Method of preparing carbon-coated metal nanowire conductive thin film

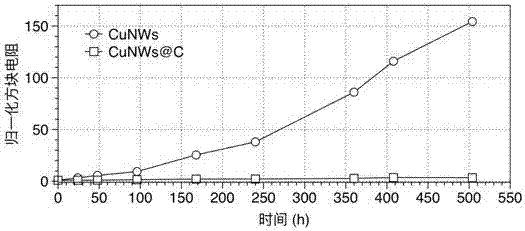

A metal nanowire, conductive thin film technology, applied in the field of solar cells, can solve the problems of damage to the conductivity of the thin film, corrosion, damage to the conductivity and light transmittance of the thin film, etc., to achieve controllable carbon film thickness, improve stability, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

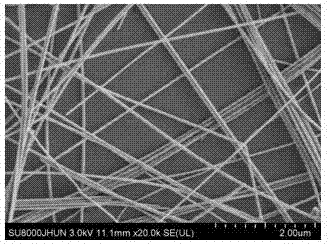

[0020] The preparation method of the copper nanowire used in the following examples is as follows:

[0021] Dissolve 50mg cuprous chloride dihydrate, 300 hexadecylamine, and 150mg glucose in 20ml deionized water, heat at 100°C for 6 hours to generate copper nanowires, and disperse them in isopropanol to obtain a copper nanowire dispersion after purification.

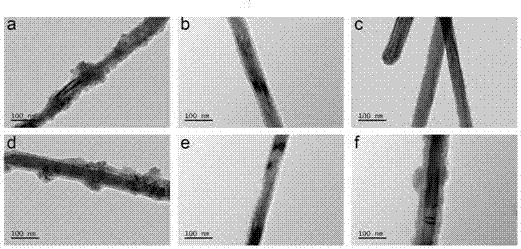

Embodiment 1

[0023] (1) Prepare 15ml of a mixed solution of isopropanol and water, wherein the volume ratio of isopropanol to water is 2, and then add 0.5g of glucose into the solution.

[0024] (2) Add 18.75 mg of copper nanowires to the solution of (1).

[0025] (3) Put the solution of (2) in a 30ml hydrothermal reaction kettle and react at 170°C for 3 hours.

[0026] (4) Centrifuge and wash.

Embodiment 2

[0028] (1) Prepare 15ml of a mixed solution of isopropanol and water, wherein the volume ratio of isopropanol to water is 1, and then add 1.5g of glucose to the solution.

[0029] (2) Add 18.75 mg of copper nanowires to the solution of (1).

[0030] (3) Put the solution of (2) in a 30ml hydrothermal reaction kettle and react at 170°C for 3 hours.

[0031] (4) Centrifuge and wash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com