Preparation method of lithium silicate material with high purity

A lithium silicate, high-purity technology, applied in silicate, alkali metal silicate and other directions, can solve the problems of high synthesis temperature, complex preparation process, expensive equipment, etc., achieve high purity, simple synthesis process, easy The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

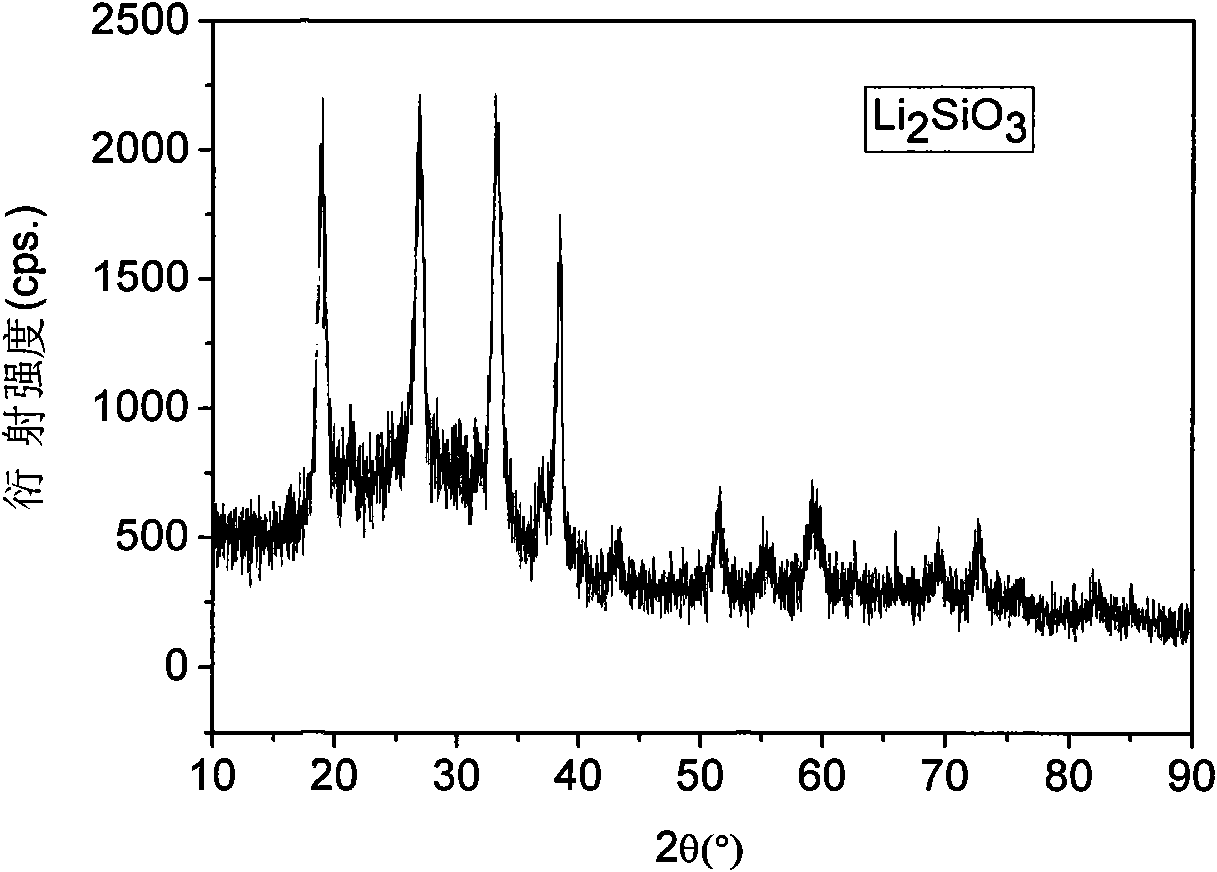

[0023] Ethyl orthosilicate and lithium hydroxide are used as initial raw materials, absolute ethanol is used as a solvent, and 25% ammonia water is used to adjust the pH value of the solution. Add 8 milliliters of ammonia water to 240 milliliters of absolute ethanol, adjust the pH value of the solution to be approximately equal to 8, add 4 milliliters of tetraethyl orthosilicate to the above solution in 4 times and react for 22 hours to prepare suspension A. The lithium source is Li Weigh and Si molar ratio 2:1, dissolve in absolute ethanol, prepare a lithium salt mixture with a concentration of 1.0 mol / L, add the lithium salt mixture dropwise to suspension A, and react for 3 hours to form suspension B. The suspension was dried in an oven at 90°C in an air atmosphere. figure 1 For the high-purity Li synthesized by the improved solution method of the present invention 2 SiO 3 The XRD pattern of the precursor material (without heat treatment, only the material dried after liqu...

