Preparation method of coated controlled-release fertilizer and coating equipment thereof

A technology of controlled-release fertilizers and coatings, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as limited resource utilization and environmental impact, and achieve the effects of reducing soaking time, reducing waste, and saving production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

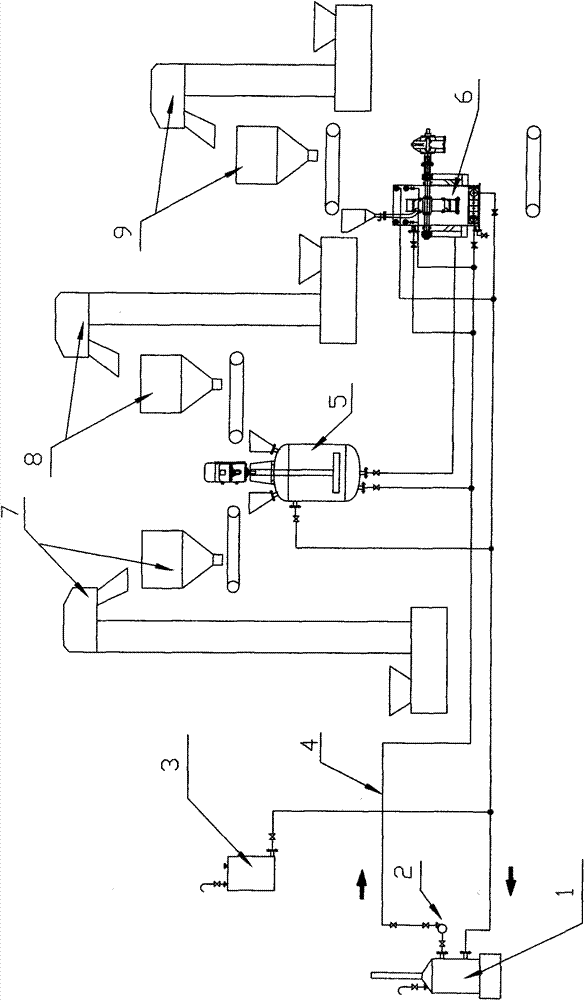

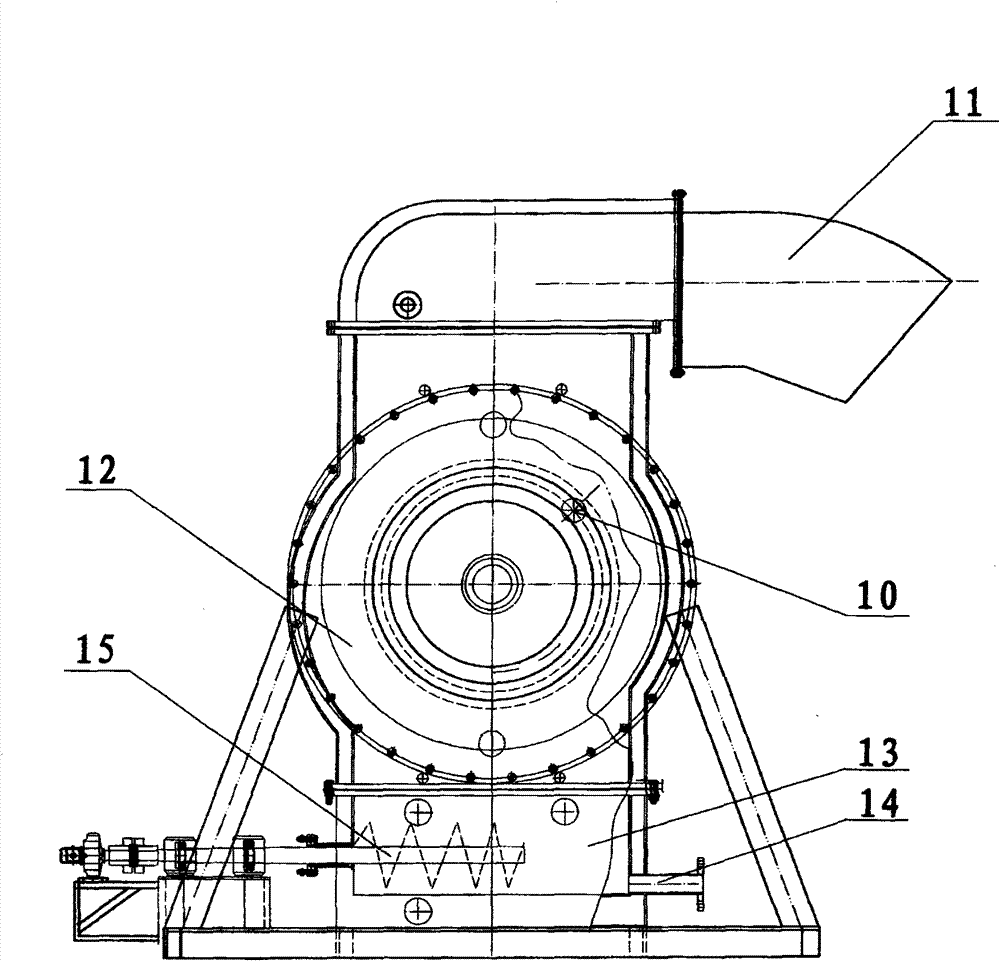

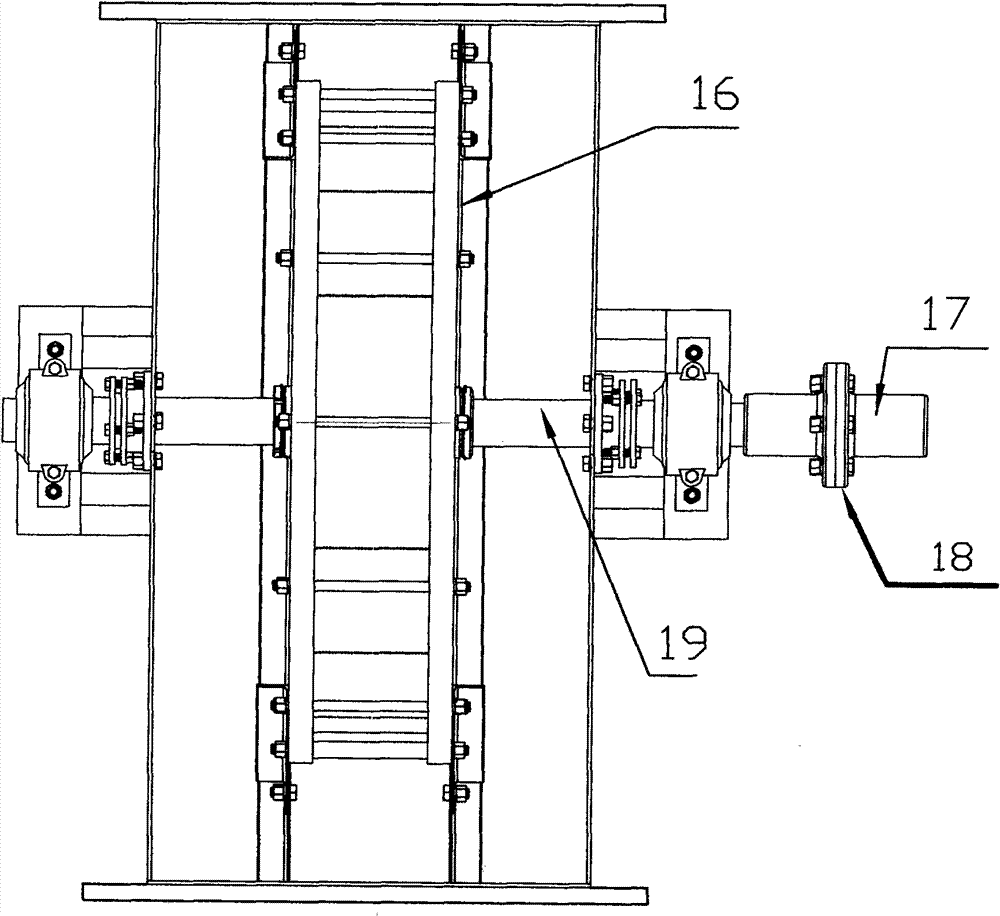

[0031] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] The coated fertilizer of the present invention includes fertilizer and its outer coating, wherein the fertilizer can be nitrogen fertilizer, phosphorus fertilizer, potash fertilizer or compound fertilizer, as long as it is round granular and the hardness of the fertilizer meets the requirements of the industry standard, coating can be carried out; The coating material adopts sulfur added with a regulator, so that the thickness of the coating is uniform, dense, complete, and free of cracks, which improves the strength of the coating and reduces the amount of coating material. It can not only ensure the slow release of nutrients in the early stage of the fertilizer, but also It can achieve the release of nutrients during the calibration period, effectively realize the controlled release of nutrients, and reduce the pollution to the envir...

Embodiment 2

[0059] The technological process of producing film-coated fertilizers, including:

[0060] Step 1: The sulfur is transported and measured by the sulfur conveying and measuring equipment 7, and added to the sulfur melting kettle 5, and heated and melted to form sulfur liquid.

