Combined LED lamp cup

A LED lamp cup and combined technology, which is applied to the damage prevention measures of lighting devices, lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of scratching and scalding human hands, improve the heat dissipation effect and reduce the quantity , The effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

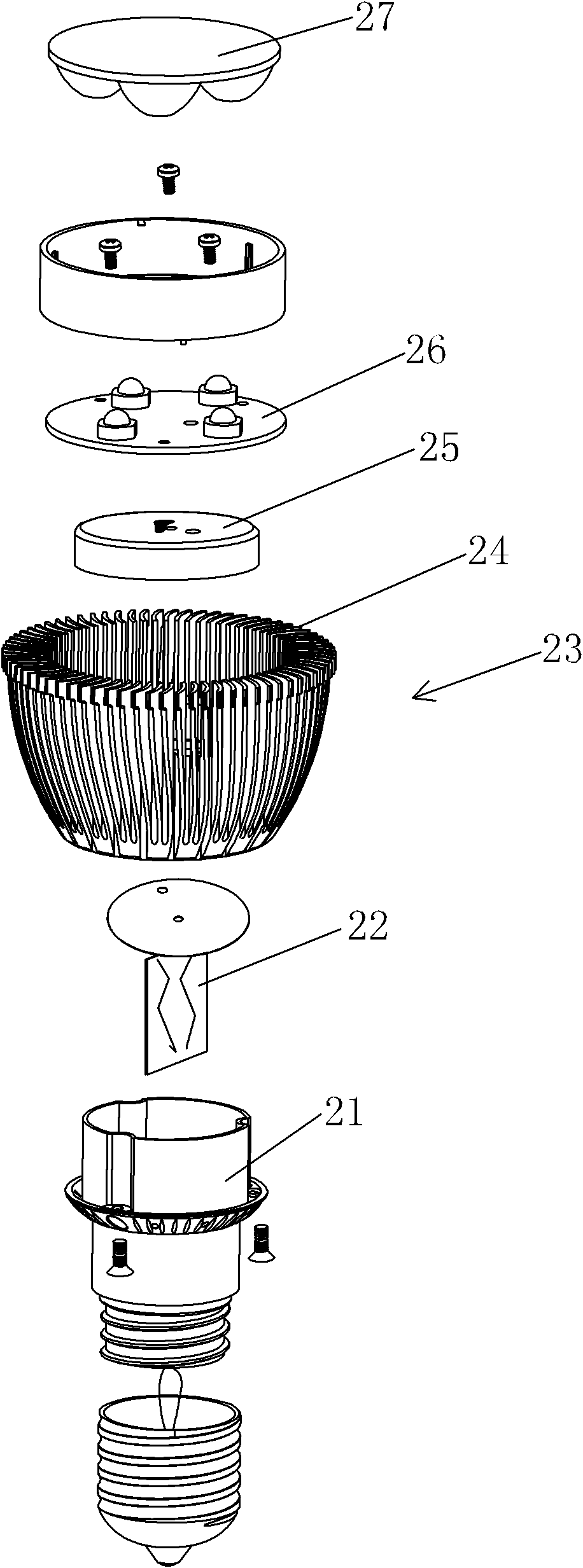

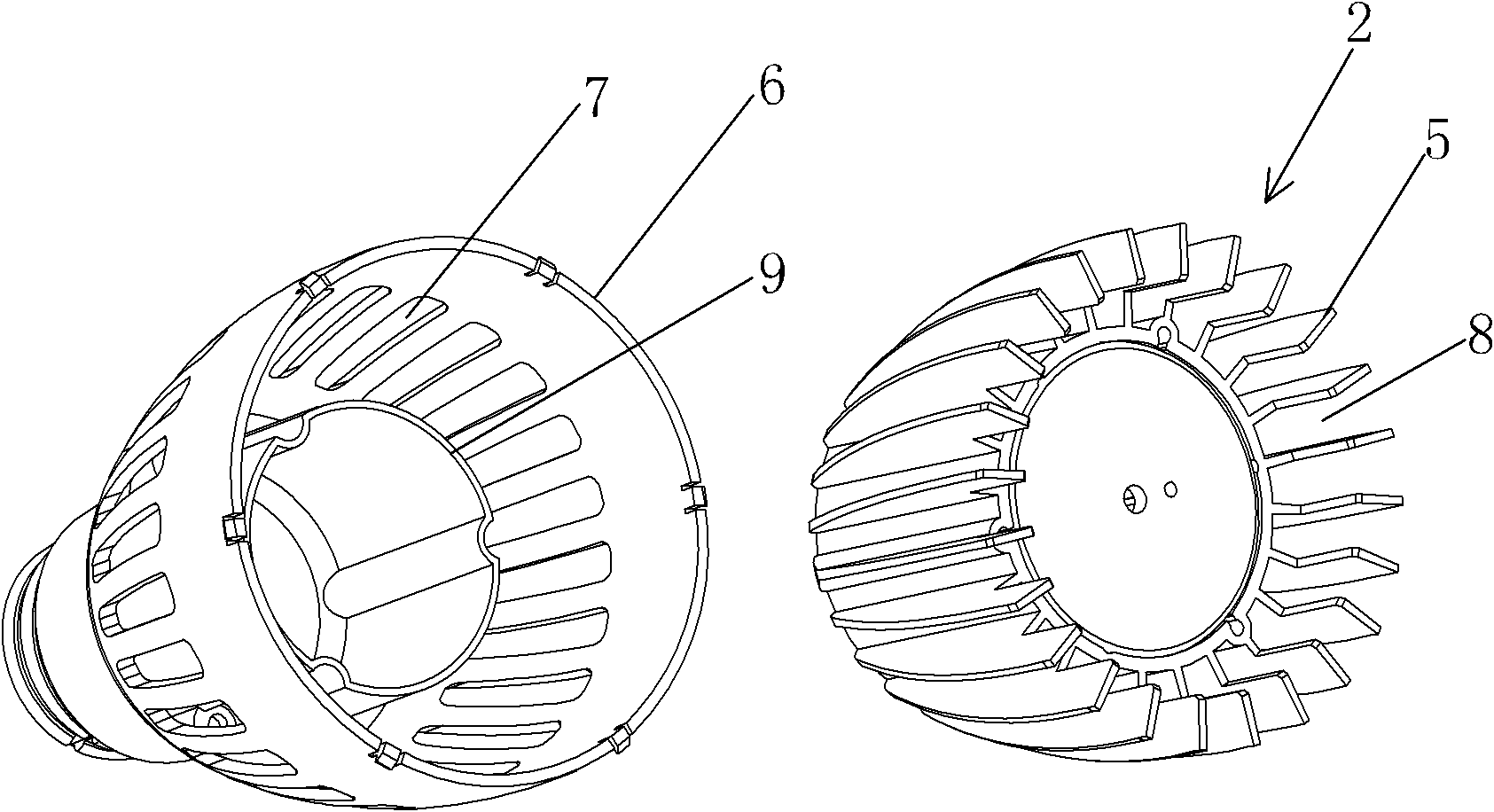

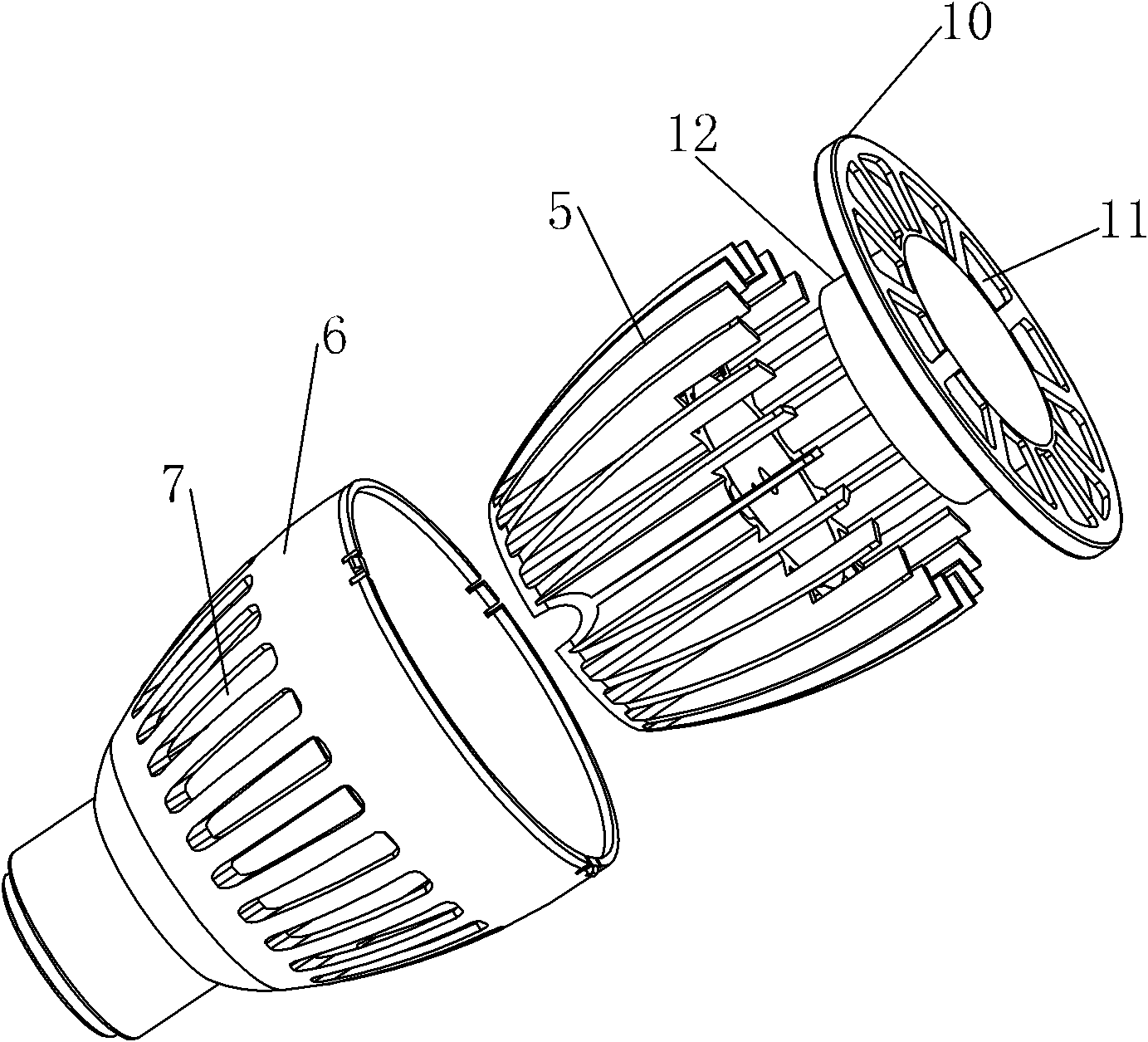

[0038] Embodiment 1: A combined LED lamp cup, such as figure 2 As shown, the heat dissipation device 2 is included, and a cavity is arranged inside the heat dissipation device 2, and a plurality of longitudinally arranged heat dissipation fins 5 