Catalytic cracking slurry oil solid content removal method

A technology for catalytic cracking oil slurry and solid content, which is applied in the distillation control/regulation of hydrocarbon oil, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of long flushing time, large filtration resistance, and easy blockage of filter holes, etc., and achieves Strong raw material adaptability, high removal efficiency, and the effect of reducing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

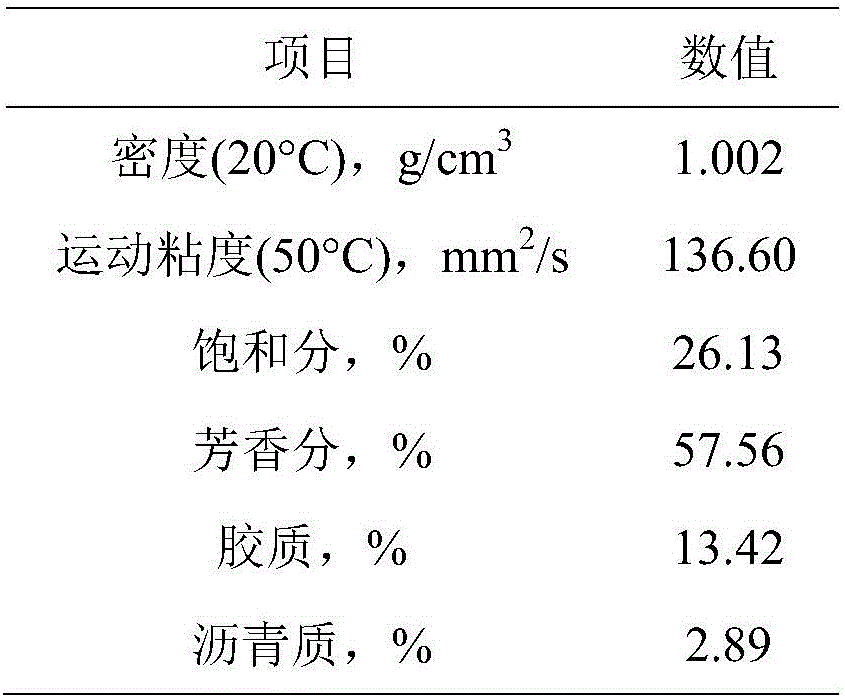

[0025] (1) Thermal pretreatment was performed on the catalytic cracking oil slurry under nitrogen atmosphere, the thermal pretreatment temperature was 420°C, and the thermal pretreatment time was 30 minutes.

[0026] (2) Perform vacuum distillation on the catalytic cracking oil slurry after thermal pretreatment, the liquid phase temperature is not higher than 340°C, and cut the distillate before 500°C.

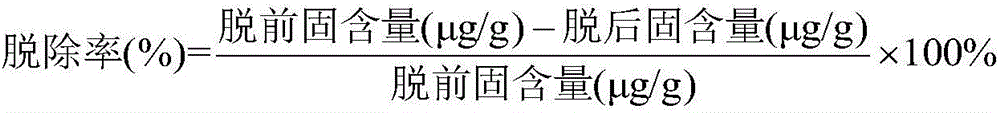

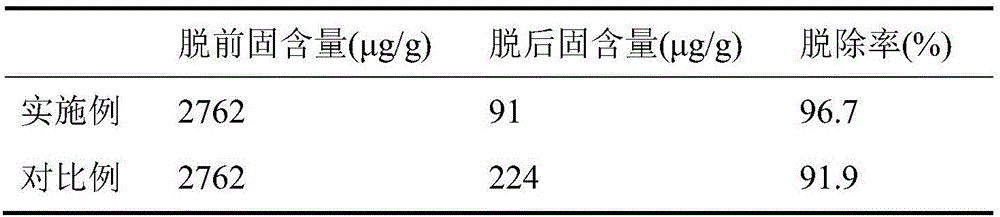

[0027] The results of solid content and removal rate before and after desolidification are shown in Table 2. It can be seen that the solid content after desolidification dropped below 100 μg / g, and the removal rate reached 96.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com