Safety pin for elevator and manufacturing method thereof

A safety pin and elevator technology, applied in the field of safety pins, can solve problems affecting the reliability of safety pins, environmental corrosion, rust, etc., and achieve better passivation effect, high reliable locking effect, uniform and tight thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

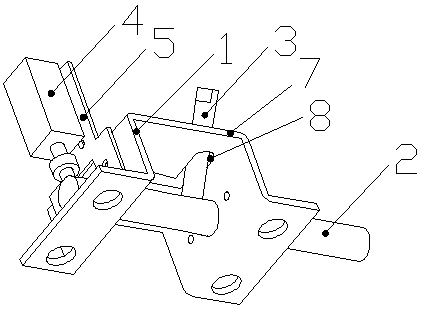

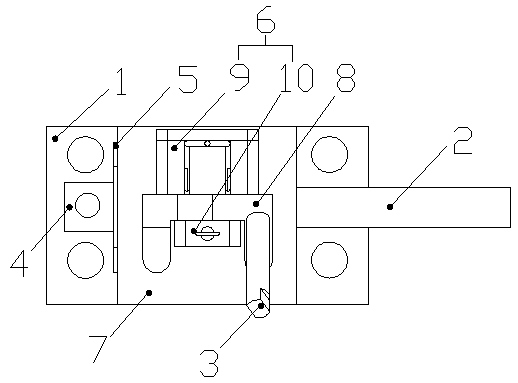

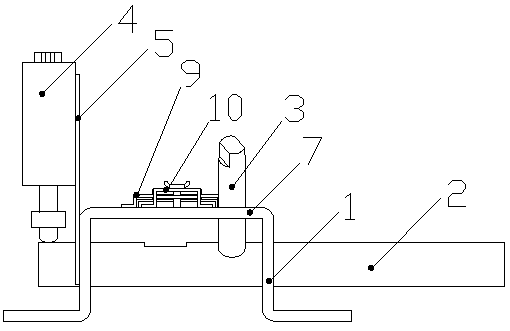

[0057] combine Figure 1 to Figure 15 An embodiment of a safety pin for an elevator and a manufacturing method thereof according to the present invention will be further described.

[0058] A safety pin for an elevator, comprising a base 1, a gear plane 7, a gear groove 8, a latch rod 2, a latch slide bar 3, a limit switch 4, a bracket 5 and a locking device 6, the base 1 is positioned horizontally A gear plane 7 protrudes from the middle position of the gear plane 7, and a gear slot 8 is opened on the gear plane 7, and a locking device 6 is installed on the upper surface of the gear plane 7, and the locking device 6 includes a sliding device 9 and a tightening device 10, the sliding device 9 is arranged at the rear position of the gear slot 8, and the sliding device 9 includes an extending piece 11, a sliding fixing seat 12, a blocking seat 13, two short rods 14, connecting Rod 15 and pull rod 16, the protruding piece 11 includes a first plate body 17, two first legs 18, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com