Manganese dioxide/graphene lithium ion battery cathode material and preparation method thereof

A lithium-ion battery, manganese dioxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low capacity and unstable cycle performance of manganese dioxide/graphene materials, saving time and cost , The preparation process is simple and the operability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

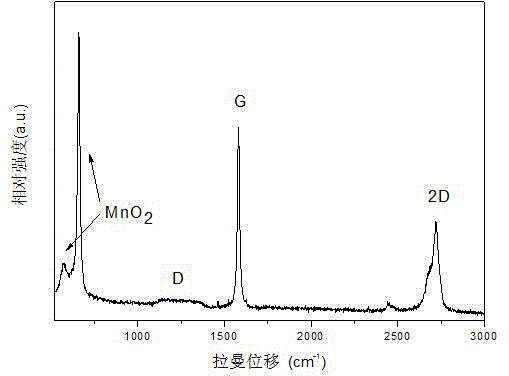

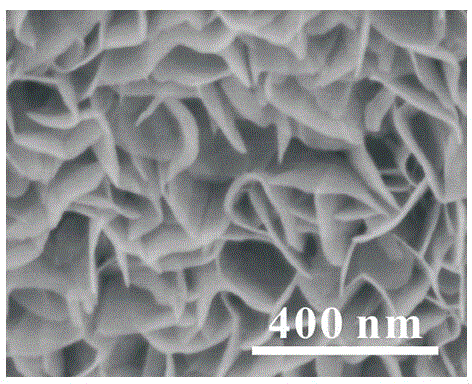

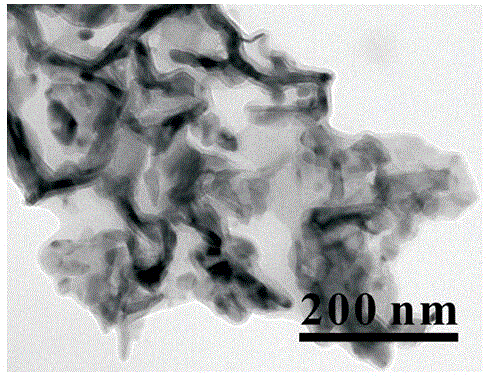

[0052] Manganese dioxide / graphene of the present invention (MnO 2 / GF) Lithium-ion battery negative electrode material and its preparation method. Its preparation method comprises the following steps:

[0053] (1) Preparation of three-dimensional graphene foam by chemical vapor deposition;

[0054] (2) Add potassium permanganate and manganese sulfate monohydrate into ultrapure water and stir evenly to obtain a mixed solution;

[0055] (3) Add the mixed solution into the inner tank of a high-temperature-resistant closed stainless steel reactor, then add the three-dimensional graphene foam prepared in step (1) into the inner tank of the stainless steel reactor, and then tighten the stainless steel reactor and place it Heating in a program-controlled oven and maintaining a constant temperature to separate and react the compound;

[0056] (4) washing the compound obtained in step (3) with water and ethanol, drying in vacuum, and then annealing at a constant temperature under ga...

Embodiment 1

[0058] (1) 0.60 mg of three-dimensional graphene foam was prepared by chemical vapor deposition.

[0059] (2) Take 0.4mmol of potassium permanganate and 0.15mmol of manganese sulfate monohydrate, add them into 20mL of ultrapure water and stir evenly to form a mixed solution.

[0060] (3) Add the mixed solution into the high-temperature-resistant closed stainless steel reactor liner, then add the three-dimensional graphene foam prepared in step (1) into the stainless steel reactor liner, and then tighten the stainless steel reactor and place it in the Heating to 140° C. in a program-controlled oven and maintaining the temperature for 12 hours. The resulting complex was isolated from the reaction.

[0061] (4) Wash the compound obtained in step (3) with water and ethanol, then vacuum-dry it, and then put it into annealing at 450°C for 2 hours under the condition of argon gas flow rate of 100 sccm to obtain a manganese dioxide / graphene lithium-ion battery composite Negative mat...

Embodiment 2

[0068] (1) 0.80 mg of three-dimensional graphene foam was prepared by chemical vapor deposition.

[0069] (2) Take 2 mmol of potassium permanganate and 0.5 mmol of manganese sulfate monohydrate, add them into 50 mL of ultrapure water and stir evenly to obtain a mixed solution.

[0070] (3) Add the mixed solution into the high temperature-resistant closed stainless steel reactor inner tank, then add the three-dimensional graphene foam prepared in step (1) into the stainless steel reactor inner tank, then tighten the stainless steel reactor and place it in the program Heating to 100° C. in a controlled oven and maintaining a constant temperature for 20 h, and separating the complex obtained from the reaction.

[0071] (4) The compound obtained in step (3) was washed with water and ethanol, dried in vacuum, and then annealed at 100°C for 4 hours under an air flow rate of 300 sccm to obtain a manganese dioxide / graphene lithium-ion battery composite Negative material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com