Preparation method for laser hot stamping foil of metal coin and prepared product

A technology of anodized aluminum and hot stamping foil, applied in the direction of copying/marking, application, printing, etc., can solve the problems of not being able to peel off very cleanly, poor adhesion of the aluminized layer, poor ink adhesion, etc., to achieve not easy to fall off, adhesion Strong, firm adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

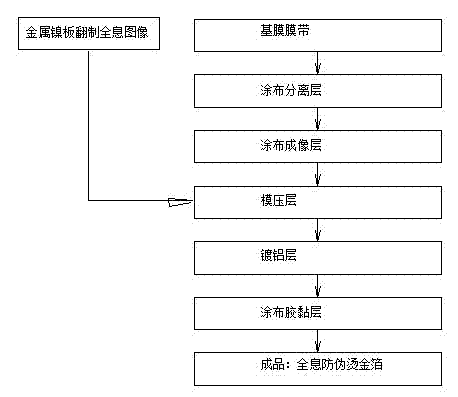

[0025] Such as figure 1 Shown is the production flow chart of the present invention for laser anodized hot stamping foil on metal coins. exist figure 1 Among them, the preparation method of laser anodized aluminum hot stamping foil for metal coins of the present invention comprises the following steps:

[0026] Step 1), making the metal nickel plate: use a photolithography machine to engrave the image and text on the photosensitive rubber plate to produce a laser holographic plate, and then use the electroforming method to make the laser holographic plate into a metal nickel plate for molding;

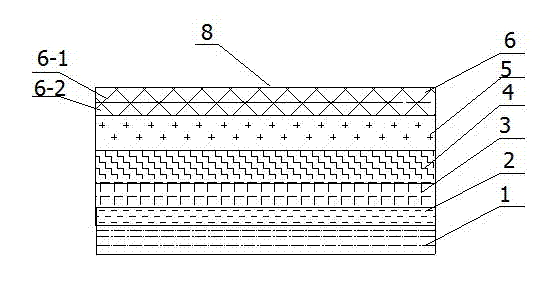

[0027] Step 2) as in figure 2 As shown, coating the release layer 2 on the base film film belt 1: prepare the melamine resin release layer coating according to the release layer composition components: in parts by mass, the raw material solvent of the melamine release agent is 40 mass of alcohol parts, 30 parts by mass of butanone, 0.007 parts by mass of auxiliary agent, and 70 p...

Embodiment 2

[0033] This embodiment can also have the following differences, and the rest are the same as in Example 1, and the same parts will not be repeated. In step 2) of the present invention, the following differences can also be found: 2) In the basic Coating release layer 2 on film tape 1: prepare melamine resin release layer coating according to release layer composition components: in parts by mass: melamine release agent whose raw material solvent is 45 parts by mass of alcohol, 35 parts by mass of methyl ethyl ketone Parts by mass, 0.008 parts by mass of auxiliary agent, 80 parts by mass of melamine resin were stirred and mixed uniformly for 20 minutes to make a release layer coating and coated on a base film tape 1 by a coating machine to form a release layer 2. The auxiliary agent is Hardener;

[0034] Molding in step 4): the holographic anti-counterfeiting pattern on the metal nickel plate is molded and transferred to the imaging layer 3 by a molding press equipped with the ...

Embodiment 3

[0037] This embodiment can also have the following differences, and the rest are the same as in Example 1, and the same parts will not be repeated. In step 2) of the present invention, there can also be the following differences: step 2) in the described Coating release layer 2 on the base film film belt 1: the release layer 2 is a melamine release layer, and the melamine resin release layer coating is prepared according to the composition of the release layer: in parts by mass: solvent alcohol 50 Parts by mass, 32 parts by mass of methyl ethyl ketone, 0.008 parts by mass of additives, 82 parts by mass of melamine resin were stirred evenly and mixed with a high-speed mixer for 20 minutes, and the two coating adhesive materials in step 6) of the present invention were two The thermoplastic adhesive of two components, the thermoplastic adhesive of the first coating is polyurethane, the thermoplastic adhesive of the second coating is acrylic, and the adhesive is coated with a coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com