Loop circuit heat pipe condenser

A loop heat pipe and condenser technology, used in heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problems of insufficient condensation area and limited contact area between pipes and fins, and achieve increased area, Increase the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

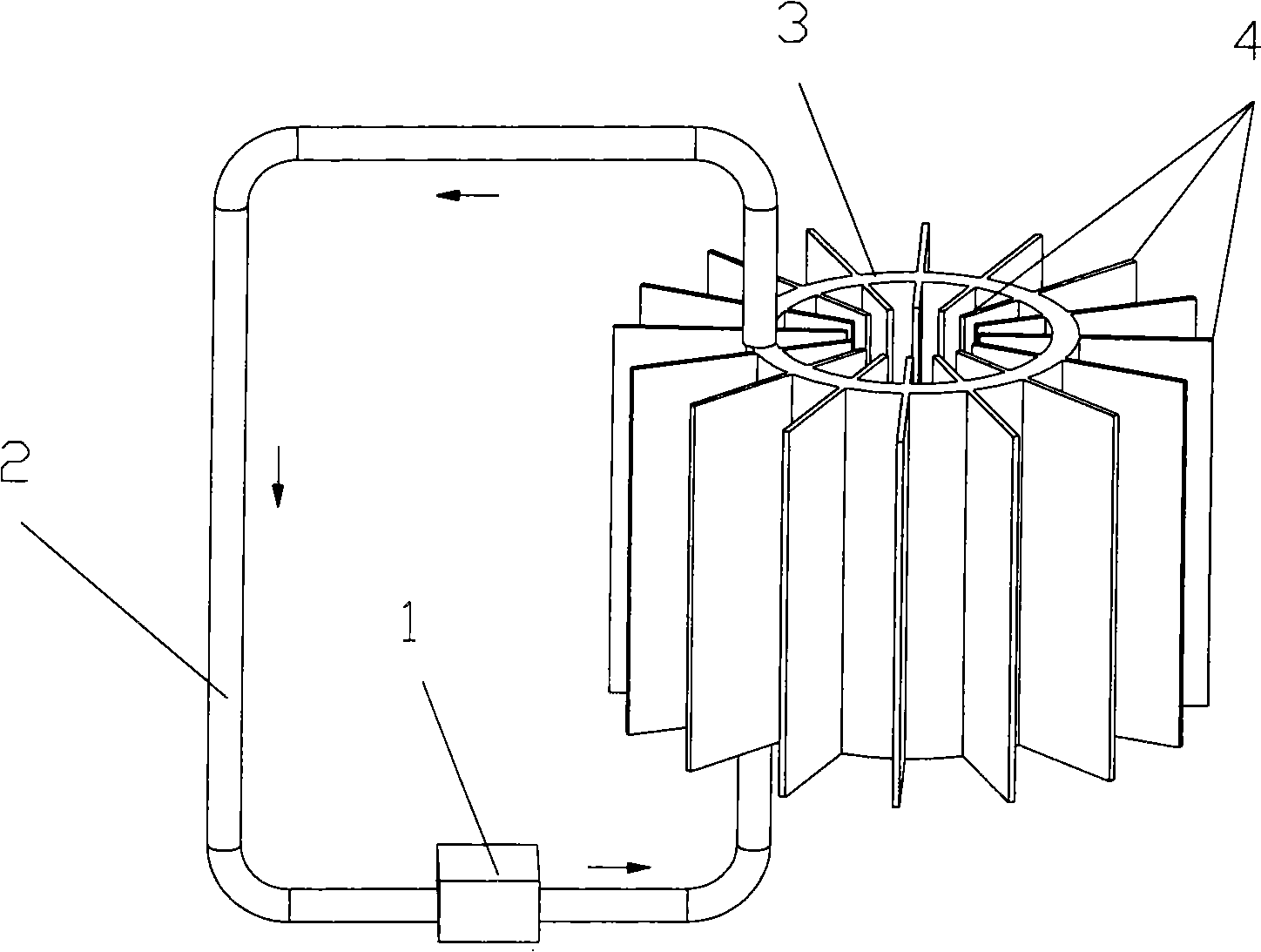

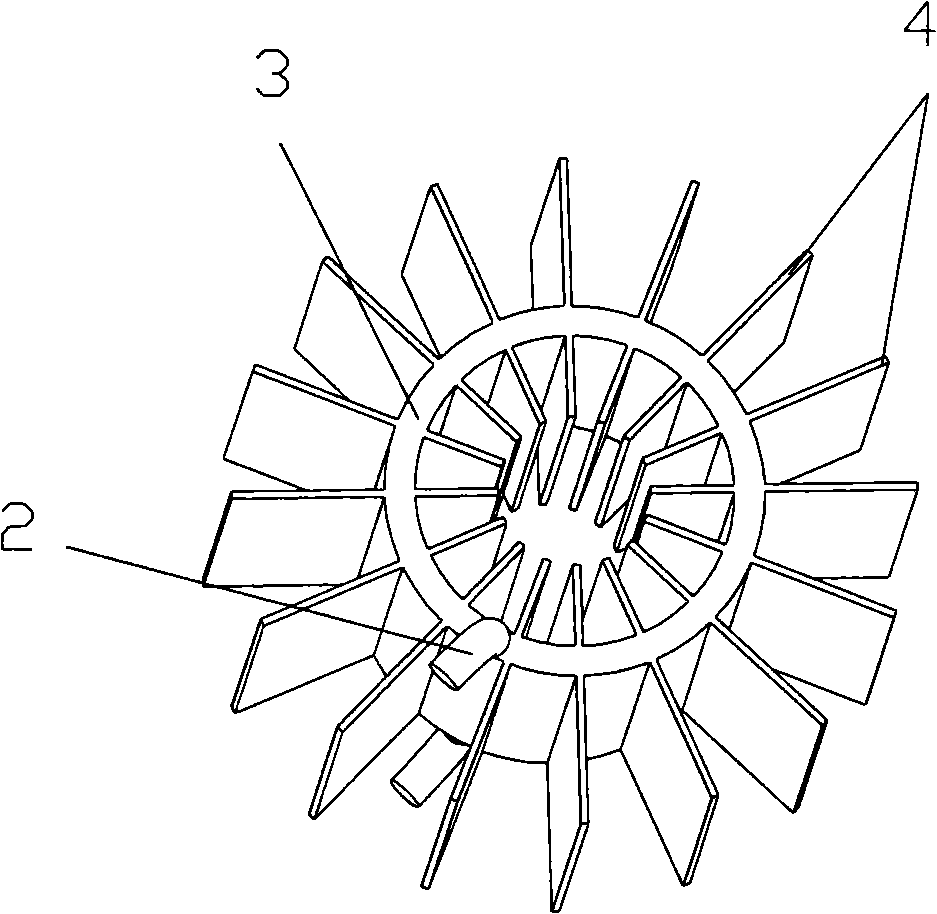

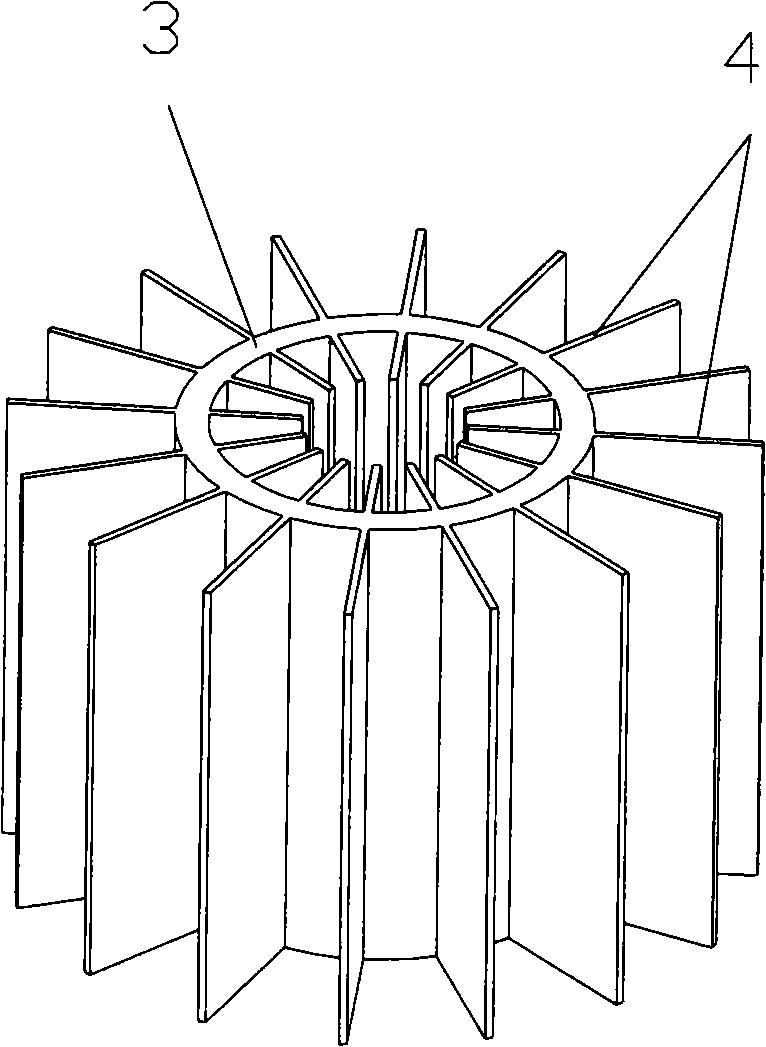

[0016] Such as figure 1 As shown, a loop heat pipe condenser includes an evaporation chamber 1, a pipe 2, and a sealed and hollow condensation chamber 3. Both the condensation chamber 3 and the evaporation chamber 1 are provided with a working fluid inlet and a working fluid outlet, and the evaporation chamber 1 is The outlet of the working medium communicates with the inlet of the working medium on the condensation chamber 3 through the pipeline 2, and the outlet of the working medium on the condensation chamber 3 communicates with the inlet of the working medium of the evaporation chamber 1 through another pipeline 2, and several fins are arranged on the surface of the condensation chamber 3 4. The shape of the condensation chamber 3 is a torus structure.

[0017] The condensation chamber 3 is made of a metal plate material with good thermal conductivity, such as copper, nickel, aluminum, stainless steel or a mixture thereof. The loop heat pipe condenser is filled with wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com