are uniformly distributed on the outer surface of the heat dissipation device 2, and between any two adjacent heat dissipation fins 5 A heat dissipation channel 8 is formed, the lower end of the heat dissipation channel 8 is an air inlet, and a plastic shell 6 is provided on the outer cover of the heat dissipation device 2. The size and shape of the plastic shell 6 are just matched with the heat dissipation device 2, and can be just wrapped on the outside of the heat dissipation device 2; A plurality of heat dissipation holes 7 corresponding to the heat dissipation channels 8 are provided on the plastic housing 6 , and the number of the heat dissipation holes 7 is the same as the number of the heat dissipation channels 8 .

[0039] Th...

Embodiment 2

[0052] Embodiment 2: The difference between this embodiment and Embodiment 1 is that, as Figure 5 , Figure 6 As shown, the heat dissipation holes 7 are triangular in shape and arranged longitudinally. The width of the heat dissipation holes 7 gradually increases from bottom to top, and the number of heat dissipation holes 7 is the same as the number of heat dissipation channels 8 . The length of the cooling hole 7 is 15 mm, and the maximum width is 2.5 mm.

Embodiment 3

[0053] Embodiment 3: The difference between this embodiment and Embodiment 1 is that, as Figure 7 , Figure 8 As shown, the heat dissipation holes 7 are arc-shaped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com