Cooler with defroster, and refrigerator having cooler with defroster

A cooler and cooling fin technology, applied in defrosting, refrigeration and liquefaction, household refrigeration equipment, etc., can solve the problems of difficult surface temperature of glass tube 12, limit and decrease in improving defrosting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the present invention will be described in further detail with reference to the accompanying drawings. However, the drawings are schematic diagrams, and the dimensions showing the relationship between positions are not correct. In addition, this invention is not limited to this embodiment.

[0049] (Embodiment 1)

[0050] use Figure 1 to Figure 6 Embodiment 1 will be described.

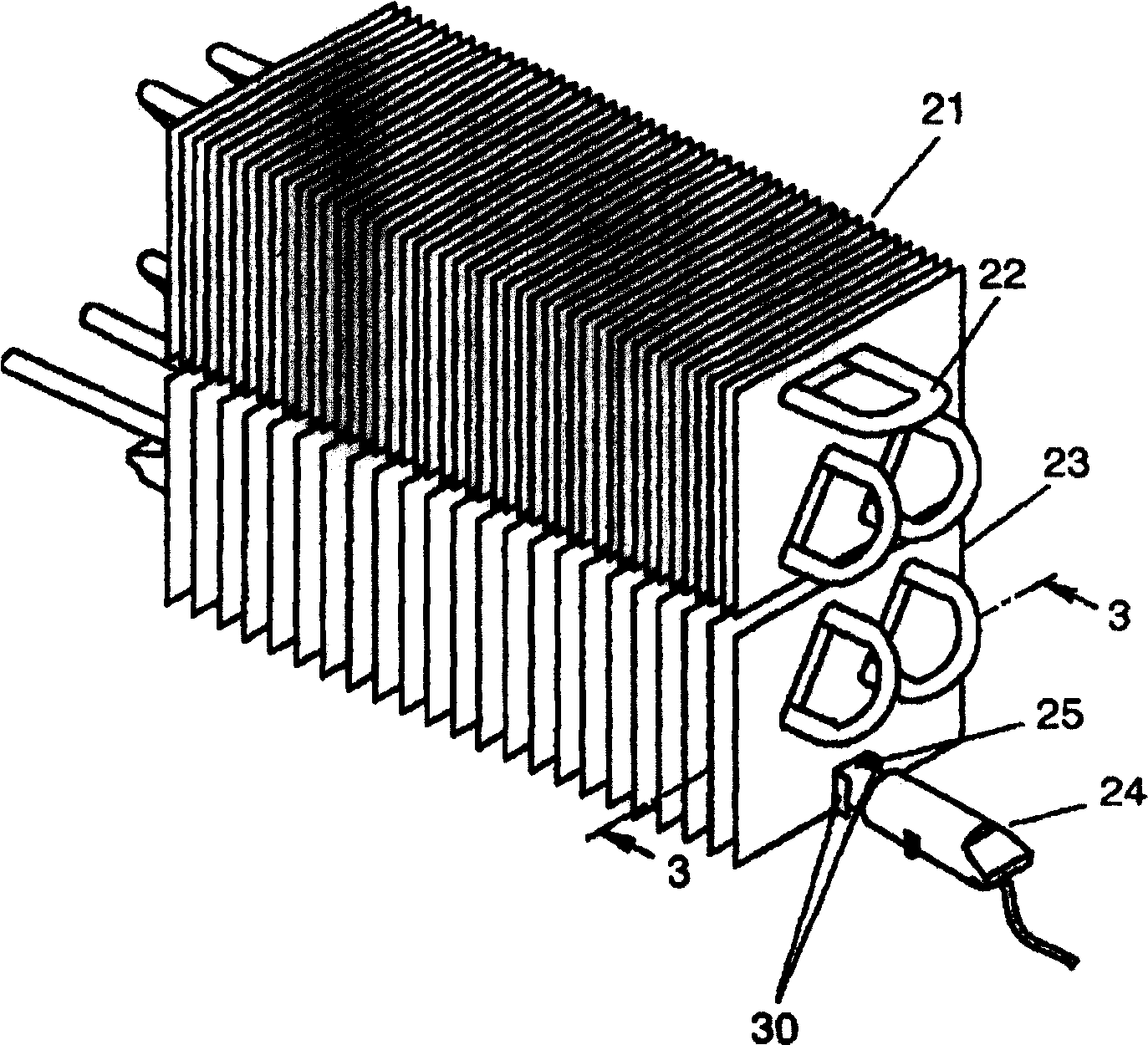

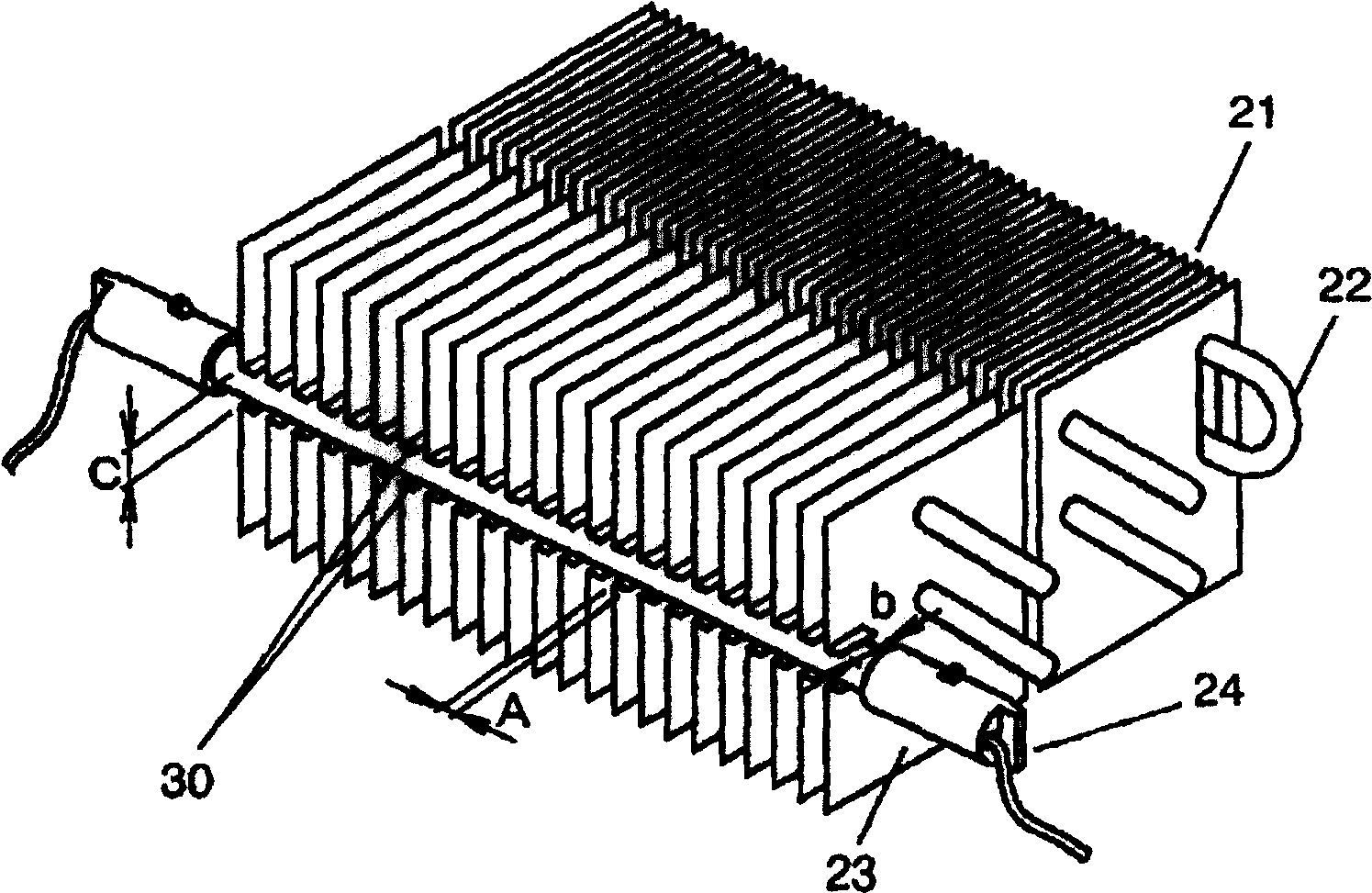

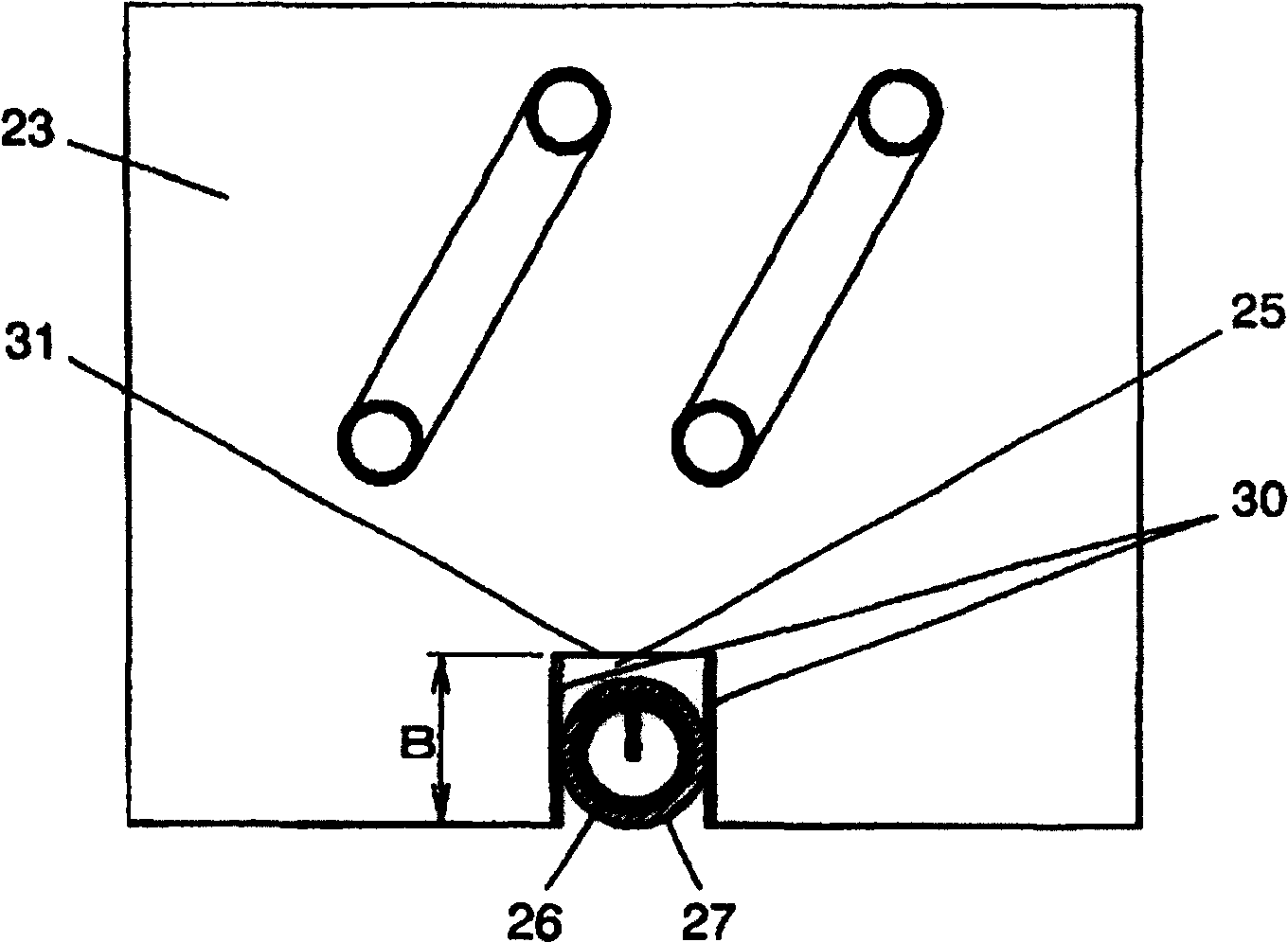

[0051] exist figure 1 Among them, a cooler with a defrosting device (hereinafter referred to as a cooler) includes: a cooler 21 composed of a plurality of cooling fins 23 and refrigerant tubes 22 passing through the cooling fins 23; The glass tube heater 24 of the defrosting device.

[0052] Isobutane, which is a flammable refrigerant, is sealed in the refrigerant tube 22 .

[0053] The glass tube heater 24 includes: a coiled heating wire 26 made of a metal resistor; a glass tube 27 covering the heating wire 26 ; a cover 28 covering the opening of the glass tube 27 ; and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com