Copper alloy material for parts of electronic and electric machinery and tools

a technology of electronic and electric machinery and parts, applied in the direction of coupling contact members, transportation and packaging, contacts, etc., can solve the problems of inability to meet the requirements of cu-zn alloys, cu-fe alloys and cu-sn alloys, and the inability of cu-zn alloys to be used for a long period of time, and achieve the effect of maintaining mechanical strength and elasticity, improving bending properties, and improving bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0055] the present invention will be described hereinafter.

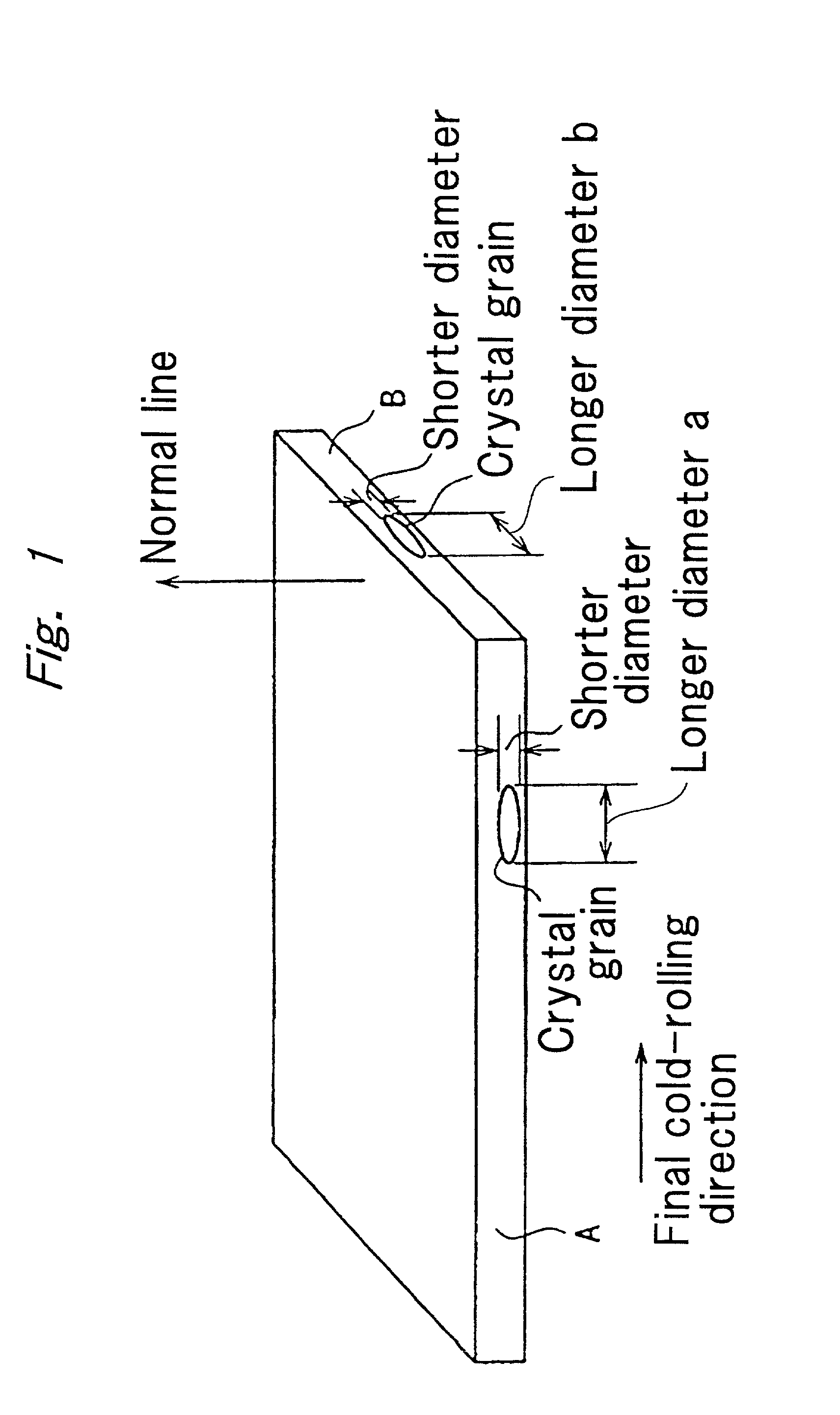

[0056] In the first embodiment of the present invention, bending property and stress relaxation property are particularly improved, without compromising essential characteristics such as mechanical property, heat and electric conductivity, and plating property, by allowing the alloy elements in the above copper alloy material such as Ni, Si, Mg, Sn and Zn to contain in appropriate quantities while suppressing the content of S in a trace amount, and by defining the crystal grain diameter and the shape of the crystal grain.

[0057] In the first embodiment of the present invention, the crystal grain diameter is defined to be from more than 0.001 mm to 0.025 mm. This is because the recrystallized texture tends to be a mixed grain texture to decrease bending property and stress relaxation property when the crystal grain diameter is 0.001 mm or less, while, when the crystal grain diameter exceeds 0.025 mm, bending property decreases...

second embodiment

[0062] the present invention will be then described.

[0063] The second embodiment of the present invention is the copper alloy material for parts of electronic and electric machinery and tools that can be used in the preset invention as described in the above, in which the surface roughness of the alloy is defined so that the surface becomes smooth, particularly property of plating of Sn and the like is improved. The inventors of the present invention have been able to realize practically excellent materials for the parts of electronic and electric machinery and tools by precisely defining the contents of the components of the alloy material and the surface roughness of the alloy material.

[0064] Since the components in the copper alloy material are the same as those in the first embodiment, the reason of restricting the surface roughness will be described hereinafter.

[0065] The surface roughness is used as an index representing the surface state of the material.

[0066] Ra defined in t...

example

[0080] The present invention is described in more detail with reference to the following examples, but the present invention is by no means restricted to these examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com