A kind of high flux heat exchange tube and its preparation method and application

A heat exchange tube, high-flux technology, applied in coatings, electrolytic coatings, etc., can solve the problem that the thermal conductivity of the heat exchange tube cannot meet the requirements of engineering applications, achieve excellent bonding, improve surface brightness and flatness, and improve The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

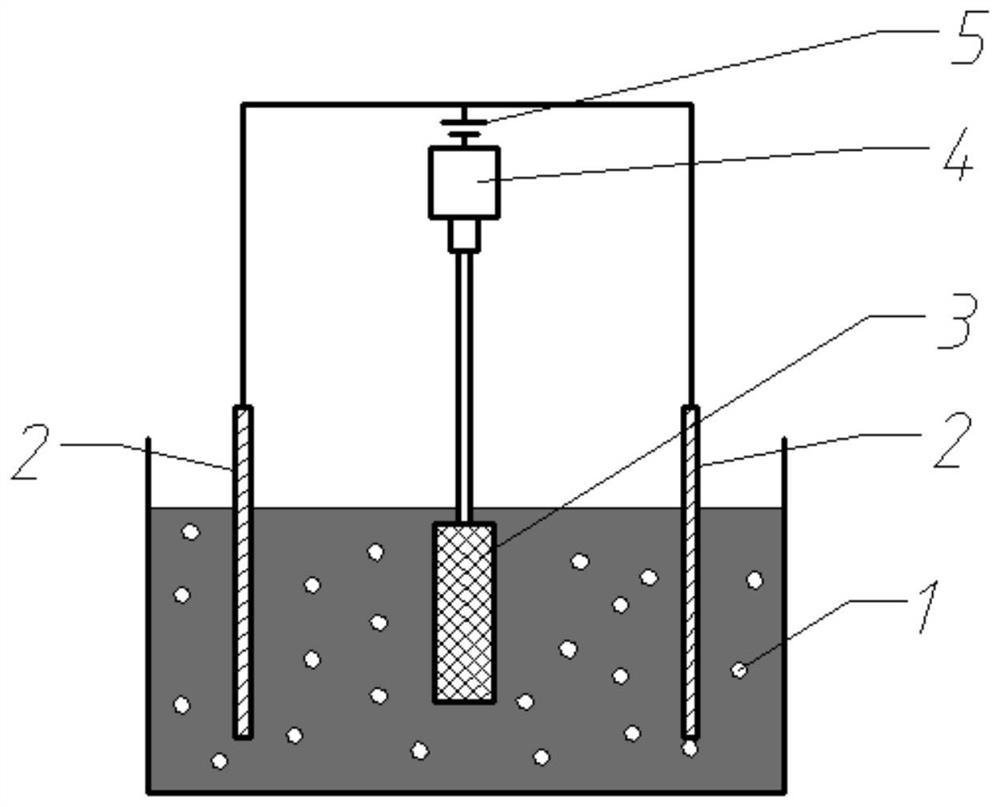

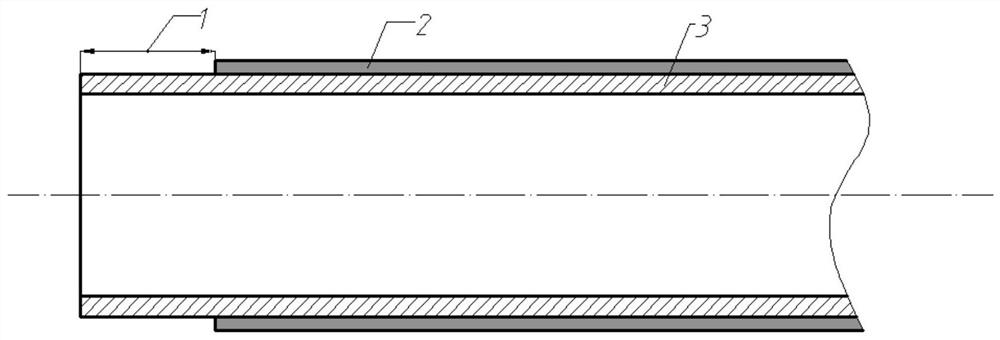

Method used

Image

Examples

Embodiment 1

[0030] The composition ratio of the copper-based graphene composite electrodeposition solution is: copper sulfate pentahydrate 120g / L, graphene 0.24g / L, polydisulfide sodium sulfonate concentration 50mg / L, chloride ion concentration 10mg / L , the balance is deionized water; the process environment of the deposition solution is: temperature is 45°C, pH=3.5, cathode rotation speed is 60r / min, and the electrical parameters of pulse electrodeposition are: 3V / -0.5V (10ms on / 5ms off). In this case and under the process conditions, the deposited layer has a flat surface, dull surface, poor compactness, and a thickness ratio of 24%. The thermal conductivity of the deposited layer can reach 456W / (m·K ), the heat dissipation efficiency of the high-flux heat exchange tube is increased by 10%.

