Coil structure for improving zone-melting radial resistivity uniformity

A technology of resistivity and uniformity, which is applied in the field of coil structure to improve the radial resistivity uniformity of zone melting, can solve the problem of large fluctuation of radial resistivity uniformity of zone melting silicon single crystal, and avoid local electromagnetic field excessive Dense, uniform thickness, reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

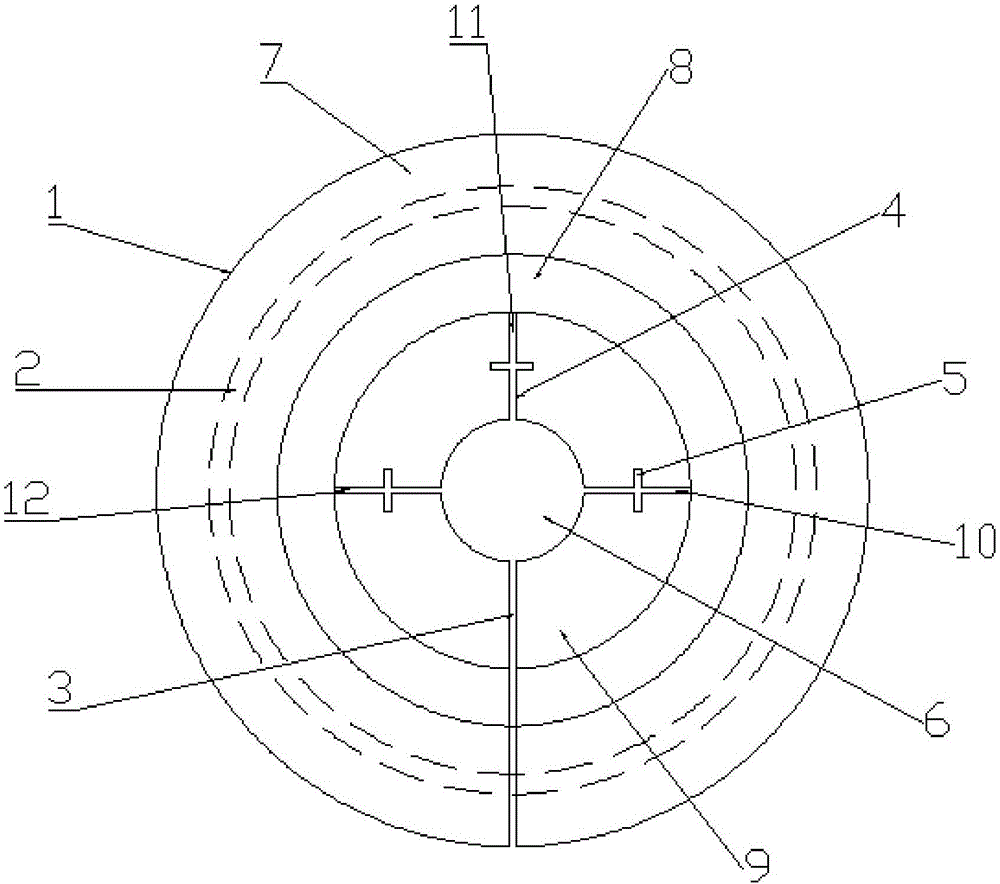

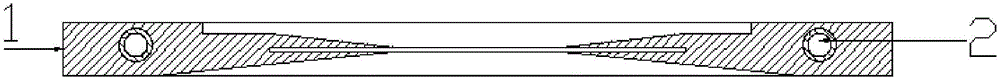

[0036] Such as figure 1 , figure 2 As shown, a coil structure for improving the uniformity of radial resistivity in the molten zone includes a coil main body 1, a cooling water pipe 2, a main slot 3, several auxiliary slots 4 and several transverse slots 5;

[0037] The coil main body 1 is a flat coil, and the upper surface of the coil main body 1 is recessed toward the inside of the coil to form a stepped structure symmetrical about the center; the geometric center of the coil main body 1 is provided with a coil eye 6, and the coil eye 6 is a through hole;

[0038] The cooling water pipe 2 is located inside the outermost step of the coil main body 1 and arranged along the circumference; the inner surface of the cooling water pipe 2 is a mechanochemical polished surface;

[0039] The main seam 3 is radially arranged on the coil body 1 and penetrates the upper surface and the lower surface of the coil body 1; one end of the main seam 3 communicates with the coil eye 6, and t...

