Manufacturing technology of protective belt component of automobile safety belt

A manufacturing process and seat belt technology, applied in the manufacturing process of belt components, can solve the problems of single function, restricting the safety protection of drivers and passengers, and being unable to provide safety protection functions, etc., to achieve reasonable structural design, enhanced wear resistance, Comfortable material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

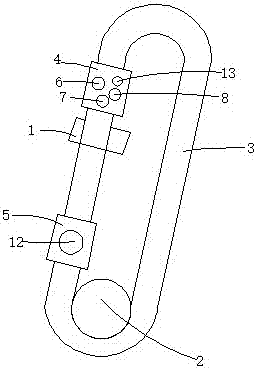

[0026] see figure 1 and figure 2 , the present invention provides a car safety belt, comprising: a buckle 1, a belt take-up 2, a webbing 3 arranged between the buckle 1 and the belt take-up 2, a chest protector sleeved on the webbing 3 Belt 4, the waist belt 5 set on the webbing 3, the heart rate sensor 6 and the blood pressure sensor 7 set on the chest belt 4, and the heart rate sensor set on the chest belt 4 6. A vibrator 8 electrically connected to the blood pressure sensor 7;

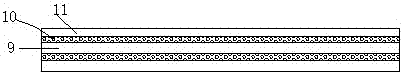

[0027] Both the chest support belt 4 and the waist support belt 5 include a substrate layer 9, honeycomb energy-absorbing layers 10 respectively arranged on both sides of the substrate layer 9, and jackets respectively arranged on both sides of the two honeycomb energy-absorbing layers 10 Layer 11.

[0028] Specifically, the car seat belt further includes a Bluetooth module 12 electrically connected to the heart rate sensor 6 and the blood pressure sensor 7 .

[0029] Specifically, the car safe...

Embodiment 2

[0032] A kind of manufacturing process of the protective belt assembly of automobile safety belt, the steps are as follows:

[0033] ①, structure and molding

[0034] The support belt assembly, including the chest support belt and the waist support belt, both include a substrate layer, two honeycomb energy-absorbing layers respectively arranged on both sides of the substrate layer, and outer jacket layers respectively arranged on both sides of the two honeycomb energy-absorbing layers;

[0035] Both the base layer and the coat layer are made of nylon material; the honeycomb energy-absorbing layer is made of EVA foam material;

[0036] ②, pretreatment

[0037] Soak the base layer and the coat layer in the pretreatment solution for at least 15 minutes, take them out, drain them, and then dry them at 60°C;

[0038] The pretreatment liquid is composed of 17 parts of polyurethane resin, 6 parts of ultrafine polytetrafluoroethylene powder, 4 parts of titanium dioxide, 5 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com