Laser shock treatment device taking flowable liquid as energy absorption layer

A technology of energy absorption and flowing liquid, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low efficiency, affecting the popularization and application of laser shock processing technology, poor operability, etc. Industrialization promotion and application, stable impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

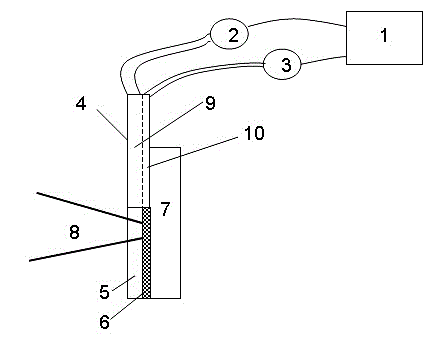

[0013] Such as figure 1 As shown, taking multiple continuous laser shocks at the same point as an example, the laser shock energy source is Nd 3+ : The pulse width of the 1064nm laser output by YAG is on the order of nanoseconds. The liquid in the flowable constrained layer can be any liquid with high transmittance to the incident laser. In this embodiment, water is selected as the liquid in the constrained layer; the liquid in the absorbing layer can be any liquid that strongly absorbs the incident laser. In this embodiment, liquid The black paint is used as a flowable absorbing layer liquid, and the black paint can also be diluted with a diluent to adjust the proportion of black paint in the absorbing layer liquid to obtain different light absorption efficiencies.

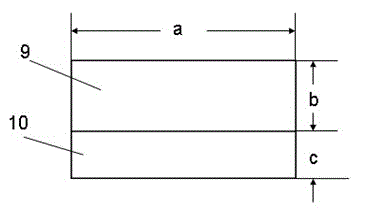

[0014] Such as figure 2 As shown, the cross-sectional shapes of the two channels of the dual-channel pipeline 4 are rectangular, the length of the rectangular cross-section of the constrained layer channel 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com