Copper alloy and copper alloy plate and preparation method and application thereof

A copper alloy and plate technology, applied in the field of metal materials, can solve problems such as environmental pollution, and achieve the effects of solving environmental pollution, good corrosion resistance, and improving surface oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

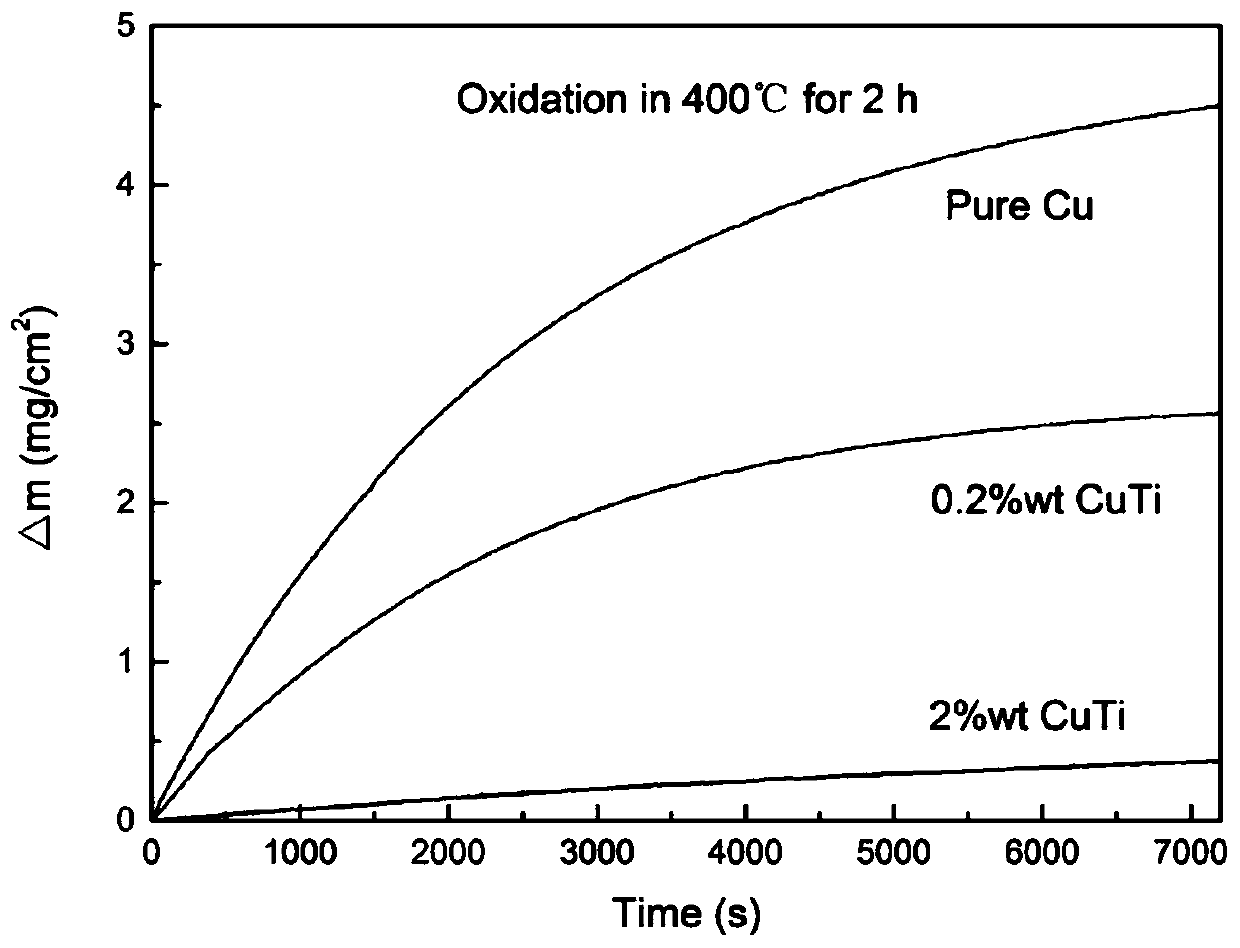

[0033] A copper alloy containing 0.2wt% of Ti and the remainder consisting of Cu and unavoidable impurities.

[0034] In the present embodiment, the preparation method of described copper alloy, the steps are as follows:

[0035] 1) Mix 0.2g of granular titanium with a purity of 99.99% and 99.8g of granular pure copper with a purity of 99.99% to obtain a mixture, wherein the titanium is a cylinder with a diameter of 3mm and a height of 5mm, and the specifications of pure copper are the same , it should be noted that block or granular samples must be used for smelting, one is that block or granular samples are easy to melt uniformly, and the other is because the samples required by the embodiment of the present invention have higher purity, so the melting furnace used is argon Gas shielding gas vacuum melting furnace, the instantaneous high temperature of the melting furnace will make the powder sample volatilize, which is prone to danger;

[0036] 2) The mixture is placed in ...

Embodiment 2

[0043] A copper alloy containing 2 wt % of Ti and the remainder consisting of Cu and unavoidable impurities.

[0044] In the present embodiment, the preparation method of described copper alloy, the steps are as follows:

[0045] 1) Mix 2g of granular titanium with a purity of 99.99% and 98g of granular pure copper with a purity of 99.99% to obtain a mixture, wherein the titanium is a cylinder with a diameter of 3mm and a height of 5mm, and the specification of pure copper is the same as that of pure copper. It should be noted that block or granular samples must be used for smelting, one is that block or granular samples are easy to melt evenly, and the other is because the samples required by the embodiment of the present invention have high purity, so the melting furnace used is protected by argon Gas vacuum melting furnace, the instantaneous high temperature of the melting furnace will make the powder sample volatilize, which is prone to danger;

[0046] 2) Put the mixed m...

Embodiment 3

[0051] A copper alloy containing 1 wt% of Ti and the remainder consisting of Cu and unavoidable impurities.

[0052] In the present embodiment, the preparation method of described copper alloy, the steps are as follows:

[0053] 1) Mix 1g of granular titanium with a purity of 99.99% and 99g of granular pure copper with a purity of 99.99% to obtain a mixture, wherein the titanium is a cylinder with a diameter of 3mm and a height of 5mm, and the specification of pure copper is the same as that of pure copper. It should be noted that block or granular samples must be used for smelting, one is that block or granular samples are easy to melt evenly, and the other is because the samples required by the embodiment of the present invention have high purity, so the melting furnace used is protected by argon Gas vacuum melting furnace, the instantaneous high temperature of the melting furnace will make the powder sample volatilize, which is prone to danger;

[0054] 2) Put the mixed ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com