High-efficiency environment-friendly stabilizing agent used for PVC section bars

An environmentally friendly stabilizer and high-efficiency technology, which is applied in the field of PVC processing aids and can solve problems such as thermal decomposition of PVC profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Accurately weigh calcium stearate and calcium zinc stearate, pentaerythritol ester, antioxidant 1010, ultraviolet absorber, magnesium aluminum hydrotalcite, stearyl benzoyl methane, 1-methyl-2-benzene Kelindole, after mixing, kneading, and granulating according to the conventional process, take out 4 parts, add it to the following PVC formula, put it into a small high-speed mixing mixer, raise it to 115°C, release it, and cool it for later use.

[0039] Table 1 PVC formulation

[0040] pvc

100

1.0

CaCO 3

8

Toughener CPE

8

Processing aid ACR401

2

Titanium dioxide

5

0.3

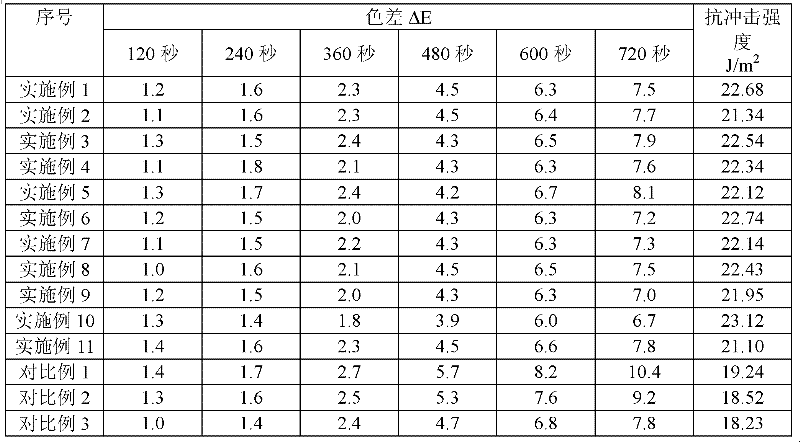

[0041] (2) Dynamic thermal stability

[0042] Put the materials mixed in the previous step into the double-roller plastic refining machine, and continue to knead at a constant roll temperature (about 190°C) and roll distance (1mm). Take 7 samples for each for...

Embodiment 2~3

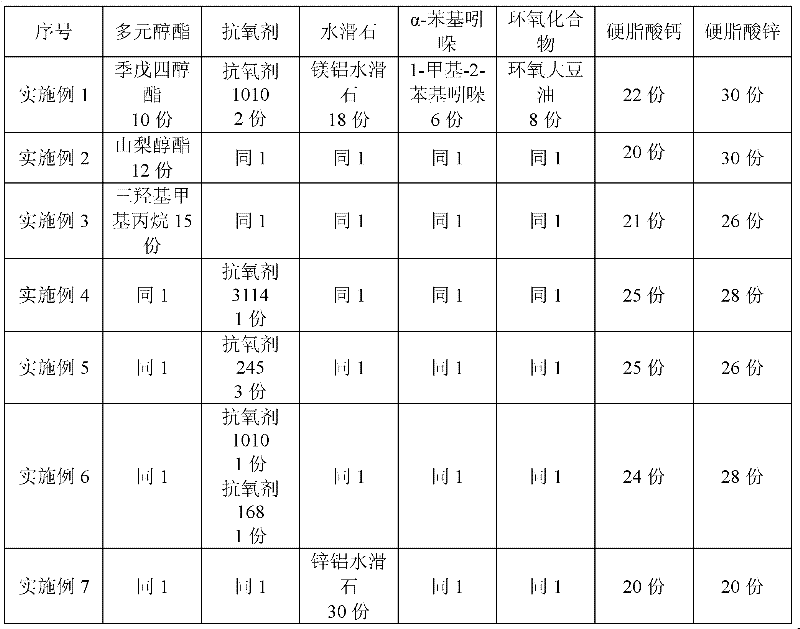

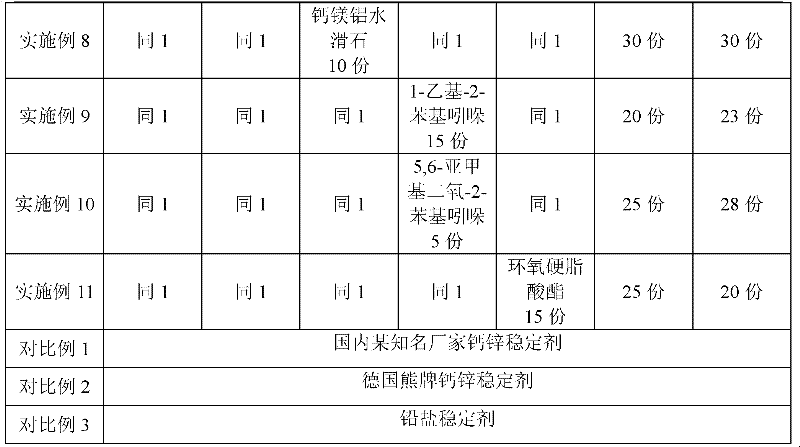

[0046] Except that the addition of polyol ester is different, the others are the same as in Example 1, and the details and performance test results are shown in Table 2 and Table 3.

Embodiment 4~6

[0048] Except for the addition of different antioxidants, all the others are the same as in Example 1, and the details and performance test results are shown in Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com