Embodiment 2

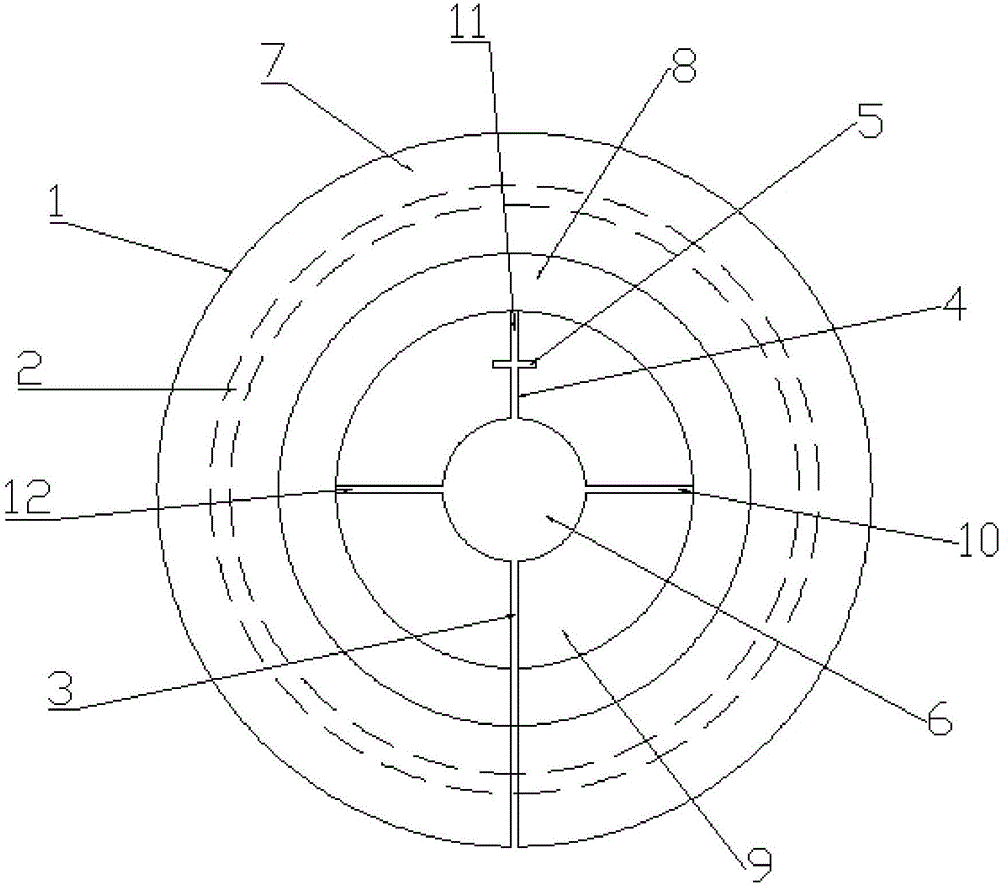

[0051] Such as image 3 As shown, a coil structure for improving the uniformity of radial resistivity in the molten zone includes a coil main body 1, a cooling water pipe 2, a main slot 3, several auxiliary slots 4 and several transverse slots 5;

[0052] The coil main body 1 is a flat coil, and the upper surface of the coil main body 1 is recessed toward the inside of the coil to form a stepped structure symmetrical about the center; the geometric center of the coil main body 1 is provided with a coil eye 6, and the coil eye 6 is a through hole;

[0053] The cooling water pipe 2 is located inside the outermost step of the coil main body 1 and arranged along the circumference; the inner surface of the cooling water pipe 2 is a mechanochemical polished surface;

[0054] The main seam 3 is radially arranged on the coil body 1 and penetrates the upper surface and the lower surface of the coil body 1; one end of the main seam 3 communicates with the coil eye 6, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com