Embodiment 2

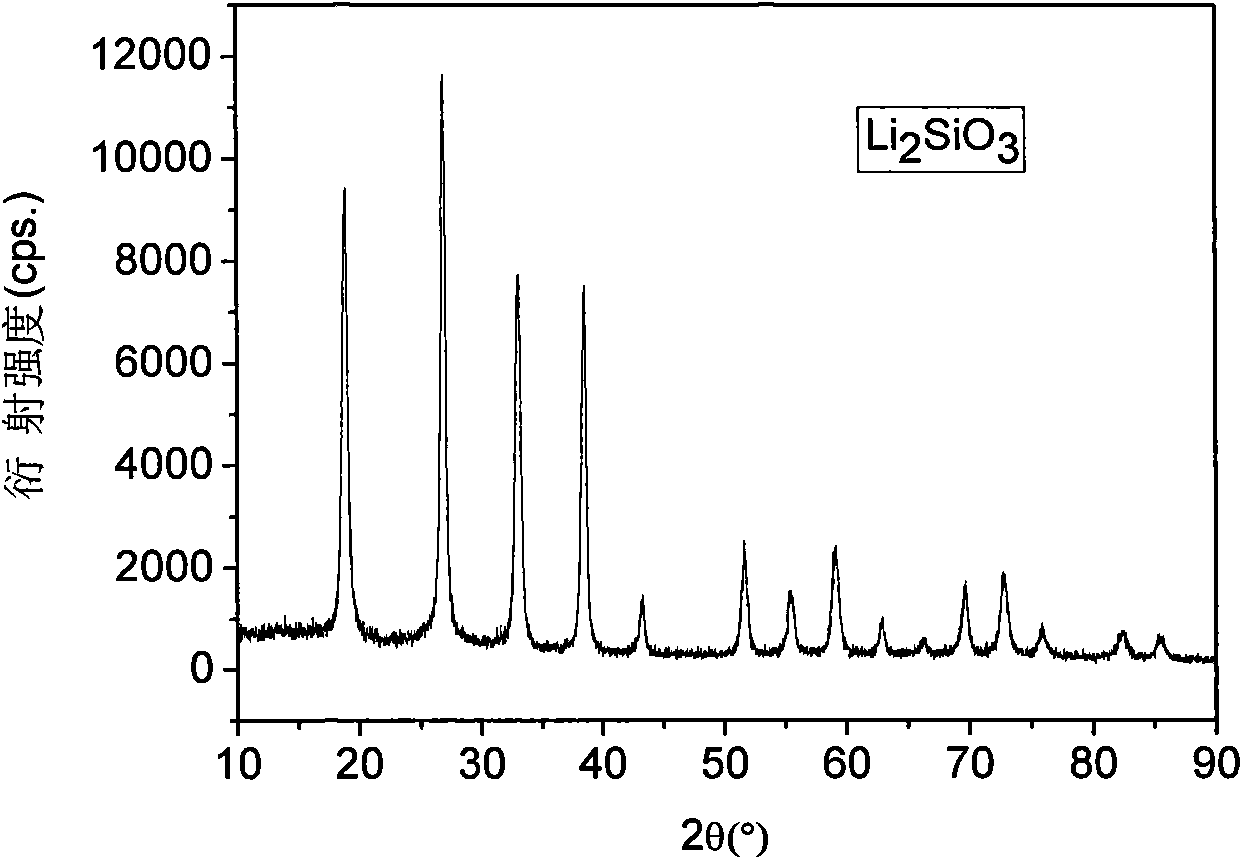

[0025] Ethyl orthosilicate and lithium carbonate are used as initial raw materials, absolute ethanol is used as a solvent, and 25% ammonia water is used to adjust the pH value of the solution. Add 10 milliliters of ammonia water to 80 milliliters of absolute ethanol, adjust the pH value of the solution to approximately 11, add 4 milliliters of tetraethyl orthosilicate to the above solution in 7 times and react for 4 hours. : 1 weighed, dissolved in absolute ethanol to prepare a lithium salt mixed solution with a concentration of 0.5mol / L, the lithium salt mixed solution was added dropwise into suspension A, and reacted for 1 hour to generate suspension B. The suspension was placed in an oven, dried under vacuum at 120°C. After the obtained solid powder was ground uniformly, it was placed in a muffle furnace, and the temperature was raised to 700°C at a rate of 5°C / min, kept for 0.5 hours, and then naturally cooled to room temperature. Such as image 3 Shown: image 3 It is ...

