Bipolar plate for a high-temperature fuel cell, and manufacturing method thereof

A technology for high-temperature fuel cells and manufacturing methods, which is applied in the direction of fuel cells, fuel cell components, and final product manufacturing. Good sealing and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

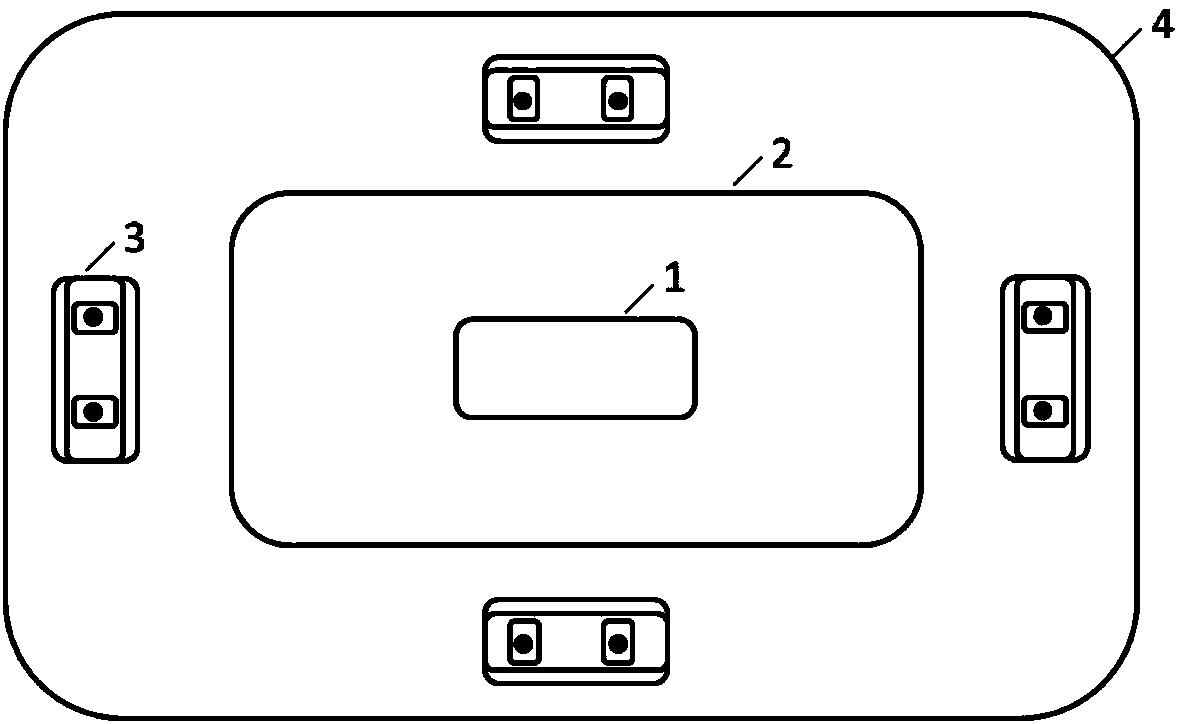

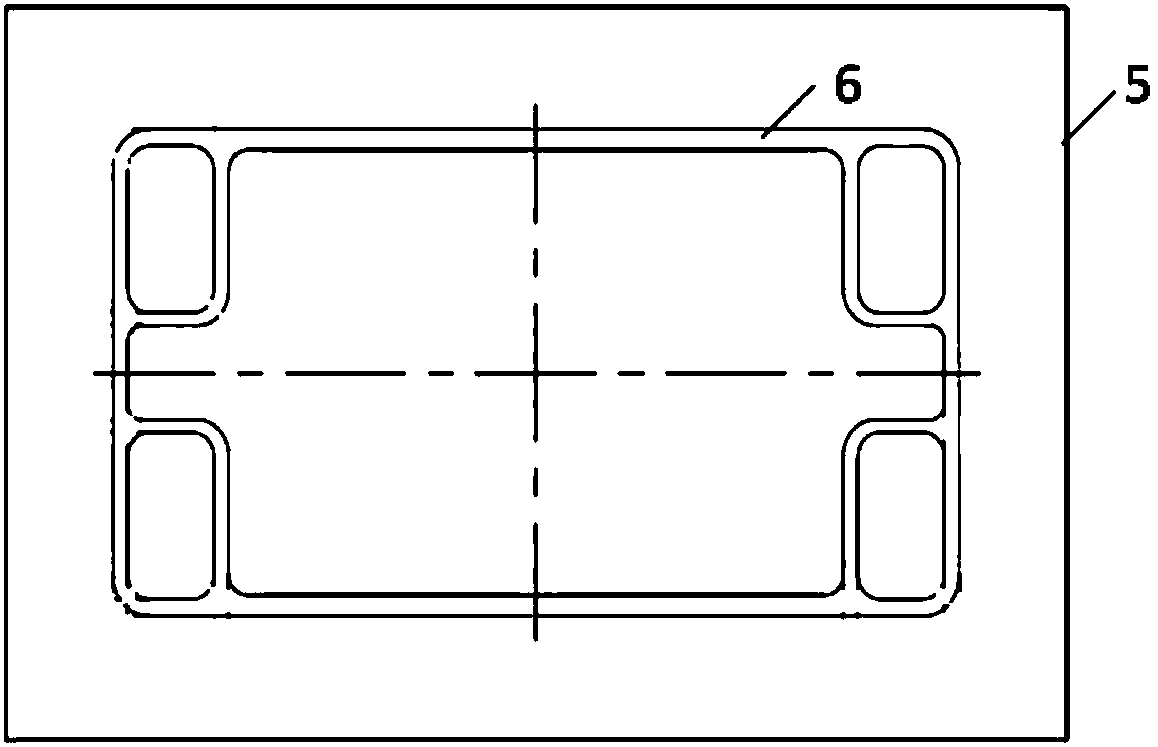

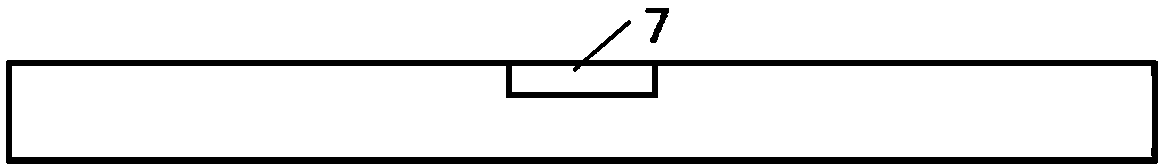

[0029] Example 1: Both the cathode plate and the anode plate are graphite composite plates, wherein the anode has flow channels on one side, and the cathode has flow channels on both sides, and grooves are engraved on the periphery of the side of the cathode plate with cooling medium flow channels, and the groove depth is 20 μm. Put the cathode plate ( Figure 4 8) placed in the groove of the positioning plate (such as figure 1 In 1) shown, the side with the cooling medium flow channel and the groove faces upward. Then spread the glue solution (viscosity 10000cPs) with a temperature resistance of 204°C on the screen printing screen (such as figure 2 As shown in 6) above (the mesh number of the screen is 100 mesh, the thickness of the sealing film is 50), and first use a scraper to evenly coat it, then put down the screen, scrape it with a scraper, remove the screen, and take out the cathode plate , the glue in the groove around the cathode plate ( Figure 4 10) The thickne...

Embodiment 2

[0032] Example 2: Both the cathode plate and the anode plate are graphite composite plates, wherein the anode side has flow channels, the cathode has flow channels on both sides, and there are no grooves around the two electrode plates. Put the cathode plate ( Figure 4 8) placed in the groove of the positioning plate (such as figure 1 In 1) as shown, select a high-temperature glue solution with a temperature resistance of 300°C and a 150-mesh screen printing screen, adopt the same screen printing process as in Example 1, adjust the screen printing parameters, and control the peripheral surface of the cathode plate Glue ( Figure 4 In 11) the thickness is 20 μm, then adopt the same positioning and curing as in Example 1 (high temperature adhesive thickness 15 μm after curing) gained graphite composite bipolar plate such as Figure 5 shown.

[0033] Using the same sealing test method as in Example 1, no leakage was found, and the test temperature was increased to 200° C., an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com