Vibration-damping and noise-reducing jacket for railway steel rail

A technology for vibration reduction and noise reduction, rails, applied in the direction of rails, roads, tracks, etc., can solve the problems of poor rail noise radiation effect of rail muffler, far insufficient restraint damping treatment, strong visual impact, etc., and achieve the effect of shock reduction and noise reduction Significant, obvious noise reduction effect, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

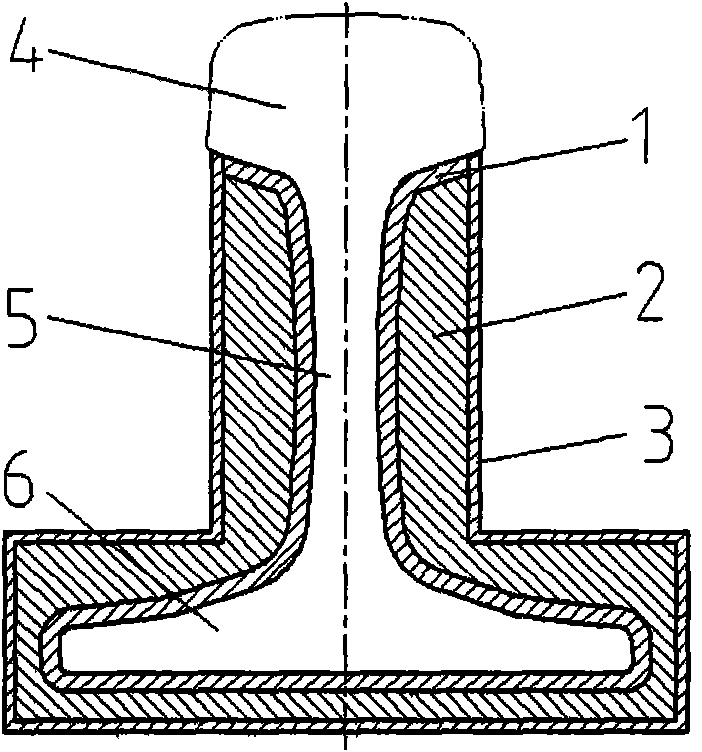

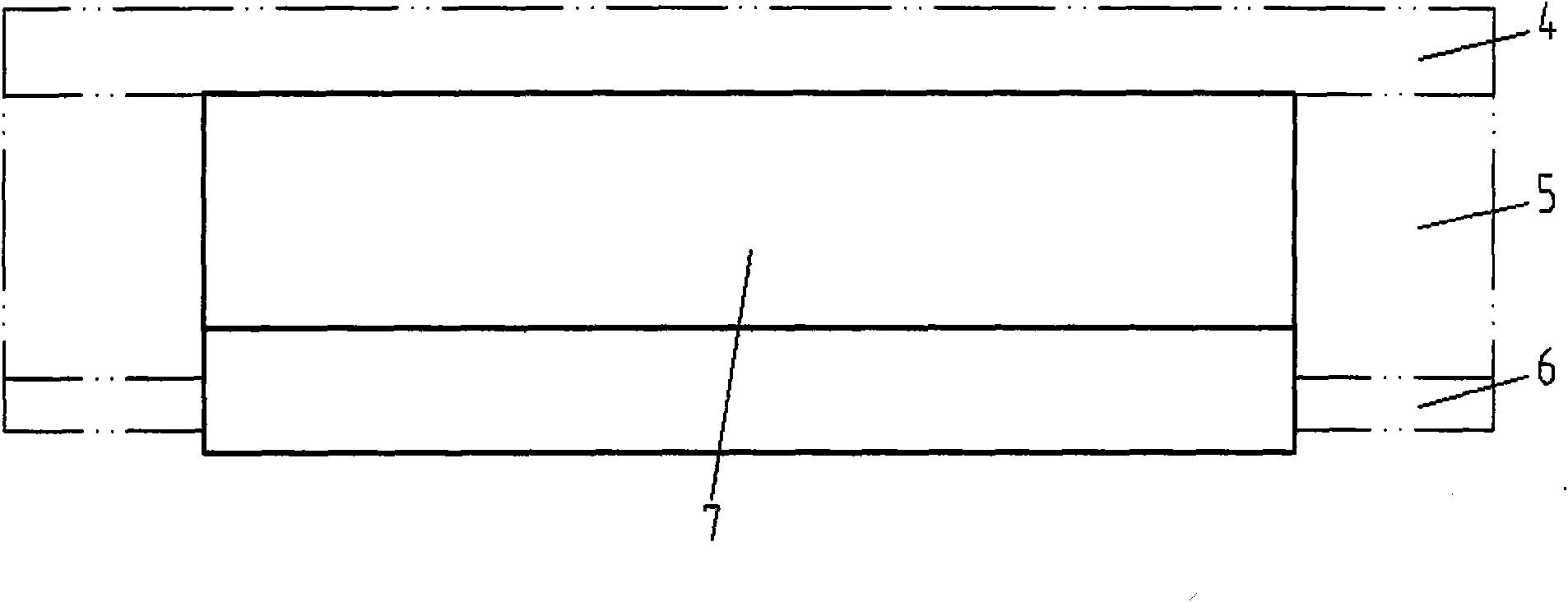

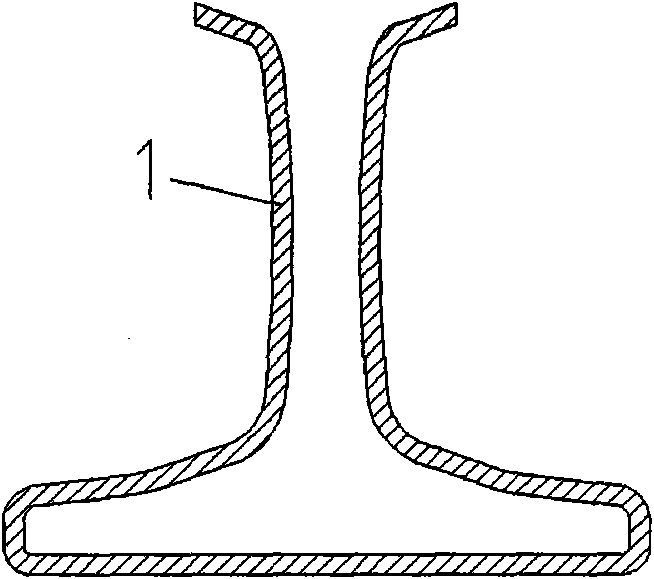

[0021] see Figure 1~2 The vibration and noise reduction sheath is composed of a grooved expansion layer 1 coated on the rail bottom 6 and rail waist 5 symmetrically along the rail center line, an inverted T-shaped constraining layer 3 arranged outside the grooved expansion layer 1 and pasted on the The damping layer 2 is formed between the grooved expansion layer 1 and the constraining layer 3 . 7 in the figure is the body of the local vibration noise reduction sheath, and the double-dot dash line is the outline of the rail. The vertical edges on both sides of the constraint layer 3 are connected to the lower end of the rail head, and together with the rail waists with different widths at different heights, the damping layer 2 pasted between the expansion layer 1 with grooves and the constraint layer 3 forms a variable thickness structure. Figure 3-5 A schematic diagram of the structure of the expansion layer with slots is given. 8 is a groove among the figure. Figure 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com