Nanowire cold cathode electron source array with self-aligned focusing structure and manufacturing method thereof

A production method and nanowire technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as difficult control of beam current, imaging distortion, intake, etc., and solve complex electrode lead layout problem, improve the effect of divergence problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

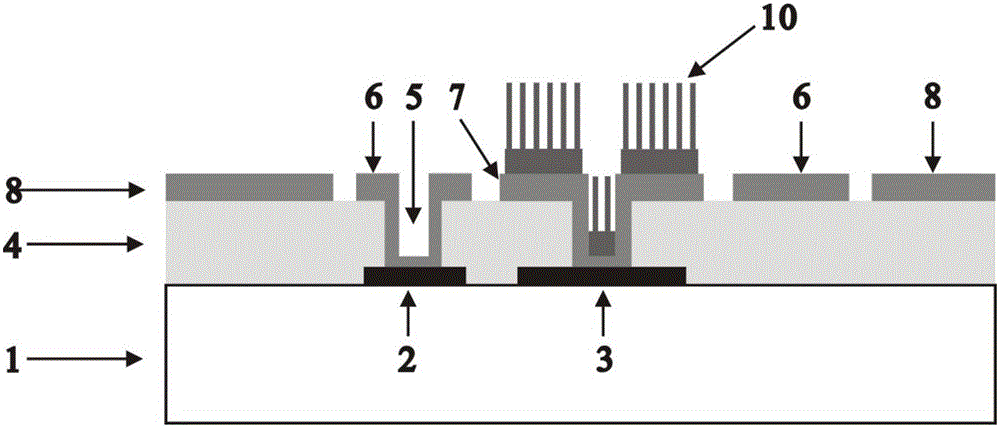

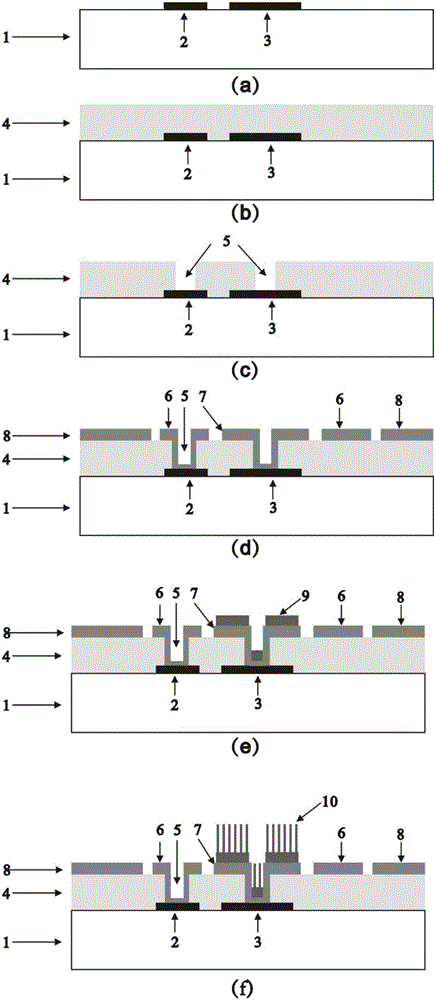

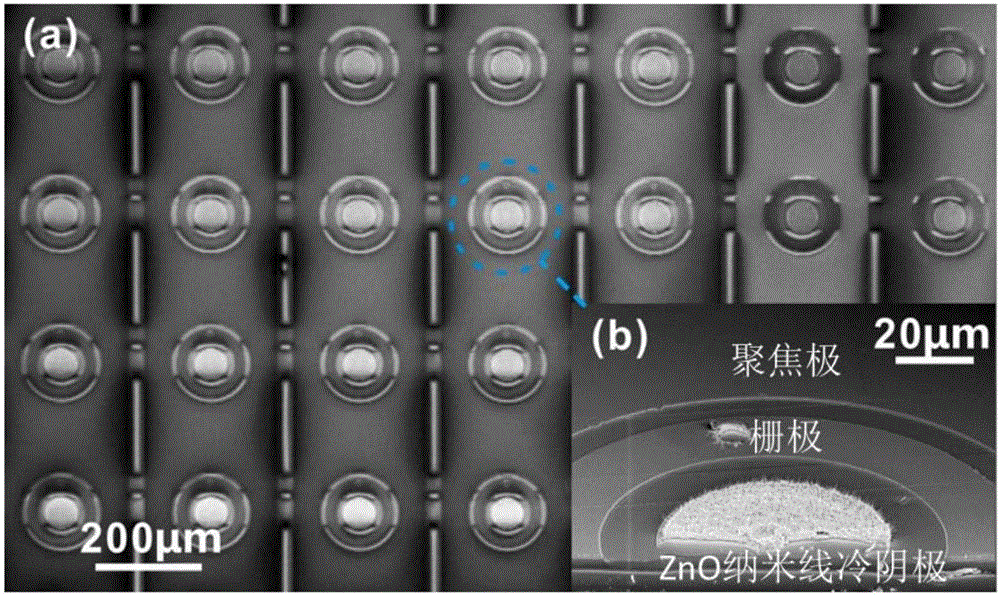

[0057] This example presents the manufacturing process of a nanowire cold cathode electron source array with a self-aligning focusing structure that uses zinc oxide nanowires as the cold cathode material and can be addressed row by row. For specific manufacturing process steps, please refer to the attached figure 2 .

[0058] First, the glass substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 20 minutes, and then blown dry with nitrogen. On the glass substrate, the bottom cathode electrode strips and the bottom grid electrode strips parallel to each other are prepared by photolithography, DC magnetron sputtering vacuum coating technology and lift-off process. The material of the two bottom electrode strips is chromium, and its thickness is about 120nm. Next, a layer of insulating film is deposited on the above two bottom electrode strips by means of plasma enhanced chemical vapor deposition. The insulating film is a silicon dioxide film with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com