Motorcycle clutch iron base friction sheet, preparation process and pairing sheet thereof

A friction plate and clutch technology, applied in friction linings, mechanical equipment, etc., can solve problems such as complex process, high cost, and high price, and achieve the effects of long service life, low cost, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

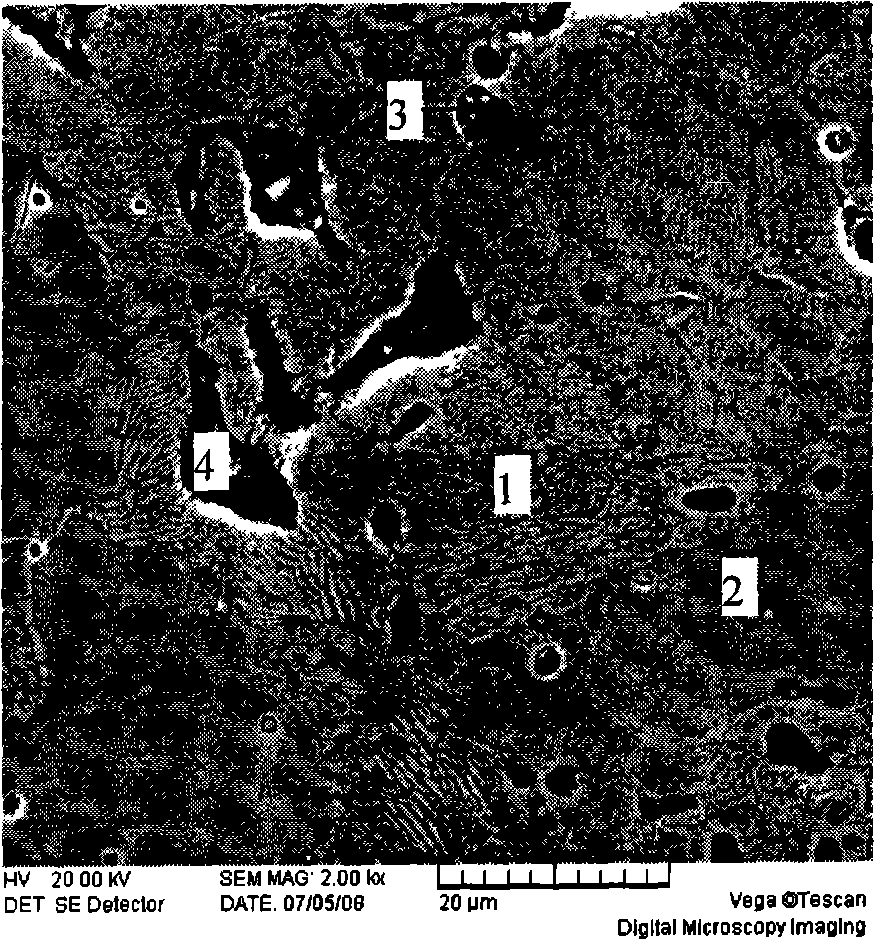

Embodiment (1

[0027] The iron-based friction plate sample is composed of 2% manganese, 0.21% silicon, 1.7% copper, 0.8% nickel, 0.6% carbon, and the rest is iron; the raw materials are loaded into the mixer according to the above formula ratio, and the evenly mixed powder Loaded into the mold, at a unit pressure of 5t / cm 2 Lower molding; put the pressed product into the sintering furnace, the firing temperature is 1130°C to 1160°C, and then cool slowly. If the surface flatness of the product does not meet the requirements, it needs to be shaped with a mold on the press, and finally to get the finished product. The friction and wear parameters measured by the above products on the screen display PV friction testing machine are: the wear amount after 8 hours of friction is 0.010mm, the amount of wear after friction for 8-35 hours is 0.029mm, the amount of wear after friction for 35-55 hours is 0.021mm, and the coefficient of dynamic friction 0.130, dynamic moment > 50N·m. The tensile streng...

