Ultrathin film of transparent high-strength and high-conductivity electrical self-supporting carbon nano-tube and preparation method thereof

A carbon nanotube film, carbon nanotube technology, which is applied in cable/conductor manufacturing, conductors, circuits, etc. Support film and other issues to achieve excellent comprehensive mechanical properties, improved electrical conductivity and strength, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

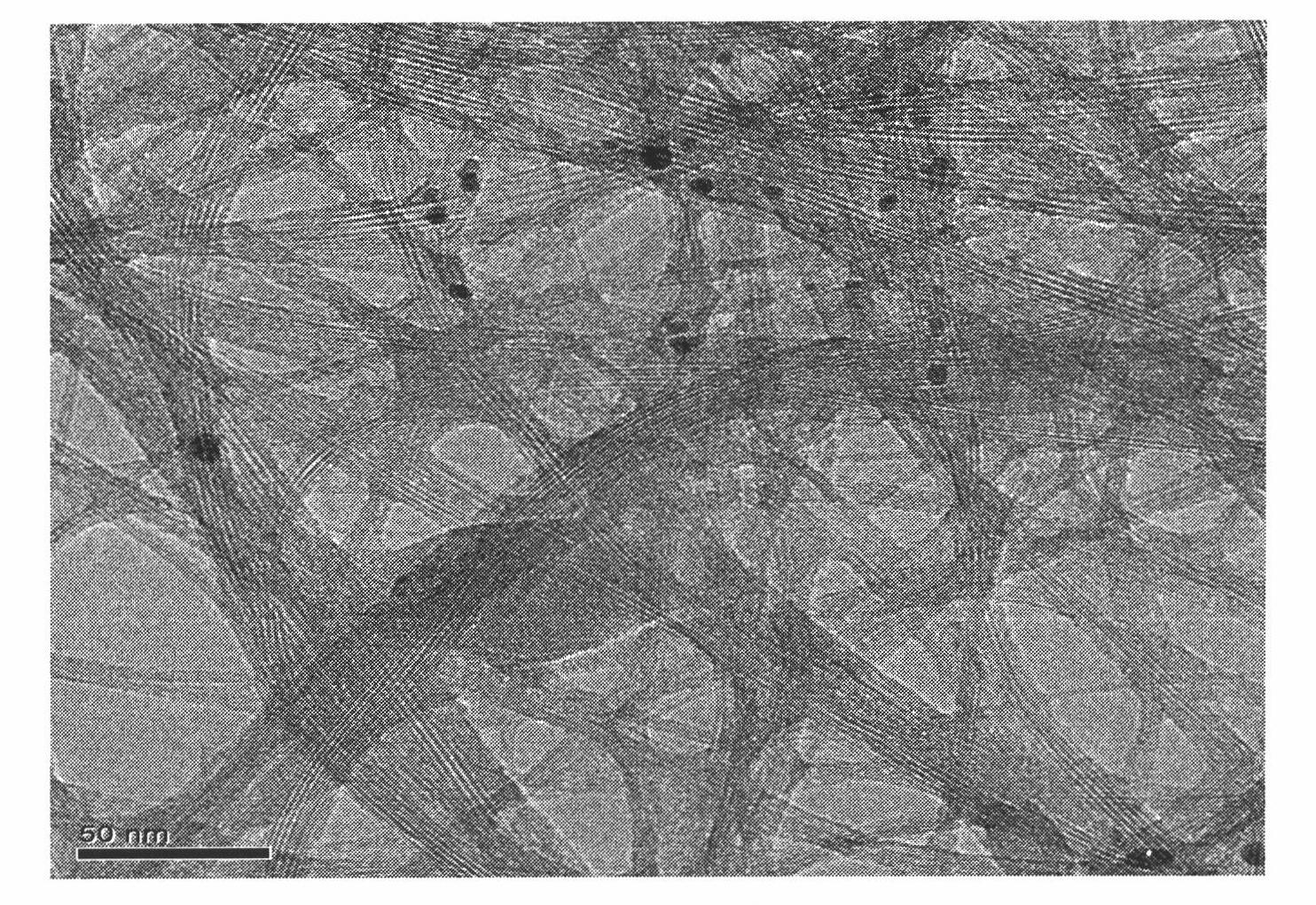

[0058] (1) Take 3 mg of single-walled carbon nanotube powder and place it in 300 ml of water, and add 3 mg of SDBS. The obtained mixture was ultrasonicated for 30 minutes in an ultrasonic water bath with a power of 270w, and then transferred to a high-energy ball mill for ball milling at a speed of 300rpm for 7 days to obtain a dispersed carbon nanotube aqueous solution. The prepared single-walled carbon nanotube dispersion was subjected to ultrahigh-speed centrifugation at a speed of 20,000 rpm for 30 minutes. The supernatant was collected for the following experiments.