[0061] Step 2: The regulator is transported and metered through the regulator conveying and metering device 8, and added to the sulfur melting kettle 5. The weight ratio of sulfur and regulator is: 100:18.

[0062] Step 3: keep heating, control the temperature in the sulfur melting kettle 5 within the range of 155°C to 180°C, and keep stirring to form a uniform liquid to form a coating liquid.

[0063] Step 4: Add the high-temperature coating liquid continuously into the sulfur-impregnated centrifugal coating machine 6 .

[0064] Step 5: Transport and measure the fertilizer granules at room temperature through the fertilizer granule conveying and metering device 9 , continuously add them to the sulfur-...

Embodiment 3

[0070] The technological process of producing film-coated fertilizers, including:

[0071] Step 1: The sulfur is transported and measured by the sulfur conveying and measuring equipment 7, and added to the sulfur melting kettle 5, and heated and melted to form sulfur liquid.

[0072] Step 2: The regulator is transported and metered through the regulator conveying and metering device 8, and added to the sulfur melting kettle 5. The weight ratio of sulfur and regulator is: 100:30.

[0073] Step 3: keep heating, control the temperature in the sulfur melting kettle 5 in the range of 120°C to 180°C, and keep stirring to form a uniform liquid to form a coating liquid.

[0074] Step 4: Add the high-temperature coating liquid continuously into the sulfur-impregnated centrifugal coating machine 6 .

[0075] Step 5: The fertilizer granules at room temperature are conveyed and measured by the fertilizer granule conveying and metering device 9, continuously added to the sulfur-impregnat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com