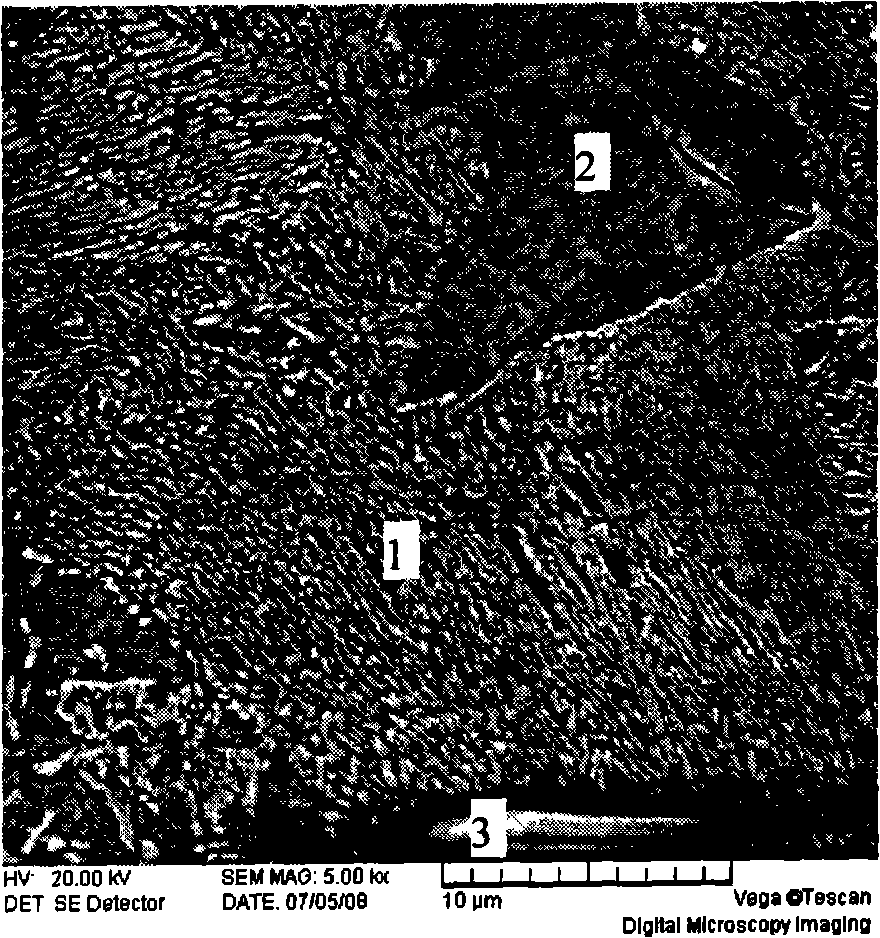

Embodiment (2

[0032] The iron-based friction plate sample is composed of 0.5% chromium, 5% manganese, 1.5% copper, 0.8% molybdenum, 1.0% carbon, and the rest is iron. It is prepared by sintering by the powder metallurgy process of Example 1. The obtained product is tested on a screen-display PV friction testing machine. The test conditions and requirements are the same as those in Example (1), and the test results are: coefficient of dynamic friction 0.118, dynamic torque > 50N m, single-chip wear in the first 28 hours 0.035mm, the wear amount after 27 hours is 0.020mm. The tensile strength of the friction plate is 90-120MPa.

[0033] The dual plate used in conjunction with this friction plate sample is made of Q235 mild steel sample, and the surface is made by soft nitriding treatment.

[0034] The friction plate has passed the motorcycle road test for 5000 hours, which proves that the performance is qualified.

Embodiment (3

[0036] The iron-based friction plate sample is composed of 1.0% manganese, 5% copper, 0.8% carbon, 0.1% silicon, 0.8% nickel, 1.6% iron sulfide, and the rest is iron. Adopt the powder metallurgy process of embodiment (1) to make, test on the screen display type PV friction testing machine, test condition is the same as example (1), wear continuously for 20 hours; test result is: dynamic friction coefficient 0.097, dynamic moment>50N m. The wear amount in the first 10 hours is 0.015mm, and the wear amount in the next 10 hours is 0.012mm. The tensile strength of the friction plate is 85-110MPa.

[0037] The dual plate used in conjunction with this friction plate sample is made of Q235 mild steel sample, and the surface is made by soft nitriding treatment.

[0038] The friction plate has passed the motorcycle road test for 5000 hours, which proves that the performance is qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com