Orderly heterogeneous nano-wire flexible conductive film and preparation method thereof

A technology of nanowires and thin films, applied in the field of nanometers, can solve problems such as the inability to realize conductance regulation, and achieve the effect of simple steps and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

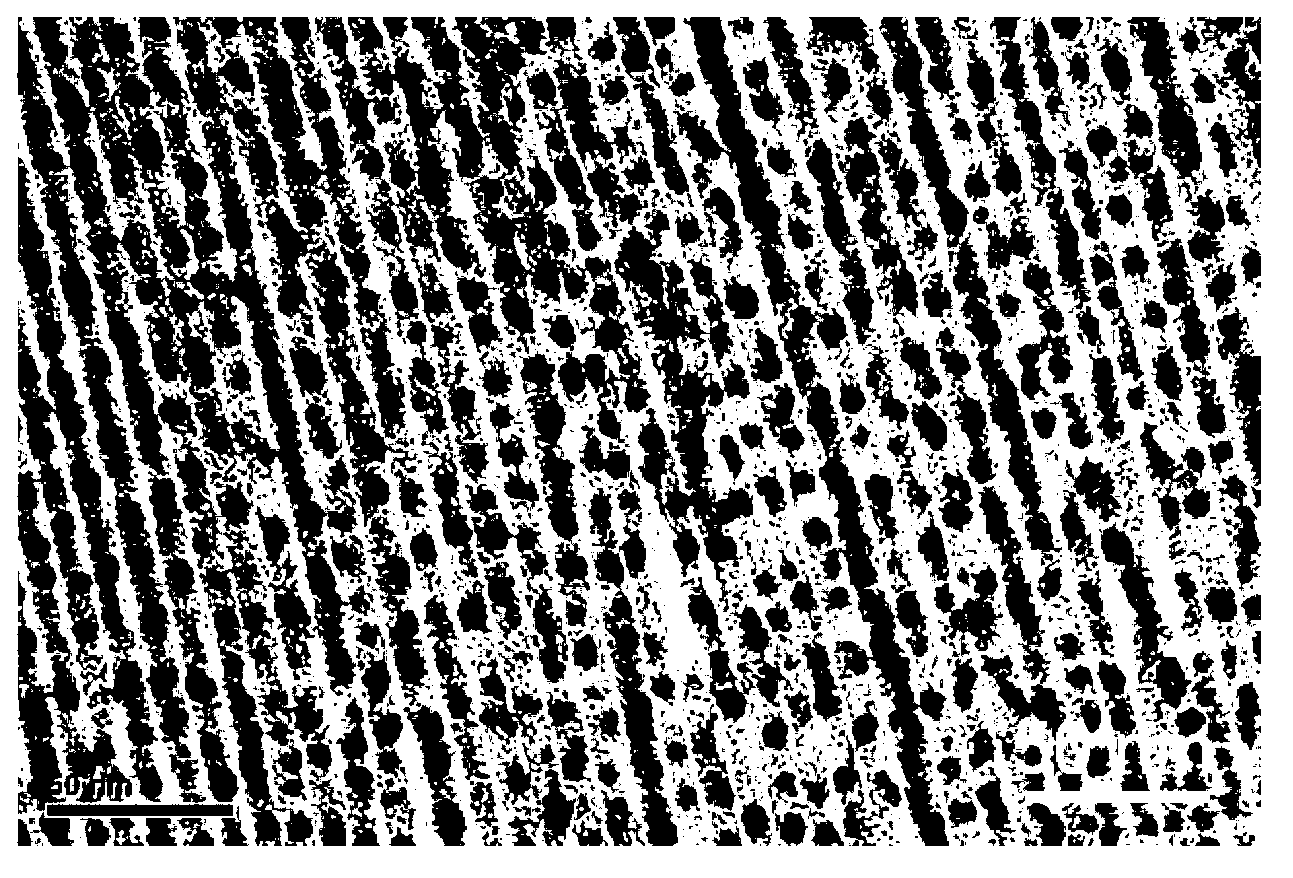

[0029] The invention provides a macro-preparation method of an ordered nanowire-nanoparticle heterogeneous assembly. The method includes the following steps: firstly prepare a tellurium nanowire by a hydrothermal method, and then obtain a tellurium nanowire by an LB assembly method. wire assembly, and then use the tellurium nanowire assembly as a template to generate a tellurium-gold assembly by reacting with a chloroauric acid solution.

[0030] After the nanomaterial assembly is obtained, it also preferably includes: transferring the nanowire film assembly to various substrates by layer-by-layer assembly, or transferring the single-layer one-dimensional nanowire film from the water-air interface to a flat surface Flexible substrates, such as: PET substrates or ordinary commercial filter paper substrates, provide the premise and guarantee for the development of the properties of nanomaterials and the design and performance of nanowire-based devices to be practical.

[0031] I...

Embodiment 1

[0039] Example 1: Preparation of Tellurium Nanowire Assembly

[0040] 1. Synthesis of tellurium nanowires with a diameter of 7 nm

[0041] Add 1.000 grams of polyvinylpyrrolidone (PVP) (Shanghai Reagent Company, molecular weight ≈40,000), 0.0922 grams of sodium tellurite (Na 2 TeO 3 ), 33 milliliters of water, 1.67 milliliters of mass percent are hydrazine hydrate of 85% and 3.33 milliliters of mass percent are the ammoniacal liquor of 25~28%; Adopt magnetic stirring to reach homogeneous solution in 10 minutes; Put polytetrafluoroethylene reactor into steel cover, After reacting at 180° C. for 3 hours and cooling naturally, a mother liquor containing tellurium nanowires with a diameter of 7 nanometers and a length of hundreds of micrometers was obtained.

[0042] 2. Preparation of tellurium nanomaterial assemblies

[0043] Take 5 ml of the above-mentioned tellurium nanowire mother liquor, add 12 ml of acetone, perform centrifugation at 5000 rpm for 5 minutes, and remove the...

Embodiment 2

[0045] Example 2: Preparation of tellurium-gold heterogeneous nanowire film

[0046] The preparation of the tellurium nanomaterial assembly is the same as in Example 1.

[0047] The above pressed tellurium nanowire assembly was transferred to a glass substrate, and then the substrate was dried. 0.0202 g of chloroauric acid (HAuCl 4 4H 2 O) dissolved in 20 milliliters of deionized water and stirred evenly. Then put the above-mentioned glass substrate carrying the tellurium nanowire assembly into the above-mentioned aqueous solution of auric acid chloride, take it out after 600 seconds and dry it to obtain the tellurium-gold heterogeneous nanowire assembly. In this process, the thickness of the tellurium nanowire film (that is, the number of layers) and the reaction time with the chloroauric acid aqueous solution can be adjusted, and will affect the resistance of the final film. Taking the ten-layer nanowire film as an example, the thickness of the nanowire film made accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com