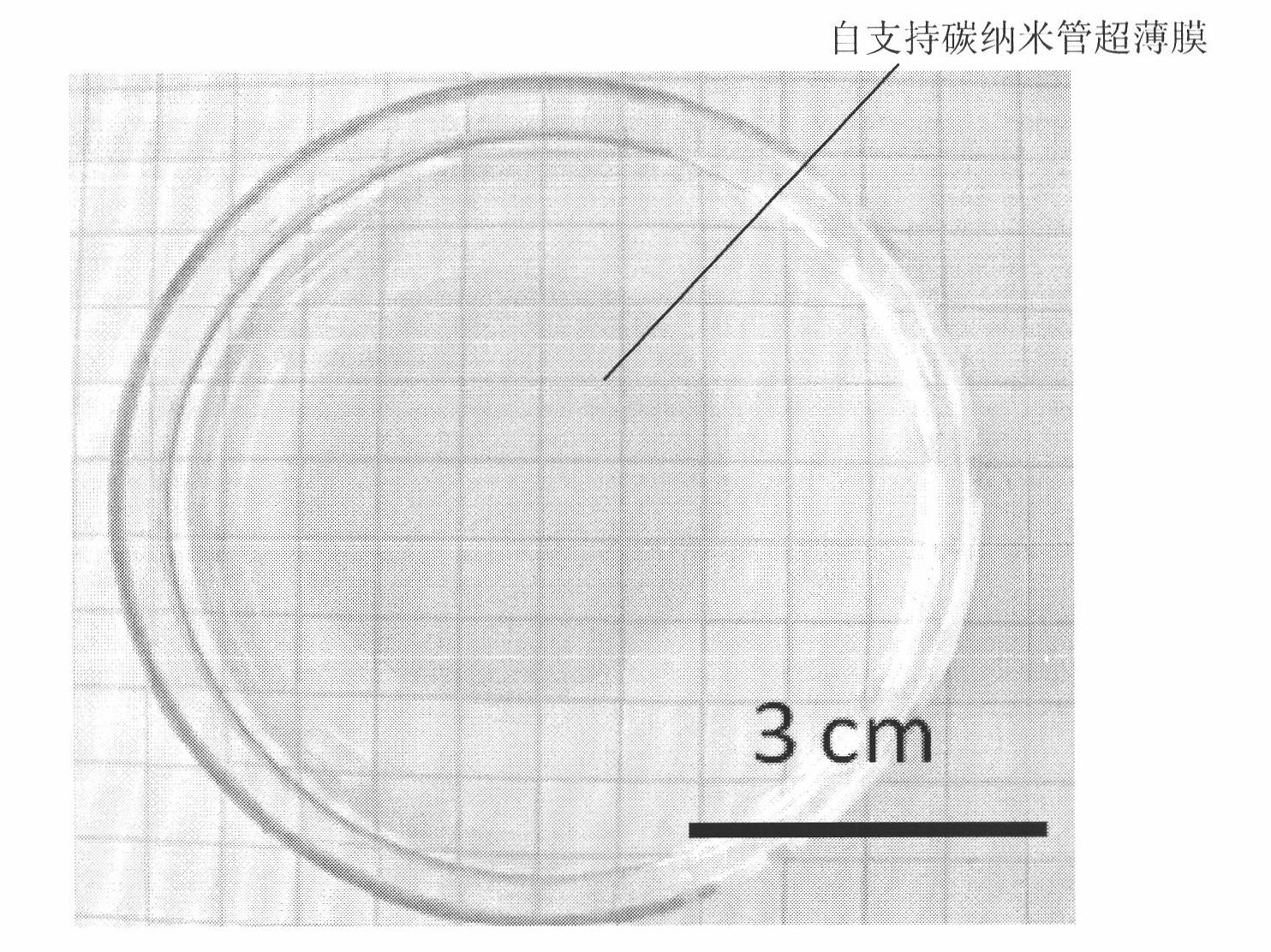

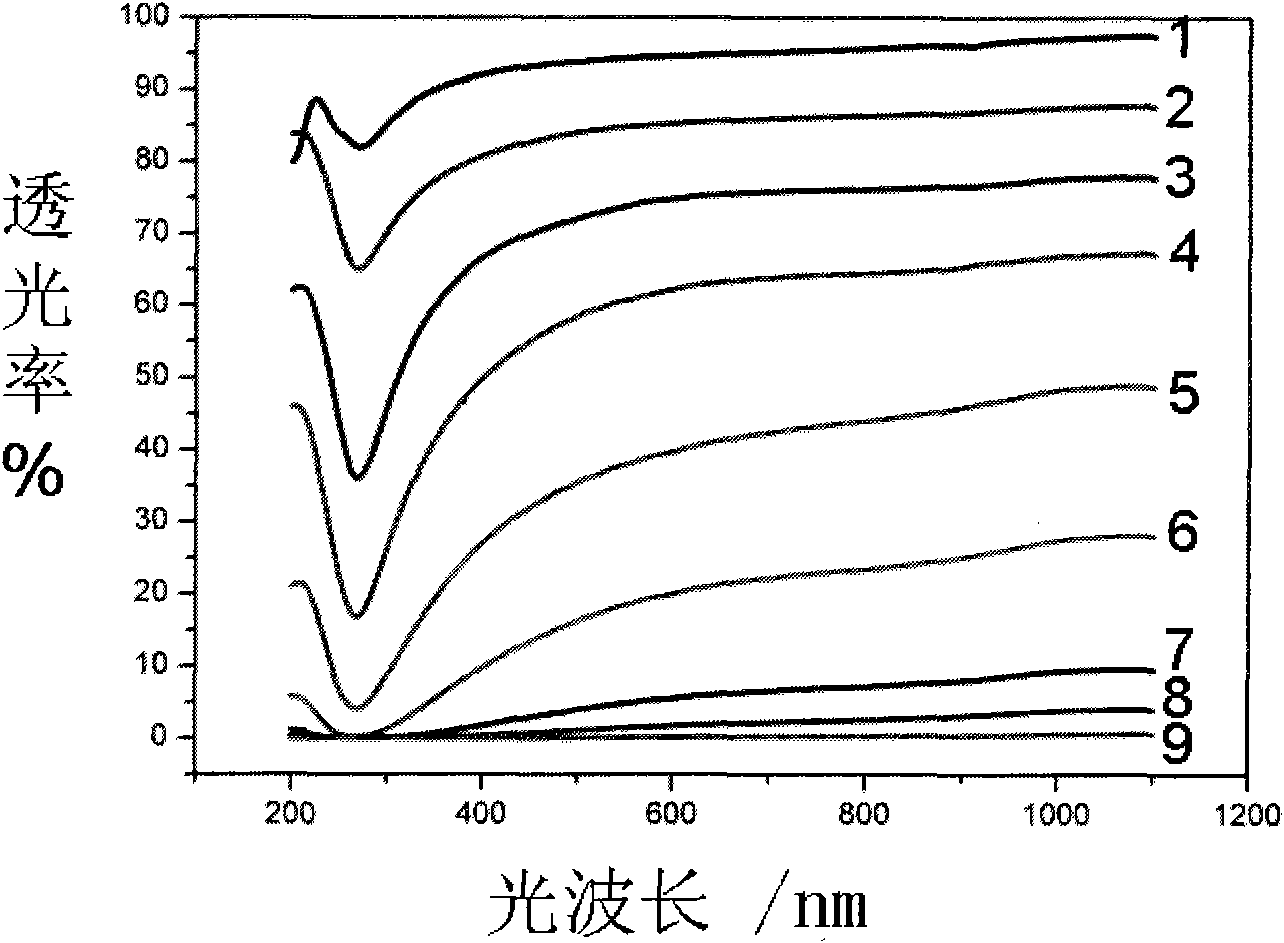

[0059] (2) Dilute the carbon nanotube dispersion obtained in step 1 by 50 times, and continue shaking for 30 minutes. Measure 1ml of the above solution, dilute it 20 times, shake well, and filter it through a mixed fiber membrane with a pore size of 450nm to form a membrane. After the filter membrane is dry, place it in acetone. After the mixed fibers are dissolved, a high-strength transparent self-support...

Embodiment 2

[0062] (1) Take 30 mg of single-walled carbon nanotube powder and place it in 300 ml of water, add 30 mg of SDBS and 15 mg of PVP. The resulting mixture was sonicated for 1 h in an ultrasonic water bath with a power of 100 w, and then transferred to a high-energy ball mill for ball milling at a speed of 800 rpm for 1 day to obtain a dispersed carbon nanotube aqueous solution. The prepared single-walled carbon nanotube dispersion was subjected to ultrahigh-speed centrifugation at a speed of 20,000 rpm for 30 minutes. The supernatant was collected for the following experiments.

