Preparation and application of super-hydrophobic/oleophobic coating layer with excellent performance

A super-hydrophobic, high-performance technology, applied in coatings, anti-corrosion coatings, cellulose coatings, etc., can solve the problems of difficult large-scale preparation, difficult liquid repellency of wear-resistant coatings, high preparation costs, etc., to achieve excellent wear resistance and chemical resistance Stability, easy large-scale production, outstanding effect of oleophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

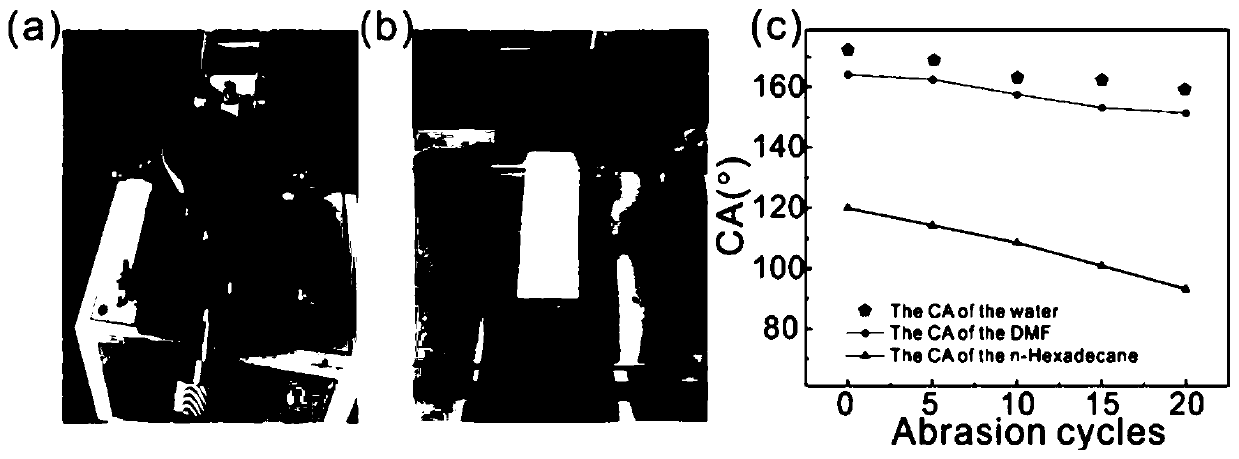

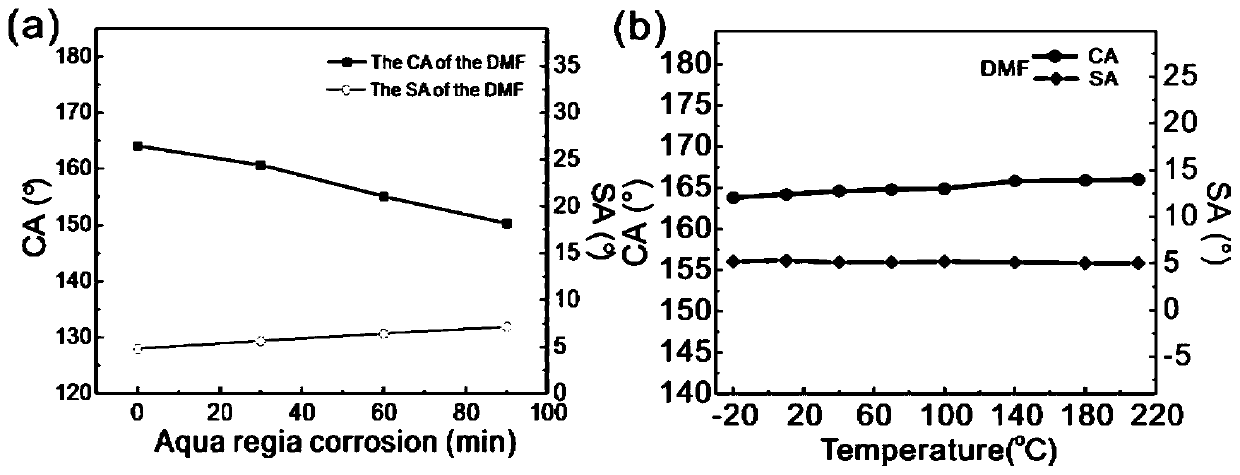

[0036] As introduced in the background technology, the lyophobicity of the current coating and the adhesion of the coating are often incompatible, that is, the lyophobic coating is not wear-resistant, and the wear-resistant coating is difficult to lyophobic. Therefore, the present invention proposes a kind of preparation method of superhydrophobic / oleophobic coating with excellent properties, comprising:

[0037] Disperse nanoparticles and cellulose in an alcohol solution containing alkaline substances, add tetraethyl orthosilicate and fluorine-containing organosilane for hydrolysis, and generate SiO 2 Coating the nanoparticles to form a solution A;

[0038] Disperse epoxy resin in alcohol solution to form solution B;

[0039] After mixing solution A and solution B evenly, add tetraethyl orthosilicate and fluorine-containing organosilane to react to form polysiloxane, which is called solution C;

[0040] Dissolving the fluorine-containing amine compound in the alcohol soluti...

Embodiment 1

[0047] 1. Preparation of superhydrophobic / oleophobic coating

[0048] 1. Preparation of superhydrophobic / oleophobic suspension

[0049] Take 0.4g 50nmSiO 2 , 0.5g 25um cellulose, dispersed in 30ml absolute ethanol and 10ml ammonia water mixture, after ultrasonic stirring for 30min, heated under 60 ° water bath conditions, 2ml tetraethyl orthosilicate (TEOS) was added dropwise to In the mixed solution, 1 ml of heptadecafluorodecyltrimethoxysilane (FAS) was added dropwise to the mixed solution, and stirred at 60° for 4 hours, which was called solution A.

[0050] Take 1g of bisphenol A epoxy resin (E51) and dissolve it in 5ml of absolute ethanol, and stir it ultrasonically for 30min to fully dissolve it, which is called solution B. Mix solution A and solution B, stir at 60° for two hours, then quickly add 0.6ml TEOS, 0.6ml FAS, continue stirring for two hours, called solution C.

[0051] Preparation of curing agent

[0052] Dissolve 2.22ml of aminoethylaminopropyltrime...

Embodiment 2

[0066] 1. Preparation of superhydrophobic / oleophobic suspension

[0067] Take 0.6g 50nmSiO 2 , 0.8g 25um cellulose, dispersed in 30ml absolute ethanol and 10ml ammonia water mixture, after ultrasonic stirring for 30min, heated under 63 ° water bath conditions, 4ml tetraethyl orthosilicate (TEOS) was added dropwise to In the mixed solution, 1 ml of heptadecafluorodecyltrimethoxysilane (FAS) was added dropwise into the mixed solution, and stirred at 63° for 3.5 hours, which was called solution A.

[0068] Take 2.5g of bisphenol A epoxy resin (E51) and dissolve it in 5ml of absolute ethanol, and stir it ultrasonically for 30min to fully dissolve it, which is called solution B. Mix solution A and solution B, stir at 63° for 3 hours, then quickly add 0.6ml TEOS, 0.2ml FAS, continue stirring for two hours, called solution C.

[0069] Preparation of curing agent

[0070] Dissolve 2.22ml of aminoethylaminopropyltrimethoxysilane (AS) in 10ml of deionized water, and dissolve 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com