High barrier and high tolerance composite proton exchange membrane and preparation method thereof

A proton exchange membrane, high barrier technology, applied in the field of proton exchange membrane, can solve the problems of high permeability and high cost, and achieve the effect of improving elastic modulus, broad application prospects, good barrier properties and mechanical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

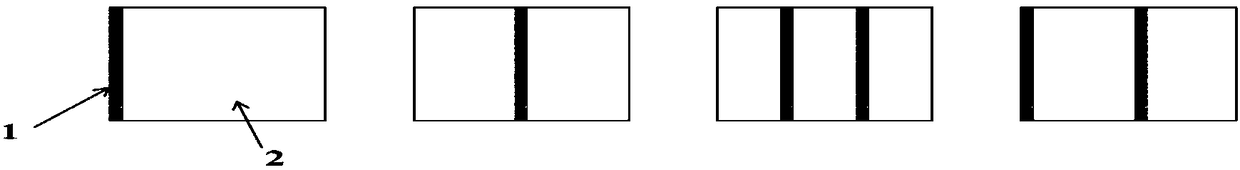

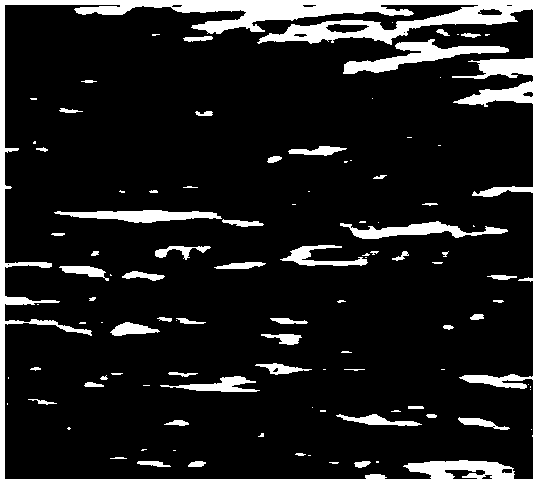

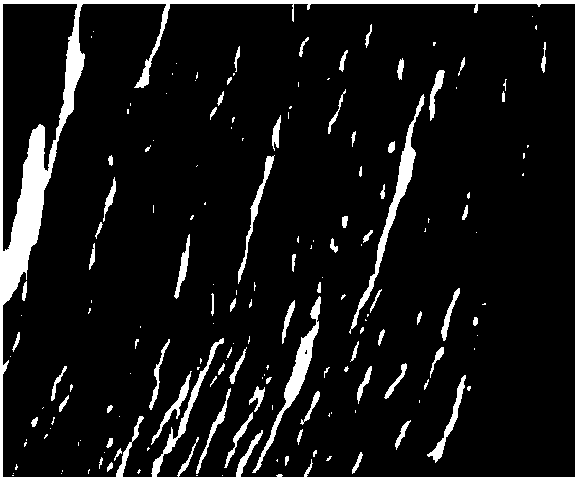

Image

Examples

Embodiment 1

[0045] Dilute the purchased graphene oxide aqueous solution to a concentration of 0.5mg / mL, take 2L of the diluted graphene oxide aqueous solution and add it to a three-necked flask, add 2mL of hydrazine hydrate to it through a constant pressure funnel, stir well and put it in a 95°C oil bath After reacting for 1 h, the obtained uniform black reduced graphene oxide solution was suction-filtered through a membrane filter, and then vacuum-dried at 50° C. to obtain an alignment layer with a metallic luster and a thickness of 2 μm.

[0046] The prepared alignment layer is placed on the base film material, and the perfluorosulfonic acid resin hydroalcoholic solution (water:ethanol=1:1) with a solid content of 25wt.% is applied by solution casting, and the resin solution is infiltrated into the reduction oxidation After the graphene alignment layer, the wet film was dried in an oven for 2 hours, the temperature gradient was 45°C, 80°C, and 120°C, and the thickness of the proton excha...

Embodiment 2

[0048] Dilute the concentration of the purchased graphene oxide aqueous solution to 0.5 mg / mL, take 2L of the diluted graphene oxide aqueous solution and filter it through a membrane filter to obtain a 2 μm thick graphene oxide film, then immerse it in hydroiodic acid and heat it at 100 °C React for 1 h under the condition of an oil bath, then wash with ethanol and acetone successively, and dry in vacuum to obtain a black reduced graphene oxide alignment layer with metallic luster.

[0049] The DMF solution of sulfonated polyether ether ketone resin with a solid content of 18wt.% is casted and coated through a die, and the above-prepared orientation layer is coated on the resin liquid film, and the material is cast again through a die. , after the resin solution penetrated into the reduced graphene oxide alignment layer, the wet film was dried in an oven for 4 hours with a temperature gradient of 90°C and 170°C, and the thickness of the proton exchange membrane was 50 μm.

Embodiment 3

[0051] Dilute the concentration of the purchased graphene oxide aqueous solution to 0.5mg / mL, take 6L of the diluted graphene oxide aqueous solution and filter through a membrane filter to obtain two 3 μm thick graphene oxide films, which are immersed in hydroiodic acid and heated at 100 The reaction was carried out under the condition of an oil bath at ℃ for 2 hours, and then washed with ethanol and acetone successively, and dried in vacuum to obtain a black reduced graphene oxide alignment layer with metallic luster.

[0052]A perfluorosulfonic acid resin hydroalcoholic solution (water: isopropanol = 4:6) with a solid content of 19 wt% is cast on the base film material through a die head, and then one of the alignment layers prepared above is Cover it on the resin liquid film, and wait until the resin solution penetrates into the reduced graphene oxide orientation layer, and then cast the material on the die head; cover the prepared second orientation layer on the resin liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com