Method of making aluminum clad copper tube with metallurgical bonding

A manufacturing method and metallurgical combination technology, applied in the field of metal composite pipe manufacturing, can solve the problems of long pipes, high cost, leaking weld defects, etc., and achieve the effects of good product quality, stable process and stable process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

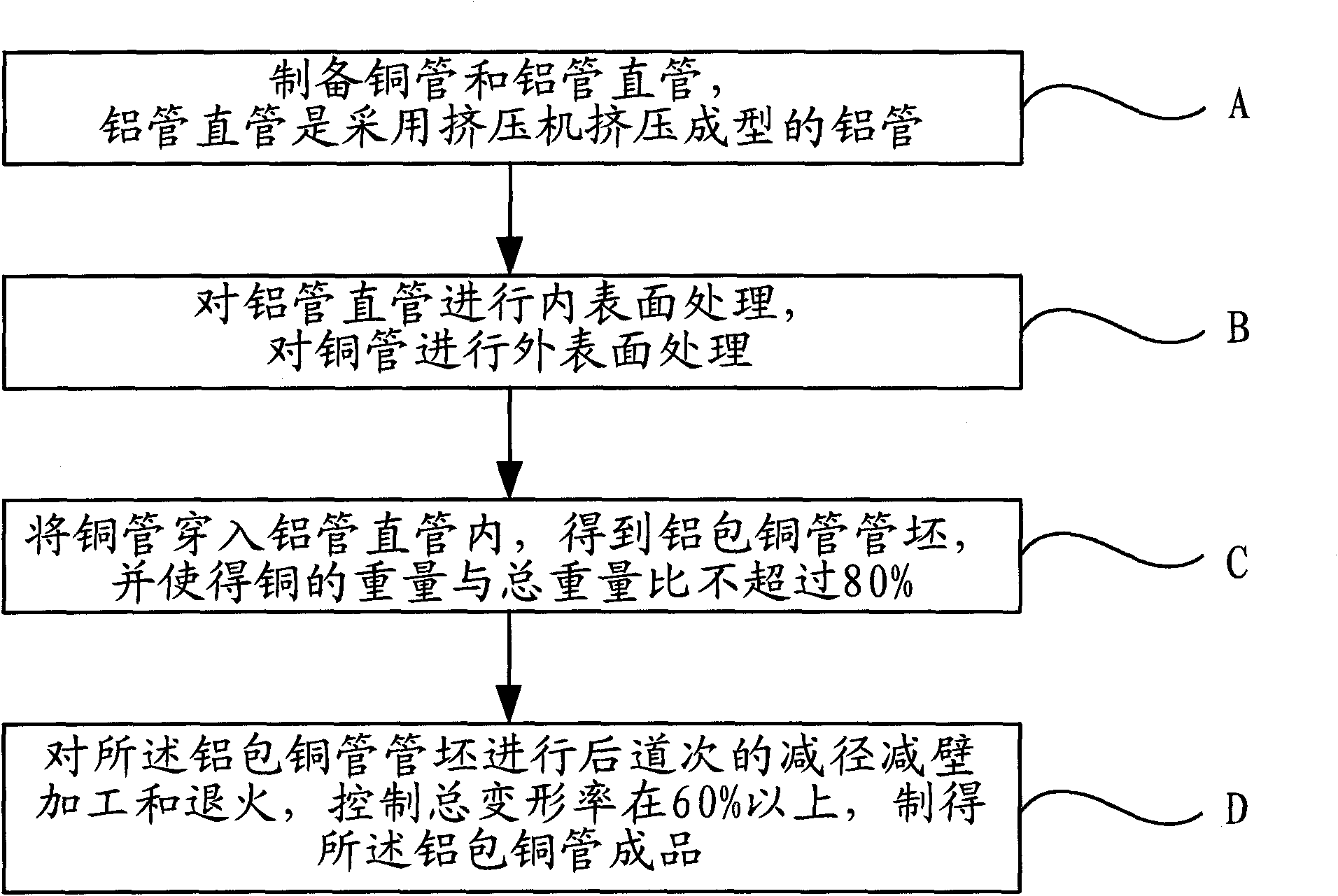

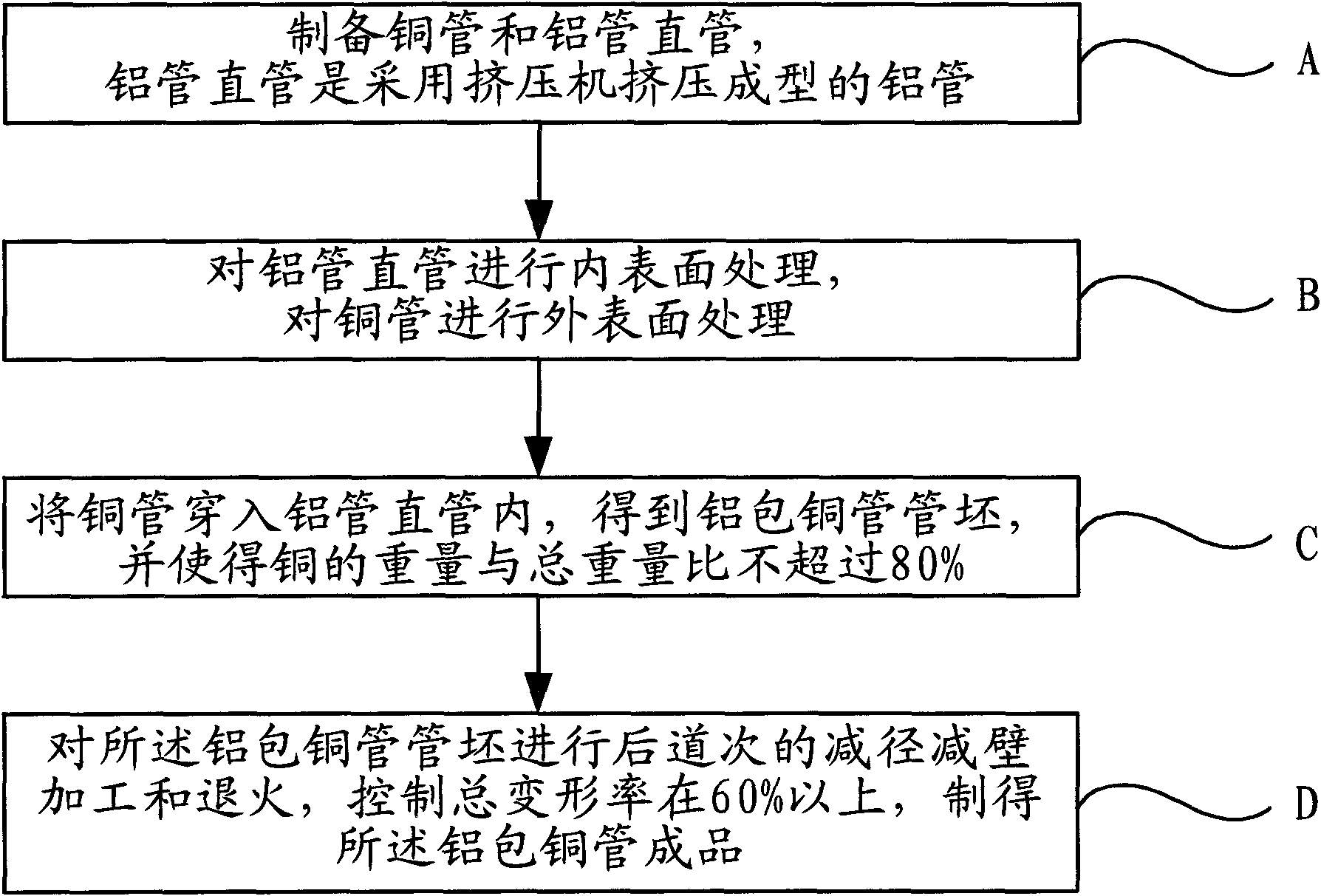

Method used

Image

Examples

Embodiment 1

[0065] 1) A horizontal extrusion machine is used to extrude Φ48×3mm aluminum tubes, the material is 3003, and the aluminum coils are harvested online after extrusion, and then the aluminum coils are straightened and cut to length, with a length of 150m. The rear specification is Φ40×0.6mm.

[0066] 2) Brush the inner surface of the aluminum tube, using a steel wire brush, put multiple steel wire brushes in series into the aluminum tube, and brush the inner surface repeatedly; also brush the outer surface of the copper tube.

[0067] 3) The copper pipe after brushing the outer surface is directly threaded into the aluminum pipe online to obtain a tube blank of an aluminum-clad copper tube. The total weight of the tube blank after piercing is about 270kg.

[0068] 4) Multi-pass linear drawing of the tube blank to Φ19.05×0.9mm, the deformation rate at this time is 89%.

[0069] The weight-to-total weight ratio of copper in the aluminum-clad copper tube is 36.8%, and the average ...

Embodiment 2

[0072] 1) A continuous extrusion machine is used to extrude a straight aluminum tube of Φ60×2.5mm. The material is pure aluminum. It is straightened on-line during extrusion. The length of the aluminum tube is 200m. The seamless copper coil tube is prepared by planetary rolling. Specifications It is Φ50×1.5mm.

[0073] 2) Clean the inner surface of the aluminum tube straight tube.

[0074] 3) After the copper tube is uncoiled and straightened, the bristles on the outer surface are directly penetrated into the aluminum tube on the line to make a tube blank of an aluminum-clad copper tube.

[0075] 4) Expand the aluminum-clad copper tube blank to Φ61×3.9mm.

[0076] 5) After multi-pass continuous straight drawing, coil drawing and annealing, it is processed to Φ9.52×0.4mm and finally softened and annealed to obtain the finished product.

[0077] According to the aluminum-clad copper tube produced in this embodiment, the thickness of the copper layer is 36% relative to the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com