Preparation method of titanium dioxide for color masterbatch

A titanium dioxide and color masterbatch technology, applied in chemical instruments and methods, dyeing physical treatment, dyeing organosilicon compound treatment, etc. The effect of interfacial surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

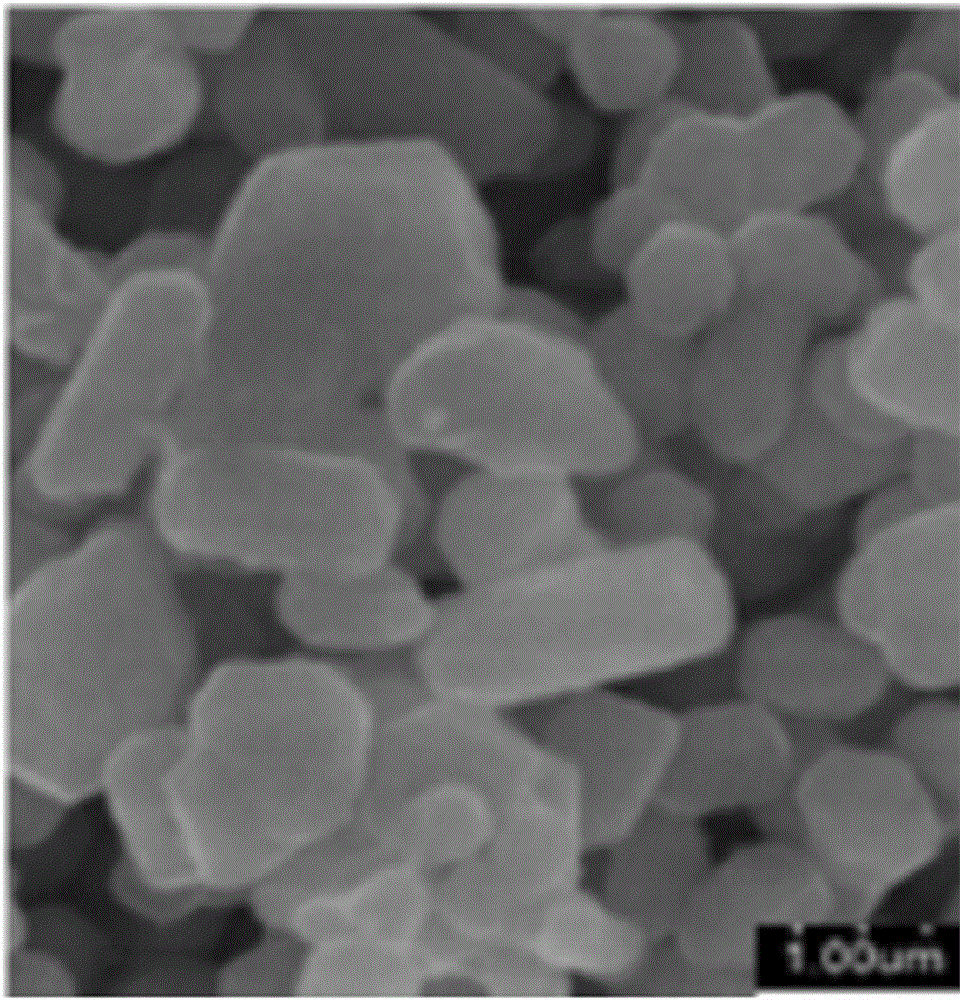

Image

Examples

Embodiment 1

[0028] A preparation method of titanium dioxide for color masterbatch, including the following steps:

[0029] a. Preparation of TiO 2 Slurry: The titanium solution added with seed crystals is heated and kept under low pressure for hydrolysis to prepare metatitanic acid, and then the metatitanic acid after washing, bleaching and salt treatment is pressed to obtain a filter cake, which is calcined at 900°C or higher to obtain Crude titanium dioxide with a rutile content ≥99.5%, pulverize and add sodium hydroxide to sand mill, adjust the PH value to 8-11, and prepare TiO with a particle size of 2 Slurry

[0030] b. Silicon coating: Dilute the TiO2 slurry obtained in step a to a concentration of 300g / L~450g / L, adjust the pH of the slurry=8~11, add dispersant ammonium dihydrogen phosphate solution, and add the amount to P 2 O 5 The proportion of titanium dioxide is 0.01%, the concentration is 48g / L, the steam is heated to 60℃, the silicon-containing compound sodium silicate is added und...

Embodiment 2

[0035] A preparation method of titanium dioxide for color masterbatch, including the following steps:

[0036] a. Preparation of TiO 2 Slurry: The titanium solution added with seed crystals is heated and kept under low pressure for hydrolysis to prepare metatitanic acid, and then the metatitanic acid after washing, bleaching and salt treatment is pressed to obtain a filter cake, which is calcined at 900°C or higher to obtain Crude titanium dioxide with a rutile content ≥99.5%, pulverize and add sodium silicate sand mill, adjust the PH value to 8-11, prepare TiO with a particle size of 2 Slurry

[0037] b. Silicon coating: Dilute the TiO2 slurry obtained in step a to a concentration of 300g / L~450g / L, adjust the pH of the slurry=8~11, and add a mixed solution of dispersant sodium hexametaphosphate and ammonium dihydrogen phosphate , The addition amount is P 2 O 5 The proportion of the total weight of titanium dioxide is 0.1%, the concentration is 50g / L, the steam is heated to 70℃, an...

Embodiment 3

[0042] A preparation method of titanium dioxide for color masterbatch, including the following steps:

[0043] a. Preparation of TiO 2 Slurry: The titanium solution added with seed crystals is heated and kept under low pressure for hydrolysis to prepare metatitanic acid, and then the metatitanic acid after washing, bleaching and salt treatment is pressed to obtain a filter cake, which is calcined at 900°C or higher to obtain Crude titanium dioxide with rutile content ≥99.5%, pulverized and sanded with a mixture of sodium hydroxide and sodium silicate, adjust the pH to 8-11, to obtain TiO with a particle size of 2 Slurry

[0044] b. Silicon coating: dilute the TiO2 slurry obtained in step a to a concentration of 300g / L~450g / L, adjust the pH of the slurry=8~11, add dispersant sodium hexametaphosphate solution, and add the amount to P 2 O 5 The proportion of the total weight of titanium dioxide is 0.2%, the concentration is 52g / L, the steam is heated to 90℃, the silicon-containing comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com