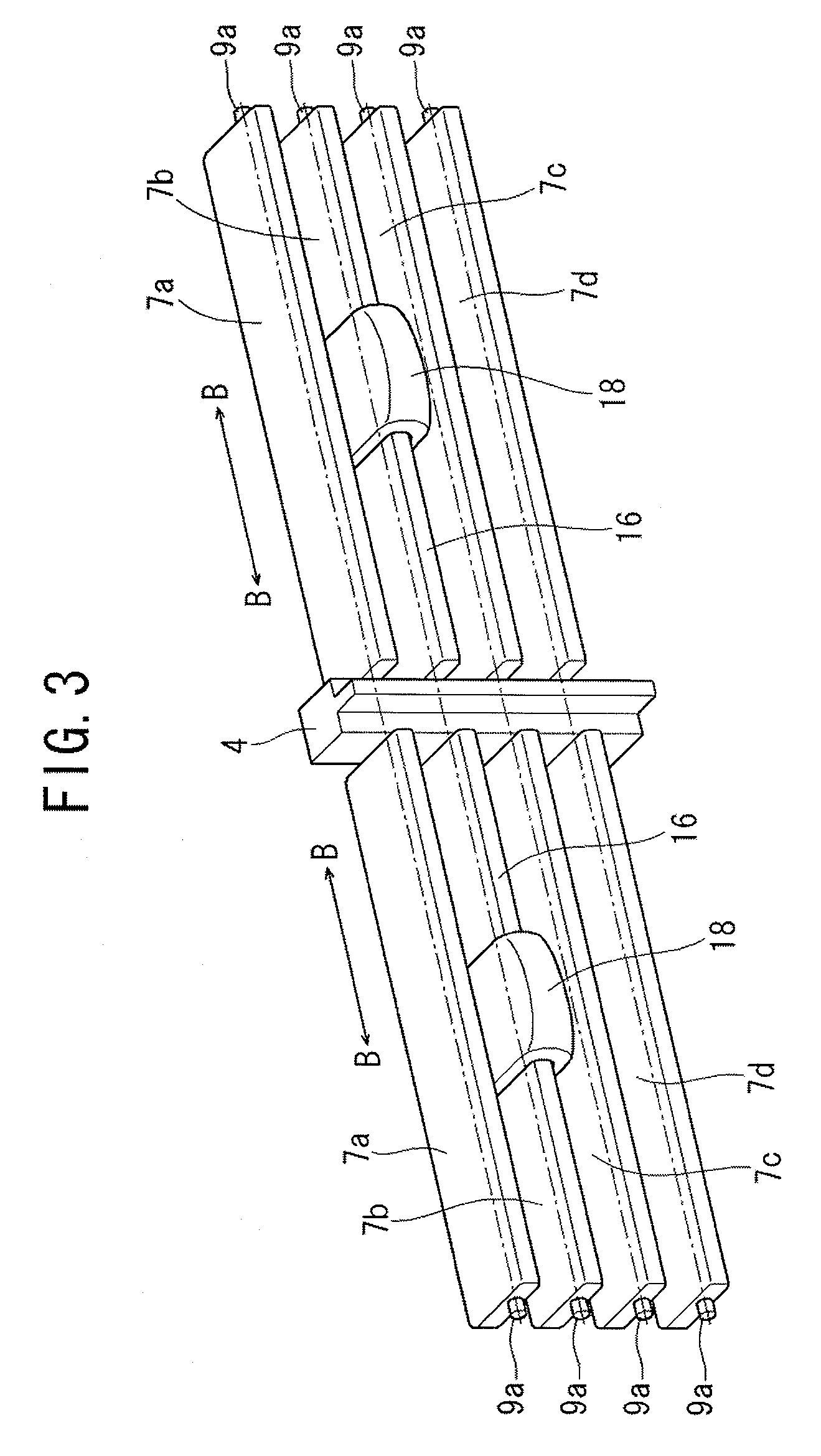

[0032]FIGS. 1-6 illustrate an embodiment of the present invention wherein the supporting structure for adjustable air guide vanes according to the present invention is embodied in an apparatus for changing the direction of airflow, which is disposed in a supply opening for air conditioning, and the supply opening opens into a vehicle interior. An opening 3 is formed in a panel portion 2 defined at the end of an air-conditioning duct 1 and a supporting member 4 is attached to the central portion of the opening 3. A cover member 4a is fitted on the front surface of the supporting member 4 and by the supporting member 4 and the cover member 4a, the opening 3 is divided into two supply openings 3a, 3b for air conditioning. As illustrated in FIGS. 2 and 5, the supporting member 4 is connected to a partition wall 5 by which two passages 1a, 1b are defined in the air-conditioning duct 1. The supply opening 3a is communicated with the passage 1a, while the supply opening 3b is communicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com