Electric heating textile based on carbon nano tubular membrane

A carbon nanotube film and fabric technology, which is applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of uneven temperature distribution of carbon fiber heating materials, low safety of heating materials, and easy breaking of metal heating wires. Flexible and thin, high thermal conversion rate, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

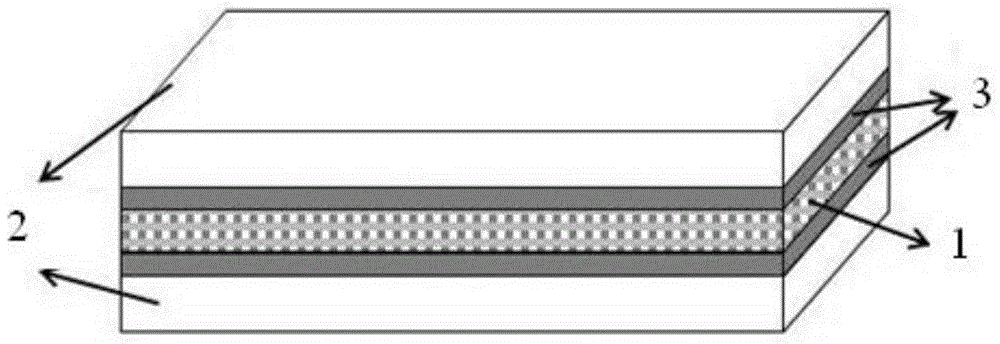

[0024] Embodiment 1 Flexible light and thin electrothermal cotton fabric

[0025] In this example, the carbon nanotube film prepared by the vertical floating catalytic process manufactured by Suzhou Jiedi Nano Technology Co., Ltd. was used. The carbon nanotube film has a thickness of 20 microns, a strength of 200 MPa, and a conductivity of 500 S / cm, such as image 3 shown. The fabric protective layer is made of pure cotton woven fabric, which has the characteristics of good hygroscopicity and alkali resistance. The adhesive layer is made of thermoplastic PE film with a melting point of 100-110°C, and the heat-generating layer and the fabric protective layer are bonded by hot pressing (such as figure 1 shown). The hot pressing machine adopts a vulcanizing machine, the temperature of the upper and lower bottom plates is set to 110°C, the pressure is 3 MPa, the preheating time is 1 minute, and the hot pressing time is 1 minute. After the hot pressing is finished, place it on ...

