Processes for Reducing the Appearance of Pastiness or Ashiness on Skin

a technology applied in the field of processes for reducing the appearance of pastiness or ashiness on the skin, can solve the problems of reducing the coverage provided to the skin, affecting the natural appearance of the skin, and white/blue hue across the skin, so as to achieve high coverage and high coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0100]The following examples further describe and demonstrate the preferred embodiments within the scope of the present invention. The examples are given solely for the purpose of illustration, and are not to be construed as limitations of the present invention since many variations thereof as possible without departing from its scope.

[0101]All weights provided in these examples are weights of the commercially available materials, including active(s) and / or solvent and / or by-products.

examples 1 to 5

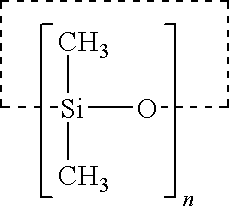

[0102]A liquid foundation of the present invention is prepared as follows: in a suitable vessel, water, glycerine, disodium EDTA and benzyl alcohol are added and mixed using conventional technology until a clear water phase is achieved. When the water phase is clear, the methylparabens are added and mixed again until clear. The resultant phase is mixed with a Silverson SL2T or similar equipment on high speed (8,000 rpm, standard head). In a separate vessel, the dimethicone & dimethicone copolyol cross-polymer, cyclopentasiloxane, pigment dispersion, other oils, dispersant and the parabens are added and the mixture is milled using a Silverson SL2T on a high speed setting until a homogeneous mixture is created.

[0103]Following this step, the water phase and the silicone phase are combined and milled using the Silverson SL2T on a high speed setting until the water is fully incorporated and an emulsion is formed. The dimethicone crosspolymer & cyclopentasiloxane is then added and the mix...

example 6 to 10

[0104]A liquid foundation of the present invention is prepared as follows: in a suitable vessel, water, propylene glycol, methyl paraben, sodium chloride and poly vinyl pyrrolidone are added, heated and mixed using conventional technology until a clear water phase is achieved. The resultant phase is cooled to room temperature. In a separate vessel, cyclopentasiloxane, pigment dispersions, other oils, dispersant, propyl paraben, Iron containing titanium dioxide, transparent iron oxides and the waxes are added and the mixture is mixed whilst it is heated. Once the waxes are well dispersed, the mixture is milled using a Silverson SL2T on a high speed setting and allowed to cool to 55° C. when the powders, trihydroxystearin and linear silicones are added. Once both phases are at room temperature, the water phase and the silicone phase are combined and milled using the Silverson SL2T on a high speed setting until the water is fully incorporated and an emulsion is formed.

Examples678910Ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com