Bagging bag special for lemons and processing method

A bagging and lemon technology, applied in chemical instruments and methods, bag making operations, paper/cardboard layered products, etc., can solve the problems of difficult opening, slow bagging speed, easy tearing of bagging, etc., to reduce absorption Liquid ability, improved water resistance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

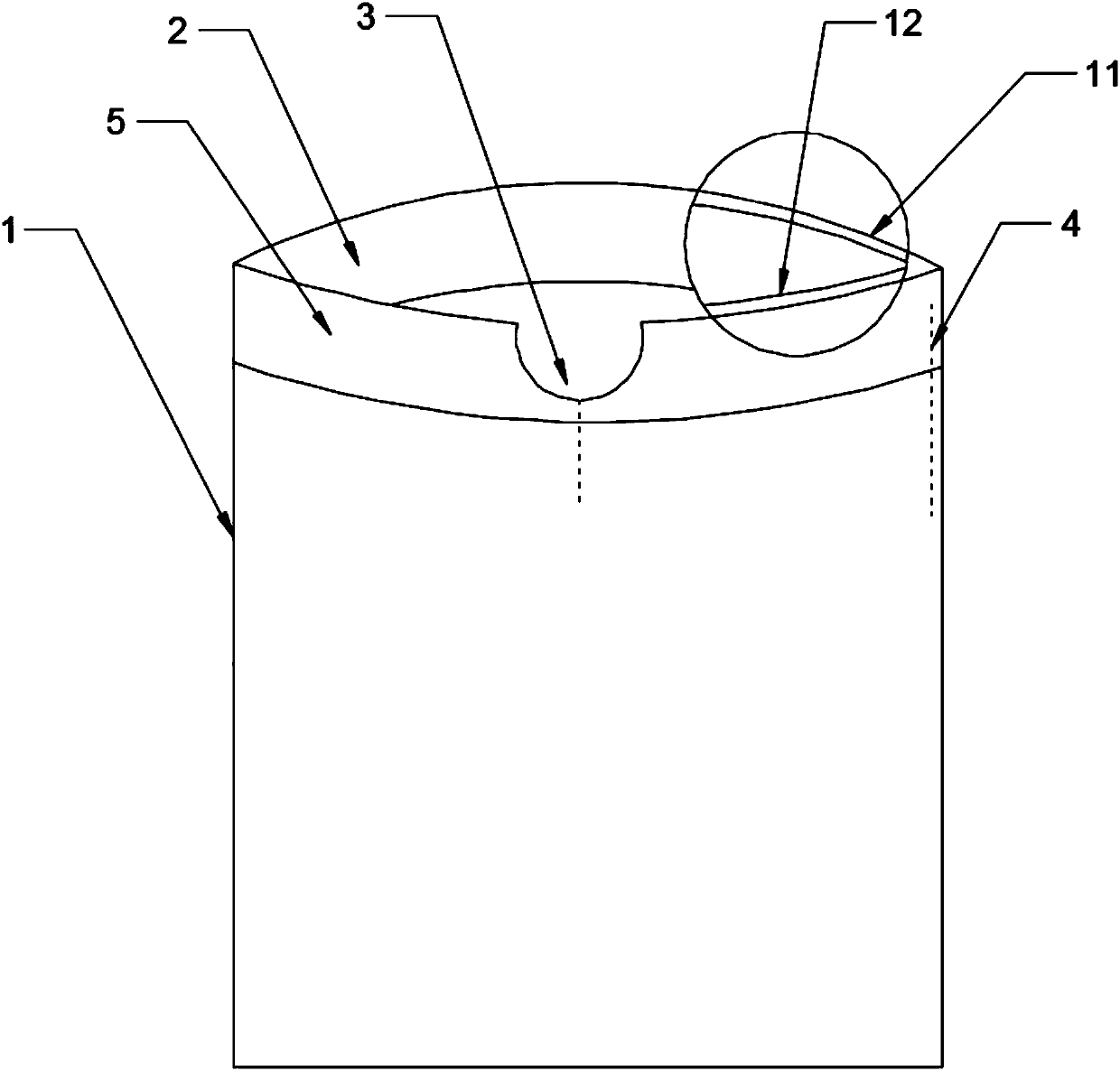

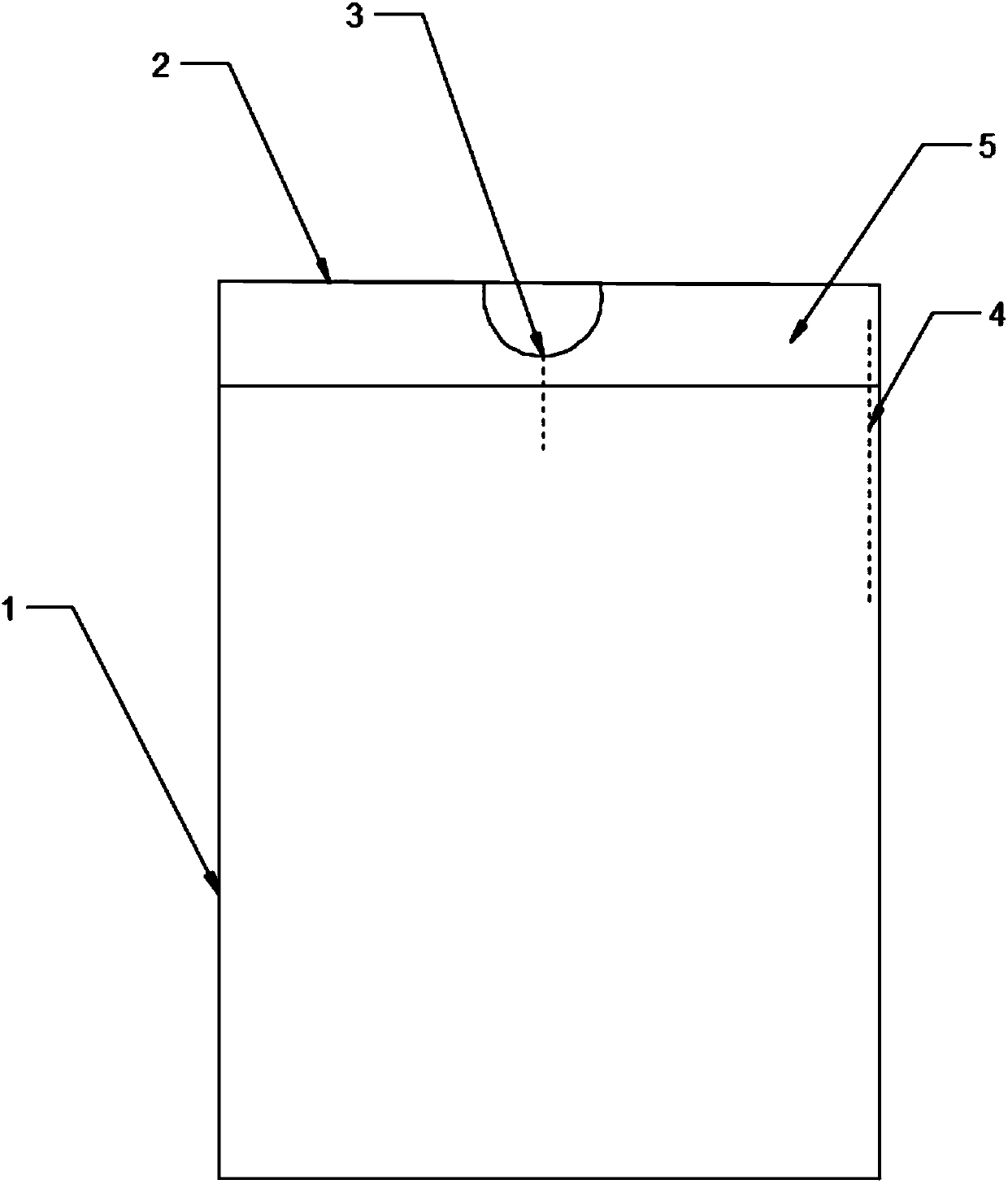

[0036] Such as figure 1 with figure 2 As shown, the present invention provides a special lemon bag, including a bag body 1, the bag body 1 adopts a double-layer structure of an outer paper layer 11 and an inner film layer 12, and the upper end of the bag body 1 is an opening 2. The front side of the opening 2 is provided with a crescent-shaped notch 3, and the outer paper layer 11 and the inner film layer 12 at the crescent-shaped notch 3 are completely bonded along the overlapping edges with environmentally friendly glue.

[0037] The outer paper layer 11 uses 56 grams of high-shading composite paper.

[0038] The outer paper layer 11 is printed with a water-resistant, hydrophobic light-colored isolation paint on the outer side.

[0039] The inner film layer 12 adopts PVDF polyvinylidene fluoride film.

[0040] The right side of the bag body 1 is perpendicular to the opening 2 and a tie wire 4 is embedded. The length of the tie wire 4 is 1 / 2 of the length of the bag body 1, and a v...

Embodiment 2

[0049] Such as figure 1 with figure 2 As shown, the present invention provides a special lemon bag and a processing method, including a bag body 1, the bag body 1 adopts a double-layer structure of an outer paper layer 11 and an inner film layer 12, and the upper end of the bag body 1 The opening 2 is provided with a crescent-shaped notch 3 on the front side, and the outer paper layer 11 and the inner film layer 12 at the crescent-shaped notch 3 are completely bonded along the overlapping edges with environmentally friendly glue.

[0050] The outer paper layer 11 uses 56 grams of high-shading composite paper.

[0051] The outer paper layer 11 is printed with a water-resistant, hydrophobic light-colored isolation paint on the outer side.

[0052] The inner membrane layer 12 adopts a polyacrylate waterproof layer

[0053] The right side of the bag body 1 is perpendicular to the opening 2 and a tie wire 4 is embedded, the length of the tie wire 4 is 1 / 3 of the length of the bag body 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com