Embodiment 2

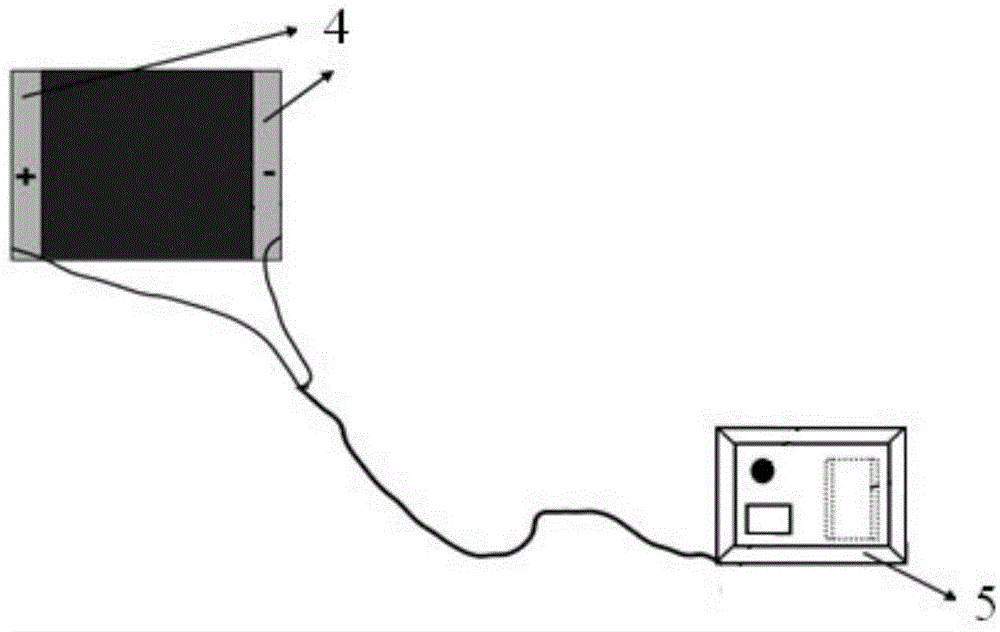

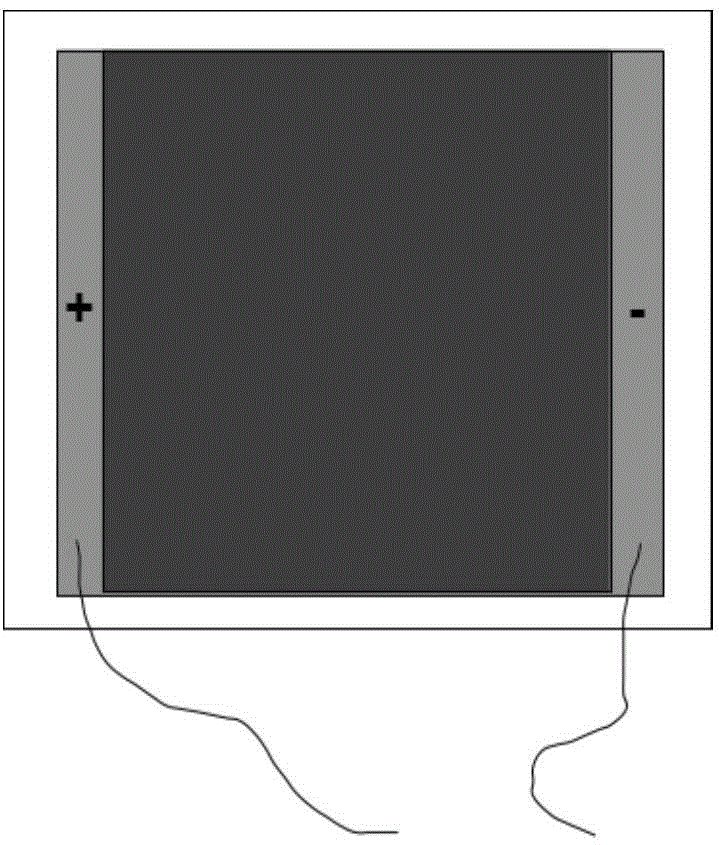

[0027] Embodiment 2 Waterproof breathable polyester electric heating fabric

[0028] In this embodiment, the heat generating layer adopts carbon nanotube films arranged in parallel strips, such as Figure 4 As shown, flexible electrode sheets are assembled on both sides of the strip-shaped carbon nanotube film, and the electrode sheet and the carbon nanotube film are connected by conductive glue to form positive and negative electrodes. The fabric protective layer is made of polyester fabric, its elastic modulus is 60-80cN / dtex, and its melting point is 240-250°C. The adhesive layer is made of waterproof and breathable PU, and the heating layer and the fabric protective layer are directly bonded and fixed by brushing, and the composite fabric is compacted when the composite pressure is 5 MPa and the composite temperature is 30 ° C. Make it evenly bonded. After bonding, place it in the fume hood for 24 hours, then connect the flexible electrode sheet with the wire and the con...

Embodiment 3

[0030] Embodiment 3 Scratch-resistant electric heating fabric

[0031] In this embodiment, the heating layer adopts a carbon nanotube film arranged in a monolithic manner, such as image 3 shown. The protective layer uses high-density nylon woven fabric as the fabric protective layer. Nylon is a common fabric for down jackets and mountaineering suits. It has low density, light fabric, good elasticity, and fatigue damage resistance. The fabric protection layer and the heat generating layer are bonded by means of PU coating. And when the composite pressure is 6 MPa and the composite temperature is 30° C., the composite fabric is compacted to make it evenly bonded. After bonding, place it in a fume hood for 24 hours. Select both sides of the carbon nanotube film to assemble flexible electrode sheets, and connect the two through conductive glue to form the positive and negative electrodes. The electrode sheet is connected with a wire and a controller, and the controller is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com