Embodiment 2

[0032] The composition ratio of the copper-based graphene composite electrodeposition solution is: copper sulfate pentahydrate 120g / L, graphene 0.24g / L, polydisulfide sodium sulfonate concentration 40mg / L, chloride ion concentration 20mg / L , the balance is deionized water; the process environment of the deposition solution is: temperature is 55°C, pH=2.5, cathode rotation speed is 60r / min; the electrical parameters of pulse electrodeposition are: 3V / -0.5V (10ms on / 5ms off). In this case and under the process conditions, the deposited layer has a flat and uniform surface, dark surface, general compactness, and a thickness ratio of 25%. The thermal conductivity of the prepared deposited layer can reach 509W / (m·K ), the heat dissipation efficiency of the high-flux heat exchange tube is increased by 15%.

Embodiment 3

[0034] The composition ratio of the copper-based graphene composite electrodeposition solution is: copper sulfate pentahydrate 120g / L, graphene 0.24g / L, polydisulfide sodium sulfonate concentration 30mg / L, chloride ion concentration 30mg / L , the balance is deionized water; the process environment of the deposition solution is: temperature is 55°C, pH=1.5, cathode rotation speed is 60r / min; the electrical parameters of pulse electrodeposition are: 3V / -0.5V (10ms on / 5ms off). In this case and under the process conditions, the deposited layer has a smooth and uniform surface, bright surface, good compactness, and a thickness ratio of 30%. The thermal conductivity of the prepared deposited layer can reach 600W / (m·K) , The heat dissipation efficiency of high-flux heat exchange tubes has increased by 25%.

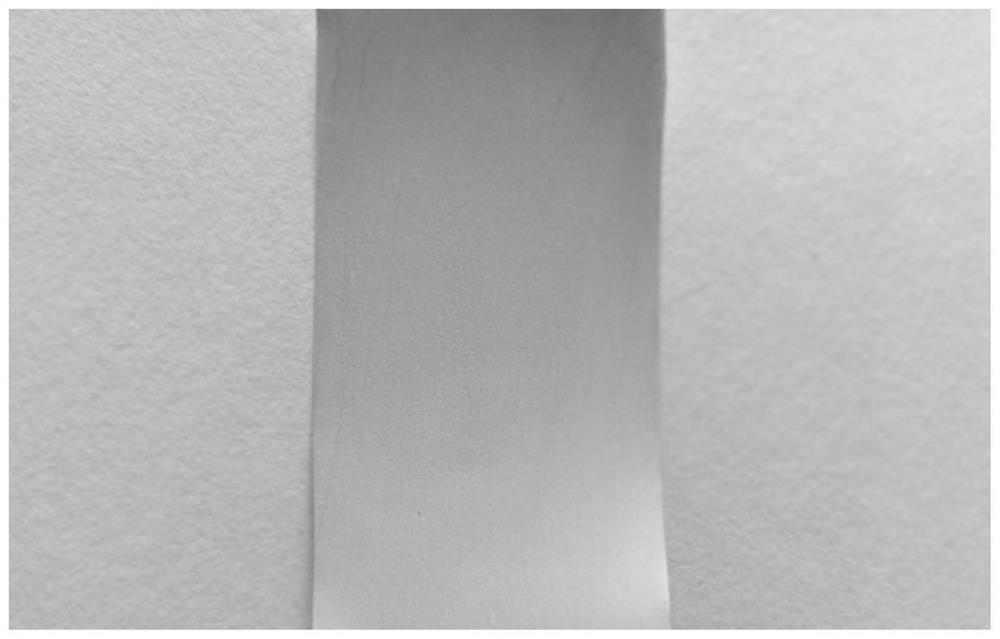

[0035] image 3 It is the deposition layer sample prepared by embodiment 3, the surface is bright, smooth and compact;

[0036] Figure 4 It is the SEM and EDS spectrogram of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com