[0063] (2) Dilute the carbon nanotube dispersion obtained in step 1 by 20 times, and continue shaking for 30 minutes. Measure 1ml of the above solution, form a layer of transparent film on the glass base by spin coating, put the glass base in water or 5M nitric acid, the carbon nanotube film will automatically fall off from the glass and float on the liquid surface, A self-supporting carbon nanotube c...

Embodiment 3

[0066] (1) Take 3 mg of single-wall carbon nanotube powder and 2 mg of multi-wall carbon nanotube powder, put them in 300 ml of water, and add 3 mg of SDBS. The resulting mixture was ultrasonicated for 200 min in an ultrasonic water bath with a power of 270w, and then transferred to a high-energy ball mill for ball milling at a speed of 300 rpm for 5 days to obtain a dispersed carbon nanotube aqueous solution. The prepared single-walled carbon nanotube dispersion was subjected to ultrahigh-speed centrifugation at a speed of 20,000 rpm for 30 minutes. The supernatant was collected for the following experiments.

[0067] (2) Dilute the carbon nanotube dispersion obtained in step 1 by 50 times, and continue shaking for 30 minutes. Measure 1ml of the above solution, dilute it 20 times, shake well, and filter it through a mixed fiber membrane with a pore size of 450nm to form a membrane. After the filter membrane is dry, place it in acetone. After the hybrid fibers are dissolved,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com