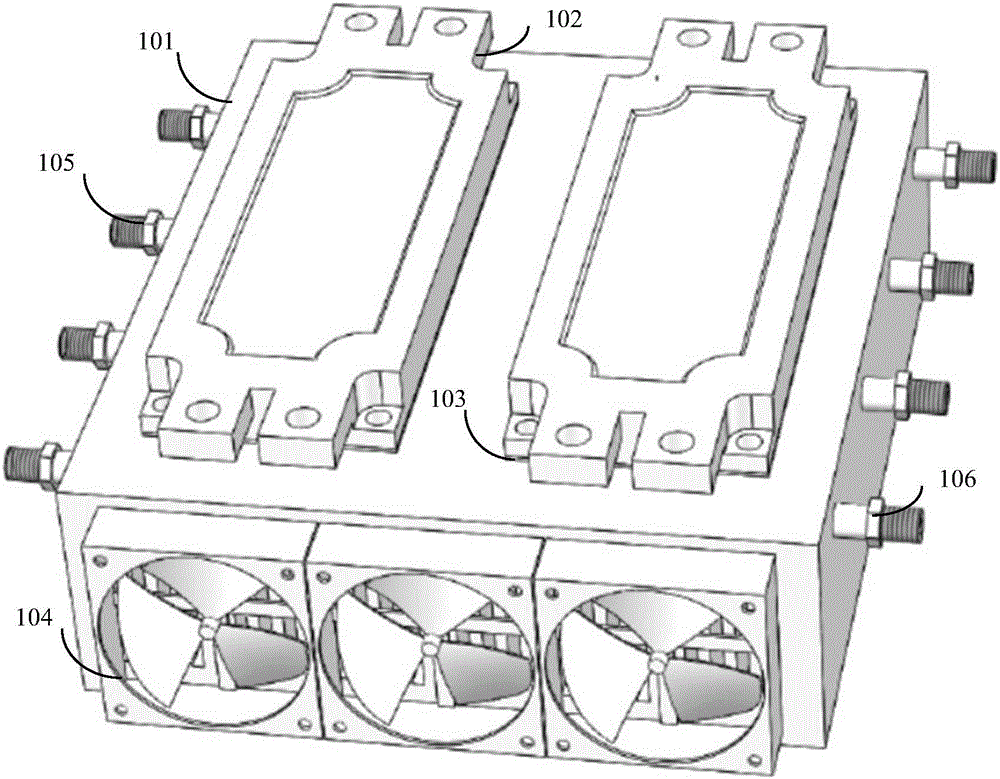

Air-cooling and water-cooling hybrid radiating module for large-power series connected IGBT (Insulated Gate Bipolar Translator)

A heat dissipation module, air-cooled and water-cooled technology, applied in the direction of cooling/ventilation/heating transformation, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems of single structure, large volume, concentrated heat generation, etc., and achieve super heat dissipation performance, the effect of ensuring thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

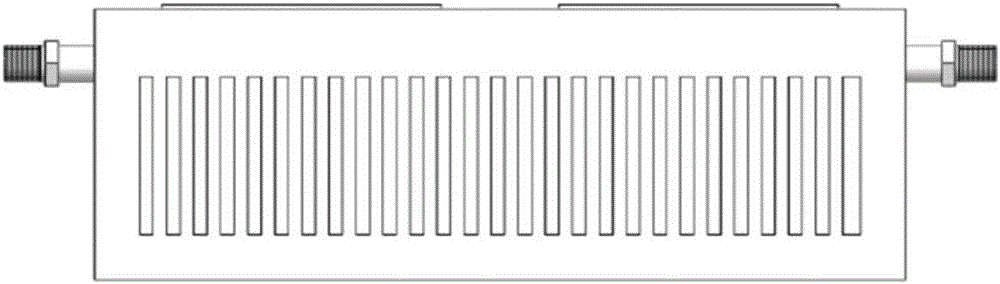

[0026] Example 1, such as Figure 5 Shown is a schematic diagram of the air-cooled water-cooled hybrid heat dissipation of the present invention; its structure includes a first radiator body 501, a first heat-conducting material 502, and a first fan 504; the first radiator body 501 includes an air-cooled channel and a water-cooled channel The IGBT module is installed on the front of the radiator through the first heat-conducting material 502; when performing heat dissipation, the air duct on the side of the radiator matches the size of the air outlet of the fan, and the air outlet of the first fan is sealed with the heat sink. Form forced air-cooled heat exchange. The water-cooling channels on the side of the radiator are arranged in parallel with the air-cooling channels with a constant distance. However, during operation, the wind direction of the air duct and the water flow direction of the water cooling channel are perpendicular to each other, forming a complementary heat...

Embodiment 2

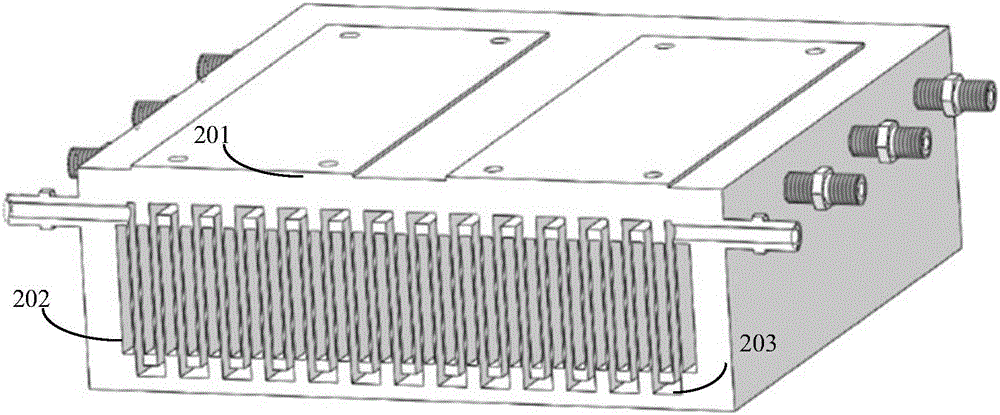

[0029] Example 2, such as Figure 6 Shown is a schematic diagram of water cooling and heat dissipation. In the figure, the water cooling channel is always open, and the fan on the air cooling channel is removed, and the air cooling channel does not work. The IGBT module is installed on the front of the radiator through heat-conducting materials; the water-cooling channels are interconnected in a bow-shaped arrangement. The side of the radiator is fed with water flow at a fixed velocity to form forced water cooling and heat exchange. And the circuitous flow mode is adopted, which can slow down the water flow speed, so that the heat of each part can be fully taken away by the water flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com