Manufacturing Method Of A Transfer Mold

A manufacturing method and mold technology, which can be used in the field of molds that can be used as transfer photo-curable adhesive films, can solve problems such as the decrease in the solid content of the coating, the influence of the flatness of the coating film, and the prolongation of the baking time, so as to achieve the effect and improve the manufacturing efficiency. , the effect of a simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the accompanying preferred embodiments are now described in detail with the accompanying drawings as follows, and the embodiments illustrated using the accompanying drawings are only used to illustrate the technical solution of the present invention , not to limit the present invention.

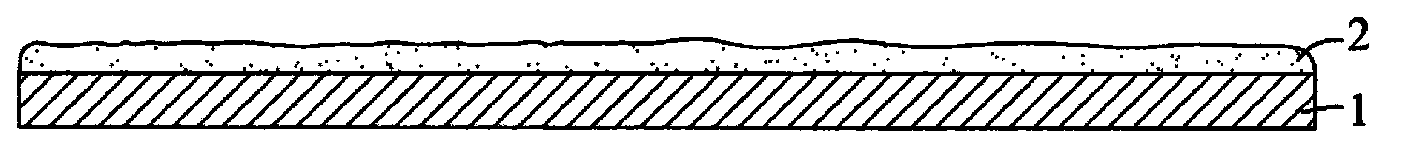

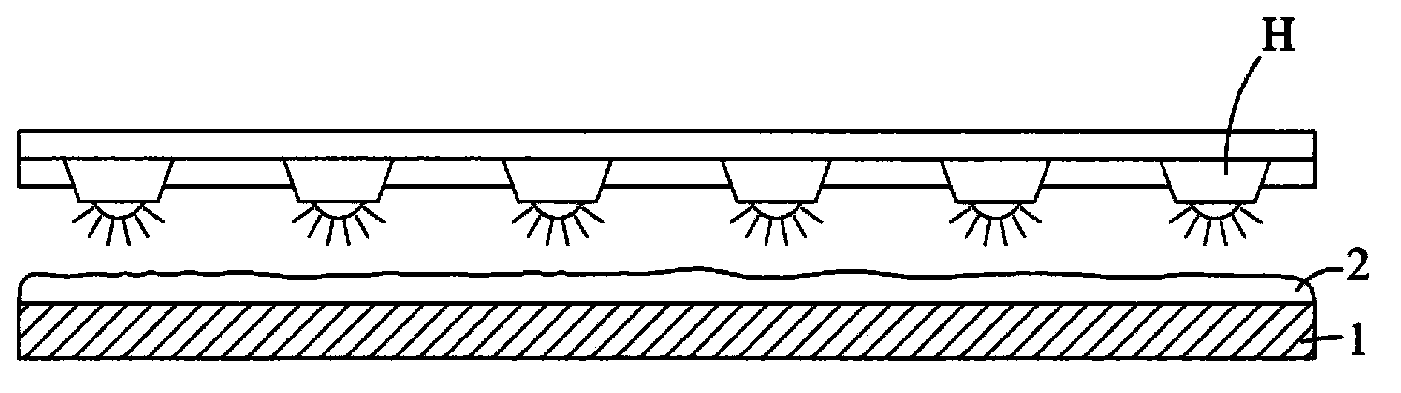

[0027] Please also see Figure 1A to Figure 1G and figure 2 , Figure 1A to Figure 1G It is a cross-sectional view of the manufacture of a preferred embodiment of the present invention, figure 2 It is a flow chart of the manufacturing method of a preferred embodiment of the present invention.

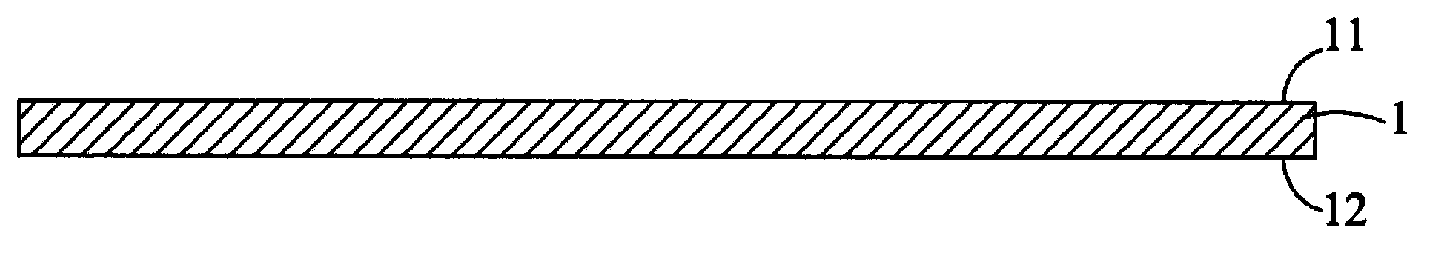

[0028] This embodiment includes the following steps: first, step S100, providing a light-transmitting substrate 1, such as Figure 1A shown. Wherein, the transparent substrate 1 may be made of polyethylene terephthalate (PET), polycarbonate (PC), polymethyl methacrylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com