Flexible wearable dry electrode and preparation method thereof

A dry electrode, flexible technology, applied in the field of flexible wearable dry electrode and its preparation, to achieve the effect of high conductivity, simple preparation method, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

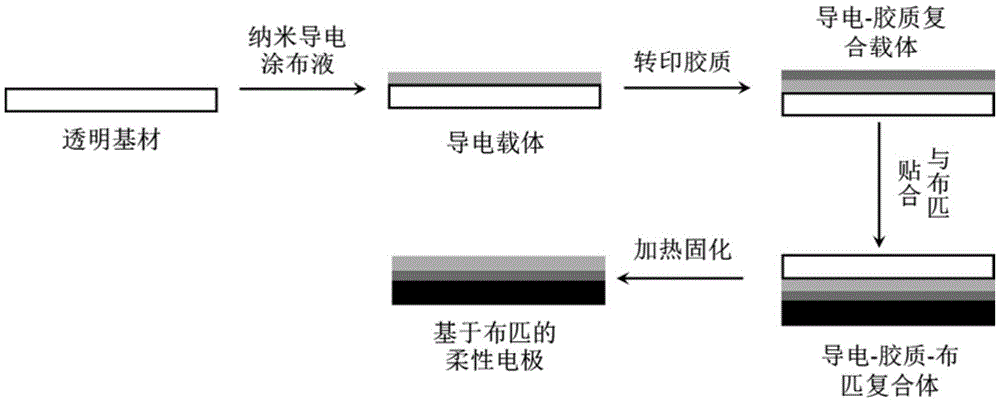

Method used

Image

Examples

Embodiment 1

[0045] A flexible wearable dry electrode:

[0046] Step (1): First prepare nano conductive coating solution, take 1 gram of copper nanowires, 1 gram of silver nanowires, and 1 gram of graphene, and disperse them in 25 grams of water, ethanol, and ethylene glycol mixed solvent at the same time, and then add 2 grams of polyethylene glycol, 0.5 grams of hydroxypropyl methylcellulose (molecular weight: 20,000), stirred thoroughly to dissolve evenly, then added 0.2 grams of isocyanate curing agent, and continued to stir until completely uniform, then placed for use.

[0047] Step (2): Prepare transfer printing glue, take 5 grams of acrylate (Shanghai Quanzhi, model R20B), 3 grams of modified silicone resin (Shanghai Resin Factory Co., Ltd., model 665) and mix evenly, add 1.5 grams of gas phase II Silicon oxide, 0.5 g of titanium dioxide, and stir thoroughly, then add 0.1 g of platinum water, 0.3 g of isocyanate, continue stirring evenly, and place it for use.

[0048] Step (3): Co...

Embodiment 2

[0054] A flexible wearable dry electrode:

[0055] Step (1): First, prepare a nano-conductive coating solution, take 2 grams of silver nanowires, 1 gram of carbon nanotubes, and 1 gram of graphene, and disperse them in 30 grams of water, ethylene glycol, and isophorone mixed solvent at the same time , then add 1 gram of polyvinyl alcohol (molecular weight 40000), 0.5 gram of hydroxypropyl methylcellulose (molecular weight 400), 1 gram of sodium laurate, stir thoroughly and dissolve evenly, then add 0.2 gram of isocyanate and 0.1 gram of urea to solidify agent, and continue to stir until it is completely uniform and then set aside for use.

[0056] Step (2): Prepare transfer printing colloid, take 20 grams of modified silicone resin (Shanghai Resin Factory Co., Ltd., model 665) and mix evenly, add 1 gram of fumed silica, 1.5 grams of titanium dioxide, and stir thoroughly, then Add 0.5 gram of platinum water and 1 gram of isocyanate, and continue stirring evenly, then set aside...

Embodiment 3

[0062] A flexible wearable dry electrode:

[0063] Step (1): first prepare nano conductive coating liquid, take 0.05 gram copper nanowire, 0.1 gram silver nanowire, 0.2 gram graphene and disperse in 300 gram water, ethylene glycol, glycerol mixed solvent at the same time, then Add 0.1 gram of polyvinyl alcohol (molecular weight 20,000), 0.15 gram of carboxymethyl cellulose (molecular weight 40,000), 0.1 gram of sodium laurate, stir thoroughly and dissolve evenly, then add 0.02 gram of isocyanate, 0.02 gram of urea linking agent and continue stirring Set aside until completely uniform.

[0064] Step (2): Configure the transfer colloid, take 45 grams of modified silicone resin (Shanghai Resin Factory Co., Ltd., model 665) and mix evenly, add 1 gram of fumed silica and 1.5 grams of titanium dioxide, and stir thoroughly, then Add 2.5 grams of Platinum Water and continue to stir evenly, then set aside.

[0065] Step (3): Apply the nano-conductive coating liquid obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com