Metal part inside-laser wire-feeding cladding laser shocked and forged composite additional material manufacturing method

A technology of metal parts and laser shock, which is applied in the field of metal additive manufacturing, can solve problems such as thermal stress and deformation cracking, shrinkage porosity, and lack of fusion, so as to reduce production costs, solve secondary heating, and save a lot of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiment:

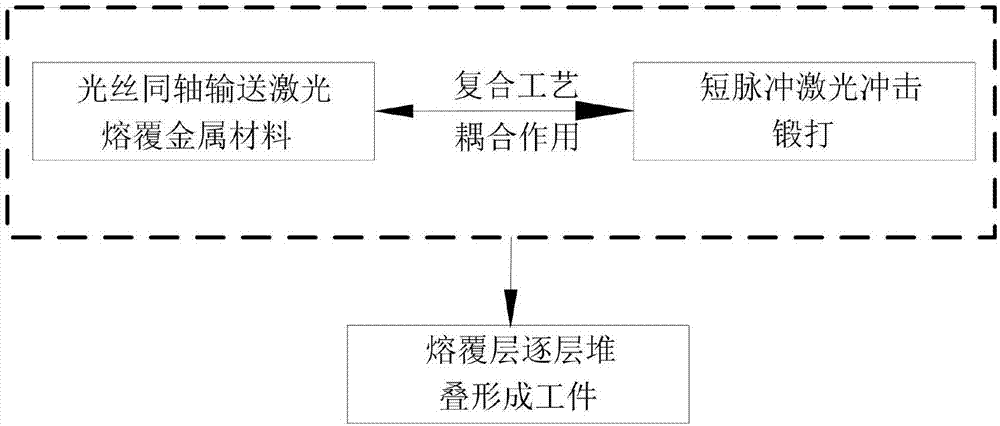

[0013] See attached figure 1 As shown in this embodiment, a metal parts laser light internal wire feeding cladding laser shock forging composite additive manufacturing method described in this embodiment, the steps are as follows:

[0014] (1) The circular solid beam of the continuous laser beam is converted into a hollow conical focused beam through the optical path, and the coaxial wire feeding method in the light is used to clad the molten metal wire by thermal effect, while another pulsed laser beam is used The shock wave mechanical effect performs synchronous impact forging on the cladding layer in the temperature region prone to plastic deformation, and performs composite manufacturing;

[0015] (2) The cladding layer is stacked layer by layer to form the workpiece.

[0016] During the manufacturing process, the coaxial wire feeding speed of the continuous laser beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com