LDMOS device and forming method thereof

A device and doping type technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve the effect of constant breakdown voltage or small change, reduced point voltage, and large drive current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

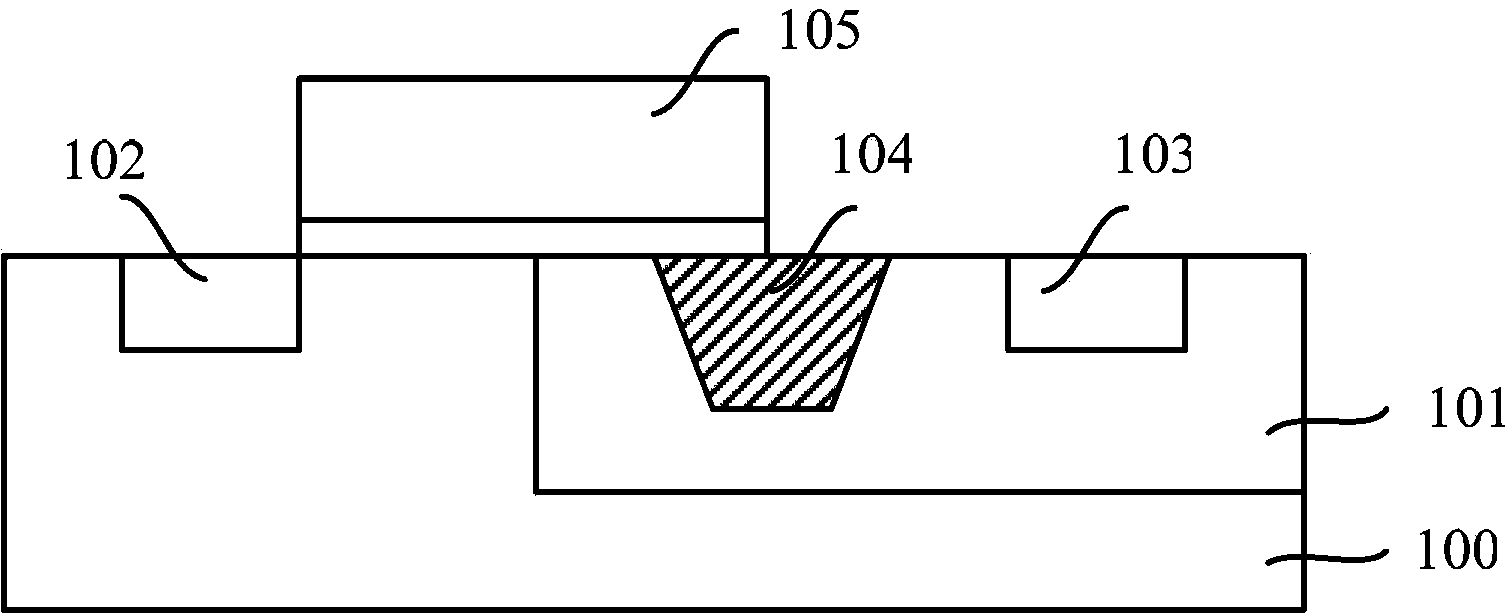

[0033] Please refer to figure 1 , in the production of existing LDMOS devices, in order to make the LDMOS device have a higher breakdown voltage, one of the ways is to form a shallow trench isolation structure 104 in the N-type drift region 101, and another way is to reduce the N The doping concentration of the type drift region 101 (or low doping concentration), but the above two methods will increase the on-resistance (equivalent on-resistance) between the source region 102 and the drain region 103 of the LDMOS device. Large, when the LDMOS device is working, when a certain operating voltage is applied to the source region 102 and the drain region 103, the driving circuit between the source region 102 and the drain region 103 will be reduced, that is, when the above method increases the driving voltage of the LDMOS device , the driving current of the LDMOS device under the same source-drain operating voltage will be correspondingly reduced, which is not conducive to the impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com