Laser shock peening method and device using high-pressure gas as constrained layer

A technology of laser shock strengthening and high-pressure gas, which is applied to laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of insufficient efficiency, inapplicability, troublesome cleaning, etc., and achieve good restraint, reliable restraint, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

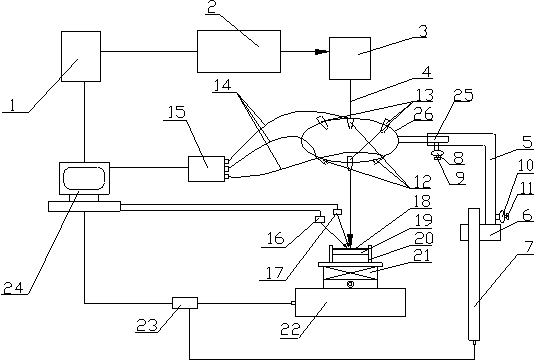

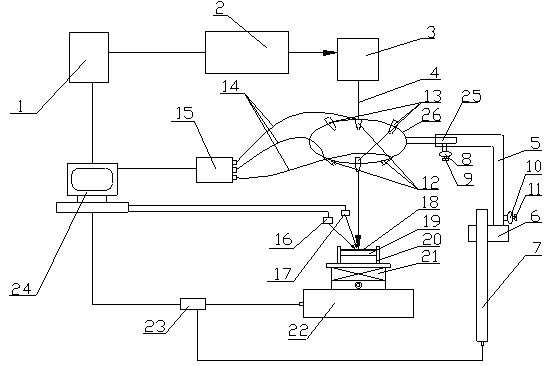

Image

Examples

Embodiment

[0032] Prepare five 2024 aluminum alloy samples with a length of 50mm, a width of 50mm, and a thickness of 10mm, which are respectively marked as sample 1, sample 2, sample 3, sample 4 and sample 5; before laser shock treatment, the surface of the sample is selected Grind with 400#-1200 sandpaper, then put it in ethanol for ultrasonic cleaning, dry it with cold wind, use 0.1mm thick American 3M company’s special aluminum foil (one side is an adhesive, and stick to the surface of the sample) as the laser energy for laser impact Absorbing layer, laser pulse energy is 8J, wavelength 1064nm, pulse width 10ns, spot diameter 6mm, single impact; sample 1 is impacted without a constrained layer, and sample 2 is impacted under a water-constrained layer. Sample 3 was impacted under the K9 glass confinement layer, sample 4 was impacted under the high-pressure gas confinement layer (the pressure of the high-pressure gas was controlled at 10MPa), and sample 5 was also impacted under the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com