mpv model sliding door combination switch

A combination switch and sliding door technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of poor durability of contact switches, complex structure of contact switches, and low production efficiency, so as to improve durability and structure Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

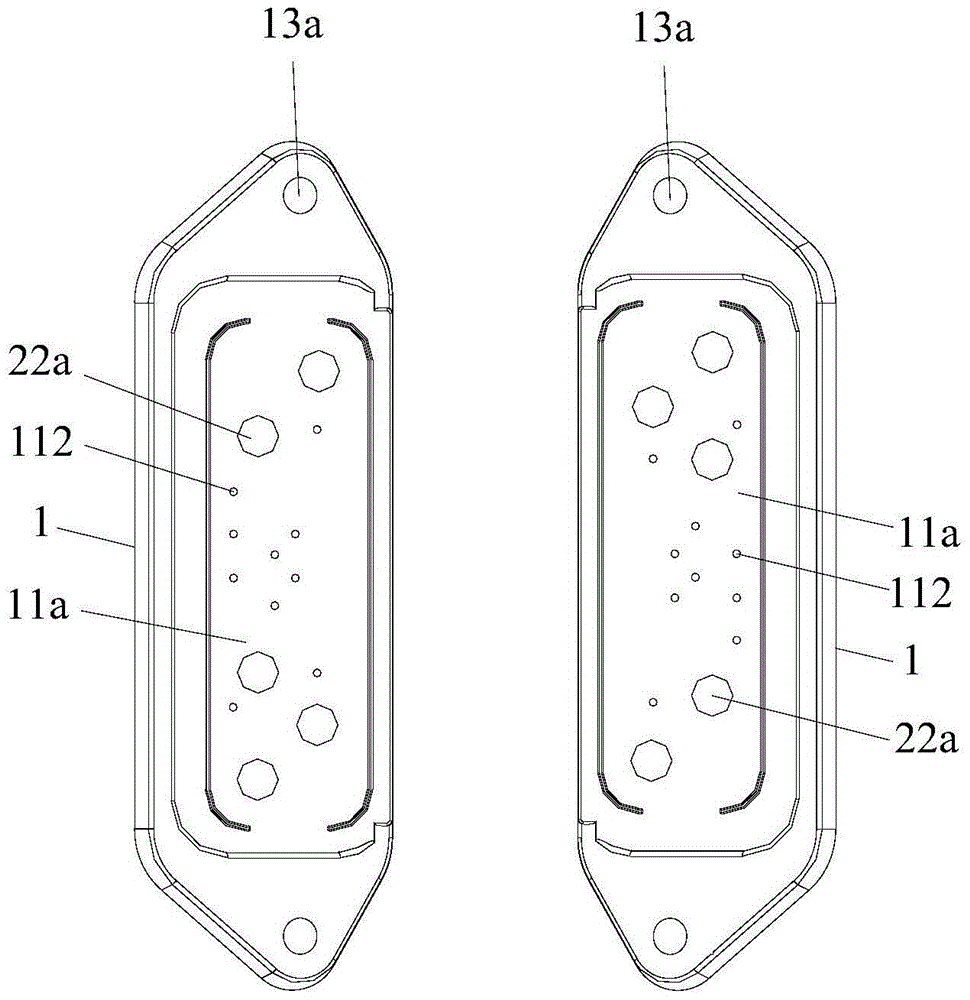

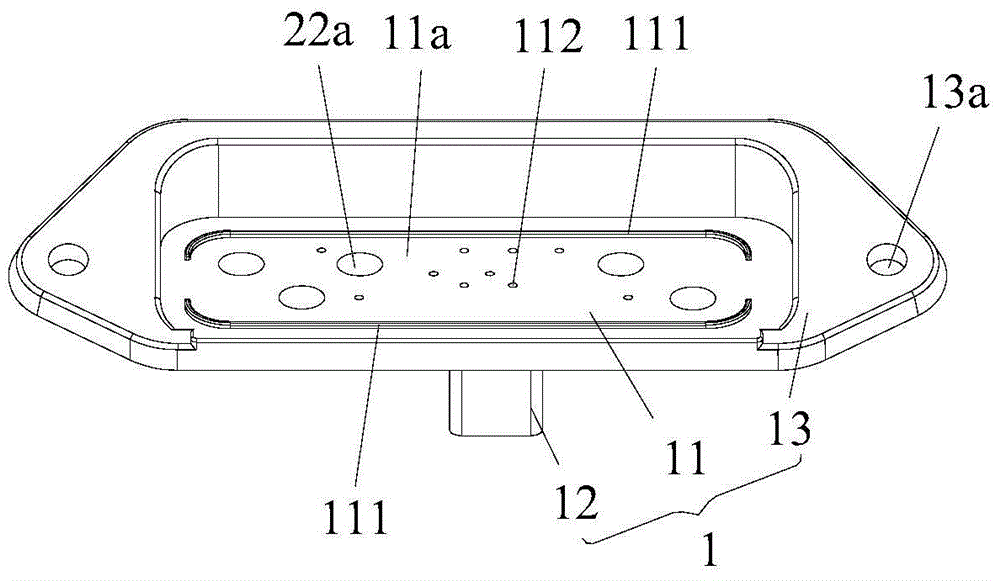

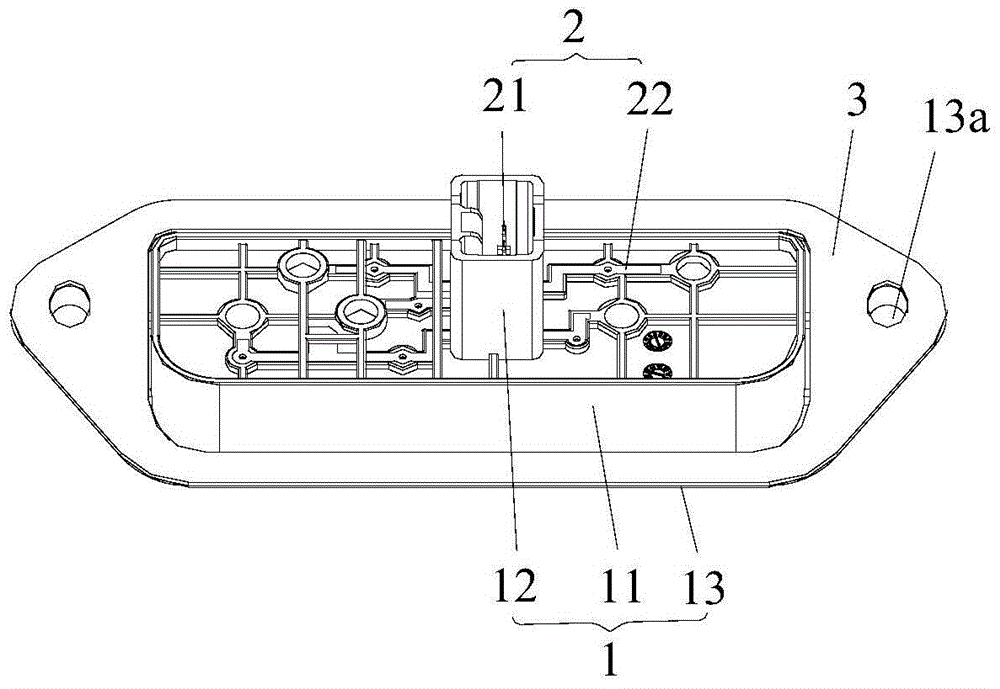

[0039] Please refer to Figure 1-17 , the MPV type sliding door combination switch includes a pair of fixed ends 100 fixed on the left and right door frames of the van and a pair of sliding ends 200 fixed on the left and right sliding doors of the van.

[0040] The fixed end 100 includes a casing 1 and a terminal 2, and the casing 1 and the terminal 2 of the pair of fixed ends 100 are respectively antisymmetrically arranged, that is, the fixed ends 100 on the left and right doors of the van have the same structure, but the installation direction is opposite, so that Many fixed ends 100 can be produced with one set of moulds, which improves the versatility of the moulds, improves the production efficiency, and realizes cost savings. The terminal 2 is embedded and molded in the shell 1, one end of the terminal 2 is a contact end, and the other end is a plug-in end, and the first composite material 22a is brazed on the contact end.

[0041] The conductive strips 22 and the first...

Embodiment 2

[0049] Please refer to Figure 18-20 , the difference between this embodiment and the above-mentioned first embodiment is only that: if there are two terminals 2, there are two conductive sheets 22, each of the conductive sheets 22 is provided with a contact end, and the two conductive