Embodiment 3

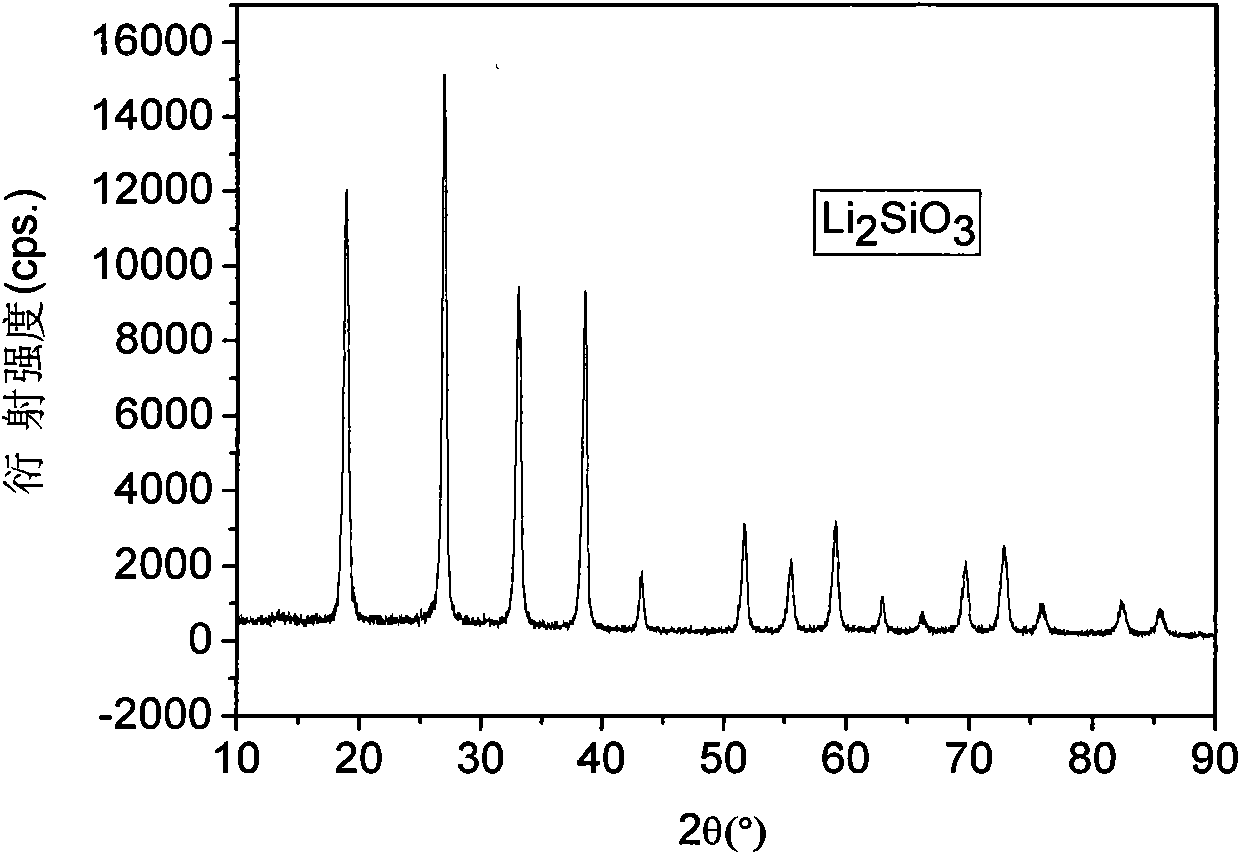

[0027] Ethyl orthosilicate and lithium acetate are used as initial raw materials, absolute ethanol is used as a solvent, and 25% ammonia water is used to adjust the pH value of the solution. Add 8 milliliters of ammonia water to 200 milliliters of absolute ethanol, adjust the pH value of the solution to approximately 9, add 4 milliliters of tetraethyl orthosilicate to the above solution in 5 times and react for 10 hours to prepare suspension A. The lithium source is Li Weigh and Si molar ratio 2:1, dissolve in absolute ethanol, prepare a lithium salt mixture with a concentration of 2.0mol / L, add the lithium salt mixture dropwise to suspension A, and react for 2 hours to form suspension B. The suspension was dried in an oven at 100°C in an air atmosphere. After the obtained solid powder was ground evenly, it was placed in an argon atmosphere furnace, and the temperature was raised to 250° C. at a rate of 20° C. / min, kept for 3 hours, and then naturally cooled to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com