Gap filling method of led lamp beads

A technology of LED lamp beads and gaps, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of limited luminous effect of phosphor powder, limited excitation effect of blue LED chips, etc., and achieve the effect of increasing the number of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

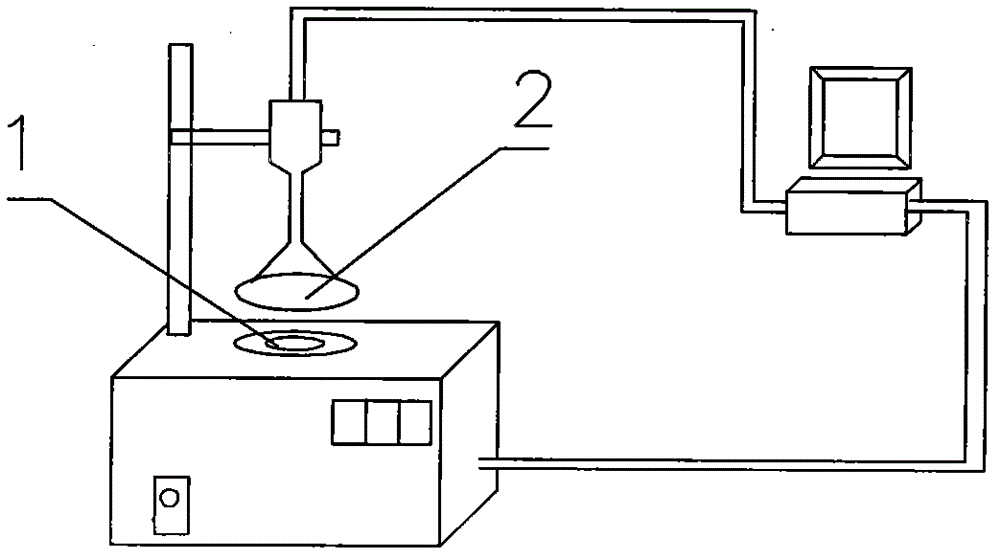

[0028] A gap filling method for LED lamp beads disclosed by the present invention, the first step is to polish the selected sapphire substrate, place the selected sapphire substrate on the supporting plate 1 of the polishing equipment, and adjust the polishing disc 2 to the supporting plate. Plate 1, and set the height that the polishing disc 2 rotates once a week; then adjust the rotating speed of the polishing disc 2; finally adjust the pressure that the polishing disc 2 applies to the sapphire substrate and start to polish the sapphire substrate, and the polishing disc 2 rotates for the first time The height dropped during one week of grinding was 30nm, and the height dropped by the polishing disc 2 increased by 80nm from the second week.

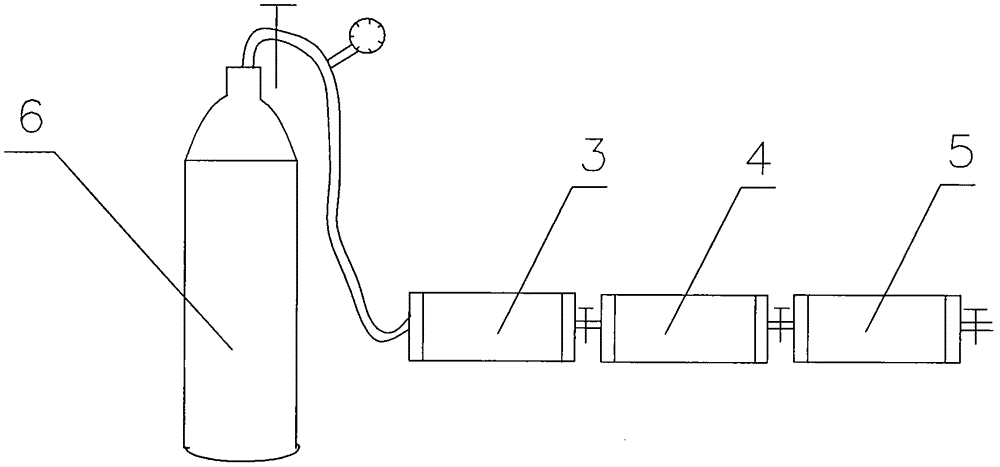

[0029] The second step is to screen the sapphire powder obtained by polishing. The screening equipment used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com