sheets 22 The contact ends are distributed on both sides of the contact surface 11a, and the plurality of floating thimble holes 112 are distributed in the area between the two contact ends. The fixed ends of the two terminals 2 in this embodiment The fixed ends of the five terminals 2 in the above-mentioned embodiment 1 can be formed by a set of molds. When producing the fixed ends of the two terminals 2, only two required copper terminals need to be inserted into the mold, and other parts Directly inject plastic for filling during injection molding, so as to realize the compression of the fixed ends of two terminals 2 and five terminals 2 formed by two sets of molds into the fixed ends of two ...

Embodiment 3

[0052] Please refer to Figure 21-22 , the difference between this embodiment and the first embodiment is that there are six terminals 2, and the contact ends of the six terminals 2 are divided into two groups, each group has three contact ends, and the three contact ends of each group are triangular distributed. The fixed ends of the six terminals 2 in this embodiment and the fixed ends 100 of the five terminals 2 in the first embodiment above can be formed by a set of molds, but when the fixed ends 100 of the five terminals are formed, the remaining One of the terminal positions is directly injected with plastic for filling during injection molding, so as to achieve the effect of reducing mold costs, thereby saving costs and improving production efficiency.

[0053] There are six electrodes 5, and the six electrodes 5 are divided into two groups, each group has three electrodes 5, and the three electrodes 5 in each group are distributed in a triangle. The casing 4 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com