Thermally conductive sheet

A heat-conducting sheet and mesh technology, used in conductors, insulated conductors, semiconductor devices, etc., can solve the problems of wrinkles, elongation, and reduced operability, and achieve reduced surface area, high strength, and good operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〔

[0087] first embodiment [ Figure 1 to Figure 11 〕:

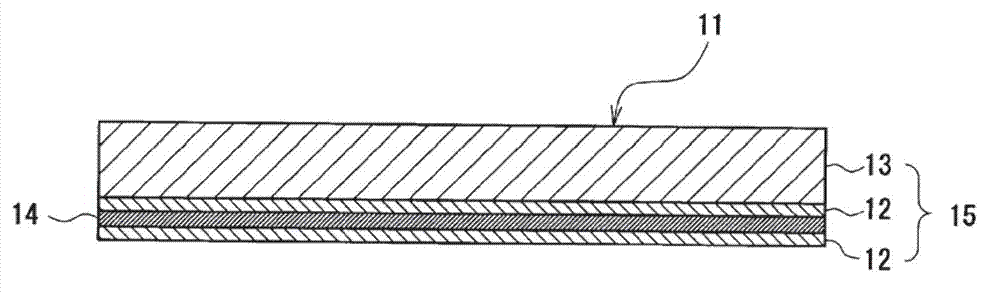

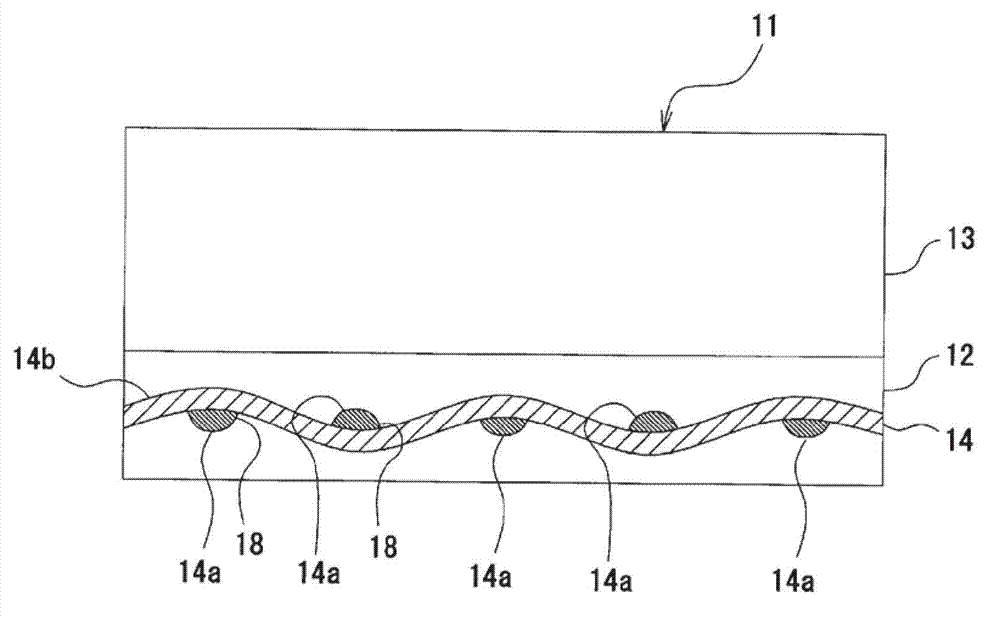

[0088] figure 1 A top view of the heat conducting sheet 11 is shown. The heat conduction sheet 11 is a component for electronic equipment with close adhesion between heating elements such as IC or CPU, or radiating elements such as heat sinks or heat pipes, and as figure 2 As shown in the sectional view of , a mesh sheet 14 is buried inside the sheet-shaped heat conduction layer 15 .

[0089] In this embodiment, in order to improve the operability, the heat conduction layer 15 adopts a double-layer structure of the adhesive layer 13 and the non-adhesive layer 12, and the mesh sheet 14 is embedded in the non-adhesive layer 12 in the heat conduction layer 15. Inside. The non-adhesive layer 12 is inserted into the mesh (through hole) formed in the grid-shaped mesh sheet 14, so that one side of the adhesive layer 13 side (interface with the adhesive layer 13) and the other surface of the outer surface side (outer surface ...

no. 2 example 〔 pic 12

[0130] In the above-mentioned embodiment, the heat conduction layer 15 has a laminated structure formed by the adhesive layer 13 and the non-adhesive layer 12, and the inside of the non-adhesive layer 12 is embedded with the mesh sheet 14, but the heat conduction sheet 21 shown in this embodiment is as follows: Figure 12 As shown, a mesh 14 is buried inside the adhesive layer 13 .

[0131] The heat conduction sheet 21 can be manufactured by the following method.

[0132] The mesh sheet 14 is embedded by the same method as the process of embedding the mesh sheet 14 in the non-adhesive layer 12 in the manufacture of the heat conduction sheet 11 shown in the previous embodiment in which the mesh sheet 14 is embedded in the non-adhesive layer 12. In the adhesive layer 13. In addition, the step of laminating the non-adhesive layer 12 on the adhesive layer 13 is performed by the same method as the step of laminating the adhesive layer 13 on the non-adhesive layer 12 . Thereby, ma...

no. 3 Embodiment 〔 pic 13

[0136] The heat conducting sheet 31 shown in this embodiment, as Figure 13 As shown, a mesh 14 is buried near the interface between the adhesive layer 13 and the non-adhesive layer 12 .

[0137] In the manufacture of the thermally conductive sheet 31 , firstly, the non-adhesive layer composition 16 constituting the non-adhesive layer 12 is coated on the film 2 . Next, on the coated non-adhesive layer composition 16 , the mesh sheet 14 is pressed and placed in an embedded manner. Subsequently, the non-adhesive layer composition 16 after dipping the mesh sheet 14 for about half a minute is coated with the adhesive layer composition 17 to form a sheet. Thereafter, by curing and molding the two thermally conductive compositions, the thermally conductive sheet 31 in which the mesh sheet 14 is embedded in the laminated interface of the non-adhesive layer 12 and the adhesive layer 13 can be obtained.

[0138] In addition, the order of the coating process of the non-adhesive layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com