Graphene heat-dissipation coating material, preparation method and applications thereof

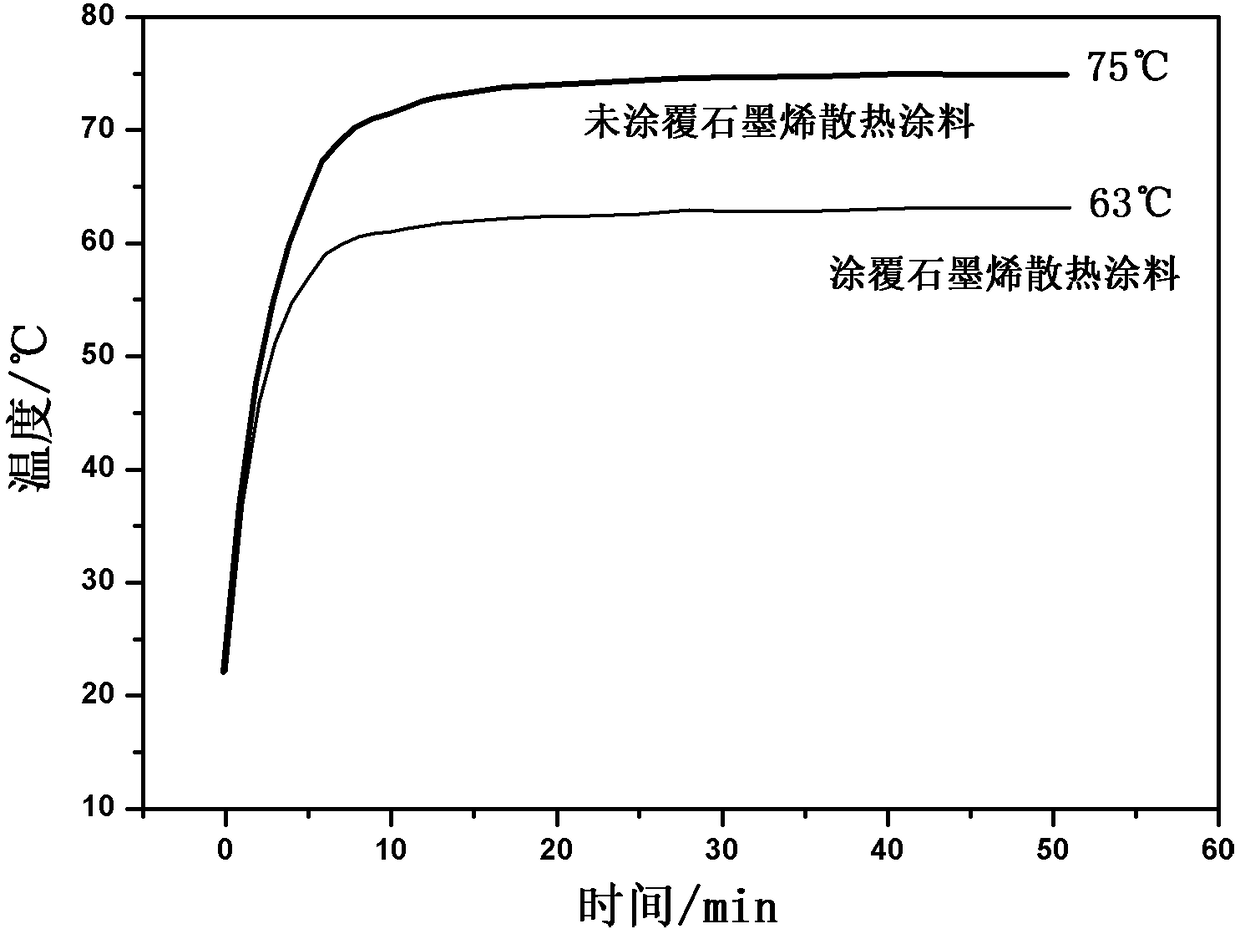

A heat-dissipating coating and graphene technology, applied in polyester coatings, anti-corrosion coatings, cellulose coatings, etc., can solve the problems of poor stability and dispersibility of thermally conductive metal powder, further improvement of heat dissipation effect, and increased cost. Excellent heat conduction and heat dissipation effect, good weather resistance, easy to play effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In parts by weight, the following raw materials are obtained:

[0050] 100 parts of epoxy resin, 10 parts of biomass graphene powder (5 parts with particle size of 8 μm, 5 parts with particle size of 50 μm), 10 parts of mica flake powder (radial size of 100 μm-200 μm, thickness of 1 μm-3 μm), α - 5 parts of alumina, 5 parts of aluminum nitride, 3 parts of talc, 3 parts of dispersant, 1 part of defoamer, 2 parts of leveling agent, 14 parts of xylene, 4 parts of n-butanol, 2 parts of diacetone alcohol .

[0051] (1) Get the biomass graphene powder with a particle size of 8 μm, add water to disperse, and prepare a graphene material dispersion, and then add mica flake powder, α-alumina, aluminum nitride and talcum powder to it, in water Ultrasonic dispersion for 2 hours, drying at 90°C for 6 hours to obtain graphene-mica composite powder;

[0052] (2) After mixing epoxy resin, graphene-mica composite powder, xylene, n-butanol, diacetone alcohol, dispersant, defoamer and l...

Embodiment 2

[0060] In parts by weight, the following raw materials are obtained:

[0061] 75 parts of silicone acrylic resin, 25 parts of amino resin, 10 parts of biomass graphene powder (1 part of particle size 10 μm, 9 parts of particle size of 100 μm), 10 parts of mica flake powder, 5 parts of carbon fiber powder, 5 parts of aluminum nitride 5 parts, 5 parts of talcum powder, 3 parts of dispersant, 1 part of defoamer, 2 parts of anti-settling agent, 14 parts of xylene, 4 parts of n-butanol, 2 parts of diacetone alcohol;

[0062] (1) Take biomass graphene powder with a particle size of 10 μm, add water to disperse it, and prepare a graphene material dispersion, then add mica flake powder, carbon fiber powder, aluminum nitride and talcum powder to it, and ultrasonically disperse in water for 3 hours , and dried at 90°C for 6 hours to obtain graphene-mica composite powder;

[0063] (2) Mix silicone acrylic resin, amino resin, graphene mica composite powder, xylene, n-butanol, diacetone a...

Embodiment 3

[0068] In parts by weight, the following raw materials are obtained:

[0069] 50 parts of phenolic resin, 20 parts of graphene oxide powder (4 parts of particle size 7 μm, 16 parts of particle size of 60 μm), 1 part of mica flake powder, 3 parts of carbon black, 1 part of diamond powder, 1 part of carbon fiber, 2 parts of graphite , 2 parts of copper powder, 2 parts of boron nitride, 2 parts of dispersant, 1 part of defoamer, 2 parts of leveling agent, 3 parts of water, 2 parts of ethanol, 4 parts of acetone, 3 parts of N-methylpyrrolidone, N , 3 parts of N-dimethylformamide, 3 parts of n-hexane, 2 parts of cyclohexane;

[0070] (1) Take graphene oxide powder with a particle size of 7 μm, add water to disperse, and prepare a graphene material dispersion, and then add mica flake powder, carbon black, diamond powder, carbon fiber, graphite, copper powder and boron nitride to it , ultrasonically dispersed in water for 4 hours, and dried at 90°C for 3 hours to obtain graphene-mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com