Explosion-proof combined cap of high-power battery

A power battery, high-power technology, used in battery pack components, circuits, electrical components, etc., can solve the problems of poor welding firmness, low welding strength, instability, etc., and improve the connection strength and deformation resistance. , Improve the surface anti-oxidation ability, improve the effect of high current passing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

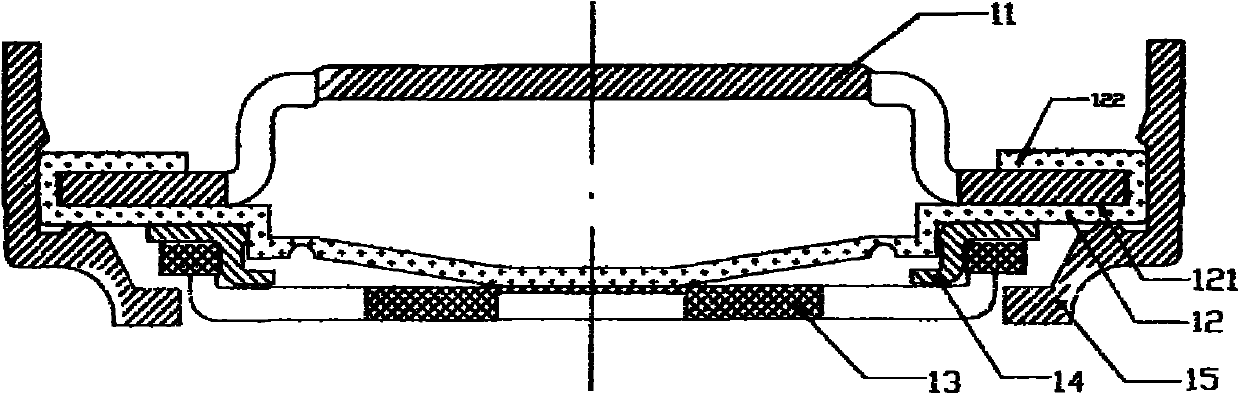

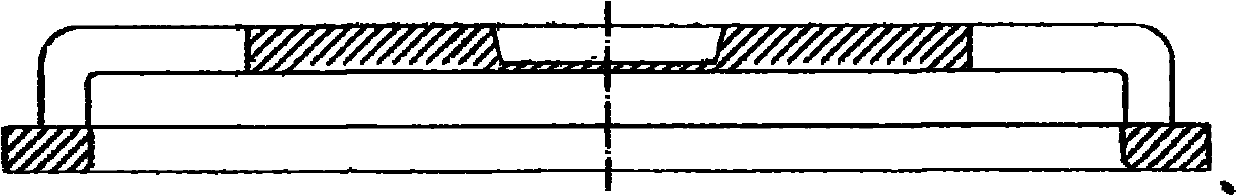

[0019] figure 1 It is a schematic cross-sectional view of an embodiment of an explosion-proof combination cap for a high-power power battery of the present invention. As shown in the figure, the explosion-proof combination cap 10 of this embodiment includes a steel cap 11, an explosion-proof plate 12, a connecting piece 13, an isolation ring 14 and the above four elements. Or the sealing ring 15 covered by the outer circumference. In particular, in the combined cap embodiment of the present invention, a nickel-plated layer 121 is added on the surface of the explosion-proof disk 12 , and a solder connection is adopted between the steel cap 11 and the explosion-proof disk 12 .

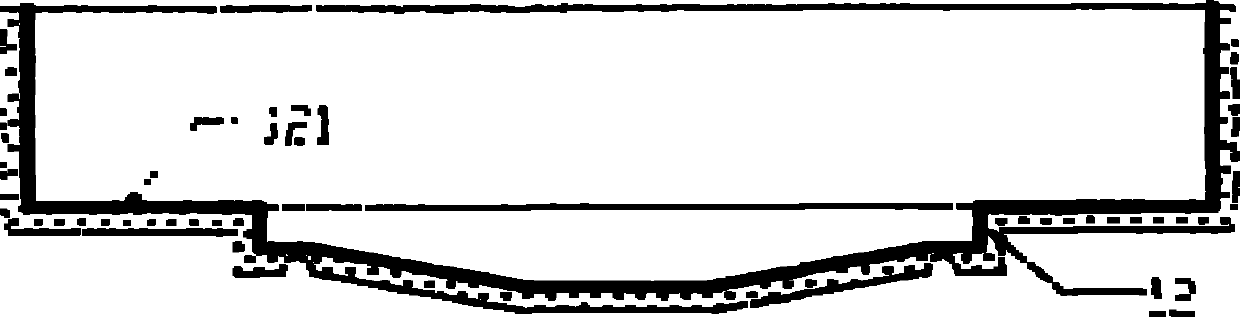

[0020] continue as figure 1 As shown, in this embodiment, the explosion-proof disk 12 is an aluminum sheet with a nickel-plated layer 121 on its inner surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com